Abstract

Highly-efficient GaN-based light-emitting diode (LED) wafers have been grown on La0.3Sr1.7AlTaO6 (LSAT) substrates by radio-frequency molecular beam epitaxy (RF-MBE) with optimized growth conditions. The structural properties, surface morphologies and optoelectronic properties of as-prepared GaN-based LED wafers on LSAT substrates have been characterized in detail. The characterizations have revealed that the full-width at half-maximums (FWHMs) for X-ray rocking curves of GaN(0002) and GaN(10-12) are 190.1 and 210.2 arcsec, respectively, indicating that high crystalline quality GaN films have been obtained. The scanning electron microscopy and atomic force microscopy measurements have shown the very smooth p-GaN surface with the surface root-mean-square (RMS) roughness of 1.3 nm. The measurements of low-temperature and room-temperature photoluminescence help to calculate the internal quantum efficiency of 79.0%. The as-grown GaN-based LED wafers have been made into LED chips with the size of 300 × 300 μm2 by the standard process. The forward voltage, the light output power and the external quantum efficiency for LED chips are 19.6 W, 2.78 V and 40.2%, respectively, at a current of 20 mA. These results reveal the high optoelectronic properties of GaN-based LEDs on LSAT substrates. This work brings up a broad future application of GaN-based devices.

Similar content being viewed by others

Recently, GaN and its alloys with AlN and InN have become the basic materials for the fabrication of light-emitting diodes (LEDs), laser diodes (LDs), etc, due to their direct band gaps which covering the entire spectrum from ultraviolet to visible ranges1,2,3. So far, high brightness blue and green GaN-based LEDs prepared on sapphire substrates have already been commercialized4,5. However, there are large lattice and coefficient of thermal expansion (CTE) mismatches existing between GaN films and sapphire substrates, which would lead to the formation of high dislocation density and high stress in the epilayers during the initial growth and cooling down process6,7. This hence hampers the further development of GaN-based LEDs grown on sapphire substrates.

Many researchers have tried hard to prepare GaN-based LEDs on SiC, LiAlO2, etc8,9,10, which share a relatively small lattice and CTE mismatches with GaN. Although the properties of these GaN films have been improved, they still need to be further enhanced to meet the recent requirement of highly-efficient GaN-based LED devices. Apart from growing GaN-based LEDs on those substrates, researchers also focused on addressing the charge separation issue by using nonpolar/semipolar InGaN QWs11 and large overlap InGaN QWs12,13, to improve the properties of LEDs. Tremendous progress in the field of III-nitride LEDs has also been achieved in the past several years14,15. After carefully study of the mentioned above, to use the substrate of much smaller lattice and thermal expansion mismatches with GaN seems to be a more easier and effective approach.

The La0.3Sr1.7AlTaO6 (LSAT) is a mixed-perovskite crystal and is very suitable for the growth of GaN films16,17. On the one hand, the lattice mismatch between LSAT and GaN is as small as 1.0%18,19. On the other hand, the CTE mismatch between LSAT and GaN is only 3.6%18,19. These superior properties make LSAT viable for the growth of high-quality GaN films. However, LSAT has high oxygen pressure20,21, which would lead to the serious interfacial reactions between GaN and LSAT when the epitaxial growth is conducted at high temperature. Therefore, a low temperature growth is of paramount importance in obtaining high-quality films. Traditional metal-organic chemical vapor deposition (MOCVD) is not appropriate for this propose due to its requirement of high growth temperature.

