Abstract

Excellent field electron emission properties of a diamond/CoSi2/Si quantum well nanostructure are observed. The novel quantum well structure consists of high quality diamond emitters grown on bulk Si substrate with a nanosized epitaxial CoSi2 conducting interlayer. The results show that the main emission properties were modified by varying the CoSi2 thickness and that stable, low-field, high emission current and controlled electron emission can be obtained by using a high quality diamond film and a thicker CoSi2 interlayer. An electron resonant tunneling mechanism in this quantum well structure is suggested and the tunneling is due to the long electron mean free path in the nanosized CoSi2 layer. This structure meets most of the requirements for development of vacuum micro/nanoelectronic devices and large-area cold cathodes for flat-panel displays.

Similar content being viewed by others

Introduction

High temperature or high field is generally required for thermionic or cold electron emission cathodes to overcome the work function or to narrow the tunneling barrier, which limits their application in display devices such as televisions and power transmitters. As for the applications related to field electron emission, application of low electric field poses a big challenge in realizing planar field emission structures, which bears low costs when compared to surface structures with sharp tips or ridges. Recently, some electron emission phenomena from some new planar cathode structures with low threshold and high emission current density were observed and explained1,2. V. T. Binh et al. proposed an approach by modifying the electronic properties of the underneath surface layer – called solid-state field-controlled emission (SSE) – by using an ultrathin wide-gap semiconductor layer (UTSC) on a metal to decrease the surface barrier3,4. M.W. Geis et al. described a new electron emission mechanism in diamond cathodes based on the enhancement of electric fields at metal-diamond-vacuum triple junction5,6. However, practical applications of these cathodes are limited due to inconsistency and a serious lack of reproducibility.

A chemical vapor deposition (CVD) diamond cold cathode for field emission displays has attracted much attention due to its low work function, negative electron affinity (NEA), high thermal conductivity and robust mechanical and chemical properties. The possibility to synthesize diamond films on a foreign substrate such as Si or Mo can provide cheap and simple planar electron emission without the requirement of submicron scale techniques, often a drawback in the case of sharply pointed field emitters. Recent studies also suggest strongly that emission is an interface-controlled phenomenon rather than a surface-controlled. M. W. Geis et al. reported an observation that the emission properties of planar-diamond emitters depend critically on the roughness of the back contact (substrate); much better emission was achieved for "rough" substrate in comparison to well-polished ones7.

At the interfaces, the contact of the diamond films and the substrates set up Schottky barriers which hinder the transmission of electrons. The reason that “rough” interfaces render better emission than polished ones is that “rough” ones have sharper points inducing higher local fields which help electrons to tunnel the interface barriers. However the roughness of the interface has not been successfully controlled and the transmission coefficient is still low. Suppose we can set another Schottky barrier close to the first one and make electrons tunnel resonantly through the two Schottky barriers – emission abilities may be improved largely because the transmission coefficient at resonance is unity. One way to realize resonant tunneling is to grow a thin layer material at the interface to form a quantum well.

CoSi2 is one of the most promising materials for microelectronics because of its low resistivity and high thermal stability; it has been used as a contact material between the metalization layer and devices in CMOS integrated circuits8. Both thermal and electrical stabilities are improved by reducing the parasitic resistance at the shallow junction; resistivity values can also be lowered. CoSi2 can also be used as an interconnect conductor in semiconductor devices and is an active material for developing devices with dimensions in nanometers. In a previous work, we succeeded in depositing (001) textured as well as randomly oriented diamond films with high quality on CoSi2 and studied the comparable nucleation and growth characteristics of CVD diamond on CoSi2 and Si9.

