Abstract

Piezoelectric response from two-dimensional layered materials with semiconducting properties is important for developing nanogenerators, piezotronics, and piezophototronics devices. However, experimental observation of piezoelectricity and semiconductor properties in monoatomic borophene has been a key challenge for the fabrication of nanogenerator devices. Here, we discover the non-centrosymmetric blue light emitting piezoelectric properties of few layered monoatomic borophene nanosheets. We develop the flexible piezoelectric nanogenerator using few layered borophene nanosheets in polydimethylsiloxane polymer, producing an output voltage of 8 V without electrical poling. The material exhibits a high piezoelectric charge coefficient (d33) of 86 pm V−1 and shows band gap opening with a high band gap of 2.32 eV. Surprisingly, the borophene nanosheets exhibit blue light emission under UV light illumination. Under UV light illumination, the device dramatically improves output performance. We find that the material exhibits a high dielectric constant of about 125 at low frequency.

Similar content being viewed by others

Introduction

Two-dimensional (2D) nanomaterials have attracted major attention from the scientific community for their unique properties and potential applications in next-generation electronics and energy conversion device1. The discovery of 2D materials including graphene, hexagonal boron nitride (h-BN) and molybdenum disulfide (MoS2) have been demonstrated various surprising properties and inspired a fervent quest for searching the new 2D materials and their unusual properties2,3,4. Compared with bulk materials, ultrathin 2D nanosheets with the majority of atoms exposed to the surface have greater surface areas, higher chemical and physical activity, and quantum confinement effects that endow them with special photonic, electronic, catalytic, and magnetic properties, and have great application potential in bio-like materials, drug carriers, biosensors, optoelectronics, energy conversion, energy storage and electronic devices, etc5,6,7,8. Recently, a new 2D borophene has been emerged as most mysterious nanoelemental due to its unique characteristic compared with other monoelemental 2D materials for high-speed, transparent, and flexible electronics application. Borophene, exhibits extraordinary properties, including anisotropic metallic behaviour, mechanical compliance, ultrahigh thermal conductance, optical transparency and phonon-mediated superconductivity and flexible (orientation-dependent) mechanical and optical properties9,10,11. It possesses low and unique lattice thermal conductivity of ~76 Wm−1K−1 along the zigzag and ~147 Wm−1K−1 along the armchair directions due to the strong phonon–phonon scattering at room temperature12. Borophene exhibits outstanding mechanical characteristics such as elastic modulus of 586.2 GPa and stiffness-to-weight ratio (~517 m2 s) due to the short B–B bonds, low mass of boron and existence of the 2-Pmmm phase, which add its superiority over other 2D nanomaterials13. In addition, due to the negative in-plane Poisson’s ratio (~−0.04 along armchair and ~−0.02 along zigzag) of borophene, it exhibits high mechanical flexibility along the armchair direction which further make it exciting materials among other 2D materials for the design and fabrication of flexible nanodevices14,15,16. However, the crystal structure of the borophene remained puzzled due to its existence in the various phase. Borophene was synthesized in 2015 which possesses graphene like structure, except that most hexagons host an extra boron atom in the centre it means one can view this as a triangular boron lattice with absence of few atoms13. Borophene structures is usually classified according to the composition patterns—(a) distorted hexagonal (DH) plane, (b) buckled triangular (BT) plane, and (c) mixed triangular-hexagonal (MTH) plane, or to coordination number (CN) α type (CN = 5, 6), β type (CN = 4, 5, 6), χ type (CN = 4, 5), δ type (CN = m, m is a single number), and ψ type (CN = 3, 4, 5)9. Moreover, borophenes synthesized by different methods and conditions can exhibits different structures, and these allotropes possess different properties such as the crystal vacancies can be arranged in many ways leading to form various structures of borophene such as β12 phase borophene shows highly anisotropic property while α phase borophene is isotropic17. However, it was reported that boron sheets grown on Ag (111) are metallic β12 and χ3 sheets18, with β12 being gapless with Dirac cones. Both β12 and χ3 sheets are atomically flat in a triangular lattice with atomic vacancies. In this regards, theoretical investigation suggested the existence of the non-centrosymmetric structure of the borophene, but piezoelectric properties of the borophene have been not yet reported. Density functional theory (DFT) calculation reports that borophene with a non-centrosymmetric structure showed an increase in the value of non-zero dipole hyperpolarizability with an increase in the number of layers19,20,21. Till date, no nanoscale piezoelectricity in the borophene nanosheets is observed. Moreover, the synthesis of non-centrosymmetric borophene is very crucial and usually centrosymmetric phase is formed. For real application, recently, atomically thin borophenes was recently reported by Mannix et al. and Feng et al. by depositing boron from high-purity solid sources onto the (111) surface of an Ag single-crystal in ultrahigh vacuum (UHV) conditions, i.e., following a physical vapour deposition (PVD) method13,18. Moreover, borophene cannot be produced via exfoliation methods because it does not have a layered bulk counterpart. Therefore, synthesis of the pristine and stable borophene is very difficult but highly required for the device fabrication. Recently, piezoelectric nanogenerators have received huge interest due to their outstanding capability to convert mechanical energy into electricity. Various piezoelectric nanomaterials such as ZnO, PZT, BiFeO3, PZT, PVDF and their different morphologies are used to design and fabricate the nanogenerators22,23,24. However, 2D materials of transition-metal dichalcogenide such as MoS2 and WS2 based piezoelectric nanogenerator have been also reported by various researchers25,26. In addition, T. Abasi et al. have studied the optical properties of the borophene that shows that change of the incident light direction occurs due to different metallic and semiconductor behaviour, in the borophene sheet and perpendicular light angles, respectively27. L. Adamska et al. have reported the first-principles study of the structural and optoelectronic properties of the two proposed structures of borophene, β12 and δ6, under strain and they have shown that optical absorbance and electronic band structure are continuously tunable upon application of few percent of strain28. C. Ma and his team have reported the ultrafast laser photonics in borophene due to its excellent broadband optical nonlinearities through the Z-scan experiments29. Most researchers reported on the electric and mechanical properties of borophene with little study on piezoelectric, dielectric, band gap opening and UV absorption properties. Moreover, monoelemental 2D material have been theoretically predicted to be piezoelectric because of its highly directional properties and non-centrosymmetric lattice structure30. The unusual anisotropic characteristics of borophene, including its crystal structures, mechanical, ionic transport and electronic properties make this materials for high interest for discovery of the piezoelectricity in borophene and device fabrication such as flexible nanogenerators for energy harvesting application.