In our previous work22, we just reported on the demonstration of GaN-based LEDs on LSAT substrates by radio-frequency molecular beam epitaxy (RF-MBE) and several measurements are deployed to study the as-grown GaN-based LED wafers and chips. In that case, the properties of the GaN-based LEDs still have place for the further improvement. The interface of GaN/LSAT and the structure of InGaN/GaN MQWs in the as-grown GaN-based LEDs on LSAT substrates need to be improved for the wide utilization. Herein, we report on the growth of GaN-based LEDs on LSAT substrates by RF-MBE with the optimized growth conditions. The MBE with low RF plasma radical generator power of 500 W is deployed to grow GaN films for obtaining sharp and abrupt GaN/LSAT heterointerfaces due to the suppression of the interfacial reactions between GaN films and LSAT substrates and is beneficial to the growth of high-quality epitaxial layers. The structure of InGaN/GaN MQWs is optimized by a modulated temperature growth mode and high-quality InGaN/GaN MQWs have been obtained. The structural properties, surface morphologies and optoelectronic properties of as-grown LEDs on LSAT are characterized in detail. This work of obtaining the highly-efficient GaN-based LEDs is of great importance for the future application of GaN-based devices.

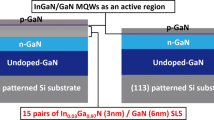

The as-received LSAT substrates were bought from Hefei Kejing Materials Technology Co., Ltd, American MTI Corporation prepared by Czochralski method. The LSAT substrates were first cleaned by acetone, ethanol and deionized water in turn to remove the surface contaminations and then were annealed at 900°C for 5 h. The as-annealed LSAT substrates were transferred into the MBE growth chamber for the epitaxial growth. During the growth, high-purity N2 with the pressure of 2 × 10−4 Torr was supplied through an inert gas purifier and a RF plasma radical generator operated at 550 W except that the RF plasma radical generator power for GaN growth is 500 W during the initial growth. High-purity solid-state Ga (7N), In (7N) and Al (7N) were used as the source of Ga, In and Al, respectively. High-purity solid-state Si (6N) and Mg (6N) were deployed as the n-type and the p-type doping sources, respectively. The GaN-based LED wafers on LSAT substrates include the following structures. A 4 μm-thick undoped GaN (u-GaN) film was firstly grown on LSAT substrates directly at 500°C with a modulated RF plasma radical generator power of 500 W in order to avoid interfacial reactions. Subsequently, a 3 μm-thick Si-doped GaN (n-GaN) film was grown at 750°C. Afterwards, 7 periods In0.13Ga0.87N (3 nm)/GaN (12 nm) MQWs were grown with a modulated temperature growth mode, that is, the growth temperatures for GaN barrier and InGaN well layers were different. In our case, the growth temperatures for barrier and well layers were 750 and 700°C, respectively. Finally, after the growth of 20 nm-thick AlGaN layer, a 300 nm-thick p-GaN layer was grown. The as-prepared GaN-based LED wafers (Supplementary Figures 1Sa–b) were fabricated into LED chips with standard process22,23. The structural properties of as-grown LED wafers were studied by X-ray diffractometer (XRD, Bruker D8 X-ray diffractometer with a Cu Kα1 X-ray source, λ = 1.5406 Å), high-resolution transmission electron microscope (HRTEM, JEOL 3000F) and micro-Raman spectroscopy (Renishaw inVia Raman spectrometer with a 532 nm laser as the excitation source). The optoelectronic properties of MQWs were studied by 325 nm He-Cd laser at room temperature (325 K) and low temperature (17 K), respectively, in order to calculate the internal quantum efficiency (IQE). The electrical properties of GaN-based LED chips were evaluated by voltage (V)-current (I), light output power (L)-I and external quantum efficiency (EQE)-I curves using the GAMMA Scientific GS-1190 RadoMA-Lite KEITHLEY 2400 system.

