Abstract

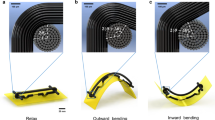

Mono-dimensional fiber-based electronics can effectively address the growing demand for improved wearable electronic devices because of their exceptional flexibility and stretchability. For practical applications, functional fiber electronic devices need to be integrated into more powerful and versatile systems to execute complex tasks that cannot be completed by single-fiber devices. Existing techniques, such as printing and sintering, reduce the flexibility and cause low connection strength of fiber-based electronic devices because of the high curvature of the fiber. Here, we outline a twisting fabrication process for fiber electrodes, which can be woven into functional threads and integrated within textiles. The design of the twisted thread structure for fiber devices ensures stable interfacing and good flexibility, while the textile structure features easily accessible, interlaced points for efficient circuit connections. Electronic textiles can be customized to act as displays, health monitors and power sources. We detail three main fabrication sections, including the fabrication of the fiber electrodes, their twisting into electronic threads and their assembly into functional textile-based devices. The procedures require ~10 d and are easily reproducible by researchers with expertise in fabricating energy and electronic devices.

Key points

-

We provide a fabrication process to twist fiber electrodes into electronic threads that can be woven into large-scale electronic textiles. Electronic textiles can then be used for functions such as energy harvesting, energy storage, displays and other customizable functions desirable for wearable devices.

-

The twisting process facilitates the flexibility, stretchability, connectivity and breathability of the textile with threads that can incorporate fibers of varying sizes and properties.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the findings of this study are available from figshare at https://figshare.com/articles/dataset/Source_data_Textile_system_zip/24511552 and the supporting primary research papers20,36,37,43. The source data of supporting primary research refs. 20,43 are available at https://figshare.com/articles/online_resource/Source_data_FLIBs/14775900 and https://figshare.com/articles/dataset/Source_data_Display_textile_rar/13573205, respectively. The source data of supporting primary research refs. 36,37 are available for research purposes from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Lee, T. H. The (pre-) history of the integrated circuit: a random walk. IEEE J. Solid-State Circuits 12, 16–22 (2007).

Beerten, K. & Vanhavere, F. The use of a portable electronic device in accident dosimetry. Radiat. Prot. Dosim. 131, 509–512 (2008).

Li, C. et al. Design, reliability, and validity of a portable electronic device based on ergonomics for early screening of adolescent scoliosis. J. Orthop. Transl. 28, 83–89 (2021).

Liang, Y. et al. A review of rechargeable batteries for portable electronic devices. InfoMat 1, 6–32 (2019).

Chen, C. et al. Functional fiber materials to smart fiber devices. Chem. Rev. 123, 613–662 (2023).

Xu, X., Xie, S., Zhang, Y. & Peng, H. The rise of fiber electronics. Angew. Chem. Int. Ed. Engl. 58, 13643–13653 (2019).

Luo, Y. et al. Technology roadmap for flexible sensors. ACS Nano 17, 5211–5295 (2023).

Chen, J. et al. Recent progress in essential functions of soft electronic skin. Adv. Funct. Mater. 31, 2104686 (2021).

Someya, T. & Amagai, M. Toward a new generation of smart skins. Nat. Biotechnol. 37, 382–388 (2019).

Sun, H., Zhang, Y., Zhang, J., Sun, X. & Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2, 17023 (2017).

Wang, L. et al. Application challenges in fiber and textile electronics. Adv. Mater. 32, e1901971 (2020).

Peng, H. Fiber electronics. Adv. Mater. 32, e1904697 (2020).

Yang, A. et al. Fabric organic electrochemical transistors for biosensors. Adv. Mater. 30, e1800051 (2018).

Luo, Y. et al. Learning human–environment interactions using conformal tactile textiles. Nat. Electron. 4, 193–201 (2021).

Libanori, A., Chen, G., Zhao, X., Zhou, Y. & Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 5, 142–156 (2022).

Lin, Z. et al. Large-scale and washable smart textiles based on triboelectric nanogenerator arrays for self-powered sleeping monitoring. Adv. Funct. Mater. 28, 1704112 (2018).

Chai, Z. et al. Tailorable and wearable textile devices for solar energy harvesting and simultaneous storage. ACS Nano 10, 9201–9207 (2016).

Xu, L. et al. A perovskite solar cell textile that works at −40 to 160 °C. J. Mater. Chem. A Mater. 8, 5476–5483 (2020).

Kang, X. et al. Hierarchically assembled counter electrode for fiber solar cell showing record power conversion efficiency. Adv. Funct. Mater. 32, 2207763 (2022).

He, J. et al. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 597, 57–63 (2021).

Liao, M. et al. Industrial scale production of fibre batteries by a solution-extrusion method. Nat. Nanotechnol. 17, 372–377 (2022).

Liao, M., Ye, L., Zhang, Y., Chen, T. & Peng, H. The recent advance in fiber-shaped energy storage devices. Adv. Electron. Mater. 5, 1800456 (2019).

Lin, H. et al. Twisted aligned carbon nanotube/silicon composite fiber anode for flexible wire-shaped lithium-ion battery. Adv. Mater. 26, 1217–1222 (2014).

Rein, M. et al. Diode fibres for fabric-based optical communications. Nature 560, 214–218 (2018).

Jamali, V. et al. Perovskite-carbon nanotube light-emitting fibers. Nano Lett. 20, 3178–3184 (2020).

Dias, T. & Monaragala, R. Development and analysis of novel electroluminescent yarns and fabrics for localized automotive interior illumination. Text. Res. J. 82, 1164–1176 (2012).

Wang, L. et al. Weaving sensing fibers into electrochemical fabric for real-time health monitoring. Adv. Funct. Mater. 28, 1804456 (2018).

Wang, L. et al. A core–sheath sensing yarn-based electrochemical fabric system for powerful sweat capture and stable sensing. Adv. Funct. Mater. 32, 2200922 (2022).

Zhai, H. et al. Twisted graphene fibre based breathable, wettable and washable anti-jamming strain sensor for underwater motion sensing. Chem. Eng. J. 439, 135502 (2022).

Choi, H. W. et al. Smart textile lighting/display system with multifunctional fibre devices for large scale smart home and IoT applications. Nat. Commun. 13, 814 (2022).

Yang, Y. et al. A non-printed integrated-circuit textile for wireless theranostics. Nat. Commun. 12, 4876 (2021).

Zhang, Y. et al. Realizing both high energy and high power densities by twisting three carbon-nanotube-based hybrid fibers. Angew. Chem. Int. Ed. Engl. 54, 11177–11182 (2015).

Chen, X. et al. Electrochromic fiber-shaped supercapacitors. Adv. Mater. 26, 8126–8132 (2014).

Zhang, Z. et al. Weaving efficient polymer solar cell wires into flexible power textiles. Adv. Energy Mater. 4, 1301750 (2014).

Zhou, Y., Wang, C.-H., Lu, W. & Dai, L. Recent advances in fiber-shaped supercapacitors and lithium-ion batteries. Adv. Mater. 32, 1902779 (2020).

Wang, L. et al. Functionalized helical fibre bundles of carbon nanotubes as electrochemical sensors for long-term in vivo monitoring of multiple disease biomarkers. Nat. Biomed. Eng. 4, 159–171 (2020).

Zhang, Z. et al. A colour-tunable, weavable fibre-shaped polymer light-emitting electrochemical cell. Nat. Photon. 9, 233–238 (2015).

Sun, H. et al. Integrating photovoltaic conversion and lithium ion storage into a flexible fiber. J. Mater. Chem. A Mater. 4, 7601–7605 (2016).

Chen, X. et al. A novel “energy fiber” by coaxially integrating dye-sensitized solar cell and electrochemical capacitor. J. Mater. Chem. A Mater. 2, 1897–1902 (2014).

Han, J. et al. Multifunctional coaxial energy fiber toward energy harvesting, storage, and utilization. ACS Nano 15, 1597–1607 (2021).

Pan, Z. et al. All-in-one stretchable coaxial-fiber strain sensor integrated with high-performing supercapacitor. Energy Storage Mater. 25, 124–130 (2020).

Wang, M. et al. Gesture recognition using a bioinspired learning architecture that integrates visual data with somatosensory data from stretchable sensors. Nat. Electron. 3, 563–570 (2020).

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240–245 (2021).

Gao, Z. et al. Flexible self-powered textile formed by bridging photoactive and electrochemically active fiber electrodes. J. Mater. Chem. A Mater. 7, 14447–14454 (2019).

Wu, H. et al. Seamlessly-integrated textile electric circuit enabled by self-connecting interwoven points. Chin. J. Polym. Sci. 40, 1323–1330 (2022).

Liu, P. et al. Polymer solar cell textiles with interlaced cathode and anode fibers. J. Mater. Chem. A Mater. 6, 19947–19953 (2018).

Zhang, Z. et al. Textile display for electronic and brain-interfaced communications. Adv. Mater. 30, e1800323 (2018).

Loke, G. et al. Digital electronics in fibres enable fabric-based machine-learning inference. Nat. Commun. 12, 3317 (2021).

Fan, W. et al. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 6, eaay2840 (2020).

Chen, M. et al. Fabric computing: concepts, opportunities, and challenges. Innovation 3, 100340 (2022).

Mo, F. et al. An overview of fiber-shaped batteries with a focus on multifunctionality, scalability, and technical difficulties. Adv. Mater. 32, e1902151 (2020).

Shi, Q. et al. Advanced functional fiber and smart textile. Adv. Fiber Mater. 1, 3–31 (2019).

Karuppasamy, K. et al. Ionic liquid-based electrolytes for energy storage devices: a brief review on their limits and applications. Polymers 12, 918 (2020).

Wan, F., Zhu, J., Huang, S. & Niu, Z. High-voltage electrolytes for aqueous energy storage devices. Batter. Supercaps 3, 323–330 (2020).

Burtscher, B. et al. Sensing inflammation biomarkers with electrolyte-gated organic electronic transistors. Adv. Healthc. Mater. 10, e2100955 (2021).

Huang, X. et al. Braided fiber current collectors for high-energy-density fiber lithium-ion batteries. Angew. Chem. Int. Ed. Engl. 62, e202303616 (2023).

Ling, S. et al. Densifiable ink extrusion for roll-to-roll fiber lithium-ion batteries with ultra-high linear and volumetric energy densities. Adv. Mater. 35, e2211201 (2023).

Wang, M. et al. Conductance-stable and integrated helical fiber electrodes toward stretchy energy storage and self-powered sensing utilization. Chem. Eng. J. 457, 141164 (2023).

Post, E. R., Orth, M., Russo, P. R. & Gershenfeld, N. E-broidery: design and fabrication of textile-based computing. IBM Syst. J. 39, 840–860 (2000).

de Mulatier, S., Nasreldin, M., Delattre, R., Ramuz, M. & Djenizian, T. Electronic circuits integration in textiles for data processing in wearable technologies. Adv. Mater. Technol. 3, 1700320 (2018).

Fang, S. et al. Thermal field distribution investigation and simulation of silver paste heating fabric by screen printing based on joule heating effect. J. Mater. Sci. Mater. Electron. 32, 27762–27776 (2021).

Zhou, Z. et al. Supersensitive all-fabric pressure sensors using printed textile electrode arrays for human motion monitoring and human-machine interaction. J. Mater. Chem. C. Mater. 6, 13120–13127 (2018).

Fu, X. et al. A fiber-shaped solar cell showing a record power conversion efficiency of 10%. J. Mater. Chem. A Mater. 6, 45–51 (2018).

Zhai, W., Zhu, Z., Sun, X. & Peng, H. Fiber solar cells from high performances towards real applications. Adv. Fiber Mater. 4, 1293–1303 (2022).

Zhong, J. et al. Fiber-based generator for wearable electronics and mobile medication. ACS Nano 8, 6273–6280 (2014).

Xiao, X. et al. An ultrathin rechargeable solid-state zinc ion fiber battery for electronic textiles. Sci. Adv. 7, eabl3742 (2021).

Senthilkumar, S. T., Wang, Y. & Huang, H. Advances and prospects of fiber supercapacitors. J. Mater. Chem. A Mater. 3, 20863–20879 (2015).

Fang, Y. et al. Coaxial fiber organic electrochemical transistor with high transconductance. Nano Res. 16, 11885–11892 (2023).

Zhong, J. et al. Stretchable self-powered fiber-based strain sensor. Adv. Funct. Mater. 25, 1798–1803 (2015).

Hatamvand, M. et al. Recent advances in fiber-shaped and planar-shaped textile solar cells. Nano Energy 71, 104609 (2020).

Qin, Y., Wang, X. & Wang, Z. L. Microfibre-nanowire hybrid structure for energy scavenging. Nature 451, 809–813 (2008).

Yang, Z. et al. One-step wet-spinning assembly of twisting-structured graphene/carbon nanotube fiber supercapacitor. J. Energy Chem. 51, 434–441 (2020).

Liu, Q. et al. Full-temperature all-solid-state Ti3C2Tx/aramid fiber supercapacitor with optimal balance of capacitive performance and flexibility. Adv. Funct. Mater. 31, 2010944 (2021).

Qian, Z. et al. An implantable fiber biosupercapacitor with high power density by multi-strand twisting functionalized fibers. Angew. Chem. Int. Ed. Engl. 62, e202303268 (2023).

Kim, S. J. et al. A new architecture for fibrous organic transistors based on a double-stranded assembly of electrode microfibers for electronic textile applications. Adv. Mater. 31, e1900564 (2019).

Lan, L., Zhao, F., Yao, Y., Ping, J. & Ying, Y. One-step and spontaneous in situ growth of popcorn-like nanostructures on stretchable double-twisted fiber for ultrasensitive textile pressure sensor. ACS Appl. Mater. Interfaces 12, 10689–10696 (2020).

Tang, X., Li, K., Liu, Y., Zhou, D. & Zhao, J. A soft crawling robot driven by single twisted and coiled actuator. Sens. Actuator A Phys. 291, 80–86 (2019).

Lin, X. et al. Industrially weavable metal/cotton yarn air electrodes for highly flexible and stable wire-shaped Li–O2 batteries. J. Mater. Chem. A Mater. 5, 3638–3644 (2017).

Wang, X. et al. Stretchable fiber-shaped lithium metal anode. Energy Storage Mater. 22, 179–184 (2019).

Fang, X. et al. A cable-shaped lithium sulfur battery. Adv. Mater. 28, 491–496 (2016).

Acknowledgements

H.P. acknowledges funding support from the Ministry of Science and Technology of China (2022YFA1203001, 2022YFA1203002), the National Natural Science Foundation of China (T2321003, 22335003) and the Science and Technology Commission of Shanghai Municipality (21511104900, 20JC1414902). X.S. acknowledges funding support from the China Postdoctoral Science Foundation (VLH1717003, KLH1717015). K.Z. acknowledges funding support from the National Natural Science Foundation of China (22105045).

Author information

Authors and Affiliations

Contributions

H.P. conceived and designed the protocol. Kailin Zhang developed the protocol. Kailin Zhang, H.J. and Z.Z. performed the experiments and analyzed the data. P.Z. and L.Z. contributed to the discussion. Kailin Zhang, X.S. and Kaiwen Zeng wrote the manuscript. H.P. edited the manuscript. All authors read, commented on and accepted the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Protocols thanks Esma Ismailova, Luyi Sun and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Related links

Key references using this protocol

He, J. et al. Nature 597, 57–63 (2021): https://doi.org/10.1038/s41586-021-03772-0

Wang, L. et al. Nat. Biomed. Eng. 4, 159–171 (2020): https://doi.org/10.1038/s41551-019-0462-8

Wang, L. et al. Adv. Funct. Mater. 28, 1804456 (2018): https://doi.org/10.1002/adfm.201804456

Shi, X. et al. Nature 591, 240–245 (2021): https://doi.org/10.1038/s41586-021-03295-8

Zhang, Z. et al. Nat. Photon. 9, 233–238 (2015): https://doi.org/10.1038/nphoton.2015.37

Extended data

Extended Data Fig. 1 Stability of interconnections.

a, The resistance change of the interconnections bonded by silver paste or low-temperature solder under different bending angles. b–d, The resistance change of the interconnections under bending at 90° (b), 5 N load friction (c) and π rad/cm twisting (d). Error bars show standard deviations of the results from 10 samples.

Supplementary information

Supplementary Information

Supplementary Figure 1 and caption for Supplementary Video 1

Supplementary Video 1

Operation of the textile system for sweat monitoring

Source data

Source Data Fig. 6

Statistical source data

Source Data Extended Data Fig. 1

Statistical source data

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, K., Shi, X., Jiang, H. et al. Design and fabrication of wearable electronic textiles using twisted fiber-based threads. Nat Protoc (2024). https://doi.org/10.1038/s41596-024-00956-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41596-024-00956-6

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.