In this work, we have successfully synthesised non-centrosymmetric monoelement few layered borophene from simple hydrothermal liquid exfoliation method. In the HR-TEM experiment, few layer of borophene with thickness of around 5–10 nm in thickness were observed. Crystal structure and formation of crystalline few/bi layer was confirmed through Raman analysis. Nanoscale piezoelectricity in the borophene nanosheets is observed through the piezoelectric force microscopy study. Subsequently, piezoelectric nanogenerator devices was fabricated on the transparent polyethylene terephthalate (PET) substrate and output voltage and current was obtained by applying vertical stress to the PET substrate. These borophene exhibits strong room temperature luminescence under UV light. Piezoelectric output performance of the nanogenerator was measured with and without UV light under same mechanical stress. High dielectric constant of about 125 was obtained from the few layered borophene sample. The energy conversion properties along with the enhanced dielectric constant, band gap is discussed.

Results and discussion

To prepare the few layered crystalline borophene nanosheets, acetone assisted liquid phase exfoliation technique was used through solvothermal method. The schematic image of the synthesis process of borophene is presented in the Fig. 1a. The crystalline borophene nanosheet was obtained from liquid exfoliation of the highly pure boric acid. The B precursor solution was transferred into a Teflon-lined autoclave and solvothermally treated at 200 °C for 24 h. The B precursors were further swelled from acetone molecules intercalating into the interlayer of B layers, that weakened the interlayer forces that make easier to exfoliate B (Fig. 1b). The obtained cloudy dispersion was centrifuged at 2400 rpm for 20 min and borophene nanosheets was obtained. It is expected that the dipole-induced dipole interaction may importantly cause for high dispersion and growth of the borophene nanosheets.

a The synthesis of the pristine monoelement few layered borophene nanosheets, (i–v) step by step growth process to achieve the borophene nanosheets. b Growth mechanism of the few layered borophene nanosheets. c Raman spectra d FTIR of the borophene nanosheets showing the formation of crystalline few layer of the borophene nanosheets.

Structural and morphological studies of the few layer borophene nanosheets

The crystal structure of borophene nanosheets was investigation using X-Ray Diffraction technique. Supplementary Fig. 1 shows the XRD pattern of borophene nanosheets recorded under 2theta range of 10–70 degree at RT. To measure the XRD pattern, the borophene nanosheets was coated on the pristine and cleaned glass substrate. The obtained XRD peak of the borophene can be indexed into rhombohedral crystal structure (JCPDS 78-1571)31. A broadened peak around 27° corresponds to (107) reflection was clearly obtained, which confirms the nanoscale size of the borophene nanosheets. In addition, XRD spectrum do not exhibits any additional peak, suggesting absence of the impurity phase and single crystalline nature of the borophene. To further examine the structure, crystallinity and defect of the borophene nanosheets, Raman investigation was carried out in the spectral range of 200–3500 cm−1 (Fig. 1c). The Raman spectrum of the borophene exhibits two sharp peaks at 550 and 1087 cm−1 which are attributed to the two breathing modes of β-rhombohedral phase of the crystalline borophene nanosheets. The two peaks can be attributed to the intra-icosahedral vibrations located at 550 cm−1 (B1 3 g) and the two-center B–B bonds located at 1087 cm−1 (B11g), respectively32. The FT-IR spectrum indicates the characteristic peak of the boron occurred on the edges of the borophene layer. The FT-IR spectra of the synthesized borophene exhibited the characteristic peaks of sample at 2931 cm−1 (B-B), 1714 cm-1 (C = O), 1365 cm−1 (B-O), 1228 cm−1 (B-O), and 1090 cm−1 B–O–B vibrations (Fig. 1d). These peaks are the characteristic peaks of β12 phase of the borophene. The FT-IR peaks obtained at 648 and 532 cm−1, are attributed to the sp2 bonded borophene. It is worth to note that no peak corresponds to hydrogenated borophene were seen in the FT-IR spectra32,33.

To further examine the crystal structure and morphology of the prepared borophene nanosheets, high resolution TEM was carried out. To record the TEM image borophene nanosheets were dispersed in methanol and a droplet of the solution was placed onto a 400-mesh carbon-coated copper grid. TEM confirmed the formation of sheet like structure. The TEM image also reveals that borophene nanosheets are well dispersed and have an average length of approximately 2–3.0 µm Fig. 2a–d. The inset of Fig. 2e depicts a spotty ring pattern with crystalline nature of the borophene nanosheets. The high resolved TEM images are also recorded and presented in the Fig. 2e–f. As can be seen in the edge of individual flake of borophene nanosheets, the as-fabricated borophene is composed of single or only few layers of boron. Figure 2f shows a highly crystalline nature of the borophene structure with an interplanar distance of about 0.22 nm, corresponding to the (404) lattice planes33,34. The structural, Raman and morphological results also suggested that the grown few layer borophene nanosheet was consist of the cluster of β12 icosahedral units.