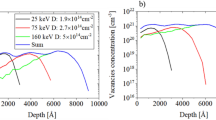

GaN-based LEDs have been grown on LSAT substrates by MBE. The crystalline quality of as-grown GaN epilayer is studied by X-ray rocking curve (XRC). The full-width at half-maximums (FWHMs) for GaN(0002) and GaN(10-12) of XRCs are 190.1 and 210.2 arcsec, respectively, as shown in Figures 1a and b. These are much smaller than those in our previous work with FWHMs for GaN(0002) and GaN(10-12) of 231.2 and 253.1 arcsec, respectively22. The possible reason may be attributed to the effectively suppress the GaN/LSAT interfacial reactions24. Because we use lower RF plasma radical generator power of 500 W during the initial growth, the interfacial reactions between N plasmas produced by RF plasma radical generator and O atoms diffused from the substrates can be suppressed and eventually results in the higher crystalline quality of GaN. Additionally, it is known that the FWHM of GaN(0002) is related to the skew dislocation that is formed by the various height of substrates and the FWHM of GaN(10-12) is respected to the pure edge and mixed dislocations which are generated during the coalescence process among the mis-oriented individual islands24,25,26. The skew dislocation density and pure edge and mixed dislocation densities in as-grown GaN epi-layer are estimated to be 7.9 × 107 and 8.8 × 107 cm−2, respectively27,28. This crystalline quality of GaN-based LEDs grown on LSAT substrates is much better than traditional GaN-based LEDs prepared on sapphire and nanopatterned sapphire substrates29,30,31,32,33.

Typical ω-2θ scans are deployed to study the structural properties, as shown in Figure 1c. It can be noted that the satellite peaks are visible up to −5th and +3rd, which are in striking contrast to that in Ref. 22 where no −5th is observed and prove the higher structural properties of InGaN/GaN MQWs. We attribute this results to two aspects. One is the high crystalline quality of GaN and the other is modulated temperature growth mode for InGaN/GaN MQWs. In the former case, the high-quality GaN may act as a good template for the nucleation of the InGaN wells. In the latter case, the high temperature for GaN growth is good for the obtaining of high-quality GaN barriers and low temperature for InGaN growth is to avoid the stress in InGaN wells that cause the fluctuation of In content and release the stress in the films to some extent. Therefore, it is beneficial to obtaining high-quality InGaN/GaN MQWs ultimately34,35. Furthermore, by fitting the experimental curve with the simulation one by LEPTOS, we obtain the thickness of InGaN well and GaN barrier is 11.9 and 3.1 nm, respectively. These values are quite close with our designed.

In order to investigate the stress in as-grown GaN-based LED wafers on LSAT substrates, the reciprocal space mapping (RSM) of GaN (10-15) is deployed. It is clear, in agreement with the conventional wisdom, that the asymmetric alignment of the epilayers from the (10-15) RSM is identified, as illustrated by the blue and red dashed lines. These results reveal that stress relaxation takes place in the InGaN/GaN MQWs, since the asymmetric alignment of MQW peaks is visible up to −3rd 36,37. This is in striking contrast to that reported in Ref. 22, which is only visible up to −2nd. This comparison shows the improvement in structural properties of GaN-based LEDs on LSAT in this work. These results once again confirm that higher quality InGaN/GaN MQWs have been obtained on LSAT with modulated temperature growth mode. Furthermore, the lattice parameters of n-GaN and InGaN in MQWs are estimated to be: aGaN = 0.3190 nm, cGaN = 0.5186 nm; aInGaN = 0.3194 nm, cInGaN = 0.5286 nm. Obviously, the layer relaxation value (R) of InGaN/GaN is estimated to be RInGaN = 10.9% and RGaN = 89.1%, respectively38,39.

The Raman spectroscopy is introduced to further study the stress in GaN-based LED wafers, as shown in Figure 2b. From Figure 2b, two peaks located at 566.1 and 733.4 cm−1, corresponding to E2(high) and A1(LO) phonon peak, are clearly observed. The E2(high) phonon peak can be deployed to calculate the in-plane stress in the GaN epilayer by the following equation40,41:

where σ is the residual stress and Δω is the E2 (high) phonon peak shift. As we know, the E2(high) phonon peak of stress-free GaN is believed to be located at 566.2 cm−1, which is blue shift of about 0.1 cm−1 corresponding to a tensile stress of about 0.023 GPa. This result agrees with the RSM measurement.

TEM is introduced to evaluate the structural properties of as-grown GaN-based LEDs on LSAT substrates. On the one hand, the interfacial properties between GaN and LSAT are studied by HRTEM, as shown in Figure 3a. There is no interfacial layer existing between GaN films and LSAT substrates in Figure 3a. Above this layer, one can clear find the outstanding arrange of GaN atoms, which means that the interfacial reactions between GaN and LSAT are effectively suppressed within this interfacial layer. On the other hand, it is obvious to find that there is no threading dislocation extends into the MQWs, which is confirmed by TEM with medium magnification in Figure 3b. Furthermore, the excellent periodicity in each InGaN well and GaN barrier, as well as very slight lattice distortion between each quantum well can be identified in Figure 3c. The thickness of InGaN well and GaN barrier is measured to be 11.9 and 3.1 nm, respectively, which are consistent well with the values obtained from the simulation of ω-2θ curve with LEPTOS42. Obviously, the periodicity in each InGaN well and GaN barrier is much better than that in Ref. 22. To conclude, these MQWs with excellent structural properties are of significant importance for the radiative recombination of carriers.

The surface morphologies of as-grown GaN-based LED wafers on LSAT substrates are studied by SEM and AFM, as shown in Figures 4a and b, respectively. It is clear and is consistent with the conversional wisdom, that the very smooth p-GaN surface only with several pits is obtained. These pits are formed during Mg-doping process. Due to the effect of surface energy, the Mg atoms on GaN films tend to concentrating on the GaN surface. These doped Mg atoms may cause the inversion of GaN from Ga-face to N-face on the growth axis, results in the partially variant domains for the surface crystal structure and eventually leads to the formation of pits43,44. Actually, the AFM measurement reveals that the surface root-mean-square (RMS) roughness is as small as 1.3 nm for p-GaN surface in this work, which is smoother than that in our previous work with a RMS roughness of 1.6 nm22. This can be ascribed to the higher-quality of InGaN/GaN MQWs achieved in this work, which is better for the growth of p-GaN layer. This flat p-GaN surface is of paramount importance for the fabrication of GaN-based LED chips. However, the RMS roughness for p-GaN layer in GaN-based LEDs on sapphire substrates grown with identical growth conditions is calculated to be 2.8 nm, revealing the relatively rougher surface when compared with that of p-GaN in GaN-based LEDs on LSAT substrates in this work.

The optical properties are measured by PL both at room temperature (RT) and low temperature (LT). From Figure 5, one can identify the sharp PL peaks located at 446 nm with an FWHM of 22.3 nm at RT and an FWHM of 20.5 nm located at 444 nm at LT, respectively. Actually, there is a ~1.5 nm blue shift in PL peak conducted at LT when compared with that at RT. This is attributed to the fact that there are high-energy carriers existing at low temperature, which lead to the low wavelength during the radiative recombination29,30,31,32,33,45. It is widely accepted that the IQE can be estimated as the ratio of the peak PL intensities IRT at RT and ILT at LT, where the LT IQE is assumed to be 100%46. Therefore, the IQE for GaN-based LEDs grown on LSAT is estimated to be 79.0%. As mentioned above, the stress in MQWs is partly relaxed, thereby the quantum confined Stark effects (QCSEs) are weakened to some extent. In this regard, the carriers can be easily recombined in the MQWs and eventually improves the IQE.

