Abstract

Biological control of bacteria with bacteriophages is a viable alternative to antibiotics. To be successful, biological control bacteriophages must be stable when exposed to the environment. Stabilization can be achieved through incorporation of bacteriophages into polymers and stabilizers that will be coated onto the seed. For this study, bacteriophages against Clavibacter michiganensis subsp. nebraskensis (Cmn), the causal agent of Goss’s wilt, were incorporated into polyvinyl polymers with alcohol, ether and pyrrolidone functional groups and coated onto maize (Zea mays L.) seeds. The objectives of this study were to evaluate polymers and stabilizers that can protect Clavibacter michiganensis subsp. nebraskensis (CN8) bacteriophages against dehydration during storage. Bacteriophages stability when coated on seed depended on the glass transition temperature (Tg), functional groups of the polymer, and the presence of stabilizers such as sugars and proteins. Polyvinyl alcohol (PVOH) provided the greatest stability for CN8 bacteriophages on seed when coatings did not contain a stabilizer. A possible reason for the greater stability of this coating is having a glass transition temperature (Tg) very close to ambient temperature. PVOH combined with whey protein isolate (WPI) maintained CN8 bacteriophage activity in storage for four months at 26 °C and seven months at 10 °C. This coating also significantly reduced bacterial loads in seedlings grown from contaminated seeds, without affecting seed germination. Bacteriophage-polymer coatings which are stable during drying and storage, and are compatible with biological systems, not only provide an alternative to traditional antibiotics in agriculture, but also provide options for food, environmental and medical applications.

Similar content being viewed by others

Introduction

Biological control of bacteria is crucial in areas were antibiotic use is restricted, and where bacteria are resistant to antibiotics or copper compounds1,2. Biological control is achieved, for example, with beneficial bacteria3,4,5,6, biological derived molecules7,8,9, and bacteriophages10,11,12,13. Compared to antibiotics or copper compounds, biologicals are more sensitive to environmental stresses including temperature, humidity, and ultraviolet (UV) radiation14,15,16. For their protection, biocontrol agents are often incorporated into powders, gels, or film coatings containing natural and synthetic polymers, sugars, proteins, and controlled amounts of water17,18,19. Biological coatings also have found applications in medicine20,21,22, food23, and agriculture24,25.

In agriculture, antibacterial seed coatings can control bacterial plant diseases by protecting the seeds from contaminated plant residue, contaminated soil, and contamination within the seeds. While most coatings include chemicals like copper compounds and antibiotics, new biologically-based coatings are increasing in importance. Biological coatings can be more selective, which preserves the soil microbiome, and are compatible with organic practices. Successful biological seed coatings include natural oils, plant extracts, beneficial microbes, and bacteriophages26,27. For example, bacteriophages coated on seed or the soaking of seed in a bacteriophage culture reduced Stewart’s wilt in maize seeds28; reduced seedling rot and blight in rice seeds29; and improved nodulation and nitrogen uptake in soybean30. All of these bacteriophages were coated on seeds without polymers or stabilizers.

In general, there are three classes of bacteriophage coatings with varying levels of bacteriophage protection: unprotected bacteriophages31,32, protected bacteriophages applied as solutions33, and protected bacteriophages incorporated into gels or powders before coating34. The protected bacteriophages are generally more stable to environmental stresses. Research shows that bacteriophages applied to tomato leaves were more stable to drying and UV radiation when formulated into a coating with skim milk35, while bacteriophages incorporated into alginate gels were more stable at pH 2.5 than those in solution36. Adding sugars or skim milk to alginate gels before drying increased bacteriophage stability37, while whey protein isolate films maintained bacteriophage activity for five months38.

Coatings not only stabilize the biocontrol agent, but also the entity to be protected. For example, in agriculture polymers are used to protect seeds in many crops. These polymers provide a barrier between the seed and chemical treatments reducing phytotoxicity, and separate multiple treatments from each other, reducing negative interactions. Bacteriophages – polymer complexes can be water soluble which allows the release of bacteriophages as biocontrol agents upon rehydration39. Polymers also improve treatment adhesion and plantability while reducing dust off27. Dust off is crucial in the final stages of testing seed treatments to ensure the treatment stays on the seed during handling and planting. However, seed coatings can inhibit seedling emergence40 and even be phytotoxic41,42,43. Due to these possible negative effects, it is necessary to test seed germination and vigor for all treatments and coatings, including biological control.

In this study, we report on the ability of bacteriophages with polymers to act as biocontrol coatings on seeds. Specifically, we investigated the ability of CN8 bacteriophages to reduce Clavibacter michiganensis subsp. nebraskensis (Cmn) on maize seeds (Fig. 1). Cmn causes Goss’s wilt, a wide spread maize disease that may cause up to 50% yield loss43,44. More importantly, Goss’ wilt can be transmitted through infected seeds or plant residue in the soil45. Although the seed transmission rate is relatively low46, Cmn is an important pathogen to the seed industry because of phytosanitary restrictions to worldwide seed shipments, and to prevent the spread of Cmn into new areas. The objective of this study was to stabilize CN8 bacteriophages in different polymer coatings, to determine bacteriophage survival on the seed and their effect on seed germination, and to assess the feasibility of using this biocontrol seed coating to prevent the spread of Cmn through infected seed.

(A) Photograph of maize seeds (b) coated equally with CN8 bacteriophages (5.0 × 107 PFU/mL) after incubation on a bacterial overlay of Cmn (a). Active CN8 bacteriophages led to lysis (c) around the seeds. (B) Visual confirmation (plaque formation) of CN8 bacteriophages presence (d) after germination around seed (e), roots (f), and shoot (g). (C) Control seeds coated with PVOH + WPI without CN8 bacteriophages showing no lysis around seeds. Lysis of Cmn only occurred when CN8 bacteriophages were added to the coating matrix. All scale bars: 10 mm.

Results

Drying of CN8 bacteriophages into biocontrol coatings

CN8 bacteriophages were stable after air-drying on plastic surfaces at ambient temperature (Fig. 2). Their stability depended on the polymer and stabilizer used. Eight of the eighteen coating combinations maintained the number of active bacteriophages during the drying process (indicated by treatments not containing a star above its bar in Fig. 2). Active CN8 bacteriophages were dried in the presences of PMVE, PVP and PVOH, and concentrations decreased between 0.3 and 0.5 log compared to the original liquid sample. Adding stabilizers improved the retention of active bacteriophages in the dry films. In the more flexible PMVE films, most stabilizers led to a 0.2 log decrease (D-mannitol log 0.4) in bacteriophage activity. In PVOH and PVP films, those including stabilizers led to the best protection and active bacteriophage concentrations in these films remained the same as those in solution (before drying). Only film combinations of D-mannitol/PVOH and maltodextrin/PVP did not maintain bacteriophage activity compared to the original liquid sample (Fig. 2).