Fabrication of the piezoelectric few layered borophene based nanogenerator

The as grown pristine borophene nanosheets are used to fabricate the flexible piezoelectric nanogenerator device to scavenge mechanical energy from the living environment. The schematic diagram for the fabrication process of the flexible piezoelectric nanogenerator device of few layer borophene nanosheet is shown in Fig. 3. The polydimethylsiloxane (PDMS) polymer was used as host matrix to disperse the borophene and to fabricate the flexible nanocomposite free standing film. The borophene nanosheet was homogeneously mixed with the PDMS in the ratio of 30:70 (vol%) at room temperature (RT). This mixture was then magnetic stirred for 2 h at RT to obtain the homogeneous solution. The homogeneous mixture of borophene nanosheet-PDMS was then spin coated on transparent and conducting Indium tin oxide (ITO) coated polyethylene terephthalate (PET) substrate under condition of 2000 rpm for 60 s. The prepared nanocomposite film was kept in the vacuum desiccator to remove the air bubbles from the sample. To prepare the top electrode, a conducting Cu tape was used. Finally, a Cu wire was connected by using Ag paste. The original photograph of the flexible piezoelectric borophene nanosheets-PDMS nanogenerator device is shown in Figure left side of the Fig. 3b. To avoid the triboelectric effect, no gap or spacer between top electrode and borophene nanosheets-PDMS composite was created. To further confirm the dispersion of the borophene nanosheet in PDMS matrix, FESEM image of the borophene-PDMS nanosheet was recorded and shown in Supplementary Fig. 2. The obtained FESEM image clearly depict that borophene nanosheets is randomly dispersed inside the PDMS polymer and almost no agglomeration was visible.

Piezoelectric output performance of the few layered borophene based nanogenerator

The performance of the flexible nanogenerator device was measured under various vertical pressure condition. The open-circuit output voltage generated from the flexible few layer borophene-PDMS based piezoelectric nanogenerators was about 0.25 V under very low vertical pressure of 0.02 kgf (forward connection) (Fig. 4a). To further verify that signal is generated from the piezoelectric phenomena, switching polarity test was carried out and the output voltage is measured under reverse bias connection mode. Flexible piezoelectric borophene-PDMS nanogenerator generated an opposite output electric signal with almost same magnitude, confirming that piezoelectric signal is produced due to the piezoelectric nature of the borophene (Fig. 4b). We have further improved the output voltage of the pristine borophene nanogenerator by applying the higher vertical mechanical stress. The piezoelectric output performance of borophene-PDMS based nanogenerator was measured under vertical pressure of the 2 kgf. The device produced a high output voltage of 8 V under 2 kgf force Fig. 4(c, d). It is obtained that output voltage was increased with the increase of the pressure, which is well known piezoelectric-force relation. The piezoelectric output voltage was higher as compared to the two dimensional nanosheet structures such as MoS2 and WS2 nanosheets. The most important, our finding confirmed the existence of the non-centrosymmetric rhombohedral phase and piezoelectric properties in the hydrothermal grown borophene nanosheets35,36. As no other 2D monoelement such as graphene exhibits the piezoelectric properties due to the limit of their structural properties37. The obtained output voltage was higher than other similar 2D or 1D based piezoelectric nanogenerators under low pressure condition. The output current from borophene-PDMS composite was also obtained under same condition and output current of about 0.02 nAcm−2 was obtained at pressure of 2 kgf (Fig. 4e). The enlarged view of the single electric current pulse under pushing and releasing of the force is shown in the Fig. 4f, confirming the piezo response of the borophene nanogenerator device. In addition, to ensure that signal is generated from the piezoelectric properties of the borophene, a separate device using pristine PDMS (without borophene) was also fabricated under same condition. The pristine PDMS based nanogenerator exhibits very minute electrical signal in the range of few mV and no switching polarity was obtained that further confirmed the piezoelectric nature of the borophene nanosheets. In addition the borophene nanosheets are also dispersed in the PMMA solvent and the similar flexible nanogenerator is constructed. The borophene-PMMA based device also generated an output voltage of 0.8 V under low pressure, showing the piezoelectric nature of the borophene (Supplementary Fig. 3). The equivalent circuit diagram of the borophene nanosheets based nanogenerator is given in the Supplementary Fig. 4. The durability test of the few layered borophene based nanogenerator device was also tested under application of the vertical mechanical pressure and almost stable output voltage is obtained even up to 1250 cycles (Supplementary Fig. 5). The output voltage was also measured from borophene based device under various bending condition/radius. The output voltage of about 0.7 V and 2.5 V were obtained under bending radius of 7 mm and 12 mm, respectively (Supplementary Fig. 6).

a, b The output performance of the few layered borophene-PDMS nanogenerator under vertical compressive strain in forward and reverse connection mode under 0.02 kgf force. c The output voltage measured under 2 kgf force in forward and (d) reverse connection mode. e Piezoelectric current density obtained from the borophene nanogenerator. f Enlarge view of the single cycle of the current density.

The output performance of the few layered monoelement borophene nanosheet based piezoelectric nanogenerator is compared with the reported 1D and 2D based nanogenerator devices is presented in Table 1. Z. H. Lin et al. have synthesized the piezoelectric BaTiO3 nanotube (1D) by hydrothermal method and flexible and nanogenerators using Au/Cr as top and bottom electrode was fabricated. They have obtained voltage of 5.5 V under vertical pressure38. 1D lead zirconate titanate (PZT) nanofibers obtained by electrospinning method was used with ITO/PEN electrode and an output voltage of 1.1 V was reported22. S. W. Kim and his team have fabricated the CVD-grown 2D monolayer of MoS2 piezoelectric nanogenerators and with Au electrode an output voltage of 20 mV were obtained39. Point defect passivated MoS2 nanosheet-based nanogenerator with output voltage of 22 mV was also reported40. 2D WS2 based piezoelectric nanogenerator was developed and an output voltage of 96.74 mV was reported41. V. Bhavanasi and his team have developed PVDF-TrFE bilayer films with graphene oxide for piezoelectric energy harvesting device with Au electrode. The obtained output voltage was 4 V42. A 3D piezoelectric nanogenerator using ZnO/PDMS composites was reported by Y Amangeldinova et al. with an output voltage and current of 9 mV43, where as X Ren et al. have developed the lead free BiFeO3 nanoparticles/PDMS piezoelectric energy harvester and an output voltage of 3 V was reported44. The output performance of the few layered borophene nanosheet based nanogenerator was quite larger than similar types of the reported piezoelectric nanogenerator devices.