After the GaN-based LEDs are made into LED chips (Supplementary Figure 2Sa), the electroluminescent (EL) spectra for the GaN-based LEDs is conducted at various currents ranging from 5 to 40 mA. It is noted that there is a slight blue shift in the wavelength as the increase in current, as shown in Figure 6a. This slight blue shift may be explained to the band filling of localized state induced by the fluctuation In content in the InGaN well47,48. Nevertheless, these results suggest that GaN-based LEDs can work normally at these states. Figure 6b shows the I-V curve for LED chips grown on LSAT substrates. The forward voltage for these LEDs in this work is about 2.78 V at the working current of 20 mA, which is much better than that in our previous work22 with the forward voltage of 3.18 V and is also smaller than that in the commercially available GaN-based LEDs prepared on sapphire substrate with the value of ~3.0 V. We attribute this mainly to higher-crystalline quality of GaN-based LEDs grown on LSAT substrates obtained in this work. Figure 6c shows L-I and EQE-I curves for the LED chips grown on LSAT substrates. On the one hand, it can be found that as the increase in current, the L is gradually increased. Especially, at a current of 20 mA, the L for GaN-based LED chips on LSAT is measured to be 19.6 mW (Supplementary Figure 2Sb). This value is much better than that of GaN-based LEDs grown on LSAT substrates reported in Ref. 22. We ascribed this to higher crystalline quality of as-grown GaN films, higher quality InGaN/GaN MQWs and smoother p-GaN surface achieved in this work. These factors are beneficial to the radiative recombination of carriers and eventually improve the light output power. On the other hand, the EQE for GaN-based LED chips on LSAT is first increased and then decreased as the increase in current, as shown in Figure 6c. The best value of EQE for GaN-based LED chips on LSAT substrates is 40.2%, which is higher than that of commercially available GaN-based LEDs on sapphire substrates49. The “droop” for the EQE may be Auger recombination, polarization field induced barrier reduction and dislocation, electron overflow, etc50,51,52 and the exact reason has not been clearly indentified.

In summary, highly-efficient GaN-based LED wafers have been grown on LSAT substrates by RF-MBE with the optimized growth conditions. The XRCs reveal the high-crystalline quality with the FWHMs for GaN(0002) and GaN(10-12) are 190.1 and 210.2 arcsec, corresponding to the skew dislocation density and the pure edge and mixed dislocation densities of 7.9 × 107 and 8.8 × 107 cm−2, respectively. The RSM and Raman spectra have show the almost fully relaxed GaN epilayers and partly relaxed InGaN/GaN MQWs with a relaxation value of RInGaN = 10.9%. The TEM measurement confirms the excellent periodicity of InGaN/GaN MQWs. The RT and LT PL measurements make us to estimate the IQE for GaN-based LED wafers to be 79.0%, indicating the excellent optical properties. There is a slight blue in EL measurement at currents from 5 to 40 mA. The V-I, L-I and EQE-I curves reveal the outstanding optoelectronic properties with the forward voltage, L and best EQE of 2.78 V, 19.6 mW and 40.2%, respectively, at a current of 20 mA. Although highly-efficient GaN-based LEDs have been grown on LSAT substrates, there are still some issues to be overcome for the industrialization of GaN-based LEDs on LSAT substrates. For example, when compared with sapphire and Si substrates, LSAT substrates are of relatively small size and the cost for LSAT substrates is still high. Furthermore, the epi-structure for GaN-based LEDs on LSAT still needs to be further optimized. However, given the obvious advantages of LSAT, i.e., small lattice and CTE mismatches with GaN, the preparation of highly-efficient LEDs on LSAT in this work is still very promising and might bring up a broad application in future.

References

Shon, J. W., Ohta, J., Ueno, K., Kobayashi, A. & Fujioka, H. Fabrication of full-color InGaN-based light-emitting diodes on amorphous substrates by pulsed sputtering. Sci. Rep. 4, 5325 (2014).

Oseki, M., Okubo, K., Kobayashi, A., Ohta, J. & Fujioka, H. Field-effect transistors based on cubic indium nitride. Sci. Rep. 4, 3951 (2014).

Kim, J. et al. Less strained and more efficient GaN light-emitting diodes with embedded silica hollow nanospheres. Sci. Rep. 3, 3201 (2013).

Wang, W. L. et al. Synthesis of homogeneous and high-quality GaN films on Cu(111) substrates by pulsed laser deposition. CrystEngComm 16, 8500 (2014).

Kobayashi, Y., Kumakura, K., Akasaka, T. & Makimoto, T. Layered boron nitride as a release layer for mechanical transfer of GaN-based devices. Nature 484, 223–227 (2012).

Liu, L. & Edgar, J. H. Substrates for gallium nitride epitaxy. Mater. Sci. Eng. R 37, 61–127 (2002).

Kukushkin, S. A. et al. Substrates for epitaxy of gallium nitride: new materials and techniques. Rev. Adv. Mater. Sci. 17, 1–32 (2008).

Härle, V. et al. GaN-Based LEDs and lasers on SiC. Phys. Stat. Sol. A 180, 5 (2000).

Liu, B. et al. Nonpolarm-plane thin film GaN and InGaN/GaN light-emitting diodes on LiAlO2(100) substrates. Appl. Phys. Lett. 91, 253506 (2007).

Khan, M. A. et al. UV, blue and green light emitting diodes based on GaN-InGaN multiple quantum wells over sapphire and (111) spine substrates. Mater. Sci. Eng. B 43 265–268 (1997).

Feezell, D. F., Speck, J. S., DenBaars, S. P. & Nakamura, S. Semipolar (20-2-1) InGaN/GaN light-emitting diodes for high-efficiency solid-state lighting. J. Dis. Technol. 9, 190–198 (2013).

Arif, R. A., Ee, Y. K. & Tansu, N. Polarization engineering via staggered InGaN quantum wells for radiative efficiency enhancement of light emitting diodes. Appl. Phys. Lett. 91, 091110 (2007).

Zhao, H. P. et al. Approaches for high internal quantum efficiency green InGaN light-emitting diodes with large overlap quantum wells. Opt. Express 19, A991–A1007 (2011).

Crawford, M. H. LEDs for Solid-state lighting: performance challenges and recent advances. IEEE J. Sel. Top. Quant. 15, 1028–1040 (2009).

Tansu, N. et al. III-nitride photonics. IEEE Photonics J. 2, 241–248 (2010).

Sakowska, H., Swirkowicz, M., Mazur, K., Lukasiewicz, T. & Witek, A. Growth and characterization of (La,Sr)(Al,Ta)O3 single crystals: a promising substrate for GaN epitaxial growth. Cryst. Res. Tech. 36, 851–858 (2001).

Łukasiewicz, T. et al. New oxide crystal (La,Sr)(Al,Ta)O3as substrate for GaN epitaxy. J. Cryst. Growth 237–239, 1118–1123 (2002).

Ohta, J., Fujioka, H., Sumiya, M., Koinuma, H. & Oshima, M. Epitaxial growth of AlNon (La,Sr)(Al,Ta)O3 substrate by laser MBE. J. Cryst. Growth 225, 73–78 (2001).

Wang, W. L. et al. Investigation on the structural properties of GaN films grown on La0.3Sr1.7AlTaO6 substrates. Mater. Res. Express 1, 025903 (2014).

Talik, E., Kruczek, M., Sakowska, H. & Szyrski, W. XPS studies of chemically etched surfaces of (La,Sr)(Al,Ta)O3 single crystals. J. Alloy. Compd. 361, 282–288 (2003).

Sumiya, M. et al. Epitaxial growth of GaN film on (La,Sr)(Al,Ta)O3 (111) substrate by metal-organic chemical vapor deposition. Jpn. Appl. Phys. Part 1 41, 5038–5041(2002).

Wang, W. L., Yang, H. & Li, G. Q. Growth and characterization of GaN-based LED wafers on La0.3Sr1.7AlTaO6 substrates. J. Mater. Chem. C 1, 4070–4077 (2013).

Wang, W. L. et al. A new system for achieving high-quality nonpolar m-plane GaN-based light-emitting diode wafers. J. Mater. Chem. C 2, 4112–4116 (2014).

Wang, W. L. et al. Nitridation effect of the α-Al2O3 substrates on the quality of the GaN films grown by pulsed laser deposition. RSC Adv. 4, 39651–39656 (2014).

Zhou, S. Z. et al. Design of wide-bottomed patterned sapphire substrates for performance improvement of GaN-based light-emitting diodes. ECS J. Solid State Sci. Tech. 3, R1–R7 (2014).

Zhou, S. Z. et al. Study of defects in LED epitaxial layers grown on the optimized hemispherical patterned sapphire substrates. Jpn. J. Appl. Phys. 53, 025503 (2014).

Liu, Y. J. et al. Performance investigation of GaN-based light emitting diodes with tiny misorientation of sapphire substrates. Opt. Express 18, 2729–2742 (2010).

Zheng, X. H. et al. Determination of twist angle of in-plane mosaic spread of GaN films by high-resolution X-ray diffraction. J. Cryst. Growth 255, 63–67 (2003).

Wang, H. Y., Zhou, S. Z., Lin, Z. T., Hong, X. S. & Li, G. Q. Enhance light emitting diode light extraction efficiency by an optimized spherical cap-shaped patterned sapphire substrate. Jpn. J. Appl. Phys. 52, 092101 (2013).

Wan, Z. X. et al. Microstructural analysis of InGaN/GaN epitaxial layers of metal organic chemical vapor deposition on c-plane of convex patterned sapphire substrate. Thin Solid Films 546, 104–107 (2013).

Ee, Y. K. et al. Metalorganic vapor phase epitaxy of III-nitride light-emitting diodes on nanopatterned AGOG sapphire substrate by abbreviated growth mode. IEEE J. Sel. Top. Quantum Electron. 15, 1066–1072 (2009).

Ee, Y. K. et al. Abbreviated MOVPE nucleation of III-nitride light-emitting diodes on nano-patterned sapphire. J. Cryst. Growth 312, 1311–1315 (2010).

Li, Y. F. et al. Defect-reduced green GaInN/GaN light-emitting diode on nanopatterned sapphire. Appl. Phys. Lett. 98, 151102 (2011).

Sun, X. J. et al. Short-wavelength light beamin situ monitoring growth of InGaN/GaN green LEDs by MOCVD. Nanoscale Res. Lett. 7, 282 (2012).

Wang, G. B. et al. Green emission from a strain-modulated InGaN active layer. Chin. Phys. Lett. 29, 068101 (2012).

Polyakov, A. Y. et al. Anisotropy of In incorporation in GaN InGaN multiquantum wells prepared by epitaxial lateral overgrowth. Appl. Phys. Lett. 94, 142103 (2009).

Cho, Y. H. et al. High resolution X-ray analysis of pseudomorphic InGaN/GaN multiple quantum wells Influence of Si doping concentration. J. Appl. Phys. 85, 3006–3008 (1999).

Moram, M. A. & Vickers, M. E. X-ray diffraction of III-nitrides. Rep. Prog. Phys. 72, 036502 (2009).

Shiao, W. Y. et al. X-ray diffraction study on an InGaN/GaN quantum-well structure of prestrained growth. J. Appl. Phys. 101, 113503 (2007).

Zhang, H. D. et al. Growth of high quality GaN on a novel designed bonding-thinned template by HVPE. CrystEngComm 14, 4777–4780 (2012).

Dai, Y. B. et al. Influence of V/III ratio on stress control in GaN grown on different templates by hydride vapor phase epitaxy. RSC Adv. 4, 21504–21509 (2014).

Yang, W. J. et al. Deposition of nonpolar m-plane InGaN/GaN multiple quantum wells on LiGaO2(100) substrates. J. Mater. Chem. C 2, 801–805 (2014).

Ramachandran, V. et al. Inversion of wurtzite GaN(0001) by exposure to magnesium. Appl. Phys. Lett. 75, 808–810 (1999).

Gao, Z. Y., Hao, Y. & Zhang, J. F. Effect of structural defects in GaN epitaxial layer on its surface morphology. Mater. Rev. 23, 1–5 (2009).

Zhu, D. D. et al. Efficiency measurement of GaN-based quantum well and light-emitting diode structures grown on silicon substrates. J. Appl. Phys. 109, 014502 (2011).

Matioli, E. & Weisbuch, C. Direct measurement of internal quantum efficiency in light emitting diodes under electrical injection. J. Appl. Phys. 109, 073114 (2011).

Zhang, J. Y. et al. Efficient hole transport in asymmetric coupled InGaN multiple quantum wells. Appl. Phys. Lett. 95, 161110 (2009).

Peng, L. H., Chuang, C. W. & Lou, L. H. Piezoelectric effects in the optical properties of strained InGaN quantum wells. Appl. Phys. Lett. 74, 795–797 (1999).

DenBaars, S. P. et al. Development of gallium-nitride-based light-emitting diodes (LEDs) and laser diodes for energy-efficient lighting and displays. Acta Mater. 61, 945–951 (2013).

Shen, Y. C. et al. Auger recombination in InGaN measured by photoluminescence. Appl. Phys. Lett. 91, 141101 (2007).

Vampola, K. J., Iza, M., Keller, S., DenBaars, S. P. & Nakamura, S. Measurement of electron overflow in 450 nm InGaN light-emitting diode structures. Appl. Phys. Lett. 94, 061116 (2009).

Kioupakis, E., Rinke, P., Delaney, K. T. & Van de Walle, C. G. Indirect Auger recombination as a cause of efficiency droop in nitride light-emitting diodes. Appl. Phys. Lett. 98, 161107 (2011).

Acknowledgements

This work is financially supported by National Science Fund for Excellent Young Scholars of China (No. 51422203), National Natural Science Foundation of China (No. 51372001), Key Project in Science and Technology of Guangdong Province (No. 2011A080801018), Excellent Youth Foundation of Guangdong Scientific Committee (No. S2013050013882), Strategic Special Funds for LEDs of Guangdong Province (Nos. 2011A081301010, 2011A081301012 and 2012A080302002) and Key Project in Science and Technology Innovation of Guangdong Province (No. cxzd1105).

Author information

Authors and Affiliations

Contributions

G.L. suggested the study and led the project. W.W. grew GaN-based LED epitaxial layers and wrote the manuscript. W.Y. and F.G. carried out the XRD, SEM, AFM, TEM and PL measurements. Y.L. fabricated the GaN-based LED wafers into LED chips and took the EL, V-I, L-I and EQE-I measurements. All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License. The images or other third party material in this article are included in the article's Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/4.0/

About this article

Cite this article

Wang, W., Yang, W., Gao, F. et al. Highly-efficient GaN-based light-emitting diode wafers on La0.3Sr1.7AlTaO6 substrates. Sci Rep 5, 9315 (2015). https://doi.org/10.1038/srep09315

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep09315

This article is cited by

-

Damage to epitaxial GaN layer on Al2O3 by 290-MeV 238U32+ ions irradiation

Scientific Reports (2018)

-

High quality self-separated GaN crystal grown on a novel nanoporous template by HVPE

Scientific Reports (2018)

-

Direct Observation of the Biaxial Stress Effect on Efficiency Droop in GaN-based Light-emitting Diode under Electrical Injection

Scientific Reports (2015)

-

Microstructures and growth mechanisms of GaN films epitaxially grown on AlN/Si hetero-structures by pulsed laser deposition at different temperatures

Scientific Reports (2015)

-

Effect of pressure and electron–phonon interaction on optical properties of GaN triangular quantum wires

Optical and Quantum Electronics (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.