CN8 bacteriophages plaque forming units (PFU) in biocontrol films from different polymer (PMVE (A), PVP (B), and PVOH (C)) and stabilizer combinations before (black bars) and after drying (spotted bars) as polymer films on plastic. A mean difference in PFU concentration before and after drying is denoted by a star. Mean differences were determined via a t-test at a significance level of 0.05. Abbreviations: PMVE – Polymethyl vinyl ether, PVP – Polyvinylpyrrolidone, PVOH - Polyvinyl alcohol, SM – Skim Milk, MD – Maltodextrin, WPI – Whey Protein Isolate. Glass transition temperatures: PMVE (−82–22 °C)†, PVP (54–86 °C)†, PVOH 35–85 °C)†, SM (39–46 °C)§, Sucrose (28–70 °C)¶, MD (112–180 °C)‖, D-Mannitol (10–18 °C)‡, WPI (90–106 °C)§. Glass transition temperatures from †89‡90§52¶53‖54.

Similar results were observed when coating bacteriophages on seeds. All CN8 bacteriophages dried on seeds showed infectivity (Figs. 1 and 3). Seeds placed directly on an overlay showed visual lysis of Cmn bacteria, which decreased after drying and storage (Fig. 1). While the size of the lysis area is related to the number of active bacteriophages for two dimensional materials, e.g., paper47, for three dimensional seeds inconsistent contact between the seeds and the overlay did not allow for quantification. Visual lysis was used only to confirm that bacteriophages in the biocontrol coatings can infect bacteria in a moist environment, similar to seeds planted in soil.

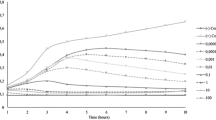

Concentration of active bacteriophages coated on maize seeds decreased with drying time depending on coating formulation. Open square: PVOH and WPI, closed square: PVOH, closed circle: PMVE, closed triangle: PVP, open diamond: bacteriophages in buffer. Error bars: two standard deviations. Only positive error bars shown for clarity.

The number of active bacteriophages on the seed depended on the time of drying and the polymer and stabilizers used in the biocontrol coatings (Fig. 3). The number of active bacteriophages decreased rapidly during the first 10 h of drying (0.2 to 1.3 log) and then slowed to between 0 to 0.4 log. For most coating formulations, the number of active bacteriophages reached a plateau after 24 h. At 24 h, the number of bacteriophages applied in buffer had the largest decrease (1.1 log), followed by those in polymers (0.4 to 0.7 log) and those in PVOH/WPI, which showed no decrease.

When applied in commercially available seed coating formulations from BASF (Secompla 67c, FloRite 1197, FloRite 1706, and FloRite 1127) CN8 bacteriophages showed similar results to polyvinyl polymers. FloRite 1127 provided the best protection maintaining 1.1 × 106 PFU/seed, followed by PVOH/WPI (9.67 × 105 PFU/seed), and FloRite 1706 (2.8 × 105 PFU/seed) (data not shown).

Storage stability of CN8 bacteriophages coatings on seeds

With the multiplicity of infection (MOI) of 100 bacteriophages to a single bacteria cell48, we measured the storage stability of dry bacteriophages in polyvinyl-based biocontrol coating formulations on maize seeds stored at 4 °C, 10 °C, and 26 °C (Fig. 4) and at 26 °C for BASF coating formulations. The temperatures of 4 °C and 10 °C mimic ideal short-term storage conditions for seeds49,50, while 26 °C is commonly found in a farm warehouse42.

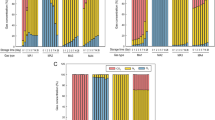

CN8 bacteriophages stability in biocontrol coatings on maize seeds stored at 4 °C (A), 10 °C (B) and 26 °C (C) for up to four months. The line indicates the limit of detection at approximately 600 PFU/seed. Values below that line are artificially spread to show all symbols. Open square: PVOH and WPI, closed square: PVOH, open circle: PMVE and WPI, closed circle: PMVE, open triangle: PVP and WPI, closed triangle: PVP, open diamond: bacteriophages only. Error bars: two standard deviations. (A,B) Only positive error bars shown for clarity.

Bacteriophages infectivity after storage was enhanced when using lower storage temperatures. Coatings containing WPI maintained higher bacteriophages infectivity over storage time compared to polymer-only and buffer-only coatings, regardless of storage temperature (Fig. 4A). Bacteriophages infectivity in PMVE and buffer-only coatings decreased after week four, and was undetectable at week 16 of storage at 4 °C. A slow linear decline in bacteriophages infectivity was recorded for all other coatings after week four of storage at 4 °C, but some bacteriophages infectivity could still be detected at week 16. At 10 °C, a slow linear decrease in bacteriophages infectivity occurred for the first three to four months. The number of active bacteriophages at this temperature either decreased below the limit of detection (600 PFU/seed) or reached a plateau after seven months (Fig. 4B). Bacteriophages infectivity decreased below the detection limit in four months for PMVE, buffer-only coatings, while in PVP coatings infectivity lasted for five months. The loss of active bacteriophages at four months was more pronounced at 10 °C (1.5 to 2.1 log) than at 4 °C (0.9 to 1.0 log), with otherwise similar infectivity-reduction trends. CN8 bacteriophages infectivity further decreased when seeds were stored at 26 °C (Fig. 4C). After one month, only coatings with WPI or PVOH showed active bacteriophages present (0.5 to 1.3 log decrease). PVOH/WPI showed active bacteriophages at two months (1.3 log decrease), and decreased by 1.7 log when storage was extended to four months. With one hundred bacteriophages commonly used to kill a single bacteria48, this storage data indicates that the PVOH/WPI coating could eliminate up to 1.1 × 105 Cmn bacteria when treatment first occurs and up to 3.8 × 103 Cmn bacteria after storage (10 °C, four months) based on the number of bacteriophages that were initially coated on each seed.

Bacteriophage biocontrol coatings using BASF polymers provided different degrees of storage stability at 26 °C depending on polymer formulation. While Secompla 67c showed no active bacteriophages after five weeks, bacteriophage infectivity decreased approximately 1 log in FloRite 1197 and 1706, and only 0.5 log in FloRite 1127. At two months, the FloRite coatings continued to lose active bacteriophages at the same rate as seen in the five-week time point, with the exception of FloRite 1127, which only showed a 0.9 log decrease from the initial concentration. At three months, however, only FloRite 1127 showed any bacteriophages activity (2.0 log decrease), which was similar to that for PVOH/WPI at the same storage time and temperature.

Biological control of Cmn on maize seeds

Maize seeds were artificially contaminated, internally and externally, and coated with CN8 bacteriophages in PVOH/WPI. Bacteria and bacteriophage concentrations were determined before and after germination in sterile blotter boxes (Fig. 5). Visual confirmation of treated seeds showed that bacteriophages were present on the seeds and roots after germination for both internally and externally contaminated seeds (Fig. 1). Prior to germination, the bacteriophage coating significantly reduced the bacteria concentration on externally contaminated seeds by 1.85 × 105 CFU/seed (76%). After germination, the CN8 bacteriophage coating reduced the Cmn concentration of externally contaminated seed by 3.17 × 106 CFU/seed (58%) in the seeds and 9.67 × 105 CFU/seedling (20%) in the roots and shoots (seedling), compared to the untreated control. Additionally, the bacteriophage coating reduced the Cmn concentration of internally contaminated seed after germination by 2.03 × 105 CFU/seed (51%) in the seeds and 2.52 × 106 CFU/seedling (78%) in the shoots and roots (seedling), compared to untreated control (Fig. 5).

CN8 bacteriophages effect on Cmn mean colony forming units (CFU) in externally (A) and internally (B) Cmn-contaminated seeds before and after germination. Coated = black bars, non-coated = striped bars. Seeds were coated with CN8 bacteriophages in PVOH and WPI (5.0 × 105 PFU/seed) and dried for 24 h prior to testing or germinating. Non-coated seeds were the untreated controls. Significance at the 0.05 level of probability is denoted by a star if the difference among the means was greater than the least significant difference (LSD).

Germination and seedling vigor

Germination was not affected (P > 0.05) by biocontrol coatings or their components. Germination rates ranged from 97.5% to 99.5%. Seedling vigor, determined by the seedling dry weight test51, ranged from 42.1 mg to 49.2 mg per seedling. Analysis of variance indicated that seed vigor was not significant (P > 0.05); however, the overall variation among treatments suggested individual coatings produced more vigorous seedlings than the untreated control. A t test comparison between untreated seed and some of the seed coatings indicated significant differences. Seed coatings of WPI, and CN8 bacteriophages produced heavier seedlings (more vigorous) than the untreated seeds.

Discussion

Bacteriophages can be protected during drying by reducing dehydration stresses19,37,38. These stresses can be reduced by controlling hydrogen bonding, glass formation, osmolarity, and the amount of residual water52,53. All polymers and stabilizers in this study allowed hydrogen bonding, had similar osmolarity (determined by the buffer), and were hygroscopic. Changes in CN8 bacteriophages infectivity in dry coatings were likely due to changes in their glass formation of the matrix as determined by its glass transition temperature (Tg) (Fig. 2). Poly(methyl vinyl ether) films with a Tg below ambient temperature were more flexible and provided less physical stabilization, than PVP and PVOH films with above ambient temperature Tg54. Bacteriophage stability in PMVE films improved when combined with above ambient temperature Tg stabilizers. The Tg probably was not the only mechanism responsible for CN8 bacteriophage stability. PVP and maltodextrin films, with the highest Tg47, did not improve bacteriophage stability (Fig. 2). Other potential factors described for bacteriophage stabilization include water exclusion from the protein surface55, and the stabilization of the folded state of proteins56. Proteins could potentially stabilize bacteriophages through hydrogen bonding with polar groups on the protein surface57, which all our polymers and stabilizers could do. On the seeds, the hydrophilic groups of the polymers could also interact with the carbohydrates of the outer layer of the maize seed58 adding another factor influencing CN8 bacteriophage stability after drying.

Not only the properties of the matrix can influence the number of active bacteriophages after drying, but also its thickness. CN8 bacteriophages belong to the order of Caudovirales and family of Siphoviridae59,60 with an icosahedral head (approximately 55 nm by 55 nm), a long non-contractile tail (approximately 220 nm) and tail fibers. Stabilization requires a dry coating that is at least as thick as the bacteriophage is long to allow full incorporation independent of orientation. Before drying coatings were approximately 63 μm thick, assuming equal distribution of active CN8 bacteriophages (106 PFU/seed) and a surface area of 160 mm2 for the maize seeds61. After drying polymer and polymer/stabilizer, coatings were about 2 and 3 μm thick, respectively making them ten times thicker than the size of the CN8 bacteriophages. Buffer-based coatings would be significantly thinner, explaining their reduced stabilization of the bacteriophages.

After 24 h of drying, all polymer coatings showed similar retention of active bacteriophages, which was larger than the retention for bacteriophages coated only with buffer (Fig. 3). During long term storage, however, whey protein isolate (WPI) containing coatings provided significantly more protection and maintained more bacteriophages on the seeds than polymer-only coatings. These results were similar to those in WPI films38 and likely due to protein-protein interactions between the WPI in the film and the bacteriophage proteins62,63, and the protection of bacteriophage proteins and DNA from oxidative stresses64. Whey protein isolate provides an excellent barrier to oxygen and light, thus reducing these oxidative stresses65. WPI also protects the viral head of bacteriophages from desiccation, thus slowing bacteriophages of infectivity35,66. Our results were also similar to those seen for bacteriophages in electrospun PVP fibers67,68. In the fibers, there was no significant decrease in the bacteriophage’s infectivity directly after drying. During long-term storage, however, PVP fibers with sucrose or trehalose showed higher bacteriophages infectivity.

Cooler storage temperatures also improved bacteriophage stability and infectivity after storage. Temperature is the most important factor for bacteriophage stability69. Gonzalez-Menendez et al. reported a similar trend in which the storage time of alginate-encapsulated philPLA-RODI bacteriophages could be lengthened from one month to six months when storage temperature was reduced from 20 °C to 4 °C. When these same bacteriophages were spray dried in skim milk, their storage increased from six months at 20 °C to 12 months at 4 °C70. Storage temperature and relative humidity are as crucial for seeds49,50 as they are for bacteriophages. Corn seed is typically stored in a controlled environment at 10 °C and 50% relative humidity (RH). This temperature requirement is compatible with those of bacteriophages in our coating formulations and allows bacteriophage infectivity to remain active for at least 20 weeks storage. Our coatings could also protect bacteriophages coated on vegetable seeds because they are typically stored at 4 °C. The lower temperature would favor bacteriophages survival and infectivity after storage.

CN8 bacteriophages in PVOH/WPI coated on artificially contaminated seeds significantly reduced the number of bacteria present in the seedlings. Reduction depends on seed size and composition, pathogen location (internal or external), and transmission, amount of inoculum, and bacteriophage transmission to the site of infection71,72,73. In our study, pathogen location influenced the level of biocontrol. Our seeds coated with 5 × 105 PFU/seed CN8 bacteriophages significantly reduced Cmn concentration on externally infected seed and seedlings from internally infected seeds. While our coatings did not completely eliminate Cmn from the seed or seedling, these seeds were intentionally artificially inoculated with a very high pathogen load to easily visualize bacteria mortality. Pathogen concentration in naturally infected seeds are much lower43. Our study indicates that bacteriophage-coatings have a similar biocontrol effect that a contact fungicide has on seed-transmitted fungi. To be effective, the bacteriophage-coatings must come in direct contact with Cmn. These coatings lowered the bacteria concentration on externally infected seeds, but not on internally infected seeds. The bacteriophages attached and lysed external Cmn decreasing its concentration, but did not penetrate into the seed. Similar results were reported in rice where bacteriophages decreased seedling rot incidence by eliminating Burkholderia glumae and B. plantarii bacteria from the surface of infested rice seed29. Even though our bacteriophage-coatings did not penetrate the seed, they effectively lysed Cmn in germinated seedlings. As seed germinated and Cmn was transferred from the seed to the seedling, bacteriophages released from the coatings interacted and lysed Cmn, reducing its concentration around the seedling roots and shoots.

While some biological control can negatively affect seed germination and seedling vigor41, other biocontrol coatings improved germination, e.g., of cucumber, areca palm, corn and canola seeds74,75,76. In our study, seed coatings had no effect on germination, presumably due to the high quality of seed used (all treatments >97% germination). However, seed vigor was positively affected by some of the biocontrol coatings. Whey protein isolate and CN8 bacteriophage seed coatings increased seed vigor over seeds without a coating. We speculate that this increase in vigor might be associated with a seed priming effect from the coatings. Seed priming is the controlled hydration of the seed to begin metabolic activities associated with germination, followed by dehydration77. Seed coatings used in these experiments are water-soluble and are applied onto the seed with small amounts of water. The water may rehydrate the seed, which is later dehydrated for storage. Other authors have reported improved seed vigor in seeds coated with polyethylene glycol, fish protein hydrolysates, Trichoderma harzianum, and water in seed priming78,79,80. These biocontrol coatings may not only provide disease management, but might also provide a positive effect on seed vigor.

Conclusion

In conclusion, incorporating CN8 bacteriophages into polymer-based coatings in maize seeds significantly increased the stability of bacteriophages to dry storage without affecting the seed. While the focus of this study was on biological control of a plant pathogen with a seed coating, our unique findings on the influence of Tg, hydrophilic functional groups, stabilizers, and temperature on bacteriophages stability can be applicable to a wide range of biocontrol coatings on other surfaces. Future studies should investigate the use of bacteriophage coatings in the greenhouse, the compatibility of multiple bacteriophages in a single coating to control a wide range of diseases, and the use of bacteriophage coatings on other species. This understanding may allow us to prevent or treat a wide range of bacterial contaminations and diseases in agriculture.

Materials and Methods

Bacteria isolation and seed preparation

Bacteria and bacteriophages preparation and storage

Clavibacter michiganensis subsp. nebraskensis (Cmn-91R) was isolated from a maize field in Ames, Iowa, while CN8 bacteriophages were bought from the Félix d’Hérelle Reference Center for bacterial viruses of the Université Laval, Canada. CN8 bacteriophages were received as a glycerol stock containing 5.3 × 106 PFU/mL. Bacteria were routinely cultured for 72 h in Nutrient Broth Yeast Extract (NBY) medium81 at 26 °C with shaking at 350 rpm (speed on incubating mini shaker to provide proper mixing) or on NBY agar82. In disease control experiments NBY base medium was supplemented with antifungal and antibiotic components (sCNS: potassium dichromate 0.02 g/L, thiabendazole 0.025 g/L, naladixic acid 4 mL/L, and cycloheximide 1 mL/L) to inhibit unwanted growth on the plate43.

CN8 bacteriophages were propagated on Cmn double agar overlays83. Briefly, 200 μl of CN8 bacteriophages in lambda buffer (5.8 g NaCl, 2.0 g MgSO4·7 H2O, 50 mL 1 M Tris-HCl pH 7.4, 0.1 g gelatin in 1 liter dH2O) were spread on NBY overlays (bottom layer: 1.5% agar, top layer: 0.5% agar) with 100 μl of Cmn (5.0 × 107 colony forming units/mL) (CFU/mL) in the top layer and incubated for 72 h at 26 °C. After incubation, 5 mL of lambda buffer were added, the top layer and liquid removed, and centrifuged. The supernatant was filtered through a 0.2 μm cellulose membrane and the bacteriophage titer was determined using a spot assay with appropriate dilutions83. Bacteria and bacteriophages were stored at 4 °C.

Maize seed sterilization

A Goss’s wilt susceptible maize hybrid (Variety: H001872, Brand: 34C17, Lot: 1T34MA-3 MF) was purchased from Blue River Hybrids (Ames, Iowa). Maize seeds were surface sterilized, or surface and internally sterilized84 for all but germination and vigor testing. For surface sterilization, they were immersed in 50% ethanol for 5 min followed by 1% (w/w) NaOCl for 10 min. For surface and internal sterilization, seeds were immersed in 1% (w/w) NaOCl for 10 min, rinsed with sterile deionized water, and then soaked in sterile water at ambient temperature for 4–5 h followed by sterile water at 60 °C for 5 min. All sterilized seeds were rinsed with sterile water, transferred to sterile petri dishes and allowed to air dry overnight in a laminar flow hood.

Seed contamination

Surface and internally sterilized seeds were contaminated with Cmn (5.0 × 107 CFU/mL) in NYB medium via vacuum-infiltration (internal contamination)43 or immersion (external contamination). For vacuum-infiltration, seeds were immersed in a 5-day-old culture of Cmn with one drop of Tween 20 under vacuum for 5 min. Contaminated seeds were surface sterilized in 1% (w/w) NaOCl for 10 min, rinsed with sterile water and left to dry in laminar flow hood overnight. For external contamination, seeds were soaked in a 5-day-old culture of Cmn at ambient temperature for 15 min on a shaker at 250 rpm. Seeds were air dried overnight prior to use.