The working mechanism of the borophene based piezoelectric nanogenerator is explained on the basis of the creation of the piezoelectric potential and formation of the electric dipoles in the borophene in PDMS matrix. The origin of the piezoelectricity and piezoelectric charge coefficient measured using piezoelectric force microscopy technique is discussed in details in the next section. The schematic diagram of the working mechanism is presented in the Fig. 5. In starting, when no vertical force is applied on the borophene piezoelectric nanogenerator device, no electric dipoles are created inside the borophene-PDMS matrix, which result no electric charges are developed (Fig. 5a). When a perpendicular pressure is applied on the top side of the device, the electric dipoles are developed due to piezoelectric properties of the borophene and electric dipoles are aligned in one direction which leads to the creation of potential difference across both the electrodes side. This causes the current to flow from top electrode (Cu) to bottom electrode (ITO) through the external loads (Fig. 5b) and electric pulse is obtained in the positive direction. When the vertical pressure is released, the piezoelectric charges are disappeared and the collected electrons at bottom electrode side starred to flow towards top electrode side and current pulse in the opposite direction is obtained. Therefore, under continuous pressure and release condition on the device generated AC type electric signal (Fig. 5c).

a original condition (b) when vertical pressure/force is applied the piezoelectric charge is developed and current started to flow from top to bottom electrode side, giving positive signal (c) when vertical pressure is released, the piezoelectric potential disappeared and accumulated charge at bottom side transported back side and negative pulse is obtained from the device. Red circle in crystal structure represent the boron atom of the borophene.

Piezoelectric force microscopy analysis of the few layer borophene nanosheets

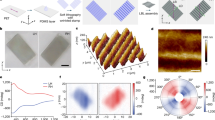

To further probe the unusual piezoelectric nature of the few layered borophene, piezoelectric force microscope (PFM) technique was employed. PFM of the borophene sample was measured using the Asylum Research MFP-3D Model Oxford Instrument in piezoelectric force microscope mode. The sharp conductive cantilever made of Si with Ti/Ir coating with tip radius and spring constant of value 25 nm and 2.8 Nm−1 respectively was used. The natural resonance frequency of cantilever tip in air was measured to be 75 kHz. The frequency of cantilever tip in contact with the sample varied from 250–260 kHz. Figure 6a depicts the schematic presentation of the PFM used to determine the piezoelectric charge coefficient (d33), amplitude and phase image of the pristine borophene nanosheets. The topographical amplitude and phase image recorded for the pristine borophene nanosheets are shown in the Figs. 6b and 6d, respectively. To avoid any artifacts or electrostatic effect during PFM measurement, borophene was spin coated on the highly conducting ITO coated substrate and bottom electrode was grounded. The AFM topographical (height) image of few layered borophene nanosheets was also recorded to confirm the thickness of the nanosheets. The formation of the nanosheets like morphology can be easily seen in the AFM image (Fig. 6b). The average thickness of as grown borophene nanosheet was estimated to about 1.8 nm, confirming the formation of 2–3 layer of the sheets (Fig. 6c). This result is in good agreement with the Raman and HR-TEM results. The piezoresponse of pristine borophene nanosheets was measured by applying the electric voltage through the AFM tip to the borophene sample. The PFM amplitude and phase image of borophene nanosheet are displayed in Fig. 6d and Fig. 6e, respectively. The change in PFM amplitude in the few layered borophene was measured with respect to the electrical signal applied through PFM tip. It is worth to point out that a linear and strong piezoelectric response was also observed from borophene nanosheets (Fig. 6f). Using the same PFM technique, an amplitude-voltage curve (Fig. 6f) is also obtained and few layered borophene nanosheets exhibits well known symmetrical curve which further confirmed the piezoelectric properties in the borophene nanosheets. The piezoelectric charge coefficient (d33) of the borophene nanosheets is measured from the displacement-voltage curve and very high value of 86 pmV−1 is obtained. The observation of the such piezoelectric properties of the borophene is due the non-centrosymmetric crystal structure of the few layer borophene. Such property from monoelement 2D borophene have been not yet reported. This results also confirmed that piezoelectric output voltage generated from the borophene nanosheets are due to the piezoelectric property of the borophene nanosheets. The existence of the well known butterfly and phase hysteresis curve (Fig. 6g) clearly proved the piezoelectricity and local dipoles alignment under electric field in borophene nanosheets, however a very minute shift of the peak from origin is due to the electrostatic interaction of the PFM tip with piezoelectric potential developed in the sample. The observation of the nanoscale piezoelectricity in the borophene nanosheets is not reported till date and thus it will open a new area for development of the monoelement flexible next generation devices.

a Schematic of PFM measurement setup for few layered borophene nanosheets, (b) amplitude and (c) height-line profile of the few layered borophene nanosheet (d) PFM amplitude and (e) phase image and (f) displacement vs voltage curve (d33) of the borophene nanosheets (g) phase voltage curve of the borophene nanosheets showing the dipole switching in the borophene nanosheets.

Band gap and photoluminescence studies of the few layered borophene nanosheets

Due to outstanding highly anisotropic metallic and semiconducting behaviour of the borophene, it has been used in the photovoltaic and optoelectronic application. As optical properties of borophene varies due to the strong anisotropy characteristics, their band gap may also change depends on the growth procedures45,46. We have measured the optical properties such as absorption and band gap of the few layered borophene nanosheets under wave length range of 200–1100 nm. The UV-Vis spectra of the borophene nanosheets is shown in the Fig. 7a. An absorption band around 324 nm was observed from the pristine borophene nanosheets sample. In addition, the optical band gap of the borophene was calculated via the well known Tauc plot formula47.

a UV absorption and bandgap calculations of the as grown few layer borophene nanosheets, inset of the left figure shows the blue light emission from the as prepared borophene under UV irradiation. b Band gap calculation of the borophene nanosheets. c Photoluminescence spectra of the few layered borophene.

The formula is well known tauc plot formula and can be read and written as

Where α is absorption coefficient, h is Planck’s constant, υ is frequency, A denotes energy independent constant, Eg symbolises optical band gap in eV and n represents the nature of transmission (n = 2 for direct band gap material while n = 1/2 for indirect band gap material). (Fig. 7b).

The optical band gap was estimated to be 2.32 eV, which is much higher than that of the reported band gap value of the bulk boron sample (1.80 eV). The increase in the band gap is due to the nanoscale size and quantum confinement effect. Z–Q Wang et al. have recently reported semiconductor phase of the hydrogenated borophene and reported the existence of the indirect semiconductor with a 0.82 eV band gap of BH1/4 borophene48. They have also observed that borophene with BH1/2 hydrogenation has direct semiconductor with a 0.78 eV. In addition, N. D.Nazar et al., have reported an opening of the band gap in the 8-Pmmn borophene through the many-body perturbation study. They have reported that many-body effects increase the bandgap at the S point from 0.81 eV (LDA) to 1.67 eV (GW) in the borophene sample49. Interestingly, in present case, borophene nanosheets showed high band gap of 2.32 eV. It is worth to point out that as prepared liquid phase of the borophene nanosheets emitted blue light under illumination of the UV light with the wavelength of the 264 nm under UV illumination intensity of ~230 Wm−2. The original image of the blue emission from the borophene nanosheets is given in the inset of the Fig. 7a.

To understand the origin of the blue emission, the photoluminescence spectra (PL) of the few layered borophene nanosheets was recorded at room temperature with the excitation wavelength of 365 nm. The observed PL spectrum of few layered borophene nanosheets is shown in the Fig. 7c. The few layered borophene exhibited a sharp emission peak at 491 nm (~2.46 eV), which corresponds to the wavelength of the blue-green light range. However, it was reported that bulk boron showed emission spectrum around 415 nm (2.15 eV), suggesting blue shift of 60 nm due to the quantum size effect. The blue emission is caused by the recombination of the electron and hole near band gap edge of the few layered borophene nanosheets.

Piezoelectric output performance of the few layered borophene based nanogenerator under UV light illumination

To further demonstrate the sensitivity/detection of the UV light from the borophene nanosheets, piezoelectric output performance was measured under the illumination of the UV light with the wavelength of the 264 nm. We have constructed a dark set up room and flexible borophene-PDMS device was placed inside the dark condition. The output voltage was measured under dark and UV light illumination condition under low vertical mechanical pressure. The actual set up for the measurement of the output performance under UV light is shown in the Fig. 8c, d. The piezoelectric output voltage was about 2.5 V under no UV light and mechanical pressure. When the same vertical mechanical pressure is applied on the device and UV light is illuminated the output voltage suddenly increased to 8.5 V under pressure of about 0.5 kgf. The output performance under UV light is also measured from the pristine PDMS based device. No output voltage or change in the electric potential without or with UV light is obtained (Fig. 8a, b). The output results clearly indicates that borophene nanosheets not highly responded towards the UV light but piezoelectric output voltage is also increased from 2.5 to 8.5V. Such high change in the output voltage is mainly due to the reduced piezoelectric screening effect cause of the free charge carrier in the borophene nanosheets. The output results also confirmed the semiconducting nature of the borophene nanosheets. Piezoelectric screening effect is caused by the excess presence of the free electrons/charge carriers in the nanomaterials. Moreover, it was reported that the interaction between hydrogen H atoms /ions and borophene surface is very strong, which results H ion are usually absorbed on the borophene nanosheet surface. It was proposed that, upon the UV light illumination on borophene, the electron and hole pairs are generated by valance band-to- conduction band transitions and the electron generated from UV illumination interact with hydrogen ions on borophene surface and naturalise/neutralised the charges, which suppress the excess electrons charge carriers in the borophene nanosheets and prevent the piezoelectric screening effects, resulting high output voltage under UV illumination. The fabricated piezoelectric nanogenerator device can be also used as self-powered UV sensors for the 2D electronics application. Xiaoyuan Wang et al. have reported that band structure of the borophene nanosheets can be modulated under application of applied strain and theoretical study reveals that resistance of borophene decreases with the increase of applied strain, due to the expansion of the buckled structure in the charge density of the strained borophene50.

a The piezoelectric output voltage measured under vertical pressure under without and with UV light of wavelength 264 nm from flexible borophene based nanogenerator. b The piezoelectric output voltage measured under vertical pressure under without and with UV light of wavelength 264 nm from pristine PDMS polymer based device showing no electric output voltage. c The original photograph of the output voltage measurement setup of borophene nanosheet based device under UV light and pressure. d The original photograph of the output voltage measurement setup of pristine PDMS based device under UV light and pressure.

Dielectric analysis of the few layered borophene nanosheets

To further examine the effect of the dielectric constant on the piezoelectric output performance of the borophene nanosheet based nanogenerator, dielectric property of pristine few layered borophene nanosheets was measured under frequency range of 20 Hz- 2 MHz using the impedance analyser. The variation of the dielectric constant (εʹ) of borophene-PDMS nanocomposite with frequency is shown in the Fig. 9a. The dielectric constant of few layered borophene-PDMS nanocomposite was found to be very high of 125 at low frequency of the 100 Hz. It was observed that as the frequency increases the dielectric constant of the borophene nanocomposite gradually decreases. At higher frequencies side, electric dipole fails to cope up with the sharp variations of the electric field and almost no dispersion was observed, resulting decrease in dielectric constant. The high dielectric constant observed from the borophene nanosheets based nanocomposite is due to the formation of the large number of the electric dipoles per unit volume and therefore high polarisation increased and high dielectric constant was obtained. Moreover, the interfacial polarization within the borophene and PDMS polymer leads to archive the high dielectric constant. Therefore, high piezoelectric output voltage observed from the borophene nanogenerator is also due to the high dielectric constant. It is worth to pointing out that formation of nanocapacitor and induction of large number of conductive paths or networks in the matrix and their synergistic effect causes high output voltage and current from the flexible piezoelectric nanogenerator51,52. It is worth to point out that dielectric constant of the pristine PDMS sample was about 8 at 100 Hz, which is almost 14 times lower than borophene nanosheets based nanocomposite sample. Dielectric tangent loss of borophene-PDMS was also investigated in the same frequency range and very low dielectric loss of about 0.9 was obtained even in the low frequency side (Fig. 9b). This result also indicates the formation of the semicrystalline phase of the borophene, as metallic phase exhibits very high dielectric loss due to the rotation of the electric dipoles and thus thermal energy dissipated. The optical dielectric function of the borophene nanosheets was predicated to the 4–5 through first principal study by B. Peng et al.53. To further confirmed the capacitive response of the few layered borophene-PDMS based nanogenerator, an electrical impedance and Z-theta curve was recorded. The internal electrical impedance was obtained using the Z- value in the frequency range 20 Hz-2MHz (Fig. 9c, d). The logarithm of the impedance -frequency curve shows a slope of value −0.99, which indicates the well-known capacitive response of the piezoelectric flexible borophene nanogenerator. In addition, in the phase frequency curve, a phase angle with value of −90° phase was seen, which further proves the capacitive response of the nanogenerator device. Therefore, our finding demonstrates the first-time observation of the semiconducting and non-centrosymmetric phase in the hydrothermal grown borophene nanosheets. The current finding also opens the new ways to fabricate the flexible 2D based nanoelectronics energy harvesting and self-powered nano devices for numerous applications.

Conclusion

In summary, two-dimensional monoatomic highly crystalline borophene nanosheets are synthesised via cost effective solvothermal cum sonication method. XRD and Raman analysis confirmed the formation of the non-centrosymmetric rhombohedral phase of the few layer borophene nanosheet. HR-TEM and AFM studies confirmed the formation of few layered borophene with average length of 2 µm. Flexible piezoelectric nanogenerator are was constructed using few layered borophene nanosheets in PDMS polymer matrix in ratio of 30:70. Flexible piezoelectric borophene nanogenerator produced a high output voltage of about 8 V under application 2 kgf force. The borophene nanosheets demonstrated the blue light emission under UV light irradiation. The band gap of few layered borophene was found to be very high of 2.32 eV. Dramatically, output performance of piezoelectric borophene nanosheets nanogenerator exhibited 8.5 V under UV light and under low mechanical pressure. The output voltage generated under normal visible light was only 2.5 V. The photoluminescence spectrum of borophene nanosheets was recorded and origin of blue light emission was discussed. The enhancement in the output voltage under UV light illumination was analysed in terms of charge screening effect, high dielectric constant and crystalline structures of the borophene. Moreover, very high dielectric constant of about 125 was obtained from the few layered borophene nanocomposites. The current work not only demonstrated the first-time observation of non-centrosymmetric piezoelectric phase and blue light emission from hydrothermal borophene nanosheets but also provide a new path to develop the flexible nanogenerator and photodetector for next generation 2D electronics.

Methods

Synthesis of pristine few layer borophene nanosheets and fabrication of flexible devices

To synthesis the highly crystalline borophene nanosheets, high purity boric acid was used (Sigma Aldrich, USA) as starting material. Initially, 2 g of boric acid was mixed in 80 mL acetone at room temperature and solution is kept on magnetic stirrer for 3 h under 140 rpm condition to get the clear solution. Then, 0.2 g of cetyltrimethyl ammonium bromide (CTAB) was added to prepared solution. Afterwards, the whole solution was transferred to 100 mL Teflon-lined stainless-steel autoclave and kept at 200 °C for 24 h. The obtained sample was centrifuged under 2400 rpm and solution was filtered and washed with DI water for several times. Finally, a black colour powder and solution was obtained.

To fabricate the flexible piezoelectric nanogenerator, the as obtained borophene nanosheets powder was mixed in the PDMS polymer in the ratio of the 30:70 vol%. The thin nanocomposites was spin coated on the pre-cleaned ITO/PET transparent substrate for 60 s under 1000 rmp condition. Copper electrode was used as top electrode of the device.

Measurements

Crystal structure of borophene was obtained via the X-ray diffraction (Rigaku Mini Flex II) with Cu Kα radiation (λ = 1.5401 Å). FTIR spectra was recorded using Thermi Nicolet Is50, USA spectrometer. Raman spectrum was collected to analysis the structural information and number of layers using laser Raman spectrometer by M/s Airix Corp., Japan of resolution 0.3 cm−1 in the range 1200–3500 cm−1. Morphological investigation were carried out using the HR-TEM experiments under an accelerating voltage of 200 kV using TEM (FEI TALOS 200 S). Dielectric constant and tangent loss of nanosheets were measured at room temperature using an Agilent E4980A LCR metre in frequency range of 20 Hz–2 MHz. The Piezoelectric output voltage was measured using mixed domain oscilloscope (Tektronix-MDO3052) and current was measured using Keithley electrometer (6517B).The vertical force on the nanogenerator device was applied through the function generator interfaced with dynamic shaker (K2007E01).

Data availability

The authors declare that all the relevant data are available within the paper and its Supplementary Information file or from the corresponding author upon reasonable request.

References

Zeng, M., Xiao, Y., Liu, J., Yang, K. & Fu, L. Exploring two-dimensional materials toward the next-generation circuits: from monomer design to assembly control. Chem. Rev. 118, 6236–6296 (2018).

Randviir, E. P., Brownson, D. A. C. & Banks, C. E. A decade of graphene research: production, applications and outlook. Mater. Today 17, 426–432 (2014).

Sharma, C., Badatya, S., Srivastava, A. K. & Gupta, M. K. Unraveling anomalous dielectric phase transition in few-layered 2H/1T MoS2 nanosheets. J. Phys. Chem. C 125, 14089–14097 (2021).

Zhang, K., Feng, Y., Wang, F., Yang, Z. & Wang, J. Two dimensional hexagonal boron nitride (2D-hBN): synthesis, properties and applications. J. Mater. Chem. C 5, 11992–12022 (2017).

Zhang, H., Fan, T., Chen, W., Li, Y. & Wang, B. Recent advances of two-dimensional materials in smart drug delivery nano-systems. Bioact. Mater. 5, 1071–1086 (2020).

Gong, C. et al. 2D nanomaterial arrays for electronics and optoelectronics. Adv. Funct. Mater. 28, 1706559 (2018).

Oh, S.-H. et al. Nanophotonic biosensors harnessing van der Waals materials. Nat. Commun. 12, 3824 (2021).

Peng, L. et al. Holey two-dimensional transition metal oxide nanosheets for efficient energy storage. Nat. Commun. 8, 15139 (2017).

Kaneti, Y. V. et al. Borophene: two-dimensional boron monolayer: synthesis, properties, and potential applications. Chem. Rev. 122, 1000–1051 (2022).

Mannix, A. J., Zhang, Z., Guisinger, N. P., Yakobson, B. I. & Hersam, M. C. Borophene as a prototype for synthetic 2D materials development. Nat. Nanotechnol. 13, 444–450 (2018).

Zhao, Y., Zeng, S. & Ni, J. Superconductivity in two-dimensional boron allotropes. Phys. Rev. B 93, 014502 (2016).

Mortazavi, B., Le, M.-Q., Rabczuk, T. & Pereira, L. F. C. Anomalous strain effect on the thermal conductivity of borophene: a reactive molecular dynamics study. Physica E: Low-dimensional Sys. Nanostruct. 93, 202–207 (2017).

Mannix, A. J. et al. Synthesis of borophenes: anisotropic, two-dimensional boron polymorphs. Science 350, 1513–1516 (2015).

Zhang, Z., Yang, Y., Penev, E. S. & Yakobson, B. I. Elasticity, flexibility, and ideal strength of borophenes. Adv. Funct. Mater. 27, 1605059 (2017).

Pang, Z., Qian, X., Wei, Y. & Yang, R. Super-stretchable borophene. EPL (Europhysics Letters) 116, 36001 (2016).

Mortazavi, B. et al. Borophene hydride: a stiff 2D material with high thermal conductivity and attractive optical and electronic properties. Nanoscale 10, 3759–3768 (2018).

Ou, M. et al. The emergence and evolution of borophene. 8, 2001801 (2021).

Feng, B. et al. Experimental realization of two-dimensional boron sheets. Nat. Chem. 8, 563–568 (2016).

Albert, B. & Hillebrecht, H. Boron: elementary challenge for experimenters and theoreticians. Angew. Chemie Int. Ed. 48, 8640–8668 (2009).

Kunstmann, J. & Quandt, A. Broad boron sheets and boron nanotubes: an ab initio study of structural, electronic, and mechanical properties. Phys. Rev. B 74, 035413 (2006).

Piazza, Z. A. et al. Planar hexagonal B36 as a potential basis for extended single-atom layer boron sheets. Nat. Commun. 5, 1–6 (2014).

Lee, H., Kim, H., Kim, D. Y. & Seo, Y. Pure piezoelectricity generation by a flexible nanogenerator based on lead zirconate titanate nanofibers. ACS Omega 4, 2610–2617 (2019).

Kim, K.-H. et al. Piezoelectric two-dimensional nanosheets/anionic layer heterojunction for efficient direct current power generation. Sci. Rep. 3, 2017 (2013).

Persano, L. et al. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat. Commun. 4, 1633 (2013).

Sharma, C., Srivastava, A. K. & Gupta, M. K. Unusual nanoscale piezoelectricity driven high current generation from self S-defect neutralised few layered MoS2 nanosheets based flexible nanogenerator. Nanoscale https://doi.org/10.1039/D2NR02347D (2022).

Cui, C., Xue, F., Hu, W.-J. & Li, L.-J. Two-dimensional materials with piezoelectric and ferroelectric functionalities. NPJ 2D Mater. Appl. 2, 18 (2018).

Abasi, T., Boochani, A. & Masharian, S. R. Metallic and intra-band investigation of optical properties for Borophene nano-sheet: a DFT study. Int. Nano Lett. 10, 33–41 (2020).

Adamska, L., Sadasivam, S., Foley, J. J., Darancet, P. & Sharifzadeh, S. First-principles investigation of borophene as a monolayer transparent conductor. J. Phys. Chem. C 122, 4037–4045 (2018).

Ma, C. et al. Broadband nonlinear photonics in few-layer borophene. 17, e2006891 https://doi.org/10.1002/smll.202006891 (2021).

Ma, W. et al. Piezoelectricity in multilayer black phosphorus for piezotronics and nanogenerators. Adv. Mater. 32, 1905795 (2020).

Hao, J. et al. Crystalline semiconductor boron quantum dots. ACS Appl. Mater. Interfaces 12, 17669–17675 (2020).

Güngör, S. et al. Copper phthalocyanine-borophene nanocomposite-based non-enzymatic electrochemical urea biosensor. Appl. Phys. A 128, 89 (2022).

Taşaltın, C., Türkmen, T. A., Taşaltın, N. & Karakuş, S. Highly sensitive non-enzymatic electrochemical glucose biosensor based on PANI: β12 Borophene. J. Mater. Sci. Mater. Electron. 32, 10750–10760 (2021).

Tsai, H.-S. et al. Fabrication of multilayer borophene on insulator structure. Small (Weinheim an der Bergstrasse, Germany) 12, 5251–5255 (2016).

Huang, H., Feng, W. & Chen, Y. Two-dimensional biomaterials: material science, biological effect and biomedical engineering applications. Chem. Soc. Rev. (2021).

Fan, F. R., Wang, R., Zhang, H. & Wu, W. Emerging beyond-graphene elemental 2D materials for energy and catalysis applications. Chem. Soc. Rev. (2021).

Bhimanapati, G. R. et al. Recent advances in two-dimensional materials beyond graphene. ACS Nano 9, 11509–11539 (2015).

Lin, Z.-H. et al. BaTiO3 nanotubes-based flexible and transparent nanogenerators. J. Phys. Chem. Lett. 3, 3599–3604 (2012).

Kim, S. K. et al. Directional dependent piezoelectric effect in CVD grown monolayer MoS2 for flexible piezoelectric nanogenerators. Nano Energy 22, 483–489 (2016).

Han, S. A. et al. Point‐defect‐passivated MoS2 nanosheet‐based high performance piezoelectric nanogenerator. Adv. Mater. 30, 1800342 (2018).

Kim, J., Lee, E., Mehta, G. & Choi, W. Stable and high-performance piezoelectric sensor via CVD grown WS2. Nanotechnology 31, 445203 (2020).

Bhavanasi, V., Kumar, V., Parida, K., Wang, J. & Lee, P. S. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 8, 521–529 (2016).

Amangeldinova, Y. et al. Enhancing electrical outputs of piezoelectric nanogenerators by controlling the dielectric constant of ZnO/PDMS composite. Micromachines 12, 630 (2021).

Ren, X., Fan, H., Zhao, Y. & Liu, Z. Flexible lead-free BiFeO3/PDMS-based nanogenerator as piezoelectric energy harvester. ACS Appl. Mater. Interfaces 8, 26190–26197 (2016).

Xie, Z. et al. Two-dimensional borophene: properties, fabrication, and promising applications. Research 2020, 2624617 (2020).

Kaneti, Y. V. et al. Borophene: two-dimensional boron monolayer: synthesis, properties, and potential applications. Chem. Rev. 122, 1000–1051 (2021).

Viezbicke, B. D., Patel, S., Davis, B. E. & Birnie, D. P. III Evaluation of the Tauc method for optical absorption edge determination: ZnO thin films as a model system. Physica Status Bolidi (B) 252, 1700–1710 (2015).

Wang, Z.-Q., Lü, T.-Y., Wang, H.-Q., Feng, Y. P. & Zheng, J.-C. Band gap opening in 8-pmmn borophene by hydrogenation. ACS Appl. Electron. Mater. 1, 667–674 (2019).

Nazar, N. D., Vazifehshenas, T., Ebrahimi, M. & Peeters, F. Strong anisotropic optical properties of 8-Pmmn borophene: a many-body perturbation study. Phys. Chem. Chem. Phys. 23, 16417–16422 (2021).

Wang, X., Wu, R., Xu, T. & Gao, Y. Mechanical and electrical properties of borophene and its band structure modulation via strain and electric fields: a first-principles study. Mater. Res. Exp. 8, 065003 (2021).

Badatya, S., Kumar, A., Srivastava, A. K. & Gupta, M. K. Flexible interconnected Cu‐Ni nanoalloys decorated carbon nanotube‐poly (vinylidene fluoride) piezoelectric nanogenerator. Adv. Mater. Technolog. 7, 2101281 (2022).

Lu, L., Ding, W., Liu, J. & Yang, B. Flexible PVDF based piezoelectric nanogenerators. Nano Energy 78, 105251 (2020).

Peng, B. et al. The electronic, optical, and thermodynamic properties of borophene from first-principles calculations. J. Mater. Chem. C 4, 3592–3598 (2016).

Acknowledgements

Authors are very thankful to the Director, CSIR-AMPRI, Bhopal for giving permission to publish this work. Manoj K Gupta is thankful to CSIR for CSIR Young scientist award project OLP-201 and CSIR Raman Research Fellowship-2022-2023 award.

Author information

Authors and Affiliations

Contributions

C.S., M.K.G., and S.B conducted the literature search, performed the measurements and prepared the first draft of the paper and the figures. N. S. and A.K.S proposed the idea and performed the TEM and Raman experiments. M.K.G. supervised, reviewed, edited the paper, and acquired the funding. All authors revised and discussed the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Aleksey Kochaev, Wenzhuo Wu, and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Jet-Sing Lee and Aldo Isidori.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sharma, C., Gupta, M.K., Badatya, S. et al. Blue light emitting piezoelectric few-layered borophene nanosheets for flexible nanogenerators. Commun Mater 4, 54 (2023). https://doi.org/10.1038/s43246-023-00375-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-023-00375-2

This article is cited by

-

Self-Poled Graphene Quantum Dots-Reinforced PVDF-HFP Nanocomposite Based Flexible Triboelectric Nanogenerator

Transactions of the Indian National Academy of Engineering (2024)