Abstract

Biopesticides are biological pest control agents that are viewed as safer alternatives to the synthetic chemicals that dominate the global insecticide market. A major constraint on the wider adoption of biopesticides is their susceptibility to the ultraviolet (UV: 290–400 nm) radiation in sunlight, which limits their persistence and efficacy. Here, we describe a novel formulation technology for biopesticides in which the active ingredient (baculovirus) is micro-encapsulated in an ENTOSTAT wax combined with a UV absorbant (titanium dioxide, TiO2). Importantly, this capsule protects the sensitive viral DNA from degrading in sunlight, but dissolves in the alkaline insect gut to release the virus, which then infects and kills the pest. We show, using simulated sunlight, in both laboratory bioassays and trials on cabbage and tomato plants, that this can extend the efficacy of the biopesticide well beyond the few hours of existing virus formulations, potentially increasing the spray interval and/or reducing the need for high application rates. The new formulation has a shelf-life at 30 °C of at least 6 months, which is comparable to standard commercial biopesticides and has no phytotoxic effect on the host plants. Taken together, these findings suggest that the new formulation technology could reduce the costs and increase the efficacy of baculovirus biopesticides, with the potential to make them commercially competitive alternatives to synthetic chemicals.

Similar content being viewed by others

Introduction

Baculoviruses are dsDNA viruses that infect insects and have, since the 1980s, been used in crop protection as commercial biological insecticides1,2. Baculoviruses are seen as attractive biological control agents against insect crop pests for many reasons: they have a long and detailed history of research, so basic knowledge of their taxonomy, biology and pathogenicity is available3; they have an established profile of safety and environmental acceptability4; they are highly efficacious pathogens of some of the world’s most important crop pests, such as the various Heliothis / Helicoverpa species, Spodoptera spp. and Plutella xylostella5; and, finally, their use as biological pesticides is feasible because commercially-viable mass production systems are well advanced for many baculoviruses6. These factors have motivated the establishment of a growing commercial production of baculovirus insecticides in the Americas, Europe, Asia, Australasia and Africa5,7. Moreover, biopesticides are now seen as a major candidate for replacing the many chemical pesticides that have been, and continue to be, withdrawn from the market due to safety concerns5,8, and/or where the insect pests have developed resistance to conventional chemical pesticides9.

Baculovirus products, however, still represent only a $50–70 million per annum sector of a global biopesticides market estimated to be worth $2.8 billion dollars a year10. While a number of factors have been identified as restricting the adoption and expansion of the use of baculovirus biopesticides by growers5, a central problem over the last 40 years has been their short persistence on the crop after application, due to degradation by the ultraviolet (UV: 290–400 nm) radiation in sunlight6,11,12,13,14. In temperate cropping systems, the half-life of baculoviruses on crops can be just 2–10 days15,16,17. In the tropics, on unshaded crop surfaces, a half-life of 8 h or less has been reported18. This susceptibility to UV degradation severely limits their attraction to farmers as the need to apply to the crop at weekly intervals is more frequent than competing chemical insecticides, adding significantly to costs5,19. This higher cost in large part accounts for their current use being limited to the high-value horticulture sector where high produce prices can offset their cost5,19.

Overcoming this limited UV stability has been a major goal of baculovirus research since the 1980s20,21. Although attempts to develop UV-resistant baculoviruses through strain selection or genetic modification have been reported22, these have yet to identify improvements significant enough to support commercial adoption6,23. There has been some limited success in improving on-crop persistence through the use of tank-mixed adjuvants but these, while increasing the persistence to a limited extent, have failed to meet users’ need for a pest control level that matches that of chemical pesticides5. Only through the development of improved novel formulations can performance be enhanced sufficiently to expand their usefulness beyond current niche uses into major field crops19,24.

There have been many efforts to identify suitable additives to enhance the UV stability of baculovirus biopesticides6,20, and this work has yielded some promising results25,26. The diaminostilbene disulfonic acid-based optical florescent brighteners (e.g. BLANKOPHOR) that act as specific UV-absorbants, and are used as commercial sunscreens, have been a focus of research to evaluate their use with baculoviruses27,28. Metal oxides, including titanium dioxide and zinc dioxide, have also shown promise as UV protectants29,30, but field trials have generated mixed results with no conclusive benefits16,31,32.

An important issue for combining UV protectants with biopesticides is that at the inclusion rates proposed, combined with the high water volumes used to apply the biopesticide (up to 400–1,000 L per ha33), the quantities and cost of additives become very significant. The UV additive may be needed at 5–20 kg per ha, at a cost many times that of the active ingredient16; at these rates, the cost can then become prohibitive in most cropping systems23. It has been argued that for baculoviruses to be acceptable for use on broad field crops, any formulated product needed to fall below a cost of $20 US per treatment per ha in order to meet the economic constraints of growers and to be competitive with chemical pesticide alternatives23.

If the UV protectants, instead of being tank-mixed in solution or in suspension with the infectious baculovirus occlusion bodies (OB), could instead be formulated so as to be bound intimately to the OB (i.e. encapsulated by protectant formulation), then much lower rates of additive could be used. Such a formulation would need to comprise elements that were environmentally stable in the field for days to weeks, but readily able to release the encapsulated OB within the insect gut upon ingestion, so enabling the baculovirus to initiate infection.

There have been a number of reports using encapsulation as a means of protecting baculovirus OB against harmful UV radiation20,25,34,35,36,37,38. However, none of these technologies has been adopted commercially. This may be partly due to factors such as high cost, phytotoxicity, storage incompatibility and blocking of spray filters, as occurs with some particulate additives5. However, this is probably because the advantages conferred by the encapsulation have so far failed to meet adequately the goal of substantially improving UV-stability6. Previously, Cydia pomonella GV (CpGV), a baculovirus effective against codling moth pests, had been successfully microencapsulated with Titanium dioxide using the Particles from Gas Saturated Solutions (PGSS) system, giving a biologically-viable formulation with enhanced UV protection, as measured by spectral analysis37,39. However, information on the efficacy of this formulation on crops is not available.

