Abstract

Conventional silicon junction detectors encounter significant carrier recombination within the heavily doped p+ and n+ layers, as well as beneath the metal contact regions, creating the so-called “dead layers”, especially on the detector side. In this study, we present the tunnel oxide passivating contact with doped polysilicon on oxide, which demonstrates exceptional surface passivation and carrier selectivity. The key innovation lies in an ultra-thin (~ 1.5 nm) interfacial oxide layer that facilitates efficient majority carrier transportation via tunneling while effectively block minority carriers. Remarkably low saturation current densities, ranging from 5 to 10 fA/cm2 even with the metal contact, underscore the superiority of both n-type and p-type tunnel oxide passivating contacts. In contrast, conventional p–n junction or high-low junction exhibit saturation current densities ranging from 10 to 90 fA/cm2 in the studied p+ and n+ layers with surface passivation schemes due to Auger recombination and surface recombination, and 1000–6000 fA/cm2 with metal contacts due to intense metal-induced recombination at the interface. These findings indicate the potential and superiority of implementing n-type tunnel oxide passivating contact on the detector side and p-type contact on the back side for advanced silicon radiation detectors. This approach would enable thorough collection of generated charge carriers along the track of incident ionizing radiation particles, leading to improved energy resolution and reduced noise levels.

Similar content being viewed by others

Introduction

Since the 1960s, silicon detectors have dominated numerous radiation detection applications, including heavy charged particles, alpha particles and fission fragments, X-ray spectroscopy in medical facilities, and personnel monitors1,2. Silicon detectors, based on semiconductor technology, offer several advantages such as good energy resolution, fast timing characteristics, compactness and ruggedness, surpassing typical gas-filled detectors1. Notably, silicon detectors exhibit a low ionization energy of approximately 3.6 eV, enhancing energy solution and signal-to-noise ratio, whereas typical gas-filled detectors require around 30 eV to produce an ion pair3,4. Various configurations of silicon detectors exist, including diffused junction detectors, surface barrier detectors, and passivated planar detectors that represents the latest fabrication technology for silicon junction detectors. The state-of-the-art silicon radiation detector technologies include PIN diodes with a wide and undoped intrinsic silicon region between a p-type and an n-type silicon region, Silicon Drift Detectors (SDD) with a structure where the signal charge is transported to a small collection electrode through a drift field, Charge-coupled Devices (CCD), Active Pixel Sensors (APS) combining pixel sensors with readout electronics in each pixel, and Monolithic Active Pixel Sensors (MAPS) integrating sensors and readout electronics on the same chip1,2. All of these silicon detectors are involved with heavily doped p+ and/or n+ silicon layers or regions for electron–hole carrier separation and collection. Although also utilizing the semiconductor properties of silicon, silicon solar cells are developed to convert sunlight mainly in the wavelength range of 300–1200 nm into electrical energy via photoelectric effect. (Note that photons with wavelength below 300 nm are typically absorbed by the glass of solar panel, while photons beyond 1200 nm can not be absorbed in silicon due to their energies lower than the silicon band gap of ~ 1.12 eV.) In contrast, silicon radiation detectors are designed to detect and measure ionizing radiation, such as high-energy photons (X-rays, gamma rays) as well as particles (like protons, neutrons, alpha and beta particles). The interaction mechanisms of these high-energy photons inside the silicon radiation detectors include not only photoelectric effect, but also Compton scattering and pair production. In addition, in terms of performance characteristics, while solar cells focus on energy conversion efficiency, cost-effectiveness and durability under sunlight exposure, silicon radiation detectors aim to energy resolution, noise reduction, and response time that requires a proper bias voltage1.

