Abstract

Vacancies and interstitial atoms are primary lattice (point) defects that cause observable microstructural changes, such as the formation of dislocation loops and voids in crystalline solids. These defects' diffusion properties determine the phase stability and environmental resistibility of macroscopic materials under ambient conditions. Although in situ methods have been proposed for measuring the diffusion energy of point defects, direct measurement has been limited. In this study, we propose an alternative in situ method to measure the activation energy for vacancy migration under laser irradiation using a pulsed laser beam from a laser-equipped high-voltage electron microscope (laser-HVEM). We made in situ observations that revealed the formation and growth of vacancy dislocation loops in an austenitic stainless steel during laser irradiation. These loops continued to grow when thermal annealing was performed after laser irradiation at the same temperature. We anticipate that laser-HVEM will provide a new method for investigating lattice defects.

Similar content being viewed by others

Introduction

Since the 1960s, interstitial dislocation loops (I-loops) in irradiated face-centred-cubic (fcc) crystals have been conveniently observed in situ by high-voltage electron microscopy (HVEM)1,2,3. However, because the clustering of vacancies into dislocation loops may occur rapidly when point defects become supersaturated, due to the methods of high-energy-particle irradiation, plastic deformation, or thermal quenching4,5,6,7,8,9, these methods are unsuitable for in situ observation.

High-power pulsed laser beams have been used to enhance surface-dependent properties10,11,12 because they can deliver controlled energy densities with precise temporal and spatial distributions. Melting and solidification occur within a notably short interaction time, generating a large temperature gradient across the boundary between the melted surface and the substrate, which results in rapid self-quenching and resolidification13. Consequently, laser irradiation is expected to introduce supersaturated vacancies into irradiated crystals. HVEM have large specimen chambers, which makes them suitable for in situ experimental measures14. It is expected that laser-HVEM systems15 can be used to perform in situ observations of vacancy dislocation loop (V-loop) formation and evolution under both laser irradiation and simultaneous laser-electron-beam irradiation.

Because migration plays an important role in vacancy-driven phenomena, the activation energy for vacancy migration (Emv) has attracted considerable interest for many years16,17,18,19,20,21. The Emv of a metal was first measured in the 1950s based on the resistivity change induced by quenching and annealing9,22. In the 1970s, Emv was obtained from the temperature dependence of the I-loop growth rate in an in situ experiment involving electron-beam irradiation using an HVEM2. Investigation of the vacancy equilibration process in pulse-heating experiments by positron annihilation techniques was applied to measure the Emv in the 1980s23. Approximately 30 years later, the present study reports the generation of V-loops in SUS316L austenitic stainless steel under laser irradiation and the in situ observation of the evolution of these V-loops. Moreover, we propose two new methods for measuring Emv. The chemical composition of the steel is shown in Supplementary Table 1.

Because the formation and evolution of dislocation loops under electron-beam irradiation have been thoroughly studied, this study treats the results of electron-beam irradiation as a standard and compares them with those obtained with laser irradiation.

Results

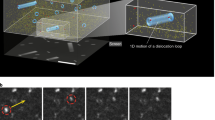

Faulted loops formed under both electron and laser irradiation. These loops were analysed by the inside-outside technique24,25 and it was found that Frank I-loops (Burgers vector: b = 1/3<111> on {111} planes) formed under electron-beam irradiation (Figs. 1(a)(c)) in agreement with previous studies26,27. However, Figs. 1(d)(f) show that a V-loop was formed by laser irradiation; this is the first time that V-loop formation under laser irradiation has been observed in situ. Moreover, this loop was also a Frank loop with a Burgers vector of b = 1/3< \(\overline{1}\)\(\overline{1}\)\(\overline{1}\) > on {111} planes.

Analysis of the nature of dislocation loops introduced under different types of irradiation.

The white arrows in the figure are used to compare the loop sizes obtained under different conditions. (a)(c) I-loops formed under electron-beam irradiation. When g (diffraction vector) >0, the loop decreased in size when s (deviation parameter) was changed from s <0 to s >0 and the sample was tilted at a large angle. (d)(f) V-loops formed under laser irradiation. When g >0, the loop first increased in size when s was changed from s <0 to s >0. The loop subsequently decreased in size when the sample was tilted at a large angle.

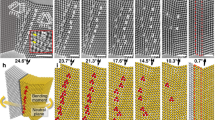

Both loops grew continuously under both types of irradiation, as shown in Figs. 2(a)(h). After every pulsed-laser irradiation, the specimen was immediately thermally annealed for 90min at the laser irradiation temperature. The loops introduced by the laser beam also continued to grow during the annealing process (see Figs. 2(i)(l)).