The concentration of Cmn was determined by extracting the bacteria from the seeds. For internal contamination, 10 seeds were ground in a coffee grinder (KitchenAid Model: BCG111OB), followed by 2 min of vortexing in 10 mL of lambda buffer, and left to sit at ambient temperature for 1 h. For external contamination, the whole seeds were vortexed for 2 min in 10 mL of lambda buffer followed by 1 h rest. Concentrations were determined on sCNS agar.

Seed aging for germination inhibition

Seeds were aged using Accelerated Aging (AA) in accordance with the Assiociation of Official Seed Analysts (AOSA) Seed Vigor Testing Handbook85 to prevent germination of seeds on overlays. In short, a single layer of surface sterilized maize seeds was spread on an elevated screen, placed in an acrylic AA box containing 40 mL of water, and sealed with a tight lid. The boxes were placed into an AA chamber at 43 °C and 100% relative humidity for 96 h. Aged seeds were immersed in water at 65 °C for 10 min before sterilization and drying.

Polymeric seed coating formulations

Coating formulations contained: Polyvinylpyrrolidone (PVP, 58,000 g/mol), polyvinylalcohol (PVOH, low molecular weight), or poly(methyl vinyl ether) (PMVE, 30% solution in water), or Secompla 67c, FloRite 1706, FloRite 1127, and FloRite 1197 from BASF (Ames, IA). Polymers were dissolved in deionized water (10% w/v) and stored at ambient temperature before use. Polyvinylalcohol required heating at 80 °C for 20 min to dissolve. Seed coating formulations contained 3.5% (w/v) or 3.5% (v/v) polymer, 5.0 × 107 to 5.3 × 108 plaque forming units/mL (PFU/mL) CN8 bacteriophages in water (94.5%) and 2% (w/v) stabilizers or 2% water, as appropriate. Stabilizers included whey protein isolate (WPI), skim milk, sucrose, maltodextrin, and D-mannitol. Coating solutions were prepared fresh before use.

CN8 bacteriophages in polymeric seed coating formulation

The polymeric seed coating formulations described in the prior section (polymeric seed coating formulations) were tested for CN8 bacteriophage survival and activity in four separate experiments (dry polymer films, on seed storage stability, germination and vigor, and disease control). Each experiment was replicated three times, with the exception of germination, which was replicated two times before the next experiment was under taken.

Dry polymer films

CN8 bacteriophages in the seed coating formulations were dried into films and their activity was assessed by spot testing the dissolved films. In detail, 10 µl of seed coating formulation with 5.0 × 107 to 5.3 × 108 PFU/mL CN8 bacteriophages were added to 48 well plates and dried for 20–24 h in a laminar flow hood. Dry films were dissolved in 2 mL of lambda buffer and shaken at 300 rpm at ambient temperature for 4 h. CN8 bacteriophage titer was determined using a spot assay with appropriate dilutions.

Dry coatings on maize seeds

Sterilized maize seeds were coated with CN8 bacteriophages by immersion and dried in a laminar flow hood. In detail, 105 maize seeds were covered with 40 mL of coating formulation. After 15 min, seeds were removed, placed in sterile petri dishes, and dried for 20–24 h in a laminar flow hood. CN8 bacteriophage titer was determined using a spot assay with appropriate dilutions after dissolving the coatings. Three replications of ten seeds each were vortexed in 10 mL lambda buffer for 2 min, followed by standing at ambient temperature for 30 min. Vortexing CN8 bacteriophages (5.20 × 107 PFU/mL) for 2 min in lambda buffer showed no change in concentration.

Coated seeds were placed embryo-side up on NBY overlays containing Cmn and incubated at 26 °C for 72 h, in order to test the infectivity of CN8 bacteriophages directly in the bioactive coating.

Storage stability of dry CN8 bacteriophage coatings on maize seeds

Coated seeds were stored at three temperatures and low humidity for up to 7 months. In detail, 100 coated and dried seeds were stored at 4 °C, 10 °C, and 26 °C with relative humidities of 23%, 23.2%, and 22.5%, respectively. Relative humidity levels were achieved with potassium acetate solutions of different concentrations86. The number of remaining active CN8 bacteriophages was determined every four weeks by dissolving the biocontrol coating in buffer and determining the concentration of bacteriophages in the solution via appropriate dilution and spot testing. While some bacteriophages remained on the seeds, a consistent number of bacteriophages was removed into solution.

Seed germination and vigor

Germination tests were conducted using the rolled paper towel method87. In short, 50 seeds were placed down the middle of two moist paper towels (Anchor Paper Co., St. Paul, MN) and one moist paper towel was placed on top of the seeds. Paper towels were rolled up and held in place with a rubber band. Two replicates of 50 seeds were used for each coating, placed in their own bucket, and covered with a plastic bag secured with a rubber band. Buckets were randomly placed into modified food service carts (Lincoln Foodservice Products). Germination was performed at 25 °C in the dark, and seedlings were evaluated on day 7 using a standard scale87.

Seedling vigor was determined by separating germinated seeds from the roots and shoots, and drying the roots and shoots at 75 °C for 16–20 h51. Dry seedlings were weighed and the average weight per seedling calculated. Germination and vigor experiments were replicated twice by planting each replication 7 days apart.

Seed Infection

Internally and externally contaminated seeds were treated with PVOH (3.5% (w/v)), WPI (2% (w/v)) and 94.5% CN8 bacteriophages (9.5 × 105 PFU/mL) in water. Contaminated seeds were coated and dried following the same procedure as for the storage experiments. Coated and uncoated seeds were germinated at 25 °C for 7 days inside sterile boxes (6 × 9 inch hinged plastic box) containing two pieces of blotter paper (Anchor Paper Co., St. Paul, MN) moistened with 75 mL of sterile water. Each coating had 60 seeds separated equally into 3 boxes.

After 7 days, 10 seeds were separated from their roots and shoots. Separately, the seeds and roots/shoots were ground up and placed in 10 mL of lambda buffer or virucide solution (a ratio of 33: 70 mL was used. 33–7.5% black tea, and 70–10 mM FeSO4)88, vortexed for 1 min and left to sit for 1 h. One drop of chloroform was used to lyse bacteria before bacteriophage testing. Concentration of bacteria and bacteriophages were determined using spot tests on NYB sCNS agar and overlays, respectively. Roots, shoots and seeds were also directly placed on overlays to visualize plaque formation.