In the silicon radiation detectors, the p–n junction on the detector side is typically formed by ion-implanting phosphorus or arsenic dopants onto high-resistivity p-type float zone (FZ) silicon wafer, followed by annealing at high temperatures to eliminate implantation damage and activate dopants, resulting in a heavily doped n+ layer. This kind of junction with a heavily doped layer on the opposite type substrate is the so-called rectifying contact, and also serves as a blocking contact with low minority carrier concentration inside. On the back side of these conventional silicon detectors, a heavily doped p+ layer is typically formed by implanting boron dopants and annealing at high temperatures to heal implantation damage and activate dopants. This p+ layer also creates a blocking contact to suppress leakage current as minority carriers traverse the junction.

However, when a charged particle travels through the heavily doped layer n+ layer on the detector side, as shown in Fig. 1, generated hole carriers can quickly recombine with surrounding high-concentration electrons, leading to annihilation before traversing the depleted region, due to serious Auger recombination. This results in low energy resolution, as some charge particle energy is lost when electron–hole pairs quickly recombine within this dead layer, failing to contribute to the output electrical signal. Additionally, metal-induced trapping and recombination centers at contact regions induce a high recombination velocity, severely deteriorating detector’s energy resolution. Similarly, as a charged particle penetrates to the back side of the detector and reaches to the p+ layer to create electron–hole pairs, generated electrons also quickly recombine with surrounding high-concentration holes before traversing the depleted region toward the n-type side, due to high recombination velocity caused by severe Auger recombination. Moreover, metal-induced recombination at rear contact regions also causes significant carrier loss. Consequently, the energy resolution of conventional silicon junction detectors is notably reduced due to charge carrier loss within heavily doped p+ and n+ layers, as well as at metal contact regions.

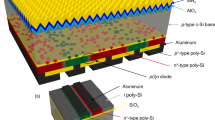

Hence, this work introduces a tunnel oxide passivating contact for novel silicon radiation detectors, aiming to eliminate heavily doped dead layers (both p+ and n+ layers) to reduce charge carrier loss, as well as metal-induced recombination beneath metal contact regions. Figure 2 illuminates the cross-section sketch of a silicon radiation detector enabled by the tunnel oxide passivating contact, comprising an ultra-thin oxide layer capped with a phosphorus-doped n+ polysilicon layer on the detector side and a boron-doped p+ polysilicon layer on an ultra-thin oxide layer on the back side.

Experimental

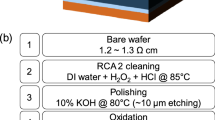

Initially, the high-resistivity <111> silicon FZ wafers underwent thorough cleaning in a piranha solution and hydrofluoric acid. Subsequently, they were immersed in the 68 wt% nitric acid (HNO3) heated at 100 °C to simultaneously grow an ultra-thin (~ 1.5 nm) tunnel oxide on both sides. It’s important to note that to achieve maximum depletion region for a given applied bias voltage, the dopant concentration on the higher-purity side of the junction should be minimized.

Next, heavily doped n+ and p+ amorphous silicon thin films (< 20 nm) were deposited on the detector side and the back side to cap the tunnel oxide layer using a single-side plasma enhanced chemical vapor deposition (PECVD) equipment. Dopant precursors diluted B2H6 and PH3 were mixed with SiH4. The samples were then annealed at 650–900 °C for 30 min in tube furnace in nitrogen ambient to form the n+ and p+ polysilicon layers. This high-temperature annealing facilitated solid-phase crystallization of the amorphous silicon films and dopant activation in the resulting polysilicon. Alternatively, these polysilicon layers could be grown by low-pressure chemical vapor deposition (LPCVD), but sacrificial masking is required to protect one side of the wafer since the polysilicon film can be simultaneously grown on both sides of the wafer in the LPCVD tube5.