Fig. 3(a) shows the loop growth rates obtained under different irradiation conditions at 780K. Based on the loop growth rates at different temperatures, Arrhenius plots for different irradiation conditions were obtained to estimate the Emv (see Fig. 3(b)). In the present study, the value of Emv for SUS316L steel under electron-beam irradiation was evaluated to be 1.110.10eV, which agrees with previously reported values of 1.04eV28 and 1.35eV29. The values of Emv obtained for laser irradiation at wavelengths of 532 and 1064nm are both 1.13eV. This value agrees with those obtained by electron-beam irradiation. Figure 3(c) shows the mean loop size plotted against annealing time after pulsed-laser irradiation. Figure 3(d) shows an Arrhenius plot for the thermal annealing. From this plot, the apparent activation energy is estimated to be 1.050.14eV, which corresponds to the Emv value reported in a previous study28.

Loop growth rates and Arrhenius plots under different conditions.

(a) Loop size under different irradiation conditions at 780K. The error bar indicates the maximum and minimum values of the measured loop size. (b) Temperature dependence of the loop growth rate under different irradiation conditions fitted with equations (1) and (2). The error bar represents the standard deviation. (c) Mean loop size vs. annealing time after laser irradiation ( = 1064 nm) fitted with equation (5). D denotes the diameter (loop size) of the loop (D = 2R). The error bar indicates the maximum and minimum values of the measured loop size. (d) Arrhenius plot of the exponential factor in equation (5). The error bar indicates the standard deviation.

Discussion

According to Kiritani et al.2, in the case of Frenkel-pair introduction, the loop growth rate under electron-beam irradiation at temperatures at which vacancies are mobile is given by

where R is the loop radius, Dv is the vacancy diffusivity, Emv is the activation energy for vacancy migration, k is the Boltzmann constant and T is the working temperature. Therefore, the Arrhenius slope in Fig. 3(b) is half the value ofEmv.

After irradiation by 5-6-ns laser pulses, the heated surface layer (100150nm) was rapidly cooled, causing supersaturated vacancies to form. Excess vacancies subsequently diffused into the interior of the specimen and were annihilated at internal sinks, such as dislocation loops. It is thus hypothesised that dislocation loops formed in the interior of the specimen and grew only during the intervals between laser pulses; and the excess vacancy concentration, Cv was constant interior of the specimen because of the excessive pulses. It was assumed that the number of vacancies annihilated at a dislocation loop with a radius of R is proportional to the reaction volume (V) around the loop  (this model is shown in Supplementary Fig. S1 online), where t is the interval between laser pulses and

(this model is shown in Supplementary Fig. S1 online), where t is the interval between laser pulses and  is the diffusion length of vacancies during the interval t. The increase in the loop radius R is thus proportional to the number of vacancies annihilated at the loop and is inversely proportional to the loop radius:

is the diffusion length of vacancies during the interval t. The increase in the loop radius R is thus proportional to the number of vacancies annihilated at the loop and is inversely proportional to the loop radius:  . The average loop growth rate during laser irradiation can then be expressed as

. The average loop growth rate during laser irradiation can then be expressed as

From equation (2), it can be deduced that the Arrhenius slope of the loop growth rate during laser irradiation is equal to Emv(see Fig. 3(b)). The loops exhibited different growth rates at different temperatures under laser irradiation, which indicates that laser irradiation mainly introduces supersaturated vacancies and does not enhance vacancy migration; rather, vacancy migration is expected to depend on the working temperature.

Excess vacancies were no longer generated during thermal annealing after irradiation by successive laser pulses and the number of excess vacancies gradually decreased due to annihilation of vacancies at internal sinks, such as grain boundaries or other secondary lattice defects, including dislocation loops in the interior of the material or at the surface sink after long-range diffusion. The excess vacancy concentration, Cv, in the vicinity where a dislocation loop grows can later be expressed as a function of annealing time t as simply  or

or

where ka is the sink strength with the contribution of the other all microstructures within the foil and kaDv is the rate at which vacancies escape from the ambient of the loop because the number of supersaturated vacancies decreases during thermal annealing. Cv,excess is the initial concentration of excess vacancies, which cause V-loops to grow in the interior of the specimen prior to annealing. The growth rate of a V-loop during annealing is given by

where b is the magnitude of the Burgers vector b . Thus, the change in loop size due to thermal annealing can be expressed as

where R0 is the loop radius at t = 0(i.e., the measurement start time) and kaDv is proportional to exp(Emv/kT). The mean loop size plotted against annealing time is shown in Fig. 3(c). An Arrhenius plot of the exponential factor in equation (5) is shown in Fig. 3(d). The apparent activation energy corresponds to the value of Emv obtained from equations (5) and (2).