This paper reports on the development and evaluation of a novel wax-encapsulation formulation for baculoviruses that substantially improves UV stability at low cost. The new formulation developed and tested here utilises the proprietary ENTOSTAT waxes. ENTOSTAT is a platform technology consisting of wax particles that can be co-formulated with a range of biological and chemical active ingredients. It has been previously successfully formulated with entomopathogenic fungi such as Beauveria bassiana40 and chemistries such as spinosad41. ENTOSTAT has not, however, previously been used as an encapsulating agent, and neither has it been used before with baculoviruses, which differ from these other active ingredients in entering their insect host via oral ingestion, rather than via the insect cuticle/skin. Therefore, this application has significant innovative potential for both ENTOSTAT technology and baculovirus formulations.

Preliminary work tested both representative stilbene-derived optical brighteners and metallic oxide absorbants such as titanium dioxide (TiO2), and while both showed promise, the TiO2 was selected as the most suitable to take forward for full formulation and testing. The specific ENTOSTAT waxes were selected on the basis of expected biological compatibility with baculovirus and commercial viability. Any formulation would also need to meet the other requirements of a practical biopesticide formulation and have storage stability to meet accepted standards19,20 and so this was also evaluated.

In this study, we used laboratory systems that can be calibrated to known sunlight regimen30,42. The initial trials in which virus formulations on glass slides were exposed to simulated sunlight was used to screen candidate formulations, the most promising of which was then used in trials on plants. In these plant trials, two different crops were included: tomato, as a representative of a major crop on which baculovirus biopesticides are used43, and cabbage, which has a waxy cuticle that could pose an adherence issue for a novel formulation based on waxy particulates44. All the work was carried out using Spodoptera littoralis nucleopolyhedrovirus (SpliNPV), as a model nucleopolyhedrovirus (NPV) and one already in use as a commercial baculovirus5. Its main target, the Egyptian cotton leafworm, Spodoptera littoralis, is a polyphagous caterpillar and so could be used in persistence trials on the two different target crops.

Results

Simulated sunlight slide exposure bioassays

16 h simulated sunlight exposure

Slide bioassays showed clearly that ENTOSTAT-formulated virus with TiO2 additive greatly improved the stability of NPV activity when exposed to simulated sunlight in the ATLAS SUNTEST XLS + cabinet. Across the first four bioassays, when the maximum continuous exposure to simulated sunlight was 16 h, the non-encapsulated virus and the commercial virus formulation showed a non-linear decline in efficacy with increasing simulated sunlight dose, with minimum efficacy at 16 h of around 35% (Fig. 1a). In contrast, the ENTOSTAT-TiO2-encapsulated virus showed an initial small decline in activity but thereafter activity remained at a relatively constant level at around 87%. This observation is reflected in the statistical analysis, with a significant interaction between virus formulation and the number of hours simulated sunlight exposure (Generalised linear model, GLM: Hours exposure: χ21 = 104.77, P < 0.0001; [Hours exposure]2: χ21 = 20.96, P < 0.0001; Formulation: χ22 = 158.19, P < 0.0001; Formulation*Hours exposure: χ22 = 9.59, P = 0.0083). When considered alone, there was a significant decline overall in the performance of the ENTOSTAT-TiO2-encapsulated virus (GLM: χ21 = 6.00, P = 0.014), but when the 0 h simulated sunlight-exposure time point was excluded, there was no significant decline in performance thereafter (χ21 = 1.73, P = 0.19), indicating that beyond 1 h exposure to simulated sunlight there was no further degradation of virus efficacy.

Efficacy of different NPV formulations following exposure to simulated sunlight in an ATLAS SUNTEST XLS + cabinet on glass slides for up to (A) 16 h and (B) 96 h. In both (A) and (B), three formulations were tested: non-formulated NPV (black symbols and lines), a commercial standard, LITTOVIR (blue symbols and lines), and NPV formulated in ENTOSTAT wax with Titanium dioxide, TiO2 additive (red symbols and lines). Symbols indicate the means and bars are ± S.E. Symbols are staggered slightly for clarity. The equivalent hourly dose of UV is 234 kJ m−2.

96 h simulated sunlight exposure

To explore this further, the duration of exposure to simulated sunlight in the ATLAS SUNTEST XLS + cabinet was increased up to a maximum of 96 h and the results again showed that TiO2 protects the NPV from degradation from simulated sunlight. Whilst the ENTOSTAT-formulated virus showed only a limited decline in efficacy after the first exposure to simulated sunlight and maintained > 80% efficacy throughout, the non-formulated NPV and the commercial virus showed a non-linear decline in efficacy to a minimum of around 30% (Fig. 1b). This is again reflected in the statistical analysis (GLM: Hours exposure: χ21 = 107.29, P < 0.0001; [Hours exposure]2: χ21 = 55.84, P < 0.0001; Formulation: χ22 = 190.50, P < 0.0001; Formulation*Hours exposure: χ22 = 9.34, P = 0.0094). When the ENTOSTAT-TiO2-encapsulated virus was considered alone, there was a marginally non-significant decline in performance over the 96 h exposure period (GLM: χ21 = 3.69, P = 0.055), and when the 0 h simulated sunlight-exposure time point was excluded, there was no significant decline in performance (χ21 = 0.31, P = 0.57), suggesting again that the virus is not subject to any further loss of efficacy after the first hour exposure to simulated sunlight.

Simulated sunlight plant exposure bioassays

On both tomato and cabbage plants grown under 12 h light: 12 h dark simulated sunlight via LEDs and fluorescent tubes in a constant environment room, ENTOSTAT formulations incorporating TiO2 additive greatly increased NPV stability on plants compared to the non-encapsulated commercial standard, LITTOVIR (Fig. 2). Overall, virus-induced mortality declined non-linearly with increasing exposure to UV dose (GLM: Days simulated sunlight: χ21 = 66.66, P < 0.0001; [Days simulated sunlight]2: χ21 = 26.70, P < 0.0001) and was higher for ENTOSTAT-TiO2-encapsulated virus than for the commercial standard (Formulation: χ21 = 179.05, P < 0.0001).

Efficacy of LITTOVIR and ENTOSTAT-TiO2-encapsulated NPV formulations following exposure to simulated sunlight up to 16 days in a constant environment room on tomato and cabbage plants. Cabbage = circles, solid line; Tomato = squares, dashed line. Symbols are staggered slightly for clarity. Larval mortality in the control group (dH20 only) averaged 10–20% (data not shown). The equivalent daily dose of UV is 499 kJ m−2.

Phytotoxicity

There was no effect of virus formulation on any aspect of the growth of the cabbage plants (Table 1).

Titanium dioxide toxicity

Titanium dioxide had no effect on larval mortality either when NPV-free ENTOSTAT-TiO2 was compared to controls that were fed dH20 only (z value = 0.326, P = 0.744), or when TiO2-formulated NPV ENTOSTAT was compared to ENTOSTAT NPV alone (z value = 0.174, P = 0.862). Overall, however, there was a significant difference between the four treatments in the levels of larval mortality they generated (Treatment: χ23 = 525, P < 0.0001) because the two NPV treatments caused higher mortality rates than treatments that did not include NPV (Fig. 3).

Storage stability

After six months’ storage, virus-induced mortality was significantly lower for viruses stored at 30 °C than at 4 °C (GLM: χ21 = 24.70, P < 0.0001) and differed across the three virus formulations (χ22 = 29.54, P < 0.0001), with non-formulated NPV causing lower mortality in S. littoralis larvae than the two formulated NPVs (z value = -4.414, P < 0.0001) (Table 2). There was no significant difference between the mortality rates caused by the commercial standard and the wax-encapsulated NPV (z value = − 1.287, P = 0.198); the interaction between temperature and formulation was also non-significant (χ22 = 0.86, P = 0.65), indicating additive effects of temperature and formulation.

Discussion

Overall, the results of the work reported here using simulated sunlight show that ENTOSTAT-TiO2 formulated NPV is considerably more resistant to UV degradation than either non-formulated NPV or an existing commercial NPV product, and that it has storage and crop safety characteristics that are at least equal to those of existing formulations.

In any formulation of an infectious biological agent, it is important that the formulation processes result in little or no significant loss of activity19,45. The bioassay results confirmed that the ENTOSTAT encapsulation process, which involves heating and milling the mixture, does not reduce the infectivity of the baculovirus. Thus, the encapsulation process does not appear to damage the virus OB and, upon ingestion, the protective ENTOSTAT-TiO2 wax coat successfully dissolves in the insect midgut to liberate the infectious virions.

A key finding from the current study is that by combining ENTOSTAT wax with a UV protectant (TiO2), the efficacy of the wax-encapsulated baculovirus could be dramatically improved, even under intense UV radiation, from just a few hours to at least several days. This ENTOSTAT-TiO2-NPV formulation is superior to both non-formulated NPV and a commercial NPV formulation (LITTOVIR). The non-formulated virus and commercial NPV formulation had half-lives on glass slides of < 17 h continuous simulated sunlight exposure (Fig. 1b), while the ENTOSTAT-TiO2 formulated virus retained > 80% activity even after 96 h continuous exposure. The initial drop in the efficacy of ENTOSTAT-TiO2 formulated virus during the first hour of UV exposure, is most likely due to denaturing of virus that was on not fully encapsulated, whilst subsequent long-term persistence was probably due to virus that was completely encapsulated with the wax. The results from both the slide and plant systems show that the half-lives for non-formulated virus and commercial formulation fall within the reported persistence values of about 24 h in continuous simulated sunlight, and within the half-lives of 1–7 days reported in the field, depending on sunlight intensity and the degree of crop shading2,6,20,46. The results from the ENTOSTAT-formulated virus are very promising as no previously reported studies using a baculovirus formulation have demonstrated anything approaching this degree of UV-stability.

The slide exposure system used here (ATLAS SUNTEST XLS + cabinet), differs from many other published formulation studies in that it was calibrated to an actual sunlight exposure level, and the intensity and duration was monitored throughout using a system already validated for UV-stability studies with baculoviruses30,35,47. It has been pointed out that laboratory studies of baculovirus sunlight stability using ad hoc arrangements of UV or germicidal lamps not calibrated to real sunlight can be very hard to relate to field conditions30. The slide simulated sunlight exposure system used here also involved controlling the slide temperature, avoiding the confounding effects of the heating of glass slides, sometimes seen when slides are exposed to artificial or natural sunlight without adequate temperature control20. Thus, the ATLAS SUNTEST system is seen as giving a realistic model of natural sunlight under temperate conditions and has previously been used with both the bacterium Bacillus thuringiensis and the baculovirus Anagrapha falcifera multiple nucleopolyhedrovirus, MNPV35,48. It is widely used as an industry standard equipment for testing products for solar stability and temperature (Atlas 2018), conforming to American Society for Testing and Materials (ASTM) and International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) standards for coatings, cosmetics and pharmaceutical products.

Formulations showing improved UV stability in the laboratory, however, do not always show improved persistence or efficacy in crop trials6,35. For example, although the UV protectant BLANKOPHOR BBH increased baculovirus persistence in lab trials, it did not increase effectiveness in field trials49. The crucial test of UV formulations must remain the use of plant studies, as this alone can most adequately approximate to the on-crop situation. The plant-based system used here draws on approaches that are standard in plant UV research to ensure radiation treatments were as close to the field as possible, for example filtering the UVB sources to remove wavelengths below those present in sunlight50,51. The crop results on tomato and cabbage show that the ENTOSTAT-TiO2 formulated baculovirus is substantially better than non-formulated virus or an existing commercial formulation, showing > 80% activity after 16 d diurnal simulated sunlight exposure, while the natural and commercial formulations both retained < 20% activity under these conditions. It remains to be established whether these findings are replicated in field trials under a range of natural sunlight conditions.

The bioassays reported here indicate that TiO2 does not, in itself, have any insecticidal activity, as the mortality of insects fed on ENTOSTAT-TiO2 encapsulated virus, was no greater than that of the virus alone (but possible sub-lethal effects of TiO2 nanoparticles have been reported in larvae of the waxworm moth, Galleria mellonella52). Photostabilized Titanium dioxide is widely used in sunscreens and cosmetic products because it has been identified as safe, a factor in its favour as a potential formulation ingredient for biopesticides30,53.

An issue for some formulation additives is the potential for phytotoxicity. It has been reported that when stilbene-derived UV blockers were sprayed onto plants, they had significant negative effects on the growth of several crop species tested54. Trials here showed that ENTOSTAT-TiO2 had no adverse effect on cabbage plant growth. This could be ascribed to the very low application rate of TiO2 when delivered as part of the ENTOSTAT formulation, which are substantially lower than in previous studies. Titanium dioxide used in suspension when sprayed at 200 L per ha would require 2 kg of TiO2 per ha30, whereas in an ENTOSTAT formulation, because the TiO2 is intimately bound to the wax-encapsulated OB rather than in general suspension, ≤ 20 g per ha only would be applied.

The research reported here is the first use of ENTOSTAT technology for encapsulating a biopesticide, as previous work has involved biopesticides being formulated to adhere to the outside of ENTOSTAT wax particles40,55. ENTOSTAT-encapsulation of baculovirus is a novel technology developed and patented during this research collaboration (see Competing Interests below for patent information). There have been previous studies using encapsulation of baculoviruses using polymers or lignin20,35,37,39,56. Some showed enhanced storage or UV-protection but none for the duration reported here, and only one of these studies with lignin formulation progressed to successful plant trials56.

An absolute requirement for a biopesticide formulation is that it can be applied through existing commercial spray systems6. Preliminary results, using a spray boom attached to a Hardi ilemo 1,000 L orchard sprayer using a lilac Albuz ATR80 nozzle, show that the ENTOSTAT formulation is sprayable (data not shown).

Another important issue for any biological pesticide is storage stability, as agents that cannot be formulated to remain stable for long periods have low viability as commercial biopesticides33,45. Baculoviruses are relatively stable robust agents23, but as formulated in water or glycerol have struggled to match the 2–4 years storage stability of chemicals and require freezer or cool chain storage5,20,25. The results presented here show that ENTOSTAT-TiO2-NPV has storage properties at least equal to that of a commercial glycerol-based formulation at 30 °C over 6 months. However, longer-term trials are needed to see if the ENTOSTAT-formulated NPV can reach the 18–24 month target proposed for biopesticides20.

A key issue with any commercial formulation is to ensure that the financial benefits outweigh the costs19. Whilst many studies have highlighted formulation additives that improve the performance of biological agents20,57, very few discuss the cost–benefit ratio of the additives/formulations. The use of UV protectants in biopesticides has been constrained because the typical inclusion rates are too high and too costly for routine field use5,13,30. With ENTOSTAT-TiO2, the UV protectant is tightly bound to the baculovirus OB, so only small quantities (g per ha) are required compared to when blockers are used in suspension (Kg per ha). For example, TiO2 applied as a suspension at an effective 187 L per ha was costed at $18.06 per ha, a significant issue that has constrained its adoption so far in commercial formulations30. In an ENTOSTAT-TiO2 formulation the equivalent cost for the TiO2 would be around $0.08 per ha (in 2003 prices). Thus ENTOSTAT-TiO2 can be said to address this issue as the key ingredients, wax and photo-stabilizing TiO2, are readily and cheaply available, and at the rates that would be used in the field would cost < $1 per ha.

A major cost associated with any commercial biopesticide is that associated with producing the active ingredient, and this is particularly true of baculoviruses, which commercially are produced in vivo. If the UV persistence of baculoviruses can be increased by using the ENTOSTAT-TiO2 formulation, then the amount of baculovirus applied might be drastically reduced. The current high application rates of around 1–5 × 1012 OB/ha are needed to overcome the short persistence issues. It has been suggested that with more effective UV protection, application rates could be reduced by a factor of × 1030. It is thus conceivable that adopting ENTOSTAT-TiO2 formulation could enable producers to reduce active ingredient rates and that this would have a drastic effect on the cost of baculovirus products. It may even enable baculovirus products to reach the goal proposed by Reid et al.23 of bringing biopesticide product costs below US$ 20/ha; making them, for the first time, competitive in broad acre crops. This could vastly increase their potential market share. Greater UV persistence could also allow biopesticides to be sprayed prophylactically in response to cues of imminent pest attack (e.g. large numbers of reproductive adults in traps) rather than timed precisely to coincide with pest appearance on crop. Moreover, it may be hypothesised that baculoviruses could be successfully micro-encapsulated in ENTOSTAT waxes with a broad range of different additives to give additional desirable characteristics, such as phagostimulation, broader host ranges, enhanced kill rates, etc., to deliver much ‘smarter’ biopesticides that enhance the beneficial properties of these biological entities24.

The issue of limited UV persistence is not restricted to baculovirus biopesticides, but also affects all of the major groups of pathogens used in crop protection20. Thus, it is possible that the ENTOSTAT-encapsulation system described here could be used with other pathogens, such as the widely-used bacterium Bacillus thuringiensis, whose on-crop persistence while longer than that of baculoviruses, is similarly limited to a few days20,48.

Conclusion

We present here a novel formulation technology that effectively safeguards the efficacy of a baculovirus biopesticide by protecting the sensitive viral DNA from damaging UV radiation in sunlight on the crop by encapsulating it in an ENTOSTAT-TiO2 waxy coat. This technology is a highly promising candidate formulation, whose adoption in baculovirus and other biopesticide formulations could greatly increase the persistence and effectiveness of biopesticides while reducing costs. This novel formulation could be a means of greatly expanding the use of biopesticides to move them from the role of niche products for high-value and protected crops into large-scale field crop use. This would meet the need for a safer, more ecologically-acceptable, pest control approach to replace those chemical pesticides that have been, or are currently being, removed from the market-place in response to public pressure for more environmentally-sustainable crop production.

Materials and methods

Insects

Egyptian cotton leafworm (Spodoptera littoralis) used were originally collected in Egypt and had been maintained at Lancaster University since 2011. Except where stated, larvae were reared in isolation in 25 mL plastic pots containing a wheatgerm-based semi-artificial diet58,59.

Virus

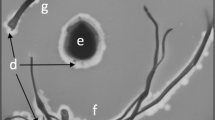

The S. littoralis nucleopolyhedrovirus (SpliNPV) used here was NRI strain #0,084 produced in the laboratories of the Natural Resources Institute, University of Greenwich, and purified for formulation using a standard purification technique for NPV45,58. The virus was enumerated using a Neubauer improved haemocytometer and viewed under phase contrast microscopy at × 400 using a Leica DMR microscope45. The virus was freeze-dried using the published protocol58 in a SUPERMODULOYO 20 (Edwards).

Surface dose bioassays

The laboratory bioassays reported here employed a modified surface dose bioassay method58,60 that utilised 96-well flat-bottomed cell culture plates (CORNING COSTAR). The bioassay used a smooth semi-synthetic diet using ground wheatgerm58 and was dispensed into each well before being stored in a fridge (4 °C) for later use. For bioassays, virus formulations were prepared in dH20 containing 4% food dye (Dr. Oetker). After vortexing, 10 µl of test suspension was pipetted onto the surface of the diet in the 96-well plates in a structured randomised pattern. After drying, a single starved L2 larva was added to each well and each plate was wrapped in PARAFILM. These were then left for 24 h in an incubator at 27 °C after which, each larva was transferred to an individual 25 mL plastic pot containing fresh diet. After two days, handling deaths and missing larvae were recorded and mortality assessed at 8 and 15 days post-inoculation.

Formulation process

The formulation process is proprietary information and so only brief details are provided here. Pilot studies tested a range of different waxes, chosen based on their suitability for formulation with NPV. The NPV was incorporated into the selected ENTOSTAT wax in a melt phase with a virus loading of 2% NPV/wax (w/w) and stirred to form a uniform liquid using a high sheer blender. The UV protectant was then added, and the mixture cooled before being milled using a kibbling mill and micronized in a jet mill to a fine powder (X50 ~ 5–15 um). Photo-stabilised Titanium dioxide (TiO2) was selected as the formulation UV protectant. The suspended concentrate (SC) formulation was made by suspending the NPV/wax micro-powder with a blend of proprietary combinations of wetting agents, dispersers, rheology modifiers and other co-formulants with TiO2, to create a uniform SC. Unlike non-formulated NPV, it is not possible to visually determine the concentration of OBs in wax-formulated virus, therefore the virus loading for the ENTOSTAT-TiO2-encapsulated NPV is an estimate based on how much NPV was added into the formulation.

Simulated sunlight slide exposure bioassays

Slide exposure

Test formulations were applied to blank ground glass slides. 200 µL of formulation was applied to each slide as ten 20 µL droplets then air dried at room temperature prior to exposure. The slides were exposed to UV using an ATLAS SUNTEST XLS + cabinet with the SunCool attachment comparable to other UV studies35,47. The chamber was set to apply 65 W m−2 using the daylight filter and was calibrated to match standard sunlight exposure at solar noon on the vernal equinox at Miami, Florida61; the chamber temperature was standardised to 20 °C using the SunCool attachment. Five slides of each formulation were exposed for each time point tested over 0–96 h. Slides were arranged within the cabinet in a randomised three by five formation, to minimise the effect of any variation in UV exposure across the cabinet. After exposure, slides were immersed in 0.02% sodium dodecyl sulphate (SDS) and brushed to re-suspend and recover the exposed formulation that was then placed into a universal vial for storage at 4 °C until bioassaying.

Seven replicate bioassays were completed across eighteen blocks in a structured randomised design. Three formulations were tested: non-formulated virus, a commercial standard (LITTOVIR), and NPV formulated in ENTOSTAT wax with TiO2 additive. The first four replicates included UV doses up to 16 h continuous exposure (0, 1, 2, 4, 8 and 16 h). The final three replicates included doses up to 96 h continuous exposure (0, 4, 16, 32, 48 and 96 h), again comprising 24 larvae per formulation per UV dose.

Simulated sunlight plant exposure bioassays

Virus formulations were applied to plants that were then exposed to artificial lighting that included wavelengths in the UV range of the spectrum (see below). Two plant species were used: tomato (variety Ailsa Craig) and cabbage (variety Greyhound). These were grown from seed (Moles Seeds, Colchester, U.K.) in a glasshouse in John Innes No. 2 compost. When the plants were at an appropriate stage of growth (8–12 weeks old), the plants were sprayed with either dH2O (control), LITTOVIR (6 × 108 OB/mL) or ENTOSTAT-TiO2-encapsulated NPV (~ 7 × 108 OB/mL). Between one and three plants were used per UV dose per treatment group. The suspension was applied evenly to the plants using 1.25 L pressure sprayers (Hoselock, Birmingham, U.K.) immediately following preparation. Plants were then left to dry overnight in a glasshouse before being moved to the controlled environment (CE) room the following morning (25 ± 2 °C).

Plant exposure to simulated sunlight used facilities and approaches that we have described previously50. Plants were arranged in a completely randomised design in a CE room under artificial illumination provided by LED arrays (Valoya BX180, Valoya Oy, Helsinki, Finland) for photosynthetically active radiation (400–700 nm, mean irradiance over the growing area 300 micromole quanta m-2 s−1), and fluorescent tubes for UVA and UVB radiation (UVA340 and UV313 respectively, both from Q-Panel Laboratory Products, Bolton, UK). The UVB tubes were filtered with 0.13 mm thick cellulose diacetate (Clarifoil, Courtaulds Ltd, Derby, UK) to remove wavelengths below ~ 290 nm. The light environment was measured using a double monochromator scanning spectroradiometer (model SR991-v7; Macam Photometrics, Livingston, UK). The UV treatment provided a mean total UV irradiance (290–400 nm) of 11.55 W m−2. The LED lights were switched on for 12 h per day, which gave a daily UV dose in the plant system roughly equivalent to 2 h in the ATLAS SUNTEST system (i.e. 499 kJ m−2 day−1). The control treatment (no UV) was provided on the same bench as the UV treatments, but used UV313 UVB tubes wrapped in clear UV-opaque polyester (Lee Filters, Andover, UK) which absorbed 97% of the UV less than 400 nm (unweighted UV irradiance 0.36 W m−2).