To compare the charge carrier recombination loss between the conventional p–n junction and the tunnel oxide passivating contact, the quasi-steady-state photoconductance (QSSPC) characterization technique6 and the contactless photoconductivity decay method7 were utilized to quantify their emitter saturation current density (J0) from the carrier lifetime measurement. J0 was extracted from the slope of linear fit of the measured Auger-corrected inverse effective lifetime as a function of the injection level, using Eq. (1):

where W is the silicon wafer substrate thickness, Δn the excess carrier density, q the electron charge, ni the intrinsic carrier concentration of crystalline silicon wafer, Nd the bulk doping level, τSRH the defect-related bulk lifetime–Shockley–Read–Hall (SRH) recombination in the bulk, τAuger the intrinsic Auger lifetime, and τeff the measured effective excess carrier lifetime. A lower J0 value indicates higher carrier lifetime due to less carrier recombination, including Auger recombination in the heavily doped layer and the surface recombination. Note that a symmetric structure is required to apply this characterization technique for the investigated configurations, as shown in Fig. 3.

For comparison purposes, conventional p–n junctions or high-low junctions were included in this study. These conventional heavily doped n+ and p+ layers were formed by ion-implanting phosphorus and boron on high-quality silicon wafers, followed annealing at high temperatures (850–1000 °C) for 30–60 min. To minimize surface recombination, the heavily doped n+ layer was passivated by thermally grown SiO2, and the heavily doped p+ layer was passivated by an Al2O3 layer formed through plasma-enhanced atomic-layer deposition (ALD). The use of Al2O3 passivation on p+ surfaces in preference to SiO2, as shown in Fig. 3a and b, is mainly due to a high density (on the order of 1013 cm−2) of built-in negative charges, which might be present at the tetrahedrally coordinated Al site at the interface, in contrast to the octahedrally coordinated site where Al has a charge of 3+8. This high negative charge density strongly reduces the electron concentration at the silicon interface via electrostatic shielding. Therefore, Al2O3 has a very strong field-effect passivation function for p+ surface layer9. Additionally, a silicon nitride (SiNx) layer was typically deposited on top using plasma-enhanced chemical vapor deposition (PECVD) to introduce hydrogen and further enhance passivation performance.

Results and discussions

Tunnel oxide passivating contact

The core component of the tunnel oxide passivating contact is the ultra-thin oxide layer sandwiched between the silicon wafer and the doped polysilicon film. Figure 4 illuminates a high-resolution transmission electron microscopy (TEM) image of the fabricated tunnel oxide passivating contact, clearly depicting a ~ 1.5 nm ultra-thin oxide layer capped by polysilicon film on the silicon wafer.

This ultra-thin intermediate oxide layer serves as both a surface passivation layer and a transport barrier for minority carriers within the tunnel oxide passivating contact structure. Silicon oxide layers for surface passivation have been instrumental in microelectronics industry10,11, and have found successful application in conventional silicon junction detectors12, such as passivated planar detectors13. Typically, an oxide dielectric layer is grown on the surface of conventional silicon detectors to reduce surface leakage current. In surface barrier detectors, while the bulk leakage current depends on the quality of silicon wafer substrate and volume of the depleted region (with its maximum width being the wafer thickness for fully-depleted configuration), the surface leakage current is determined by the conductivity of the surface between the front and back electrodes. For passivated planar detectors, the surface leakage current is considerably lower due to oxide passivation at the surface, compared to surface barrier detectors1.

Due to its low interface state density (Dit) in the range of 1010 eV−1 cm−2, highly asymmetric capture cross sections for electrons and holes (σn ≈ 100 × σp, in unit of cm−2), and low positive fixed charge density (Qf ≈ 1011 cm−2) resulting in a small negative shift of the flat-band voltage, SiO2 has become a crucial surface passivation material for complementary metal oxide semiconductor (CMOS) technology since the 1970s11,14. Its passivation mechanism relies heavily on the reduction of the interface state density, as its fixed oxide charge density is relatively low, also known as chemical passivation15,16. Typically, a relatively thick (~ 10 nm) SiO2 layer is used to provide effective surface passivation for passivated planar detectors1.