The seedling’s bacteria concentration was evaluated at 7 days to determine bacteriophage stability and survival, bacteria control, as well as its effect on germination.

Statistical methods

Analysis of variance and T-tests for germination and vigor testing were conducted using SAS PROC GLM (SAS Institute Inc., 2012) to analyze seed treatment effects. Two-sample T-tests were conducted to compare treated versus untreated samples in disease control experiments, and polymer film drying using SAS PROC GLM. Equal variance was determined using Hartley’s F-max test, thus a pooled variance was used. Data was log transformed for disease control and polymer film t-tests and transformed back for presentation. Statistical analysis of storage stability studies was done using SAS PROC GLM.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

US Food and Drug Administration. Judicious Use of Antimicrobials (2018).

Gerhardson, B. Biological substitutes for pesticides. Trends Biotechnol. 20, 338–343 (2002).

Haas, D. & Défago, G. Biological control of soil-borne pathogens by fluorescent pseudomonads. Nat. Rev. Microbiol. 3, 307–319 (2005).

Ryan, R. P., Germaine, K., Franks, A., Ryan, D. J. & Dowling, D. N. Bacterial endophytes: Recent developments and applications. FEMS Microbiol. Lett. 278, 1–9 (2008).

Verschuere, L., Rombaut, G., Sorgeloos, P. & Verstraete, W. Probiotic Bacteria as Biological Control Agents in. Aquaculture. 64, 655–671 (2000).

Weller, D. Biological Control of Soilborne Plant Pathogens in the Rhizosphere with Bacteria. Ann. Rev. Phytopathol. 26, 379–407 (1988).

Abriouel, H., Franz, C. M. A. P., Omar, N. B. & Galvez, A. Diversity and applications of Bacillus bacteriocins. FEMS Microbiol. Rev. 35, 201–232 (2011).

Defoirdt, T., Sorgeloos, P. & Bossier, P. Alternatives to antibiotics for the control of bacterial disease in aquaculture. Curr. Opin. Microbiol. 14, 251–258 (2011).

Montesinos, E. Antimicrobial peptides and plant disease control. FEMS Microbiol. Lett. 270, 1–11 (2007).

Álvarez, B. & Biosca, E. G. Bacteriophage-Based Bacterial Wilt Biocontrol for an Environmentally Sustainable Agriculture. Front. Plant Sci. 8, 1–7 (2017).

Chan, B. K., Abedon, S. T. & Loc-Carrillo, C. Phage cocktails and the future of phage therapy. Future Microbiol. 8, 769–783 (2013).

Cooper, I. R. A review of current methods using bacteriophages in live animals, food and animal products intended for human consumption. J. Microbiol. Methods 130, 38–47 (2016).

Greer, G. G. Bacteriophage Control of Foodborne Bacteria. J. Food Prot. 68, 1102–1111 (2005).

Beales, N. Adaptation of Microorganisms to Cold Temperatures, Weak Acid Preservatives, Low pH, and Osmotic Stress: A Review. Compr. Rev. Food Sci. Food Saf. 3, 1–20 (2004).

De Angelis, M. & Gobbetti, M. Environmental stress responses in Lactobacillus: A review. Proteomics 4, 106–122 (2004).

Somero, G. N. Proteins and Temperature. Annu. Rev. Physiol. 43–68, https://doi.org/10.1146/annurev.ph.57.030195.000355 (1995).

Anal, A. K. & Singh, H. Recent advances in microencapsulation of probiotics for industrial applications and targeted delivery. Trends Food Sci. Technol. 18, 240–251 (2007).

de Vos, P., Faas, M. M., Spasojevic, M. & Sikkemaa, J. Encapsulation for preservation of functionality and targeted delivery of bioactive food component. Int. Dairy J. 292–302, https://doi.org/10.1016/j.idairyj.2009.11.008 (2010).

Malik, D. J. et al. Formulation, stabilisation and encapsulation of bacteriophage for phage therapy. Adv. Colloid Interface Sci. 249, 100–133 (2017).

Curtin, J. J. & Donlan, R. M. Using bacteriophages to reduce formation of catheter-associated biofilms by Staphylococcus epidermidis. Antimicrob. Agents Chemother. 50, 1268–1275 (2006).

Shukla, A. et al. Controlling the release of peptide antimicrobial agents from surfaces. Biomaterials 31, 2348–2357 (2010).

Campoccia, D., Montanaro, L. & Arciola, C. R. A review of the biomaterials technologies for infection-resistant surfaces. Biomaterials 34, 8533–8554 (2013).

Cui, H., Yuan, L. & Lin, L. Novel chitosan film embedded with liposome-encapsulated phage for biocontrol of Escherichia coli O157:H7 in beef. Carbohydr. Polym. 177, 156–164 (2017).

Lumsden, R. D., Lewis, J. A. & Fravel, D. R. Formulation and delivery of biocontrol agents for use against soilborne plant pathogens. Biorational Pest Control Agents Formul. Deliv. 595, 166–182 (1995).

Fravel, D. R. Commercialization and Implementation of Biocontrol. Annu. Rev. Phytopathol. 43, 337–359 (2005).

Sharma, K. K., Singh, U. S., Sharma, P., Kumar, A. & Sharma, L. Seed treatments for sustainable agriculture-A review. J. Appl. Nat. Sci. 7, 521–539 (2015).

Taylor, A. G. & Harman, G. E. Concepts and Technologies of Selected Seed Treatments. Annu. Rev. Phytopathol. 28, 321–339 (1990).

Thomas, R. A Bacteriophage in Relation to Stewart’s Disease of Corn. 371–372 (1934).

Adachi, N., Tsukamoto, S., Inoue, Y. & Azegami, K. Control of Bacterial Seedling Rot and Seedling Blight of Rice by Bacteriophage. Plant Dis. 96, 1033–1036 (2012).

Basit, H. A., Angle, J. S., Salem, S. & Gewaily, E. M. Phage coating of soybean seed reduces nodulation by indigenous soil bradyrhizobia. Can. J. Microbiol. 38, 1264–1269 (1992).

Arya, S. K. et al. Chemically immobilized T4-bacteriophage for specific Escherichia coli detection using surface plasmon resonance. Analyst 136, 486–492 (2011).

Handaa, H., Gurczynskib, S., Jackson, M., Aunerc, G. & Maoa, G. Recognition of Salmonella Typhimurium by Immobilized Phage P22 Monolayers. 602, 1392–1400 (2009).

