Abstract

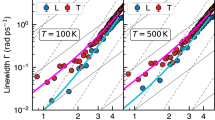

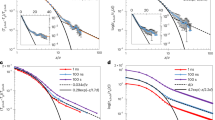

The similarity in atomic/molecular structure between liquids and glasses has stimulated a long-standing hypothesis that the nature of glasses may be more fluid-like, rather than the apparent solid. In principle, the nature of glasses can be characterized by the dynamic response of their rheology in a wide rate range, but this has not been realized experimentally, to the best of our knowledge. Here we report the dynamic response of shear stress to the shear strain rate of metallic glasses over a timescale of nine orders of magnitude, equivalent to hundreds of years, by broadband stress relaxation experiments. The dynamic response of the metallic glasses, together with other ‘glasses’, follows a universal scaling law within the framework of fluid dynamics. The universal scaling law provides comprehensive validation of the conjecture on the jamming (dynamic) phase diagram by which the dynamic behaviours of a wide variety of ‘glasses’ can be unified under one rubric parameterized by the thermodynamic variables of temperature, volume and stress in the trajectory space.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The authors declare that the data supporting the findings of this study are included within the paper and its Supplementary Information file. Source data are provided with this paper.

References

Frost, H. J. & Ashby, M. F. Deformation-Mechanicsm Maps: the Plasticity and Creep of Metals and Ceramics 165 (Pergamon Press, 1982).

Anderson, P. W. Through the glass lightly. Science 267, 1615–1616 (1995).

Langer, J. The mysterious glass transition. Phys. Today 60, 8 (2007).

Ediger, M. D. & Harrowell, P. Perspective: supercooled liquids and glasses. J. Chem. Phys. 137, 080901 (2012).

Wang, W. H. Dynamic relaxations and relaxation-property relationships in metallic glasses. Prog. Mater. Sci. 106, 100561 (2019).

Chang, K. The nature of glass remains anything but clear. The New York Times https://www.nytimes.com/2008/07/29/science/29glass.html (29 July 2008).

Williams, M. L., Landel, R. F. & Ferry, J. D. The temperature dependence of relaxation mechanisms in amorphous polymers and other glass-forming liquids. J. Am. Chem. Soc. 77, 3701–3707 (1955).

Zhu, F. et al. Correlation between local structure order and spatial heterogeneity in a metallic glass. Phys. Rev. Lett. 119, 215501 (2017).

Huang, B. et al. Density fluctuations with fractal order in metallic glasses detected by synchrotron X-ray nano-computed tomography. Acta Mater. 155, 69–79 (2018).

Argon, A. S. Plastic-deformation in metallic glasses. Acta Metall. 27, 47–58 (1979).

Spaepen, F. A microscopic mechanism for steady-state inhomogeneous flow in metallic glasses. Acta Metall. 25, 407–415 (1977).

Johnson, W. L. & Samwer, K. A universal criterion for plastic yielding of metallic glasses with a (T/Tg)2/3 temperature dependence. Phys. Rev. Lett. 95, 195501 (2005).

Chen, M. W. Mechanical behavior of metallic glasses: microscopic understanding of strength and ductility. Ann. Rev. Mater. Res. 38, 445–469 (2008).

Falk, M. L., Langer, J. S. & Pechenik, L. Thermal effects in the shear-transformation-zone theory of amorphous plasticity: comparisons to metallic glass data. Phys. Rev. E 70, 011507 (2004).

Hufnagel, T. C., Schuh, C. A. & Falk, M. L. Deformation of metallic glasses: recent developments in theory, simulations, and experiments. Acta Mater. 109, 375–393 (2016).

Ju, J. D., Jang, D., Nwankpa, A. & Atzmon, M. An atomically quantized hierarchy of shear transformation zones in a metallic glass. J. Appl. Phys. 109, 053522 (2011).

Pan, D., Inoue, A., Sakurai, T. & Chen, M. W. Experimental characterization of shear transformation zones for plastic flow of bulk metallic glasses. Proc. Natl Acad. Sci. USA 105, 14769–14772 (2008).

Puthoff, J. B., Jakes, J. E., Cao, H. & Stone, D. S. Investigation of thermally activated deformation in amorphous PMMA and Zr-Cu-Al bulk metallic glasses with broadband nanoindentation creep. J. Mater. Res. 24, 1279–1290 (2009).

Schuh, C. A., Hufnagel, T. C. & Ramamurty, U. Mechanical behavior of amorphous alloys. Acta Mater. 55, 4067–4109 (2007).

Wang, Z., Sun, B. A., Bai, H. Y. & Wang, W. H. Evolution of hidden localized flow during glass-to-liquid transition in metallic glass. Nat. Commun. 5, 5823 (2014).

Pietanza, L. D., Colonna, G., Longo, S. & Capitelli, M. Electron and phonon relaxation in metal films perturbed by a femtosecond laser pulse. Appl. Phys. A 79, 1047–1050 (2004).

Qiao, J. C. & Pelletier, J. M. Dynamic mechanical analysis in La-based bulk metallic glasses: secondary (β) and main (α) relaxations. J. Appl. Phys. 112, 083528 (2012).