In this work, we present the first experimental measurements of electron emission from diamond/CoSi2/Si nanostructured cold cathodes. The diamond emitters that are designed to optimize this mechanism exhibit some of the lowest operational voltages achieved so far. The selection of CoSi2 as an interlayer for studying the emission properties of diamond films has the virtue that CoSi2 is an excellent conducting material with a long electron mean free path and is suitable to realize the resonant tunneling in a diamond/CoSi2/Si quantum well nanostructure. Furthermore, the fabrication processes of metal silicides are compatible with the planar semiconductor processing techniques. By introducing the nanostructured diamond/CoSi2/Si quantum well, the modification of electron emission is shown to be realized via controlling the CoSi2 interlayer thickness; excellent electron emission properties with low threshold and high current density are observed. The excellent agreement of the experimental data and the prediction of electron resonant tunneling (ERT) verifies the view that the metallic CoSi2 thin film forms a quantum well, while the ERT effect has so far been reported only for semiconductor materials.

Results

The simple schematic diagram of the cathode is shown in Fig. 1. It consists of high quality diamond emitters grown on bulk Si substrate with a nanosized epitaxial CoSi2 conducting interlayer.

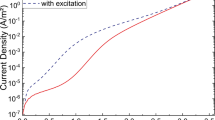

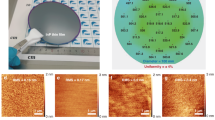

SEM images in Figs. 2a and 2b show the surface morphology of 5-μm-thick diamond films with random orientation and (001)-texture, respectively, on a 68 nm-thick CoSi2 layer. Even though the lattice mismatch of CoSi2 is about 1.2% relative to Si at room temperature, the textured diamond growth presents different characteristics on Si and CoSi29. Further, epitaxially (001)-oriented film growth like that obtained on Si (001)11,12 can not be achieved on CoSi2. Our experiments show that thickness has no obvious influence on the morphology of diamond films deposited on CoSi2 with various thicknesses under the same parameters. The typical emission current-voltage (I-V) curves obtained from diamond films grown on different thicknesses of CoSi2 interlayers are shown in Fig. 3a, the data shown in Fig. 3a are taken after 30 minutes stabilization test. For randomly oriented diamond film deposited on 68 nm thick CoSi2, the threshold voltage is 500 V (4.17 V/μm) at an emission current of 1 μA. The emission increases rapidly at an applied voltage of approximately 1000 V and reaches a value of 300 μA at 1500 V. For the randomly oriented films deposited respectively on 40 nm and 18 nm thick CoSi2 layers, the emission threshold shifts to the higher voltages of 1000 V and 1500 V, respectively. The currents clearly show an increase in their values at 1500 and 2000 V and reached 300 μA at 2000 V and 2500 V. In Fig. 3a, an emission curve from (001)-textured film deposited on 68 nm thick CoSi2 is also shown with its threshold voltage of 2000 V, the current increases rapidly as well and reaches 300 μA at 2600 V. Compared with the emission properties from (001)-oriented diamond film deposited on Si (001), shown in Fig. 3a, for which the threshold voltage is 2400 V, the current increase gradually and only reaches a value of 30 μA at 3000 V. From Fig. 3a one can see that the films deposited on CoSi2 have a tendency of a rapid increase in emission current after the threshold is reached. This indicates that enough electrons were supplied to the surface of diamond films.

I-V emission curves (a) and corresponding FN plots (b) obtained from diamond films deposited on (001) CoSi2 having different thicknesses and on (001) Si.

68 nm-R, 40 nm-R and 18 nm-R represent the randomly oriented diamond films grown on 68 nm, 40 nm and 18 nm thick CoSi2. 68 nm-T represents (001)-textured diamond film grown on 68 nm thick CoSi2. (001) Si-T represents (001) epitaxial diamond film grown on (001) Si.

The FN plots corresponding to I-V characteristics are given in Fig. 3b. We find that the F-N plots show the non-linearity with an upward bending, which can be approximately fitted with two straight lines corresponding respectively to its own field enhancement factor (β-value) in the low and high field regions. As shown in Fig. 3b, the emitted current actually reflects the tunneling phenomenon at low field, but in the high field region there is a change in the slope of curve and the emission current increases faster than predicted by the Fowler-Nordheim theory. This non-linearity of the F-N plot is often observed in CVD diamond films and diamond-like carbon films, however, the physics behind the origins of this non-linear bending of F-N plot is not understood although many explanations have been proposed13,14,15. A mechanism proposed by Bayliss et al.15 can be use to satisfactorily explain our results regarding the F-N properties, suggesting that the non-linear behavior may be attributed to the transition of the supply of emitted electrons from being controlled by the back-contact potential barrier (contact-limited) in low fields to being controlled by the transportation in the bulk region of the film (bulk-limited) in high field.

In Table 1, we summarized the emission properties including the turn-on current density and applied field strength (J0 and F0) and maximum current density (Jmax) under applied maximum field strength (Fmax). Comparing the results reported by other researchers16,17, the emission threshold voltage and maximum current density at applied maximum voltage obtained from diamond films on CoSi2 is almost at the same order of magnitude as that obtained from highly defective CVD diamond, ta-C and a-C:H films and the emission properties are obviously better than that from high quality polycrystalline diamond films deposited on Si or other substrates.

Fig. 4 shows the stabilization of emission current at an applied voltage of 1500 V for a randomly oriented diamond film on 68 nm-thick CoSi2. The results show that the emission currents change clearly in a range of 20% relative to the stable current of 300 μA in a short period of 2–10 seconds (presented with open circles) and then approach the stable current. It has a slight change of about 5% in 30 min (presented with open blocks) and finally it reaches the stable current value only at 24 hours without an obvious change (presented with solid blocks). The same phenomena in emission current is observed in a repeatable test after the sample is exposed to air; the emission current is always stable in repeatable tests in a high vacuum chamber (10−5–10−7 Torr) after the first test. A possible explanation for the current stability phenomena observed here would be that the desorption process of adatoms on diamond surface occurred only during the first test.

Discussion

In the following, we will explain the experimental results. The field emission process from the diamond/CoSi2/Si nanostructure can be attributed to a three-step model: injection of electrons from an electrical contact into the n-type Si wafer; transport through CoSi2 layer to the emitting diamond surface; and emission from the surface to the anode. It is usually not possible to obtain sustained emission from insulator materials. But undoped polycrystalline diamond has defects that contribute to emission. Some reports indicate that surface emission originates from defects18. High quality or textured diamond film has a growth characteristic of pillar/columnar structure which is advantageous for electron transport. The grain boundaries in these films can be ideally considered as passages for injected electrons for their subsequent transport through the diamond19. As for the randomly oriented diamond film – except for its defects and conducting grain boundaries – when compared to textured diamond, its surface exposed to vacuum is rough and has better emission ability20. This analysis is consistent with our experimental data wherein the randomly oriented diamond films have better emission ability than textured diamond film.

In classical physics, the resistance of a conductor is proportional to the length of the conductor. Therefore, the resistance of CoSi2 film should increase with the increase of film thickness. But this is opposite to our experimental results, where the transmission of electrons from the Si substrate to the diamond layer is enhanced with increasing thickness of the CoSi2 film. To understand this anomalous phenomenon, we must resort to quantum mechanics.

We deem that the origin of this phenomenon must lie in CoSi2 layers, according to the two facts: 1) all CoSi2 layers with different thicknesses are epitaxially grown on same Si wafers, so the Si substrates and the interfaces between CoSi2 layers and Si substrates in all cases can be looked as the same; 2) the thickness of CoSi2 layers does not affect the morphology of deposited diamond films under the same parameters, so the diamond films and the interfaces between CoSi2 layers and diamond films in all cases can be looked as the same too. The thickness L of a CoSi2 layer in our experiments is always within the bulk mean free-path [about 97 nm according Ref. 21], so the coherent system of a CoSi2 layer sandwiched between two interface barriers constructs a quantum well structure.

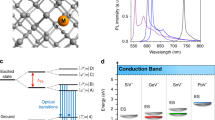

CoSi2 is a good metallic material and when it is inserted between Si substrate and diamond film, the Schottky barriers will be formed at the interfaces of this sandwich structure due to the alignment of Fermi energies. Such a quantum well with a Schottky barrier at each boundary is called double barrier22. The heights and widths of the two Schottky barriers at the boundaries of a CoSi2 film are related to the band structures and geometrical arrangement of the interfacial atoms. The Schottky barrier height at the interface of n-Si and CoSi2 was reported to be 0.64 eV23. However the Schottky barrier height at the interface of CoSi2 and diamond has not been reported so far. Since CoSi2 is a good conductor typical of common metals, we estimate the Schottky barrier height between CoSi2 and diamond by referring to that of common metals and diamond. Ref. 24 gives Schottky barrier heights between some metals and diamond which vary from about 0.4 eV to 1 eV, thus we assume the barrier height at the interface of CoSi2 and diamond is in the middle of this region, i.e., the height of CoSi2/DF interface is assumed to be a value of 0.7 eV. The schematic energy band diagram of the n-Si/ CoSi2/DF structure is plotted in Fig. 5. This figure gives us an intuitive picture of the bands of the structure and how the device works, even though the values of the bands and heights of the barriers are estimated and rough.

Schematic band edge diagram of the n-Si/ CoSi2/DF double barrier structure under (a) zero bias and (b) finite bias.

An electron with an energy within the energy window indicated as eVw tunnels the Schottky barrier from n-Si to CoSi2 film, resonant between the double barriers and tunnel the other Schottky barrier from CoSi2 to DF. Work function of the DF surface are adjusted by eVw .

According to the double barrier theory, some quasi-bound states are established between the barriers. An electron resonantly tunnels a double barrier through a quasi-bound state having the same energy as the injecting electron with transmission probability of a unity25, T(Eb) = 1, but it is badly reflected at the other energies with a much lower transmission probability, T(E≠Eb)≈0, where Eb is the energy of the quasi-bound states. So, one quasi-bound state offers one channel (or mode) for electrons to transmit. At room temperature or when the quasi-bound states couple with outside states, the energy levels of the quasi-bound states are broadened. Since the integral transmission probability for one broadened quasi-bound state is also a unity,  , one broadened level also offers one channel. If there are other neighboring broadened levels, they overlap each other and the collective broadened levels may become continuous. But the fact that one level offers one channel is still unchanged. Then for a multi-level double barrier, the total transmission of continuous levels is also proportional to the total number of the related discreet energy levels available at zero temperature. We will use density of states to describe the number of channels which describe both discreet and continuous levels. Quantum mechanics tells that when the distance between the barriers (L) is large, the density of the quasi-bound states (DOS) is proportional to L; i.e., DOS ∝ L. That means the number of channels for electrons penetrating the CoSi2 layer is proportional to the thickness of CoSi2 layer.

, one broadened level also offers one channel. If there are other neighboring broadened levels, they overlap each other and the collective broadened levels may become continuous. But the fact that one level offers one channel is still unchanged. Then for a multi-level double barrier, the total transmission of continuous levels is also proportional to the total number of the related discreet energy levels available at zero temperature. We will use density of states to describe the number of channels which describe both discreet and continuous levels. Quantum mechanics tells that when the distance between the barriers (L) is large, the density of the quasi-bound states (DOS) is proportional to L; i.e., DOS ∝ L. That means the number of channels for electrons penetrating the CoSi2 layer is proportional to the thickness of CoSi2 layer.

The current through a channel is approximately  if it is resonant and approximately zero if it is non-resonant, where

if it is resonant and approximately zero if it is non-resonant, where  and

and  denote the rates at which an electron attempts to escape through barriers 1 and 2 respectively25. The total current Itot through a double barrier under bias Vw crossing it is the summation of currents through all channels within the energy window (eVw, see Fig. 5) between Fermi levels outside the double barrier; i.e.,

denote the rates at which an electron attempts to escape through barriers 1 and 2 respectively25. The total current Itot through a double barrier under bias Vw crossing it is the summation of currents through all channels within the energy window (eVw, see Fig. 5) between Fermi levels outside the double barrier; i.e.,  . Supposed that Γ1 and Γ2 of all the modes are equal, Im is a constant for all channels and Itot = NIm, where N is the number of channels within the energy window. Taking the average value of DOS, N is thus N = DOS eVw. Then, the total current becomes Itot = Im DOS eVw. Since we have already known DOS ∝ L, we therefore obtain Itot ∝ LVw. Then the resistance of the quantum well Rw, which is defined as Rw = Vw/Itot, is inverse proportional to L; i.e., Rw ∝ 1/L. Till now, we have understood that with the increase of L, the resistance of CoSi2 layer Rw decreases, which is opposite to classical systems.

. Supposed that Γ1 and Γ2 of all the modes are equal, Im is a constant for all channels and Itot = NIm, where N is the number of channels within the energy window. Taking the average value of DOS, N is thus N = DOS eVw. Then, the total current becomes Itot = Im DOS eVw. Since we have already known DOS ∝ L, we therefore obtain Itot ∝ LVw. Then the resistance of the quantum well Rw, which is defined as Rw = Vw/Itot, is inverse proportional to L; i.e., Rw ∝ 1/L. Till now, we have understood that with the increase of L, the resistance of CoSi2 layer Rw decreases, which is opposite to classical systems.

Intuitively, voltage drops mostly on the vacuum part and little on the CoSi2 quantum well part. A question is: Is it possible that a small change of the resistance value of the quantum well can result in a large response in emitting current density? We give our explanation in the following.

We use Rw, Rv and Rr to denote the resistances of the quantum well (Rw), the vacuum (Rv) and the rest parts (Rr) of the circuit including Si substrate and DF. Since Rv ≫ Rw and Rv ≫ Rr, voltage drop at each part has the same relationship, i.e., Vv ≫ Vw and Vv ≫ Vr, where Vw, Vv and Vr denote corresponding voltage drops on Rw, Rv and Rr, respectively. So, under applied voltage V0, we can approximate Vw and Vv as  and

and  . The work function of the DF emitter,

. The work function of the DF emitter,  , is defined as the energy difference between vacuum energy and Fermi energy at the DF emitter. As shown in Fig. 5, work function

, is defined as the energy difference between vacuum energy and Fermi energy at the DF emitter. As shown in Fig. 5, work function  can be adjusted by Vw, i.e.,

can be adjusted by Vw, i.e.,  , where we have neglected the voltage drop at the DF for it is irrelevant to present discussion. According to the simplified Fowler-Nordheim (FN) equation7, current density J is:

, where we have neglected the voltage drop at the DF for it is irrelevant to present discussion. According to the simplified Fowler-Nordheim (FN) equation7, current density J is:

where F is the fraction of the area emitting electrons, E is the real emitting field at the emitter surface of the cathode. When the emitting planar cathode and planar anode are parallel, E has the expression of E≈V0/D, where D is the distance between cathode surface and anode surface. Because the emitting surfaces of randomly oriented DFs are rough and electrons emit from sharp tips on the surfaces, the emitting areas are actually very small and the emitting fields at the sharp tips are enhanced greatly. We thus use a small F and large E by letting F = 0.002 and E = 500×V0/D with some arbitrary choice. By substituting  , F = 0.002 and E = 500×V0/D into Eq. (1), we obtain,

, F = 0.002 and E = 500×V0/D into Eq. (1), we obtain,

The ratio of Rw to RV is multiplied by a large value of V0, so a very small value of Rw/Rv can induce a distinct change of work function which is at the index and could affect current density greatly. Next, we try to fit the experimental data using Eq. (2). We take D = 120 μm and 1cm2 emission area from the experiment and  from Ref. 26 and the only parameter is the ratio Rw/Rv. Figure 6 shows that the FN equation describes the experimental data well on the whole when we choose proper ratios of Rw/Rv, even though there is a little deviation around threshold voltage due to the nonlinear behavior of FN plot as shown in Fig. 3b. The fitted ratios of Rw/Rv are 0.0001, 0.00053 and 0.00077 for CoSi2 layers with 68 nm, 40 nm and 18 nm thicknesses, respectively. In our experiment the applied voltages are of the order of 103 V, so the biases crossing the CoSi2 layers with these thicknesses are of the order of 10−1 V. Obviously, these biases are much lager than the resonant level spacing (at the scale of meV) for a confined double barrier system with width of several tens of nanometers27. The results also show that (i) a very tiny change of the ratio Rw/Rv can induce a large change of J-V curve and (ii) the fitted ratio Rw/Rv decreases monotonically with the increase of the thickness of CoSi2, which agrees with our experiment that with the increase of the thickness of CoSi2 layer, the resistance of CoSi2 layer Rw decreases. Now we have given a clear picture to explain the experiment with the help of FN equation. In addition, more quasi-bound states allow higher electron accumulation in the double barrier, which lowers the effective surface barrier and improves the emission efficiency further4.

from Ref. 26 and the only parameter is the ratio Rw/Rv. Figure 6 shows that the FN equation describes the experimental data well on the whole when we choose proper ratios of Rw/Rv, even though there is a little deviation around threshold voltage due to the nonlinear behavior of FN plot as shown in Fig. 3b. The fitted ratios of Rw/Rv are 0.0001, 0.00053 and 0.00077 for CoSi2 layers with 68 nm, 40 nm and 18 nm thicknesses, respectively. In our experiment the applied voltages are of the order of 103 V, so the biases crossing the CoSi2 layers with these thicknesses are of the order of 10−1 V. Obviously, these biases are much lager than the resonant level spacing (at the scale of meV) for a confined double barrier system with width of several tens of nanometers27. The results also show that (i) a very tiny change of the ratio Rw/Rv can induce a large change of J-V curve and (ii) the fitted ratio Rw/Rv decreases monotonically with the increase of the thickness of CoSi2, which agrees with our experiment that with the increase of the thickness of CoSi2 layer, the resistance of CoSi2 layer Rw decreases. Now we have given a clear picture to explain the experiment with the help of FN equation. In addition, more quasi-bound states allow higher electron accumulation in the double barrier, which lowers the effective surface barrier and improves the emission efficiency further4.

When diamond film is deposited on Si substrate directly, there is only one barrier formed at the interface. The transmission coefficient of electrons usually attenuates exponentially with the width and the height of the barrier. However, when CoSi2 layer is inserted between diamond and Si, a double barrier is formed at the interface. Because electrons can penetrate a double barrier resonantly with the transmission coefficient of 1, the insertion of CoSi2 layer greatly improves the emission coefficient. On the other hand, since scattering would "kill" the described effect, it is essential to mention the very large coherence length of electrons in epitaxial CoSi2.

Further, for display applications, the stable, low-threshold, high-current-density emitter made of high quality diamond on CoSi2 will likely be used in integrated circuits in combination with other semiconductor devices to realize the controlled and addressed display by selective growth of epitaxial CoSi2 films of different thicknesses, which can be realized accurately and easily with the current CoSi2 growth technology. In contrast, it is difficult to repeatedly control the planar emission from CVD diamond with high defect density by modifying the parameters in the current growth technique for polycrystalline diamond films.

In summary, we have shown that a new cathode geometry which uses the novel materials, diamond and CoSi2, has properties superior to those of previous cathodes. The experimental results and theoretical models concerning the field electron emission from a diamond/CoSi2/Si quantum well nanostructure have been presented here and these indicate that electrons from the surface can be controlled by the interlayer via a resonant tunneling process. The diamond/CoSi2/Si structure not only introduces a new concept of resonant tunneling for electron emission but meets most of the requirements for the development of vacuum micro/nanoelectronic devices and large-area cold cathodes for flat-panel displays.

Methods

As to the experimental details, as a first step, 18 nm, 40 nm and 68 nm thick epitaxial CoSi2 layers are grown on 4-inch mirror-polished n-type Si (001) wafers by a molecular beam allotaxy (MBA) method10. Microwave-plasma chemical-vapor deposition (MWPCVD) reactor equipped with a 3 kW generator and a direct current (DC) bias system was used for nucleation and growth of diamond on CoSi2. A two-step process described in our previous work7 was applied, which involves bias-enhanced nucleation and textured or randomly oriented growth. Randomly oriented and (001)-textured diamond films can be synthesized on different thicknesses of CoSi2 by changing the deposition parameters (CH4 flow rate: 12.5–15 sccm; CO2 flow rate: 0–2.5 sccm; H2 flow rate: 285 sccm; Microwave power: 800–1200 W; Substrate temperature: 720–880°C; Pressure: 20–40 mbar; Bias voltage:−150 V). The morphology and crystallographic orientation and texture of the diamond films on CoSi2 (001) were evaluated by scanning electron microscopy (SEM). Field emission experiments are performed at a pressure of 10−7 Torr. Sputtered indium tin oxide (ITO) glass was used as the anode. The anode-cathode spacing was 120 μm, the emission area is 1 cm2.

References

Stepanow, S., Mugarza, A., Ceballos, G., Gambardella, P., Aldazabal, I., Borisov, A. G. & Arnau, A. Localization, splitting and mixing of field emission resonances induced by alkali metal clusters on Cu(100). Phys. Rev. B. 83, 115101 (2011).

Wu, L., Ang, L. K. & Koh, W. S. Theory of shot noise in high-current space-charge-limited field emission. Phys. Rev. B. 77, 115351 (2008).

Binh, V. T. & Adessi, Ch. New Mechanism for Electron Emission from Planar Cold Cathodes: The Solid-State Field-Controlled Electron Emitter. Phys.Rev. Lett. 85, 864–867 (2000).

Semet, V., Binh, V. T., Zhang, J. P., Yang, J., Khan, M. A. & Tsu, R. Electron emission through a multilayer planar nanostructured solid-state field-controlled emitter. Appl. Phys. Lett. 84, 1937–1939 (2004).

Geis, M. W., Efremow, N. N., Krohn, K. E., Twichell, J. C., Lyszczarz, T. M., Kalish, R., Greer, J. A. & Tabat, M. D. A new surface electron-emission mechanism in diamond cathodes. Nature 393, 431–434 (1998).

Geis, M. W., Twichell, J. C. & Lyszczarz, T. M. Diamond emitters fabrication and theory. J. Vac. Technol. B 14, 2060–2065 (1996).

Geis, M. W., Twichell, J. C., Efremov, N. N., Krohn, K. & Lyszczarz, T. M. Comparison of electric field emission from nitrogen-doped, type Ib diamond and boron-doped diamond. Appl. Phys. Lett. 68, 2294–2296 (1996).

Dass, M. L. A., Fraser, D. B. & Wei, C. S. Growth of epitaxial CoSi2 on Si (100). Appl. Phys. Lett. 58, 1308–1310 (1991).

Gu, C. Z., Jiang, X., Kappius, L. & Mantl, S. Comparison study of nucleation and growth characteristics of chemical-vapor-deposited diamond films on CoSi2 (001) and Si(001). J. Appl. Phys. 87, 1743–1747 (2000).

Mantl, S. Molecular beam allotaxy: a new approach to epitaxial heterostructures. J. Phys., D 31, 1–4 (1998).

Jiang, X., Klages, C. P., Zachai, R., Hartweg, M. & Füßer, H. J. Epitaxial diamond thin films on (001) silicon substrates. Appl. Phys. Lett. 62, 3438–3440 (1993).

Jiang, X. & Jia, C. L. Direct Local Epitaxy of Diamond on Si(100) and Surface-Roughening-Induced Crystal Misorientation. Phys. Rev. Lett. 84, 3658–3661 (2000).

Okano, K., Koizum, S., Silva, S. & Amaratunga, G. Low-threshold cold cathodes made of nitrogen-doped chemical-vapour-deposited diamond. Nature 381, 140–143 (1996).

Lerner, P., Miskovsky, N. W. & Culter, P. Model calculations of internal field emission and J–V characteristics of a composite n-Si and N–diamond cold cathode source. J.Vac. Sci. Tehcnol. B 16, 900–905 (1998).

Bayliss, K. H. & Latham, R. V. An Analysis of Field-Induced Hot-Electron Emission from Metal-Insulator Microstructures on Broad-Area High-Voltage Electrodes. Proc. Roy. Soc. A 403, 285–289 (1986).

Zhu, W., Kochanski, G. P., Jin, S., Seibles, L., Jacobson, D. C., McComack, M. & White, A. E. Electron field emission from ion-implanted diamond. Appl. Phys. Lett. 67, 1157–1159 (1995).

Amaratunga, G. A. J. &. Silva, S. R. P. Nitrogen containing hydrogenated amorphous carbon for thin-film field emission cathodes. Appl. Phys. Lett. 68, 2529–2531 (1996).

Zhu, W., Kochanski, G. P. & Jin, S. Low-Field Electron Emission from Undoped Nanostructured Diamond. Science 282, 1471–1474 (1998).

Xu, N. S., Tzeng, Y. & Latham, R. V. Similarities in the 'cold' electron emission characteristics of diamond coated molybdenum electrodes and polished bulk graphite surfaces. J. Phys. D 26, 1776–1779 (1993).

Huang, Z. H., Cutler, P. H., Miskovsky, N. M. & Sullivan, T. E. Theoretical study of field emission from diamond. Appl. Phys. Lett. 65, 2562–2564 (1994).

Hensel, J. C., Tung, R. T., Poate, J. M. & Unterwald, F. C. Specular Boundary Scattering and Electrical Transport in Single-Crystal Thin Films of CoSi2 . Phys. Rev. Lett. 54, 1840–1843 (1985).

Harrison, P. Quantum Wells, Wires and Dots (J Wiley & Sons Ltd, England, 2005).

Zhang, S. L. & Östling, M. Metal Silicides in CMOS Technology: Past, Present and Future Trends. Critical Reviews in Solid State and Material Sciences 28, 1–4 (2003).

Werner, M. Atomic force microscope study of amorphous silicon and polysilicon low-pressure chemical-vapor-deposited implanted layers. Semiconductor Sciences and Technology 18, 41–44 (2003).

Datta, S. Electronic Transport in Mesoscopic Systems (Cambridge University Press, New York, 1995).

Mackie, W. A., Plumlee, J. E. & Bell, A. e. Work function measurements of diamond film surfaces. J. Vac. Sci. Technol. B 14, 2041–2045 (1996).

Ruyter, A. & Harper, O. Quantum Wells: Theory, Fabrication and Applications (Nova Science Publishers, Inc, New York, 2009)

Acknowledgements

We wish to thank Professor Enge Wang and Professor Lifang Xu for fruitful discussions. This work is supported by the National Natural Science Foundation of China (Grand No. 50825206, 91023041, 10834012), the National Basic Research Program of China (Grand No.2009CB930502) and the Knowledge Innovation Project of CAS (Grand No. KJCX2-EW-W02).

Author information

Authors and Affiliations

Contributions

C.Z. Gu and X. Jiang planned and coordinated the experiments. C.Z. Gu, X. Jiang, J.J. Li and S. Mantl prepared the samples and performed the measurements. W.G. Lu and C.Z Gu helped with the data discussion and interpretation, C.Z. Gu, W.G Lu and X. Jiang wrote the paper.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Gu, C., Jiang, X., Lu, W. et al. Field electron emission based on resonant tunneling in diamond/CoSi2/Si quantum well nanostructures. Sci Rep 2, 746 (2012). https://doi.org/10.1038/srep00746

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00746

This article is cited by

-

Antireflection coating of barriers to enhance electron tunnelling: exploring the matter wave analogy of superluminal optical phase velocity

Scientific Reports (2017)

-

The role of Hurst exponent on cold field electron emission from conducting materials: from electric field distribution to Fowler-Nordheim plots

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.