Anany, H. et al. Print to detect: a rapid and ultrasensitive phage-based dipstick assay for foodborne pathogens. Anal. Bioanal. Chem. 410, 1217–1230 (2018).

Lone, A. et al. Development of prototypes of bioactive packaging materials based on immobilized bacteriophages for control of growth of bacterial pathogens in foods. Int. J. Food Microbiol. 217, 49–58 (2016).

Iriarte, F. B. et al. Factors affecting survival of bacteriophage on tomato leaf surfaces. Appl. Environ. Microbiol. 73, 1704–1711 (2007).

Kim, S., Jo, A. & Ahn, J. Application of chitosan-alginate microspheres for the sustained release of bacteriophage in simulated gastrointestinal conditions. Int. J. Food Sci. Technol. 50, 913–918 (2015).

Ma, Y. et al. Enhanced alginate microspheres as means of oral delivery of bacteriophage for reducing staphylococcus aureus intestinal carriage. Food Hydrocoll. 26, 434–440 (2012).

Vonasek, E., Le, P. & Nitin, N. Encapsulation of bacteriophages in whey protein films for extended storage and release. Food Hydrocoll. 37, 7–13 (2014).

Agarwal, R. et al. Inhaled bacteriophage-loaded polymeric microparticles ameliorate acute lung infections. Nat. Biomed. Eng. 2, 841–849 (2018).

Willenborg, C. J., May, W. E., Gulden, R. H., Lafond, G. P. & Shirtliffe, S. J. Influence of wild oat (Avena fatua) relative time of emergence and density on cultivated oat yield, wild oat seed production, and wild oat contamination. Weed Sci. 53, 342–352 (2005).

Christian, E. J. & Goggi, A. S. Aromatic plant oils as fungicide for organic corn production. Crop Sci. 48, 1941–1951 (2008).

Mbofung, G. C. Y., Goggi, A. S., Leandro, L. F. S. & Mullen, R. E. Effects of Storage Temperature and Relative Humidity on Viability and Vigor of Treated Soybean Seeds. Crop Sci. 53, 1086 (2013).

Taylor, A. G. & Salanenka, Y. A. Seed treatments: Phytotoxicity amelioration and tracer uptake. Seed Sci. Res. 22, 86–90 (2012).

Biddle, J. A., McGee, D. C. & Braun, E. J. Seed transmission of Clavibacter michiganese subsp. nebraskense in corn. Plant Disease 74, 908–911 (1990).

Langemeier, C. B., Robertson, A. E., Wang, D., Jackson-Ziems, T. A. & Kruger, G. R. Factors Affecting the Development and Severity of Goss’s Bacterial Wilt and Leaf Blight of Corn, Caused by Clavibacter michiganensis subsp. nebraskensis. Plant Dis. 101, PDIS-01-15-0038-RE (2016).

Block, C. C., Shepherd, L. M., Mbofung-Curtis, G. C., Sernett, J. M. & Robertson, A. E. Re-evaluation of Seed Transmission of Clavibacter michiganensis subsp. nebraskensis in Zea mays. Plant Dis. 50011, PDIS-02-18-0292 (2018).

Meyer, A., Greene, M., Kimmelshue, C. & Cademartiri, R. Stabilization of T4 bacteriophage at acidic and basic pH by adsorption on paper. Colloids Surfaces B Biointerfaces 160, 169–176 (2017).

Le, T. S., Southgate, P. C., O’Connor, W., Poole, S. & Kurtbӧke, D. I. Bacteriophages as Biological Control Agents of Enteric Bacteria Contaminating Edible Oysters. Curr. Microbiol. 75, 611–619 (2018).

Harrington, J. F. & Kozlowski, T. T. Seed Biology. Seed Storage and longevity (1972).

Harrington, J. F. Drying, storing, and packaging seeds to maintain germination and vigor. Proc. Miss. Short Course for Seedsmen 89–107 (1959).

AOSA. Seed vigor testing handbook. (Association of Official Seed Analysts, 1983).

Schuck, P. et al. Water activity and glass transition in dairy ingredients. EDP Sci. 85, 295–304 (2005).

Imamura, K., Ogawa, T., Sakiyama, T. & Nakanishi, K. Effects of types of sugar on the stabilization of protein in the dried state. J. Pharm. Sci. 92, 266–274 (2003).

Avaltroni, F., Bouquerand, P. E. & Normand, V. Maltodextrin molecular weight distribution influence on the glass transition temperature and viscosity in aqueous solutions. Carbohydr. Polym. 58, 323–334 (2004).

Clark, W. A., Horneland, W. & Klein, G. Attempts to freeze some bacteriophages to ultralow temperatures. Appl. Microbiol. 10, 463–5 (1962).

Merabishvili, M. et al. Stability of Staphylococcus aureus Phage ISP after Freeze-Drying (Lyophilization). PLoS One 8, 1–7 (2013).

Allison, S. D., Chang, B., Randolph, T. W. & Carpenter, J. F. Hydrogen bonding between sugar and protein is responsible for inhibition of dehydration-induced protein unfolding. Arch. Biochem. Biophys. 365, 289–298 (1999).

Dien, B. S., Johnston, D. B., Hicks, K. B., Cotta, M. A. & Singh, V. Hydrolysis and fermentation of pericarp and endosperm fibers recovered from enzymatic corn dry-grind process. Cereal Chem. 82, 616–620 (2005).

Shirako, Y., Vidaver, A. K. & Ackerman, H. W. Partial characterization of bacteriophages for Clavibacter michiganense subsp. nebraskense. Ann. Phytopathol. Soc. Japan 52, 793–800 (1986).

Laval, U. of. Felix d’Herelle Reference Center for Bacterial Viruses. Available at, https://www.phage.ulaval.ca/?pageDemandee=phage&noPhage=88&id=41&L=1, (Accessed: 29th March 2018) (2006).

Tarighi, J., Mahmoudi, A. & Alavi, N. Some mechanical and physical properties of corn seed. African J. Agric. Res. 6, 3691–3699 (2011).

Johnson, H. R., Hooker, J. M., Francis, M. B. & Clark, D. S. Solubilization and Stabilization of Bacteriophage MS2 in Organic Solvents. Biotechnol. Bioeng. 97, 224–234 (2007).

Puapermpoonsiri, U., Ford, S. J. & van der Walle, C. F. Stabilization of bacteriophage during freeze drying. Int. J. Pharm. 389, 168–175 (2010).

Janjarasskul, T. & Krochta, J. M. Edible Packaging Materials. Annu. Rev. Food Sci. Technol. 1, 415–448 (2010).

Huang, K. & Nitin, N. Edible bacteriophage based antimicrobial coating on fish feed for enhanced treatment of bacterial infections in aquaculture industry. Aquaculture 502, 18–25 (2019).

Vonasek, E. L., Choi, A. H., Sanchez, J. & Nitin, N. Incorporating Phage Therapy into WPI Dip Coatings for Applications on Fresh Whole and Cut Fruit and Vegetable Surfaces. J. Food Sci. 83, 1871–1879 (2018).

Koo, C. K. W., Senecal, K., Senecal, A. & Nugen, S. R. Dehydration of bacteriophages in electrospun nanofibers: Effect of excipients in polymeric solutions. Nanotechnology 27 (2016).

Dai, M., Senecal, A. & Nugen, S. R. Electrospun water-soluble polymer nanofibers for the dehydration and storage of sensitive reagents. Nanotechnology 25 (2014).

Jończyk, E., Kłak, M., Międzybrodzki, R. & Górski, A. The influence of external factors on bacteriophages-review. Folia Microbiol. (Praha). 56, 191–200 (2011).

Gonzalez-Menendez, E. et al. Comparative analysis of different preservation techniques for the storage of Staphylococcus phages aimed for the industrial development of phage-based antimicrobial products. PLoS One 13, 1–14 (2018).

Ly-Chatain, M. H. The factors affecting effectiveness of treatment in phages therapy. Front. Microbiol. 5, 1–7 (2014).

Maude, R. B. Seedborne disease and their control: principles and practice. (CAB International, 1996).

Neergaard, P. Seed pathology. 1, (The Macmillan Press LTD, 1977).

Harman, G. E. Improved Seedling Performance by Integration of Biological Control Agents at Favorable pH Levels with Solid Matrix Priming. Phytopathology 78, 520–525 (1988).

Jegathambigai, V., Wijeratnam, R. S. W. & Wijesundera, R. Trichoderma as a Seed Treatment to Control Helminthosporium Leaf Spot Disease of Chrysalidocarpus lutescens. World J. Agric. Sci. 5, 720–728 (2009).

Accinelli, C. et al. A liquid bioplastic formulation for film coating of agronomic seeds. Crop Prot. 89, 123–128 (2016).

Nawaz, J. et al. Seed Priming A Technique. Int. J. Agric. Crop Sci. 6, 1373–1381 (2013).

Devi, T., Shivasankari, M. K. & Maina, C. C. Efficacy of Seed Bio-Priming in Enhancing Seedling Vigour of Cucumber (Cucumis sativus L.) under Biotic Stress Conditions. 47, 107–111 (2013).

Horii, A., McCue, P. & Shetty, K. Enhancement of seed vigour following insecticide and phenolic elicitor treatment. Bioresour. Technol. 98, 623–632 (2007).

Salah, S. M. et al. Seed priming with polyethylene glycol regulating the physiological and molecular mechanism in rice (Oryza sativa L.) under nano-ZnO stress. Sci. Rep. 5, 1–14 (2015).

Gross, D. C. & Vidaver, A. K. Bacteriocins of phytopathogenic Corynebacterium species. Can. J. Microbiol. 25, 367–74 (1979).

Sieuwerts, S., De Bok, F. A. M., Mols, E., De Vos, W. M. & Van Hylckama Vlieg, J. E. T. A simple and fast method for determining colony forming units. Lett. Appl. Microbiol. 47, 275–278 (2008).

Kropinski, A., Mazzocco, A., Waddell, T., Lingohr, E. & Johnson, R. Bacteriophages, Methods and Protocols. (Springer, 2009).

Daniels, B. A. Elimination of Fusarium moniliforme from Corn Seed. Plant Dis. 67, 609 (1983).

AOSA. Seed Vigor Testing Handbook. (Association of Official Seed Analysts, 2009).

Greenspan, L. Humidity fixed points of binary saturated aqueous solutions. J. Res. Natl. Bur. Stand. Sect. A Phys. Chem. 81A, 89 (1977).

AOSA. AOSA Rules for Testing Seeds. (Association of Official Seed Analysts, 2017).

Liu, H. et al. Inactivation of Escherichia coli O157 Bacteriophages by Using a Mixture of Ferrous Sulfate and Tea Extract. J. Food Prot. 78, 2220–2226 (2015).

Brandrup, J., Immergut, E. H. & Grulke, E. A. Polymer Handbook (2003).

Yu, L., Mishra, D. S. & Rigsbee, D. R. Determination of the glass properties of D-mannitol using sorbitol as an impurity. J. Pharm. Sci. 87, 774–777 (1998).

Acknowledgements

We would like to thank the Leopold Center for Sustainable Agriculture and the Seed Science Center endowed assistantships for funding this research project (Grant #E2016-02) and the staff of the Iowa State Seed Testing Laboratory for their assisting in the germination testing. We would also like to thank Dr. Alison E. Robertson, Iowa State University Plant Pathology, for supplying the bacterial strain (Cmn 91-R). We would also like to thank Alexandra Wittstock, Emily Matts, Jamie Pryhuber, and Kara-Lyn Moran for helping in the laboratory to collect data. The authors declare no conflict of interest.

Author information

Authors and Affiliations

Contributions

Chad Kimmelshue conducted and analyzed all experiments, made Figures 1, 3–5, and wrote the main manuscript text. Dr. Cademartiri made Figure 2, consulted on the design of experiments and helped write and edit the main manuscript text. Dr. Goggi consulted on Figures 3–5, helped design and analyze seed-based experiments, and helped write and edit the main manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kimmelshue, C., Goggi, A.S. & Cademartiri, R. The use of biological seed coatings based on bacteriophages and polymers against Clavibacter michiganensis subsp. nebraskensis in maize seeds. Sci Rep 9, 17950 (2019). https://doi.org/10.1038/s41598-019-54068-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-54068-3

This article is cited by

-

The effect of the lignin isolation method from oil palm empty fruit bunch black liquor for seed coating material

Biomass Conversion and Biorefinery (2023)

-

Delivery of Beneficial Microbes via Seed Coating for Medicinal and Aromatic Plant Production: A Critical Review

Journal of Plant Growth Regulation (2023)

-

Recent Advances in Seed Coating Treatment Using Nanoparticles and Nanofibers for Enhanced Seed Germination and Protection

Journal of Plant Growth Regulation (2023)

-

Multifunctional silk fibroin/PVA bio-nanocomposite films containing TEMPO-oxidized bacterial cellulose nanofibers and silver nanoparticles

Cellulose (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.