Johnson, W. L., Demetriou, M. D., Harmon, J. S., Lind, M. L. & Samwer, K. Rheology and ultrasonic properties of metallic glass-forming liquids: a potential energy landscape perspective. MRS Bull. 32, 644–650 (2007).

Angell, C. A. Perspective on the glass transition. J. Phys. Chem. Solids 49, 863–871 (1988).

Ngai, K. L. Relaxation and Diffusion in Complex Systems (Springer, 2011).

Perez, J. Homogeneous flow and anelastic/plastic deformation of metallic glasses. Acta Metall. 32, 2163–2173 (1984).

Lu, J., Ravichandran, G. & Johnson, W. L. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 51, 3429–3443 (2003).

Demetriou, M. D. et al. Cooperative shear model for the rheology of glass-forming metallic liquids. Phys. Rev. Lett. 97, 065502 (2006).

Ingebrigtsen, T. S. & Tanaka, H. Structural predictor for nonlinear sheared dynamics in simple glass-forming liquids. Proc. Natl Acad. Sci. USA 115, 87–92 (2018).

Guan, P., Chen, M. & Egami, T. Stress-temperature scaling for steady-state flow in metallic glasses. Phys. Rev. Lett. 104, 205701 (2010).

Park, K.-W., Lee, C.-M., Kim, H.-J., Lee, J.-H. & Lee, J.-C. A methodology of enhancing the plasticity of amorphous alloys: elastostatic compression at room temperature. Mater. Sci. Eng. A 499, 529–533 (2009).

Song, S. X. & Nieh, T. G. Direct measurements of shear band propagation in metallic glasses – an overview. Intermetallics 19, 1968–1977 (2011).

Yoo, B.-G. et al. Increased time-dependent room temperature plasticity in metallic glass nanopillars and its size-dependency. Int. J. Plast. 37, 108–118 (2012).

Brückner, R. & Yue, Y. Non-Newtonian flow behaviour of glass melts as a consequence of viscoelasticity and anisotropic flow. J. Non-Cryst. Solids 175, 118–128 (1994).

Köpplmayr, T. et al. A novel online rheometer for elongational viscosity measurement of polymer melts. Polym. Test. 50, 208–215 (2016).

Malkin, A. Y. Non-Newtonian viscosity in steady-state shear flows. J. Non-Newton. Fluid Mech. 192, 48–65 (2013).

Roland, C. M. in The Science and Technology of Rubber 4th edn (eds Erman, B., Mark, J. E. & Roland, C. M.) Ch. 6 (Academic Press, 2013).

Mackley, M. R. et al. The observation and evaluation of extensional filament deformation and breakup profiles for non Newtonian fluids using a high strain rate double piston apparatus. J. Non-Newton. Fluid Mech. 239, 13–27 (2017).

Olsson, P. & Teitel, S. Critical scaling of shear viscosity at the jamming transition. Phys. Rev. Lett. 99, 178001 (2007).

Jeong, S. W., Locat, J., Leroueil, S. & Malet, J.-P. Rheological properties of fine-grained sediment: the roles of texture and mineralogy. Can. Geotech. J. 47, 1085–1100 (2010).

Tennenbaum, M., Liu, Z., Hu, D. & Fernandez-Nieves, A. Mechanics of fire ant aggregations. Nat. Mater. 15, 54–59 (2016).

Liu, Y. H. et al. Thermodynamic origins of shear band formation and the universal scaling law of metallic glass strength. Phys. Rev. Lett. 103, 065504 (2009).

Bird, R. B., Dai, G. C. & Yarusso, B. J. The rheology and flow of viscoplastic materials. Rev. Chem. Eng. 1, 1–70 (1983).

Doi, M. & Edwards, S. F. Dynamics of concentrated polymer systems. Part 4. Rheological properties. J. Chem. Soc. Faraday Trans. 2 75, 38–54 (1979).

Liu, A. J. & Nagel, S. R. Nonlinear dynamics: jamming is not just cool any more. Nature 396, 21–22 (1998).

Trappe, V., Prasad, V., Cipelletti, L., Segre, P. N. & Weitz, D. A. Jamming phase diagram for attractive particles. Nature 411, 772–775 (2001).

Ciamarra, M. P., Pastore, R., Nicodemi, M. & Coniglio, A. Jamming phase diagram for frictional particles. Phys. Rev. E 84, 041308 (2011).

Makse, H. A., Johnson, D. L. & Schwartz, L. M. Packing of compressible granular materials. Phys. Rev. Lett. 84, 4160–4163 (2000).

Coniglio, A., de Candia, A., Fierro, A., Nicodemi, M. & Tarzia, M. Statistical mechanics approach to the jamming transition in granular materials. Physica A 344, 431–439 (2004).

Jaiswal, A., Egami, T., Kelton, K. F., Schweizer, K. S. & Zhang, Y. Correlation between fragility and the Arrhenius crossover phenomenon in metallic, molecular, and network liquids. Phys. Rev. Lett. 117, 205701 (2016).

Wu, B., Iwashita, T. & Egami, T. Atomic dynamics in simple liquid: de Gennes narrowing revisited. Phys. Rev. Lett. 120, 135502 (2018).

Bi, D., Zhang, J., Chakraborty, B. & Behringer, R. P. Jamming by shear. Nature 480, 355–358 (2011).

Hedges, L. O., Jack, R. L., