Abstract

The study introduces a groundbreaking continuous system that combines an extruder and grinder to enable catalyst-free and solvent-free reactions under mild conditions. This temperature-controlled system facilitates the synthesis of highly functionalized chromenes, which have valuable applications in generating combinatorial libraries and complex target molecules. The newly developed mill extruder machine offers several advantages for industrial production on a large scale. It effectively reduces waste, saves energy, and enhances time efficiency. This system represents a significant advancement in the field, providing a new strategy for one-pot synthesis of various types of highly functionalized spirooxindoles and chromenes. Remarkably, these reactions can be accomplished within a short timeframe of 2–10 min, yielding impressive results of 75–98%. The results demonstrate superior performance compared to traditional reaction methods, making it an appealing tool and hotspot area of research in green chemistry.

Similar content being viewed by others

Introduction

Sustainability is playing an increasingly important role in environmental and industrial processes, and the expertise of sustainability professionals is essential in addressing the associated challenges. Solvents and catalysts are critical elements in numerous chemical processes, but their use can lead to environmental pollution due to the presence of hazardous chemicals1. Specifically, the large quantities of volatile, flammable, and toxic organic solvents, as well as metal catalysts, contribute significantly to this issue2. In recent years sustainable alternatives solvents and catalysts are being developed and implemented. Green solvents, eco-friendly catalysts and novel tools are being explored to minimize the environmental impact of chemical processes3.

Mechanochemistry has garnered significant interest among organic chemists as a versatile technique for conducting rapid, clean, and environmentally friendly synthesis without the need for harmful organic solvents4. This approach involves utilizing mechanical forces such as shearing, grinding, or milling to facilitate chemical reactions. Ball milling mechanochemistry, in particular, has proven to be a widely applicable method in solid-state phase reactions, offering advantages over conventional laboratory work involving stirrers and heaters5. Large-scale ball mills are utilized mainly for material processing but are not yet employed efficiently in organic chemistry6. Ball milling has indeed brought about a revolution in organic synthesis by enabling faster and simpler reactions in a solvent-free environment, leading to high conversion rates. However, there are two key areas that require attention and improvement in these methods: temperature control and scalability. Addressing these deficiencies is crucial given the significance of mechanical processes in organic synthesis6.

To eliminate these restrictions, scientists have introduced a twin-screw extrusion (TSE) (Fig. 1) in organic chemistry. Reactive extrusion is an innovative and efficient technique used in the synthesis of polymers. It involves combining polymerization or chemical reactions with the process of extrusion to produce functionalized or modified polymers7. This method offers several advantages over traditional polymer synthesis approaches, including improved reaction kinetics, enhanced control over the polymer structure, and simplified process integration. Furthermore, twin-screw extrusion has found applications beyond co-crystal synthesis, including the synthesis of diverse chemical species such as metal–organic frameworks (MOFs) and, deep eutectic solvents8.

This study introduces reactive extruder-grinder (REG) as a new technique in continuous mechanochemical organic syntheses for the first time. Figure 2 shows the designed REG device, which is a combination of an extruder, a mortar, and a pestle. The REG operates in a continuous manner for mechanochemical organic syntheses. The materials are fed into the REG and mixed thoroughly within the extruder. They are then pushed into the conic part of the device. REG is capable of continuous reactive synthesizing of organic compounds in quantities ranging from milligrams to several grams and above. At the end of the cylinder, the conic part is designed to play the role of the mortar, and the final process of material grinding and heat-generating occurs in it. The conic part is the most critical part of the REG. By grinding the materials between the conic part wall and the pestle, the required heat is generated. The chemical reaction is carried out quickly due to the intensive grinding and generated heat. In REG, the screw and the pestle are designed in a single piece and alignment. The connection and coherence of these two parts have made the rotation and feeding uniform. The ability to continually enter the raw material and the regular withdrawal of the reaction product has made it an efficient device that can perform various condensation reactions quickly. The materials become mills intensively, and the reaction temperature increase due to the friction. The generated temperature can effectively cause the fulfillment of the multicomponent reactions (MCRs) that require heat. The twin-axis rotational speed of the screw and pestle was adjusted to control the reaction temperature by empirically controlling the screw and pestle rotational speed. The ability to continually enter the raw material and the regular withdrawal of the reaction product has made it an efficient device that can perform various condensation reactions quickly.

Amino-4H-chromenes are versatile organic compounds characterized by a chromene ring system with an attached amino group9. These compounds exhibit a range of biological activities, including antioxidant, anticancer, anti-inflammatory, antimicrobial, and potential antiviral effects10. Their unique chemical structure and diverse activities make them attractive candidates for drug discovery and development11. With their potential to modulate various disease pathways, amino-4H-chromenes hold promise for the development of novel therapeutics targeting conditions such as cancer, inflammation, and infectious diseases12. Continued research in this field aims to uncover their full therapeutic potential and optimize their pharmacological properties for clinical applications13.

The indole ring system, known for its biologically active derivatives, plays a crucial role in the structure of numerous pharmaceutical molecules14. Among these derivatives, spirooxindole compounds have gained recognition in diverse fields, particularly as inhibitors of microtubule assembly. Compounds such as spirotryprostatin A and B have shown potential in inhibiting microtubule assembly15. Additionally, spirooxindole derivatives have demonstrated their ability to modulate Muscarinic M1 and serotonin receptors, exemplified by compounds like pteropodine and isopteropodine16. Furthermore, spirooxindole compounds, including MK-0677, exhibit promise as nonpeptidyl growth-hormone secretagogues17. Given the significance of spiro compounds in organic chemistry and pharmacology, several synthetic protocols have been reported, and ongoing research efforts are exploring this subject18. The continued exploration of spirooxindole derivatives holds potential for the development of novel therapeutic agents and the advancement of organic chemistry.

Knoevenagel condensation of malononitrile and chlorobenzaldehyde at room temperature, with only around 7% of the desired product obtained after 10 min in the solid state19. However, it has been demonstrated that conducting the reaction through a melting process at 150 °C without a catalyst can yield quantitative results. Stoichiometric Michael additions using dimedone at temperatures ranging from 100 to 130 °C have shown complete formation of 7,7-dimethyl-5-oxo-5,6,7,8-tetrahydro-4H-chromenes in quantitative yields19. Furthermore, it was shown that incorporating a mild catalyst (Na2CO3) during the milling process at ambient temperature led to quantitative yields of diverse chromene derivatives. The inclusion of Na2CO3 during kneading optimizes the overall efficiency of Knoevenagel condensations and Michael addition reactions, ensuring complete conversion. These findings underscore the significance of reaction conditions and catalysts in achieving high yields and complete conversion in the synthesis of chromene derivatives.

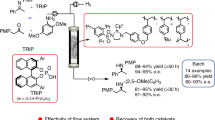

In our ongoing pursuit of environmentally friendly organic transformations20, we present a groundbreaking study introducing the REG device as a reactive reactor for the solvent-free, catalyst-free, and additive-free multicomponent synthesis of diverse pyran, 2-amino-4-aryl-3-cyano-4H-chromene, and spiroxindole derivatives. Importantly, this innovative method boasts the advantage of not relying on additives or catalysts, while ensuring remarkably short reaction times. The findings of this investigation were illustrated and presented in Fig. 3.

Results and discussion

To optimize the reaction parameters, a one-pot, multicomponent reaction (MCR) was performed involving 4-chlorobenzaldehyde (1a), malononitrile (2), and dimedone (3a) as the model reaction. The utilization of the REG device enabled the execution of a multicomponent reaction without the requirement of an external trigger. This innovative device facilitated the reaction to proceed spontaneously, eliminating the need for additional stimuli or initiators. Inside the REG device, the raw materials are initially mixed in the screw section, resulting in a uniform mixture that then enters the mortar section. In this section, the intensive friction and controlled rotation speed generate heat, which plays a crucial role in facilitating the cascade reaction of Knoevenagel condensation and Michael addition. The combination of intensive grinding and heat assistance within the REG device ensures the efficient and quantitative formation of the desired product.

Figure 4 presents the results obtained under optimized conditions for the multicomponent reaction involving various aldehyde derivatives and malononitrile with different reactants, including dimedone (3a) and 1,3-cyclohexanedione (3b), The table showcases that a wide range of aldehydes, encompassing both electron-donating and electron-withdrawing groups, yielded excellent to good yields within a remarkably short reaction time of 2–5 min. These findings demonstrate the efficiency and versatility of the reaction system in synthesizing the desired products using different aldehyde derivatives and reactants.

The scope and versatility of a one-pot reaction in REG were extended to activated phenol derivatives such as resorcinol (3c), α-naphthol (3d), and β-naphthol (3c). The results of these reactions are presented in Fig. 5. All activated phenol compounds were found to be good participants in this system, yielding good to excellent yields in short reaction times. The use of REG enabled ultrafast reactions to be conducted at ambient temperature without the need for any catalyst or additive on a 5 mmol scale. The experimental procedure was described as straightforward and easy. Initially, the raw materials were pre-mixed in a traditional mortar and pestle. The mixed materials then entered the first part of the REG machine, referred to as the screw, which featured a high homogeneous mixing rate. Subsequently, the well-mixed materials entered the mortar section of the REG system.

Spiroxindole and its derivatives are considered privileged heterocyclic cores due to their presence in many natural products and pharmacological agents21,22,23,24. These compounds have found extensive use in the pharmaceutical industry due to their versatile role in numerous biologically active substances25,26,27. These characteristics have made them highly valuable in the development of novel pharmaceutical agents28.

In the continued exploration of the method, the REG system was employed for the green synthesis of different types of spirooxindoles (Fig. 6). This synthesis involved the use of isatin derivatives (5), malononitrile (2), and various types of Michael acceptors (3). By employing different combinations of these reactants, the selected multicomponent reaction (MCR) proceeded efficiently, resulting in the synthesis of the desired products with excellent yields within a short reaction time. The REG system, played a crucial role in facilitating this green synthesis process. By providing a suitable reaction environment, the REG system allowed for the efficient and rapid formation of spirooxindoles from the selected reactants. The utilization of the REG system in this context eliminated the need for additional catalysts or additives, emphasizing its utility as an environmentally friendly and efficient method for synthesis of various spirooxindole compounds.

Scalability holds immense importance in the industry due to the cost efficiency, the resilience and reliability of industrial systems. The scalability of the reaction was evaluated using the model reaction involving 4-chlorobenzaldehyde (1a), malononitrile (2), and dimedone (3a) on a 100 mmol scale. The reaction was successfully conducted on a larger scale, yielding the desired 4H-pyran derivatives with 97% isolated yields in just 50 min. However, it is important to note that precise control of reactant feeding is crucial for maintaining the temperature of the REG system within the desired range, preferably not exceeding room temperature. In larger-scale reactions, the feeding speed of reactants tends to be slower due to the need for careful monitoring and control. As a result, the overall reaction time slightly increase compared to smaller-scale reactions. Nonetheless, by ensuring proper control over the reactant feeding process, it is possible to maintain the desired temperature conditions and successfully carry out the reaction on a larger scale.

Conclusion

To summarize, the study presents a highly efficient and additive-free method for synthesizing industrial-grade 2-amino-4-aryl-3-cyano-4H-chromenes, pyran, and spiroxindole derivatives using a mechanochemical approach. The method has distinct advantages over traditional ball mills, such as the ability to perform temperature-dependent reactions without external heating and its continuous operation, enabling easy scale-up. The heat generated during the reaction is a result of the speed of the rotating mortar and the friction between the conical part and the rotating mortar, making the process more energy-efficient. Overall, this approach represents a significant advancement in sustainable and efficient methods for organic synthesis.

Experimental section

Material and methods

In this study, the REG utilized for the experiments was custom-designed and manufactured within the laboratory conducting the research. The REG system was constructed using stainless steel 316 alloy for all its components. This choice of material ensures the system's durability and resistance to corrosion, which is important for maintaining the integrity of the equipment during the experimental process. The grinding frequency employed during the experiments using the REG system ranged between 15 and 20 Hz. This indicates the rate at which the grinding action took place within the system. The specific frequency chosen for the experiments depended on the optimization of the reaction conditions, considering factors such as the nature of the reactants, desired reaction kinetics, and the efficiency of mixing and grinding within the REG system. During the grinding process, it was observed that malononitrile, which has a melting point of 32 °C, undergoes melting when mixed with other reactants, resulting in a paste-like consistency. To determine the melting points of the compounds accurately, the Buchi B-545 Melting Point apparatus was employed.

For nuclear magnetic resonance (NMR) analysis, 500 MHz 1H NMR spectra were acquired using a Bruker DRX-500 Avance spectrometer. Additionally, 250 MHz spectra were obtained using a Bruker Avance DPX-250 spectrometer (Supplementary Information). In the experiments, solid reagents were obtained from commercial sources and used without additional purification. However, liquid reagents underwent distillation before being used. Thin-layer chromatography (TLC) was performed on silica gel plates using a 1:5 ratio of ethyl acetate to hexane as the eluent (Supplementary Information).

Typical procedure for the synthesis of 2-amino-3-cyano-4-aryl-4H-chromenes

In a typical experiment, a stoichiometric mixture of an aromatic aldehyde (1) (5.0 mmol) or isatin derivatives (5) (5.0 mmol), malononitrile (2) (5.0 mmol), dimedone (3a) or other Michel acceptors (5.0 mmol) were introduced in REG system and grinded for the required duration (Fig. 3). Upon confirming the completion of the reaction using TLC, (in few cases only a single spot is observed on a TLC plate). The absence of solvents, catalysts, or additives in the reaction system simplifies the workup procedure, making it easier and more straightforward. The resulting precipitate obtained after the reaction was collected, and a recrystallization process was employed using the solvents illustrated in Figs. 4, 5, and 6 to further purify the product and obtain a highly pure compound. The synthesized products were previously known compounds21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42, and their identification and structural characterization were confirmed.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

Achar, T. K., Bose, A. & Mal, P. Mechanochemical synthesis of small organic molecules. Beilstein J. Org. Chem. 13, 1907–1931 (2017).

Bowmaker, G. A. Solvent-assisted mechanochemistry. Chem. Commun. 49, 334–348 (2013).

Tanaka, K. & Toda, F. Solvent-free organic synthesis. Chem. Rev. 100, 1025–1074 (2000).

James, S. L. et al. Mechanochemistry: Opportunities for new and cleaner synthesis. Chem. Soc. Rev. 41, 413–447 (2012).

Crawford, D. E., Miskimmin, C. K. G., Albadarin, A. B., Walker, G. & James, S. L. Organic synthesis by Twin Screw Extrusion (TSE): Continuous, scalable and solvent-free. Green Chem. 19, 1507–1518 (2017).

Crawford, D. et al. Synthesis by extrusion: Continuous, large-scale preparation of MOFs using little or no solvent. Chem. Sci. 6, 1645–1649 (2015).

Moad, G. The synthesis of polyolefin graft copolymers by reactive extrusion. Prog. Polym. Sci. 24, 81–142 (1999).

Crawford, D. E., Wright, L. A., James, S.L., Abbott, A. P. Efficient continuous synthesis of high purity deep eutectic solvents by twin screw extrusion. Chem. Comm. 52, 4215–4218 (2016).

Bonsignore, L., Loy, G., Secci, D. & Calignano, A. Synthesis and pharmacological activity of 2-oxo-(2H) 1-benzopyran-3-carboxamide derivatives. Eur. J. Med. Chem. 28, 517–520 (1993).

Gao, Y., Yang, W. & Du, D.-M. Efficient organocatalytic asymmetric synthesis of 2-amino-4H-chromene-3-carbonitrile derivatives. Tetrahedron Asy. 23, 339–344 (2012).

Ling, R., Yoshida, M. & Mariano, P. S. Exploratory investigations probing a preparatively versatile, pyridinium salt photoelectrocyclization-solvolytic aziridine ring opening sequence. J. Org. Chem. 61, 4439–4449 (1996).

Kumar Krishnammagari, S., Lim, K. T., Cho, B. G. & Jeong, Y. T. Choline hydroxide: An efficient and biodegradable catalyst for the synthesis of 2-amino-3-nitro-4H-chromene derivatives in an aqueous medium. Phosphorus Sulfur Silicon Relat. Elem. 193, 574–581 (2018).

Anamika Yadav, C. L., Drew, M. G. B., Kumar, K. & Singh, N. Ferrocene-functionalized dithiocarbamate zinc(II) complexes as efficient bifunctional catalysts for the one-pot synthesis of chromene and imidazopyrimidine derivatives via Knoevenagel condensation reaction. Inorg. Chem. 60, 6446–6462 (2021).

Zhang, M. Z., Chen, Q. & Yang, G. F. A review on recent developments of indole-containing antiviral agents. Eur. J. Med. Chem. 89, 421–441 (2015).

Kumari, A. & Singh, R. K. Medicinal chemistry of indole derivatives: Current to future therapeutic prospectives. Bioorg. Chem. 89, 103021 (2019).

Wan, Y., Li, Y., Yan, C., Yan, M. & Tang, Z. Indole: A privileged scaffold for the design of anti-cancer agents. Eur. J. Med. Chem. 183, 111691 (2019).

Taber, D. F. & Tirunahari, P. K. Indole synthesis: A review and proposed classification. Tetrahedron. 67, 7195–7210 (2011).

Sebastião, J., Neto, S. & Zeni, G. Recent advances in the synthesis of indoles from alkynes and nitrogen sources. Org. Chem. Front. 7, 155–210 (2020).

Kaupp, G., Naimi-Jamal, M. R. & Schmeyers, J. Solvent-free Knoevenagel condensations and Michael additions in the solid state and in the melt with quantitative yield. Tetrahedron 59, 3753–3760 (2003).

Azizi, N. & Saidi, M. R. Lithium perchlorate diethyl ether solution: A highly efficient media for the abramov reaction. Phosphorus Sulfur Silicon Relat. Elements 178, 1255–1259 (2013).

Auria-Luna, F., Fernández-Moreira, V., Marqués-López, E., Gimeno, M. C. & Herrera, R. P. Ultrasound-assisted multicomponent synthesis of 4H-pyrans in water and DNA binding studies. Sci. Rep. 10, 11594 (2020).

Banerjee, B. et al. Sodium dodecyl sulphate catalyzed one-pot three-component synthesis of structurally diverse 2-amino-3-cyano substituted Tetrahydrobenzo[b]pyrans and spiropyrans in water at room temperature. Catal. Lett. 153, 3547–3560 (2023).

Naimi-Jamal, M. R., Mashkouri, S. & Sharifi, A. An efficient, multicomponent approach for solvent-free synthesis of 2-amino-4H-chromene scaffold. Mol. Divers. 14, 473–477 (2010).

Guo, R. Y. et al. Meglumine: A novel and efficient catalyst for one-pot, three-component combinatorial synthesis of functionalized 2-amino-4H-pyrans. ACS Comb. Sci. 15, 557–563 (2013).

Nagaraju, S., Paplal, B., Sathish, K., Giri, S. & Kashinath, D. Synthesis of functionalized chromene and spirochromenes using l-proline-melamine as highly efficient and recyclable homogeneous catalyst at room temperature. Tetrahedron Lett. 58, 4200–4204 (2017).

Al-Omran, F., El-Ghamry, I. & Elnagdi, M. H. New spiropyran-4-ylindolidine derivatives from the reaction of 2-oxo-3-cyanomethylidene-2,3-dihydroindoles with cyclohexanediones and phenols. Org. Prep. Proced. Int. 30, 363–367 (1998).

Shanthi, G., Subbulakshmi, G. & Perumal, P. T. A new InCl3-catalyzed, facile and efficient method for the synthesis of spirooxindoles under conventional and solvent-free microwave conditions. Tetrahedron 63, 2057–2063 (2007).

Wang, G. D., Zhang, X. N. & Zhang, Z. H. One-pot three-component synthesis of spirooxindoles catalyzed by hexamethylenetetramine in water. J. Heterocyclic Chem. 50, 61–65 (2013).

Amirnejad, M., Naimi-Jamal, M. R., Tourani, H. & Ghafuri, H. A facile solvent-free one-pot three-component method for the synthesis of 2-amino-4H-pyrans and tetrahydro-4H-chromenes at ambient temperature. Monatshefte fur Chemie 144, 1219–1225 (2013).

Balalaie, S., Bararjanian, M., Sheikh-Ahmadi, M., Hekmat, S. & Salehi, P. Diammonium hydrogen phosphate: An efficient and versatile catalyst for the one-pot synthesis of tetrahydrobenzo[b]pyran derivatives in aqueous media. Synth. Commun. 37, 1097–1108 (2007).

Hosseinchi, O., Mashkouri, S., Naimi-Jamal, M. R. & Kaupp, G. Ball milling for the quantitative and specific solvent-free Knoevenagel condensation + Michael addition cascade in the synthesis of various 2-amino-4-aryl-3-cyano-4H-chromenes without heating. RSC Adv. 4, 48191–48201 (2014).

Azizi, N., Ahooie, T. S., Hashemi, M. M. & Yavari, I. Magnetic graphitic carbon nitride-catalyzed highly efficient construction of functionalized 4 H-pyrans. Synlett 29, 645–649 (2018).

Khan, A. T., Lal, M., Ali, S. & Khan, M. M. One-pot three-component reaction for the synthesis of pyran annulated heterocyclic compounds using DMAP as a catalyst. Tetrahedron Lett. 52, 5327–5332 (2011).

Shojaee, S., Azizi, N., Mirjafary, Z. & Saeidian, H. Magnet-responsive choline carbomer ionogels as a versatile and recyclable catalyst for one-pot synthesis of benzopyran in water. Sci. Rep. 13, 21232 (2023).

Xu, J.-C., Li, W.-M., Zheng, H., Lai, Y.-F. & Zhang, P.-F. One-pot synthesis of tetrahydrochromene derivatives catalyzed by lipase. Tetrahedron 67, 9582–9587 (2011).

Zhang, G. et al. One-pot enantioselective synthesis of functionalized pyranocoumarins and 2-amino-4H-chromenes: Discovery of a type of potent antibacterial agent. J. Org. Chem. 77, 878–888 (2011).

Azizi, N., Dezfooli, S., Khajeh, M. & Hashemi, M. M. Efficient deep eutectic solvents catalyzed synthesis of pyran and benzopyran derivatives. J. Mol. Liq. 186, 76–80 (2013).

Chen, L. et al. Cheap thiamine hydrochloride as efficient catalyst for synthesis of 4H-benzo[b]pyrans in aqueous ethanol. Res. Chem. Intermed. 43, 3883–3891 (2017).

Mashkouri, S. & Naimi-Jamal, M. R. Mechanochemical solvent-free and catalyst-free one-pot synthesis of pyrano[2,3-d]pyrimidine-2,4(1H,3H)-diones with quantitative yields. Molecules 14, 474–479 (2009).

Wang, L.-M. et al. Sodium stearate-catalyzed multicomponent reactions for efficient synthesis of spirooxindoles in aqueous micellar media. Tetrahedron 66, 339–343 (2010).

Dandia, A., Parewa, V., Jain, A. K. & Rathore, K. S. Step-economic, efficient, ZnS nanoparticle-catalyzed synthesis of spirooxindole derivatives in aqueous medium viaKnoevenagel condensation followed by Michael addition. Green Chem. 13, 2135–2145 (2011).

Li, Y., Chen, H., Shi, C., Shi, D. & Ji, S. Efficient one-pot synthesis of spirooxindole derivatives catalyzed by l-proline in aqueous medium. J. Comb. Chem. 12(2), 231–323 (2010).

Acknowledgements

Financial support for this work by Chemistry and Chemical Engineering Research Center of Iran is gratefully appreciated.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study's conception and design. Omid Hosseinchi Qareaghaj performed material preparation, data collection and analysis. The first draft of the manuscript was written by Najmedin Azizi. Mohammad Ghaffarzadeh was supervised. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hosseinchi Qareaghaj, O., Ghaffarzadeh, M. & Azizi, N. Ultrafast and efficient continuous flow organic synthesis with a modified extruder-grinder system. Sci Rep 14, 9671 (2024). https://doi.org/10.1038/s41598-024-59567-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-59567-6

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.