The structure of an ultra-thin SiOx layer (1–2 nm) capped with doped polysilicon was initially investigated by the microelectronics industry in the 1970s17. At that time, bipolar junction transistors required a very thin emitter but needed to avoid a transparent emitter that could lead to significant minority carrier recombination. Thus, a doped polysilicon layer as an emitter was developed to function as a diffusion source to create a very thin junction, while an ultra-thin interfacial oxide layer was grown prior to depositing the polysilicon layer to block minority carriers from entering the emitter18. In the same era, ultra-thin SiOx layers were also studied in early metal–insulator-semiconductor (MIS) silicon solar cells to reduce interface traps and block minority carriers, while still allowing majority carriers to flow through via quantum mechanical tunneling19. To achieve low contact resistivity and low emitter resistance for this polysilicon/SiOx contact structure, high thermal annealing was typically implemented, although it could potentially cause the breakdown of the interfacial oxide layer if not properly controlled20. Recently, the tunnel oxide passivating contact has garnered significant interests in the solar energy industry for renewable energy applications21,22,23,24.

Operating principles of tunnel oxide passivating contact

The operational principles underlying the carrier selectivity of the tunnel oxide passivating contact, facilitating the transit of majority carriers while impeding minority carriers, are delineated below. Figure 5 illuminates the schematic band diagram of both n-type and p-type tunnel oxide passivating contacts.

-

(1)

The heavily doped polysilicon induces band bending in the silicon wafer with lower doping level, creating an accumulation layer due to the differing work functions. This effect results in pronounced field-effect passivation, thereby reducing the minority carrier concentration at the silicon/SiOx interface.

-

(2)

Additionally, the tunnel oxide layer somehow serves as a carrier-selective medium by presenting distinct tunneling barrier heights for electrons and holes, with band offsets of 4.7 eV for the valence band and 3.2 eV for the conduction band25. This suggests that electrons can more readily tunnel through the same ultra-thin oxide (< 2 nm) than holes.

-

(3)

Furthermore, the high-temperature annealing process during fabrication leads to the formation of an ultra-thin p–n junction or high-low junction at the silicon surface through dopant diffusion from the heavily doped polysilicon layer, enhancing majority carrier transport through the tunnel oxide. However, excessive dopant diffusion into the silicon wafer may elevate carrier recombination velocity due to increased Auger recombination in the diffused region.

-

(4)

Lastly, the high-temperature annealing may induce pinholes or breakage in the tunnel oxide, potentially resulting in direct contact between polysilicon and the silicon wafer. This phenomenon can augment majority carrier transport, particularly for p-type tunnel oxide passivating contacts (p+ polysilicon/SiOx) due to the higher tunneling barrier height for holes25. Thus, pinholes may facilitate hole transport as majority carriers, as depicted in Fig. 6. Nevertheless, pinholes may also attract electrons, and an excessively high pinhole density could increase defect-induced recombination or Shockley–Read–Hall recombination.

Prominence of tunnel oxide layer

As discussed earlier, the dopants within polysilicon layer need to be activated by thermal annealing. Figure 7 displays the effect of annealing temperature on the resulting passivation performance of the tunnel oxide passivating contact by comparing its J0 values. It is important to note that the anneal time for each plateau temperature is 30 min in this study.

Compared to the as-deposited sample (PECVD deposition temperature at 300 °C), annealing at 650 °C is insufficient to achieve solid-phase crystallization of the amorphous silicon thin film26,27 and activate the dopants, resulting in no improvement in reducing the J0 value of approximately 145 fA/cm2. However, annealing at 800 °C significantly enhances passivation performance, reducing the J0 value to ~ 15 fA/cm2. Further increasing the thermal budget to 875 °C improves passivation quality even further, yielding an ultra-low J0 value ~ 5 fA/cm2. However, annealing at 950 °C leads to a degradation in passivation performance, with the J0 value increasing to around 25 fA/cm2. This is likely due to excessive phosphorus dopants diffusing from the polysilicon layer through the intermediate oxide layer into the crystalline silicon wafer, forming a heavily doped n+ layer, a process known as in-diffusion. Consequently, Auger recombination rapidly increases. Additionally, improper pinholes and a higher density of larger pinholes are likely created at 950 °C 28, resulting in more direct contacts between polysilicon and crystalline wafers, leading to higher recombination velocity.

Furthermore, when the tunnel oxide layer is removed, the polysilicon film is directly deposited on the silicon wafer, the J0 value exceeds 1000 fA/cm2, even at the optimized annealing temperature of 875 °C (Fig. 7). This underscores the importance of the tunnel oxide layer for this tunnel oxide passivating contact structure. As shown in Fig. 8, without the tunnel oxide layer, the polysilicon thin film directly contacts crystalline silicon wafer. Consequently, electrons and holes can readily recombine at the polysilicon/Si interface due to the presence of numerous energy levels within the band gap caused by inherent defects in the polysilicon material.

Conventional p–n Junction vs Tunnel Oxide Passivating Contact

Figure 9 illuminates that the J0 of conventional n+ layer passivated with approximately 10 nm thermally-grown SiO2 (J0n-pass) dramatically decreases from about 90 to 20 fA/cm2 as its sheet resistance increases from 70 to 200 Ω per square (Ω/□). The sheet resistance was controlled by using different doses at the same implantation energy during the ion implantation process. This J0 reduction is attributed to reduced Auger recombination within the n+ layer and lower carrier recombination velocity at the surface. However, the J0 of metal contact area on this conventional n+ layer (J0n-metal) rapidly increases from around 900 to over 5000 fA/cm2 due to higher metal-induced recombination resulting from less shielding for minority carriers. Metal atoms at the contact areas can act as deep impurities, introducing energy levels near the middle of the forbidden gap and becoming active traps for charge carriers. These trapping centers capture holes or electrons, preventing them from contributing to the radiation detection pulse. Some deep impurities at the metal contact regions behave as recombination centers, capturing both electrons and holes and causing them to annihilate, as indicated in Fig. 10. The optimized J0-pass of ~ 5 fA/cm2 for the n-type tunnel oxide passivating contact is promising even without metal contact, compared to the conventional n+ layer (~ 20 fA/cm2). Impressively, even with electrode metal contact, this n-type tunnel oxide passivating contact maintains an ultra-low J0-metal of ~ 5 fA/cm2, as minority carriers are blocked away from the metal surface by the tunnel oxide passivating contact structure. This is noteworthy compared to the J0n-metal of conventional n+ layers (900–6000 fA/cm2) seen in Fig. 9.

For conventional passivated p+ layers, the J0 values (J0p-pass) effectively decreases from ~ 60 to ~ 10 fA/cm2 as the sheet resistance increases from 80 to 210 Ω/□, owing to an excellent field-effect passivation function from the atomic-layer deposited Al2O3 layer with negative charges at its interface9 This reduction is due to less Auger recombination within the p+ layer and lower carrier recombination velocity at the silicon surface resulting from lower doping levels. However, similar to conventional n+ layers, when contacted with a metal electrode, the p+ layers experience significant metal-induced recombination. Higher sheet resistance leads to less shielding function for minority carriers at the contact interface, resulting in increasing J0p-metal values from 1500 to over 5000 fA/cm2, as displayed in Fig. 11. Auger recombination within the p+ layer and metal-induced recombination at the interface are also indicated in Fig. 10. Although the obtained J0 values for the optimized p-type tunnel oxide passivating contact are only around 10 fA/cm2, they are still comparable to those of conventional passivated p+ layers with high sheet resistance. Importantly, this low J0p-pass of ~ 10 fA/cm2 is maintained even when contacted with a metal electrode, as a result of the excellent blocking function of tunnel oxide passivating contact for minority carriers. This is encouraging compared to conventional p+ layers with metal contact (1500–6000 fA/cm2) shown in Fig. 11.

Silicon radiation detectors with tunnel oxide passivating contact

As depicted in Fig. 2, high purity (intrinsic or undoped) silicon wafers with resistivity exceeding 10,000 Ωcm are utilized to fabricate high-energy-resolution detectors with low bulk leakage current. Using high-resistivity silicon wafers allows for maximization of the depletion region width by minimizing the silicon substrate’s doping concentration for a given applied bias voltage. Additionally, the applied reverse bias voltage must exceed the depletion voltage (Vd), calculated using Eq. (2)1:

where q represents the electron charge, N is the dopant concentration of the high-resistivity silicon wafer, T is the wafer thickness, and \(\epsilon\) is the dielectric constant of silicon. This ensures the extension of the depletion region to the back surface of silicon wafer, achieving a fully depleted configuration and avoiding any undepleted regions. An undepleted region implies a thick dead layer from which no charge carriers are collected due to the absence of an electric field.

Furthermore, the orientation of the path of a charge particle with respect to the silicon wafer crystal axes significantly affects the rate of energy loss of the charged particle. Particles traveling parallel to silicon wafer crystal planes tend to exhibit lower energy loss than particles directed randomly, known as “channeling”1. Therefore, high-resistivity silicon wafers with <111> crystal orientation are employed to minimize the tendency for incident particles to channel in our study. A 20-nm aluminum layer is typically deposited on the top of detector side as electrical contact to extract charge carriers, and block ambient light from reaching the depletion region to create charges29, as shown in Figs. 1 and 2. While this reduces potential noise sources, it adds a thin dead layer to the detector side.

It has been observed that chemically grown oxide exhibits very low leakage current density, good stoichiometry, and thermal stability compared to thermally grown SiO2 layers30,31. Hence, this ultra-thin tunnel oxide layer can also be grown by thermal oxidation or ultraviolet (UV)/ozone exposure32. Additionally, a guard ring structure and a passivation layer on the detector side are employed to reduce the surface leakage1,13, as shown in Fig. 12.

Due to the excellent passivation performance of the tunnel oxide passivating contact with J0 of ~ 5 fA/cm2, the top aluminum contact layer can be patterned to minimize the metal coverage area, thus allowing for more active areas (Fig. 12). This enables the minimization of energy loss of incident particles, particularly when there is no ambient light involved during detection, hence minimizing noise from background light. Consequently, by applying the developed n-type and p-type tunnel oxide passivating contact on the detector side and the back side, more generated charge carriers are collected and can contribute to the radiation detection pulse, potentially leading to higher energy resolution and lower noise level compared to the conventional silicon junction detectors.

Conclusion

Silicon detectors, utilizing conventional p–n junction or high-low junction formed by heavily doped p+ and n+ layers, dominate in some radiation detection and measurement applications. However, they still suffer from serious Auger recombination in these heavily doped layers and metal-induced recombination beneath electrode contact areas, weakening their detection performance. In this study, we have demonstrated the tunnel oxide passivating contact, consisting of an ultra-thin oxide layer capped by a doped polysilicon layer, with excellent passivation performance and carrier-selectivity. The very low J0 value of ~ 5 fA/cm2 for the n-type tunnel oxide passivating contact and ~ 10 fA/cm2 for the p-type one demonstrates their effective charge carrier selectivity compared to the conventional SiO2-passivated n+ layers (20–90 fA/cm2) and ALD Al2O3-passivated p+ layers (10–70 fA/cm2). The primary carrier transport mechanism of this passivating contact structure involves the tunneling of majority carriers through an ultra-thin oxide layer (~ 1.5 nm). A proper pinhole density may also benefit holes as majority carriers, given their higher tunnel barrier height than electrons. The resulting high J0 of ~ 1050 fA/cm2 verifies the prominence of the tunnel oxide layer when a doped n+ polysilicon is directly deposited on the silicon wafer. Furthermore, when contacted with electrode metal, conventional p+ and n+ layers suffer from intense metal-induced recombination with J0p-metal and J0n-metal in the range of 1000–6000 fA/cm2 in this study. Higher sheet resistance for studied p+ and n+ layers, and less shielding for minority carriers, lead to more metal-induced recombination. Nevertheless, the ability of both n-type and p-type tunnel oxide passivating contacts to maintain their ultra-low J0 values when contacted with the electrode metal is promising and encouraging. This demonstrates the potential and superiority of novel silicon radiation detectors enabled by the n-type tunnel oxide passivating contact on the detector side and the p-type one on the back side. Due to the extremely low J0 for the tunnel oxide passivating contact on both sides, the generated electrons and holes are effectively and efficiently collected and transported to electrodes without recombination loss, potentially resulting in a very promising energy resolution and low noise level.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Knoll, G. F. Radiation Detection and Measurement (Wiley, 2010).

Akimov, Y. K. Silicon radiation detectors. Instrum. Exp. Tech. 50, 1–28 (2007).

Weiss, J. & Bernstein, W. Energy required to produce one ion pair for several gases. Phys. Rev. 98(6), 1828 (1955).

Sakai, E. Present status of room temperature semiconductor detectors. Nucl. Instrum. Methods Phys. Res. 196(1), 121 (1982).

Schmidt, J., Peibst, R. & Brendel, R. Surface passivation of crystalline silicon solar cells: Present and future. Sol. Energy Mater. Sol. Cells 187, 39–54 (2018).

Sinton, R. A. & Cuevas, A. Contactless determination of current–voltage characteristics and minority-carrier lifetimes in semiconductors from quasi-steady-state photoconductance data. Appl. Phys. Lett. 69(17), 2510–2512 (1996).

Kane, D. E., & Swanson, R. M. Measurement of the emitter saturation current by a contactless photoconductivity decay method. In IEEE photovoltaic specialists conference, vol.18, 578–583 (1985).

Johnson, R. S., Lucovsky, G. & Baumvol, I. Physical and electrical properties of noncrystalline Al2O3 prepared by remote plasma enhanced chemical vapor deposition. J. Vac. Sci. Technol. A Vac. Surf. Films 19(4), 1353–1360 (2001).

Hoex, B., Heil, S. B. S., Langereis, E., Van de Sanden, M. C. M. & Kessels, W. M. M. Ultralow surface recombination of c-Si substrates passivated by plasma-assisted atomic layer deposited Al2O3. Appl. Phys. Lett. 89(4), 042112 (2006).

Deal, B. E. & Grove, A. S. General relationship for the thermal oxidation of silicon. J. Appl. Phys. 36(12), 3770–3778 (1965).

Nicollian, E. H. & Brews, J. R. MOS (Metal Oxide Semiconductor) Physics and Technology (Wiley, 2002).

Kemmer, J. Fabrication of low noise silicon radiation detectors by the planar process. Nucl. Instrum. Methods 169(3), 499–502 (1980).

Kemmer, J. Improvement of detector fabrication by the planar process. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 226(1), 89–93 (1984).

Glunz, S. W. & Feldmann, F. SiO2 surface passivation layers—a key technology for silicon solar cells. Sol. Energy Mater. Sol. Cells 185, 260–269 (2018).

Shockley, W. T. R. W. & Read, W. T. Jr. Statistics of the recombinations of holes and electrons. Phys. Rev. 87(5), 835 (1952).

Hall, R. N. Electron-hole recombination in germanium. Phys. Rev. 87(2), 387 (1952).

Takagi, M., Nakayama, K., Tevada, C. & Kamioko, H. Improvement of shallow base transistor technology by using a doped polysilicon diffusion source. J. Jpn. Soc. Appl. Phys. 42(Suppl), 101–1095 (1972).