Only laser- and single-electron-beam irradiation was performed in the present study. Such irradiation is expected to introduce and control V- and I-loops in metals, depending on which of the two quantum beams is employed. Laser-HVEM can also perform simultaneous irradiation by laser and electron beams, but the details of the formation and evolution of loops (defects) under dual-beam irradiation depend on the laser- and electron-beam intensities; we are currently investigating this and will discuss the results elsewhere. Supplementary Fig. S2 shows models of loop formation under electron-beam irradiation, laser irradiation and simultaneous electron-beam and laser irradiation.

In summary, in situ observations of the formation and evolution of vacancy dislocation loops in an fcc crystal were realised for the first time under laser irradiation by laser-HVEM. Laser irradiation mainly introduces supersaturated vacancies. It is expected that V- or I-loops can be introduced and controlled by irradiation with laser and electron beams, respectively. Two new methods were proposed to determine the activation energy for vacancy migration; the values of Emv obtained through electron irradiation, laser irradiation and thermal annealing are in good agreement with previously reported values. Based on the experimental results, the average value of Emv under different conditions of electron-beam irradiation, laser irradiation and thermal annealing for SUS316L stainless steel was determined to be 1.100.15eV. Laser-HVEM is thus expected to provide a new method for investigating lattice defects.

Methods

In this study, solution-treated SUS316L austenite stainless steel was investigated. Sheets were prepared by mechanical thinning to a thickness of less than 0.15mm. Disks measuring 3mm in diameter were punched from the sheets and electropolished for irradiation experiments. In this experiment, the irradiated area had a foil thickness of 450600nm.

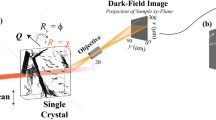

A Nd:YAG laser was installed outside of the chamber of an H-1300 high-voltage electron microscope above the specimen holder. A linearly polarised laser beam passed through a quartz window and irradiated the specimen at an angle of 60, as shown in Fig. 4(a); a photograph of the equipment is shown in Fig. 4(b). Because no optical focusing lens was employed in this study, the laser-beam intensity was assumed to be equal over the entire observation region of the specimen.

Laser irradiation by 1200 pulses (10min) was performed at 723803K, a temperature at which vacancies in the metal are highly mobile. The repetition rate of the laser pulses was 2Hz and the pulse duration was 5-6-ns. The average energy densities of the laser beam were measured to be 24 and 104mJ/cm2 at wavelengths of 532 and 1064nm, respectively. Because these energy densities are much lower than those at which the surface modification occurs (130J/cm2)13, the effects of laser irradiation on the specimen surface were considered to be negligible. During laser irradiation, the electron-beam intensity was kept as low as possible to minimise the effects of electron-beam irradiation on the specimen.

Electron-beam irradiation was performed at 623, 673, 723 and 773K using a high-voltage electron microscope at 1000kV with a damage rate of 2103dpa/s. All specimens were observed in situ along the (110) plane.

The inside-outside technique was carried out by a JEM-2000ES transmission electron microscope (TEM).

References

Makin, M. J. Electron displacement damage in copper and aluminium in a high voltage electron microscope. Philos. Mag. 18, 637 653 (1968).

Kiritani, M., Yoshida, N., Takata, H. & Maehara, Y. Growth of interstitial type dislocation loops and vacancy mobility in electron irradiated metals. J. Phys. Soc. Jpn. 38, 1677 1686 (1975).

Kiritani, M. & Takata, H. Dynamic studies of defect mobility using high voltage electron microscopy. J. Nucl. Mater. 6970, 277 309 (1978).

Yoo, M. H. & Stiegler, J. O. Point defect interactions and growth of dislocation loops. J. Nucl. Mater. 6970, 813 815 (1978).

Abromeit, C. & Wollenberger, H. Insight into cascade processes arising from studies of cascade collapse. Mater. Sci. Forum 1518, 1003 1022 (1987).

Davis, T. L. & Hirth, J. P. Nucleation rate of vacancy clusters in crystals. J. Appl. Phys. 37, 2112 2116 (1966).

Davis, T. L. Nucleation rate of vacancy clusters in aluminum. J. Appl. Phys. 38, 3756 3760 (1967).

Kino, T. & Koehler, J. S. Vacancies and divacancies in quenched gold. Phys. Rev. 162, 632 648 (1967).

Bauerle, J. E. & Koehler, J. S. Quenched-in lattice defects in Gold. Phys. Rev. 107, 1493 1499 (1957).

Picraux, S. T. & Pope, L. E. Tailored surface modification by ion-implantation and laser treatment. Science 226, 615 622 (1984).

Molian, P. A. Surface Modification TechnologiesAn Engineer's Guide. 1 (Marcel Dekker, New York, 1989).

Ohse, R. W. Laser application in high-temperature materials. Pure Appl. Chem. 60, 309 322 (1988).

Majumdar, J. D., Galun, R., Mordike, B. L. & Manna, I. Effect of laser surface melting on corrosion and wear resistance of a commercial magnesium alloy. Mater. Sci. Eng. A 361, 119 129 (2003).

Imura, T. & Fujita, H. Development of in situ observation by high voltage electron microscopy and its future. J. Electron Microsc. 28, 33 36 (1979).

Watanabe, S. et al. In situ observation of self-organizing nanodot formation under nanosecond-pulsed laser irradiation on Si surface. J. Appl. Phys. 108, 103510 (2010).

Wurschum, R., Grupp, C. & Schaefer, H. E. Simultaneous study of vacancy formation and migration at high-temperatures in B2-yype Fe aluminides. Phys. Rev. Lett. 75, 97 100 (1995).

Wurschum, R. et al. Thermal vacancy formation and self-diffusion in intermetallic Fe3Si nanocrystallites of nanocomposite alloys. Phys. Rev. Lett. 79, 4918 4921 (1997).

Matsukawa, Y. & Zinkle, S. J. One-dimensional fast migration of vacancy clusters in metals. Science 318, 959 962 (2007).

Osetsky, Y. N., Victoria, M., Serra, A., Golubov, S. I. & Priego, V. Computer simulation of vacancy and interstitial clusters in bcc and fcc metals. J. Nucl. Mater. 251, 34 48 (1997).

Woo, C. H. Intrinsic bias differential between vacancy loops and interstitial loops. J. Nucl. Mater. 107, 20 30 (1982).

Evans, J. H. &. Elerup, M. Vacancy migration and void formation during annealing of electron irradiated molybdenum. Nature 254, 685 686 (1975).

Koehler, J. S., Seitz, F. & Bauerle, J. E. Interpretation of quenching experiment on gold. Phys. Rev. 107, 1499 1505 (1957).

Schaefer, H. E. Investigation of thermal equilibrium vacancies in metals by positron annihilation. Phys. Stat. Sol. A. 102, 47 65 (1987).

Loretto, M. H. & Smallman, R. E. Defect Analysis in Electron Microscopy. 79 (Chapman and Hall, London, 1975).

Williams, D. B. & Carter, C. B. Transmission Electron Microscopy. 410 (Plenum Press, New York, 1996).

Kimoto, T., Allen, C. W. & Rehn, L. E. Growth-rate of dislocation loop in Fe-Ni-Cr alloy under Kr+ ion and electron-irradiation. J. Nucl. Mater. 191, 1194 1197 (1992).

Horiki, M., Arai, S., Satoh, Y. & Kiritani, M. Identification of the nature of small point defect clusters in neutron irradiated Fe-16Ni-15Cr by means of electron irradiation. J. Nucl. Mater. 255, 165 173 (1998).

Hidaka, Y., Ohnuki, S., Takahashi, H. & Watanabe, S. Effect of He on void formation and radiation-induced segregation in dual-beam irradiated Fe-Cr-Ni. J. Nucl. Mater. 215, 330 335 (1994).

Pokor, C., Brechet, Y., Dubuisson, P., Massoud, J. P. & Barbu, A. Irradiation damage in 304 and 316 stainless steels: experimental investigation and modeling. Part I: evolution of the microstructure. J. Nucl. Mater. 326, 19 29 (2004).

Acknowledgements

The authors are grateful to Professors H. Takahashi, T. Shibayama, S. Yatsu and Dr. T. Kato for helpful discussions regarding the present study and the authors are also grateful to Mr. K. Ohkubo, Mr. S. Mochizuki, Dr. Y. Yoshida and Mr. S. Kayashima for their help in installing and operating the laser-HVEM system.

Author information

Authors and Affiliations

Contributions

Z.B.Y. performed the experiment, collected and analysed data and wrote the paper; N.S. analysed data and derived the new equations; S.W. designed the study, analysed data and assisted with writing the paper; and M.K. was involved in the study design. All authors discussed the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareALike 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Yang, Z., Sakaguchi, N., Watanabe, S. et al. Dislocation Loop Formation and Growth under In Situ Laser and/or Electron Irradiation. Sci Rep 1, 190 (2011). https://doi.org/10.1038/srep00190

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep00190

This article is cited by

-

The Irradiation Effect of a Simultaneous Laser and Electron Dual-beam on Void Formation

Scientific Reports (2013)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.