Once exposed, the plants were removed from the CE room and 5–15 leaf discs were cut from each plant using a 5 mm corkborer. These were each immediately placed in an individual cell of a 25-well square plate (10 cm × 10 cm). Individual L2 S. littoralis larvae that had been starved for 4 h were then added to each cell of the plates and bioassayed as detailed above. Each treatment group comprised 10–15 larvae per UV dose, making a total of 120–270 larvae per bioassay.

Phytotoxicity

To determine any effects of the ENTOSTAT-TiO2-encapsulated NPV on the growth of the plants, the following attributes were measured in the 36 cabbage plants used in the final plant bioassay prior to cutting out the leaf discs at day 16 post-application: total number of leaves, number of healthy-looking leaves, plant height, fresh weight and dry weight. Two control treatments were used for comparison: dH2O (negative control) and LITTOVIR.

Titanium dioxide toxicity

To determine if there was any mortality associated with the TiO2 additive, L2 S. littoralis larvae were inoculated with one of four treatments: dH2O (control), ENTOSTAT-TiO2-encapsulated NPV, ENTOSTAT-TiO2 wax blank (lacking NPV), and non-encapsulated SpliNPV using the standard bioassay. Each bioassay comprised 60 larvae per treatment (12 in the controls) and was repeated four times.

Storage stability

To compare the storage properties of three formulations of SpliNPV, they were stored at two temperatures (4 °C and 30 °C) and sampled at three time-points (0, 3 and 6 months). The three formulations were: freeze-dried SpliNPV in aqueous suspension; LITTOVIR (commercial standard SpliNPV, Andermatt Biocontrol); and ENTOSTAT-encapsulated SpliNPV. Replicate samples of the two non-commercial virus formulations were bottled in air and sealed, as per the commercial standard LITTOVIR. Five replicate bottles of each virus sample were bioassayed at each time point and storage temperature (i.e. a total of 30 bottles per bioassay), conducted over a single 5-day period, thus providing five independent replicates of each formulation at each storage temperature and time-point. Bioassays used the standard 96-well plate surface dose assay with 30 larvae per formulation. A single dose of each virus was used (5 × 106 OB/mL), chosen to achieve close to 100% mortality at time point 0 (i.e. pre-storage). Larvae in the control group were exposed to an aqueous suspension of the wax blank formulation.

Statistical analysis

Data analyses were performed using the R statistics package (R Statistical Software, version 3.3.3 2017-03-0662). Mortality data were analysed using logistic regression (generalized linear models, GLMs, with binomial errors and logit link function) using a stepwise deletion approach. All other analyses used linear models (LMs) and data were tested for normality and transformed if required.

Data availability

All data will be made available on Dryad upon acceptance.

References

Lacey, L. A. et al. Insect pathogens as biological control agents: do they have a future?. Biol. Control21(3), 230–248 (2001).

Moscardi, F. et al. Baculovirus pesticides: present state and future perspectives. In Microbes and Microbial Technology (eds Ahmad, I. et al.) 415–445 (Springer, New York, 2011).

Harrison, R. & Hoover, K. Baculoviruses and other occluded insect viruses. In Insect Pathology (eds Vega, F. E. & Kaya, H. K.) 73–131 (Elsevier, Amsterdam, 2012).

Mudgal, S., et al., Scientific support, literature review and data collection and analysis for risk assessment on microbial organisms used as active substance in plant protection products–Lot 1 Environmental Risk characterisation, in EFSA Supporting Publications. 2013, European Food Standards Agency, EN-518. p. 149.

Lacey, L. A. et al. Insect pathogens as biological control agents: back to the future. J. Invertebr. Pathol.132, 1–41 (2015).

Grzywacz, D. & Moore, S. Production, Formulation, and Bioassay of Baculoviruses for Pest Control. Microbial Control of Insect and Mite Pests: From Theory to Practice, 109–124 (2017)

Gwynn, R. (ed.) Manual of Biocontrol Agents 5th edn. (British Crop Protection Council, Alton, 2014).

Glare, T. et al. Have biopesticides come of age?. Trends Biotechnol.30(5), 250–325 (2012).

Furlong, M. J., Wright, D. J. & Dosdall, L. M. Diamondback moth ecology and management: problems, progress, and prospects. Annu. Rev. Entomol.58, 517 (2013).

Trimmer, M. Biological control global market overview, western region state liaison representatives, in Commodity Liaison Committee Meeting and Biopesticides Workshop. Ft. Collins (2017).

Ignoffo, C. M. & Garcia, C. Combinations of environmental factors and simulated sunlight affecting activity of inclusion bodies of the Heliothis (Lepidoptera, Noctuidae) nucleopolyhedrosis virus. Environ. Entomol.21(1), 210–213 (1992).

Shapiro, M. Radiation protection and activity enhancement of viruses. Biorational Pest Control Agents595, 153–164 (1995).

Lacey, L. A. et al. Codling moth granulovirus: a comprehensive review. Biocontrol Sci. Tech.18(7), 639–663 (2008).

El Salamouny, S. et al. Black tea and lignin as ultraviolet protectants for the Beet Armyworm nucleopolyhedrovirus. J. Entomol. Sci.44(1), 50–58 (2009).

Jaques, R. P. Persistence of a nuclear polyhedrosis virus in habitat of host insect Trichoplusia ni. I. polyhedra deposited on foliage. Can. Entomol.99(8), 785 (1967).

McGuire, M. R. et al. Comparative field stability of selected entomopathogenic virus formulations. J. Econ. Entomol.94(5), 1037–1044 (2001).

Shapiro, M. et al. Field evaluation of a kudzu/cottonseed oil formulation on the persistence of the beet armyworm nucleopolyhedrovirus. J. Entomol. Sci.47(3), 197–207 (2012).

Cherry, A. J. et al. Field evaluation of Helicoverpa armigera nucleopolyhedrovirus formulations for control of the chickpea pod-borer, H. armigera (Hubn.), on chickpea (Cicer arietinum var.. Shoba) in southern India. Crop Protect.19(1), 51–60 (2000).

Behle, R. and T. Birthisel, Formulations of entomopathogens as bioinsecticides, in Mass Production of Beneficial Organisms, 483–517 (Elsevier, Amsterdam, 2014).

Burges, H. D. & Jones, K. A. Formulation of bacteria, viruses and protozoa to control insects. In Formulation of Microbial Biopesticides (ed. Burges, H. D.) 33–127 (Kluwer Academic Publishers, Dordrecht, 1998).

Grzywacz, D. Basic and Applied Research: Baculovirus. Microbial Control of Insect and Mite Pests: From Theory to Practice, 27–46 (2017).

Akhanaev, Y. B. et al. Comparison of tolerance to sunlight between spatially distant and genetically different strains of Lymantria dispar nucleopolyhedrovirus. PLoS ONE12, e0189992. https://doi.org/10.1371/journal.pone.0189992 (2017).

Reid, S., Chan, L. C. L. & Van Oers, M. M. Production of entomopathogenic viruses. In Mass Production of Beneficial Organisms (eds Morales-Ramos, J. A. et al.) 437–482 (Elsevier, Amsterdam, 2014).

Wilson, K. et al. Pest control: biopesticides’ potential. Science342(6160), 799–799 (2013).

Behle, R. W., Tamez-Guerra, P. & McGuire, M. R. Field activity and storage stability of Anagrapha falcifera nucleopolyhedrovirus (AfMNPV) in spray-dried lignin-based formulations. J. Econ. Entomol.96(4), 1066–1075 (2003).

Shapiro, M. et al. Fruit and vegetable extracts as radiation protectants for the Beet Armyworm nucleopolyhedrovirus. J. Agric. Urban Entomol.32(1), 91–100 (2016).

Shapiro, M. Use of optical brighteners as radiation protectants for Gypsy Moth (Lepidoptera, Lymantriidae) nuclear polyhedrosis virus. J. Econ. Entomol.85(5), 1682–1686 (1992).

Shapiro, M. & Farrar, R. R. Fluorescent brighteners affect feeding rates of the corn earworm (Lepidoptera: Noctuidae) and act as enhancers and sunlight protectants for its nucleopolyhedrovirus. J. Entomol. Sci.38(2), 286–299 (2003).

Bull, D. L. et al. Improved formulations of Heliothis nuclear polyhedrosis virus. J. Econ. Entomol.69(6), 731–736 (1976).

Farrar, R. R., Shapiro, M. & Javaid, I. Photostabilized titanium dioxide and a fluorescent brightener as adjuvants for a nucleopolyhedrovirus. Biocontrol48(5), 543–560 (2003).

Farrar, R. R., Ridgway, R. L. & Dively, G. P. Activity and persistence of the nuclear polyhedrosis virus of the celery looper (Lepidoptera:Noctuidae) with a feeding stimulant and a stilbene-derived enhancer. J. Entomol. Sci.34(4), 369–380 (1999).

Tamez-Guerra, P. et al. Sunlight persistence and rainfastness of spray-dried formulations of baculovirus isolated from Anagrapha falcifera (Lepidoptera : Noctuidae). J. Econ. Entomol.93(2), 210–218 (2000).

Leggett, M. et al. Formulation of microbial biocontrol agents: an industrial perspective. Can. J. Plant Pathol.33(2), 101–107 (2011).

Ignoffo, C. M., Shasha, B. S. & Shapiro, M. Sunlight ultraviolet protection of the Heliothis nuclear polyhedrosis virus through starch-encapsulation technology. J. Invertebr. Pathol.57(1), 134–136 (1991).

Arthurs, S. P., Lacey, L. A. & Behle, R. W. Evaluation of lignins and particle films as solar protectants for the granulovirus of the codling moth, Cydia pomonella. Biocontrol Sci. Technol.18(8), 829–839 (2008).

Lasa, R., Williams, T. & Caballero, P. Insecticidal properties and microbial contaminants in a Spodoptera exigua multiple nucleopolyhedrovirus (Baculoviridae) formulation stored at different temperatures. J. Econ. Entomol.101(1), 42–49 (2008).

Pemsel, M. et al. Encapsulation of codling moth granuloviruses for a sustainable biotechnical pesticide. Chem. Ing. Technol.82(3), 343–348 (2010).

Villamizar, L. et al. Eudragit S100 microparticles containing Spodoptera frugiperda nucleopolyehedrovirus: physicochemical characterization, photostability and in vitro virus release. J. Microencapsul.27(4), 314–324 (2010).

Pemsel, M. et al. Advanced PGSS process for the encapsulation of the biopesticide Cydia pomonella granulovirus. J. Supercrit. Fluids53(1–3), 174–178 (2010).

Athanassiou, C. G. et al. Delivering Beauveria bassiana with electrostatic powder for the control of stored-product beetles. Pest Manag. Sci.73(8), 1725–1736 (2017).

Rogers, C. D., Armsworth, C. G. & Poppy, G. M. Conspecific transmission of insecticidal adhesive powder through mating in the Mediterranean fruit fly, Ceratitis capitata. J. Pest. Sci.87(2), 361–369 (2014).

Behle, R. W., McGuire, M. R. & Tamez-Guerra, P. Effect of light energy on alkali-released virions from Anagrapha falcifera nucleopolyhedrovirus. J. Invertebr. Pathol.76(2), 120–126 (2000).

Arrizubieta, M. et al. Insecticidal efficacy and persistence of a co-occluded binary mixture of Helicoverpa armigera nucleopolyhedrovirus (HearNPV) variants in protected and field-grown tomato crops on the Iberian Peninsula. Pest Manag. Sci.72(4), 660–670 (2016).

Wan, N. F., Jiang, J. X. & Li, B. Effect of host plants on the infectivity of nucleopolyhedrovirus to Spodoptera exigua larvae. J. Appl. Entomol.140(8), 636–644 (2016).

Hunter-Fujita, F. R. et al.Insect Viruses and Pest Management 620 (Wiley, Chichester, 1998).

Williams, T. Viruses. In Ecology of Invertebrate Diseases 213–285 (Wiley, Hoboken, 2017).

Lacey, L. A. & Arthurs, S. P. New method for testing solar sensitivity of commercial formulations of the granulovirus of codling moth (Cydia pomonella, Tortricidae : Lepidoptera). J. Invertebr. Pathol.90(2), 85–90 (2005).

McGuire, M. R. et al. Calibration of a sunlight simulator for determining solar stability of Bacillus thuringiensis and Anagrapha falcifera nuclear polyhedrovirus. Environ. Entomol.29(5), 1070–1074 (2000).

Thorpe, K. W. et al. Aerial application of the viral enhancer Blankophor BBH with reduced rates of gypsy moth (Lepidoptera : Lymantriidae) nucleopolyhedrovirus. Biol. Control16(2), 209–216 (1999).

Wargent, J. J. et al. Increased exposure to UV-B radiation during early development leads to enhanced photoprotection and improved long-term performance in Lactuca sativa. Plant Cell Environ.34(8), 1401–1413 (2011).

Paul, N. D. et al. Ecological responses to UV radiation: interactions between the biological effects of UV on plants and on associated organisms. Physiol. Plant.145(4), 565–581 (2012).

Zorlu, T., Nurullahoglu, Z. U. & Altuntas, H. Influence of dietary titanium dioxide nanoparticles on the biology and antioxidant system of model insect, Galleria mellonella (L.) (Lepidoptera: Pyralidae). J. Entomol. Res. Soc.20, 89–103 (2018).

Anderson, M.W., et al. Broad spectrum physical sunscreens: titanium dioxide and zinc oxide, in Sunscreens-Development, Evaluation, and Regulatory Aspects, 353–397 (Dekkar, New York, 1997).

Goulson, D. et al. Effects of optical brighteners included in biopesticide formulations on the growth of crops. Agric. Ecosyst. Environ.95(1), 235–240 (2003).

George, C. G., Maria, S. K. & Christos, A. G. Efficacy of Beauveria bassiana in combination with an electrostatically charged dust for the control of major stored-product beetle species on concrete. J. Stored Prod. Res.79, 139–143 (2018).

Behle, R. W. & Popham, H. J. R. Laboratory and field evaluations of the efficacy of a fast-killing baculovirus isolate from Spodoptera frugiperda. J. Invertebr. Pathol.109(2), 194–200 (2012).

Shapiro, M., El Salamouny, S. & Shepard, B. M. Plant extracts as ultraviolet radiation protectants for the Beet Armyworm (Lepidoptera: Noctuidae) nucleopolyhedrovirus: screening of extracts. J. Agric. Urban Entomol.y26(2), 47–61 (2009).

Grzywacz, D. et al.Helicoverpa armigera Nucleopolyhedrovirus Production Manual (Natural Resources Institute, Greenwich, 2004).

Reeson, A. F. et al. Baculovirus resistance in the noctuid Spodoptera exempta is phenotypically plastic and responds to population density. Proc. R. Soc. Lond. B265(1407), 1787–1791 (1998).

Jones, K. A. Bioassays of entomopathogenic viruses. In Bioassays of entomopathogenic microbes and nematodes (eds Navon, A. & Ascher, K.) 95–140 (CAB International, Wallingford, 2000).

Atlas-mts.com, SUNTEST Xenon Test Instruments. (2018). https://www.atlas-mts.com/.

Team, R. C. R: a language and environment for statistical computing (R Foundation for Statistical Computing, Vienna, 2017).

Acknowledgements

This study was funded by an Innovate UK/BBSRC Grant awarded to KW, DG and Philip Harris (Exosect Ltd) (BB/P004970/1 and TS/P000436/1). We thank Martin Brown for his initial contributions to the project and associated patent applications, Philip Harris for his logistical support, and Phill Nott and Dave Osbaldeston for technical assistance.

Author information

Authors and Affiliations

Contributions

D.G., K.W., F.S., I.C., N.D.P. A.D. and A.R. designed the study. F.S., D.G., K.W., I.C., A.R., and K.H. collected the data. K.W. analysed the data and prepared the figures. K.W. and D.G. wrote the first drafts of the manuscript and all authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

D.G., K.W., I.C. declare below patent inventorship related to this work: (1) Organic particles containing viral bodies (1) UK patent: Patent Number GB2541175; status: granted; inventors: Martin Brown, Igor Curcic, David Grzywacz, Kenneth Wilson; applicant: Exosect Limited. (2) UV resistant biopesticide microparticles (2) European patent: Patent number: 18159610.7-1110; status: pending; inventors: Martin Brown, Igor Curcic, David Grzywacz, Kenneth Wilson; applicant: Exosect Limited. All other authors (F.S., N.D.P., A.D., A.R., K.H.) declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wilson, K., Grzywacz, D., Curcic, I. et al. A novel formulation technology for baculoviruses protects biopesticide from degradation by ultraviolet radiation. Sci Rep 10, 13301 (2020). https://doi.org/10.1038/s41598-020-70293-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-020-70293-7

This article is cited by

-

Trends in the implementation of biopesticides in the Euro-Mediterranean region: a narrative literary review

Sustainable Earth Reviews (2024)

-

Regulatory Mechanisms, Protein Expression and Biological Activity of Photolyase Gene from Spodoptera littoralis Granulovirus Genome

Molecular Biotechnology (2023)

-

Biological control: a global perspective

International Journal of Tropical Insect Science (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.