Post, I. R. C., Ashburn, P. & Wolstenholme, G. R. Polysilicon emitters for bipolar transistors: A review and re-evaluation of theory and experiment. IEEE Trans. Electron Devices 39(7), 1717–1731 (1992).

Fonash, S. J. The role of the interfacial layer in metal− semiconductor solar cells. J. Appl. Phys. 46(3), 1286–1289 (1975).

Wolstenholme, G. R., Jorgensen, N., Ashburn, P. & Booker, G. R. An investigation of the thermal stability of the interfacial oxide in polycrystalline silicon emitter bipolar transistors by comparing device results with high-resolution electron microscopy observations. J. Appl. Phys. 61(1), 225–233 (1987).

Hollemann, C. et al. 26.1%-efficient POLO-IBC cells: Quantification of electrical and optical loss mechanisms. Progr. Photovoltaics Res. Appl. 27(11), 950–958 (2019).

Glunz, S. W. et al. Silicon-based passivating contacts: The TOPCon route. Progr. Photovoltaics Res. Appl. 31, 341 (2021).

Liu, W. et al. Polysilicon passivating contacts for silicon solar cells: Interface passivation and carrier transport mechanism. ACS Appl. Energy Mater. 2(7), 4609–4617 (2019).

Kim, S. et al. Bi-polysilicon passivating contact technique for crystalline silicon solar cell. Mater. Sci. Semicond. Process. 160, 107453 (2023).

Lee, W.-C. & Chenming, Hu. Modeling CMOS tunneling currents through ultrathin gate oxide due to conduction-and valence-band electron and hole tunneling. IEEE Trans. Electron Devices 48(7), 1366–1373 (2001).

Spinella, C., Lombardo, S. & Priolo, F. Crystal grain nucleation in amorphous silicon. J. Appl. Phys. 84(10), 5383–5414 (1998).

Tao, Y. et al. Effects of annealing temperature on crystallisation kinetics, film properties and cell performance of silicon thin-film solar cells on glass. Sol. Energy Mater. Sol. Cells 101, 186–192 (2012).

Peibst, R. et al. Working principle of carrier selective poly-Si/c-Si junctions: Is tunnelling the whole story?. Sol. Energy Mater. Sol. Cells 158, 60–67 (2016).

Tindall, C. S. et al. Silicon detectors for low energy particle detection. IEEE Trans. Nucl. Sci. 55, 797 (2008).

Asuha, K., Hikaru, O. M., Takahashi, M. & Iwasa, H. Nitric acid oxidation of Si to form ultrathin silicon dioxide layers with a low leakage current density. J. Appl. Phys. 94(11), 7328–7335 (2003).

Moldovan, A. et al. Tunnel oxide passivated carrier-selective contacts based on ultra-thin SiO2 layers. Sol. Energy Mater. Sol. Cells 142, 123–127 (2015).

Moldovan, A. et al. Simple cleaning and conditioning of silicon surfaces with UV/ozone sources. Energy Procedia 55, 834–844 (2014).

Acknowledgements

This material is based upon work supported by the Department of Energy/National Nuclear Security Administration under Award Number(s) DE-NA0003921. The authors would like to thank Dr. Ajeet Rohatgi and Brian Rounsaville at the School of Electrical and Computer Engineering, and the technical staffs at the Institute for Electronics and Nanotechnology (IEN) at Georgia Institute of Technology for their supports.

Author information

Authors and Affiliations

Contributions

A.E. and Y.T. developed the project. M.D. and Y.T. performed the material growth, device fabrication, and characterization. All authors analyzed the results, prepared conclusions, and contributed to the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tao, Y., Duce, M. & Erickson, A. Tunnel oxide passivating contact enabled by polysilicon on ultra-thin SiO2 for advanced silicon radiation detectors. Sci Rep 14, 17307 (2024). https://doi.org/10.1038/s41598-024-68368-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-68368-w

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.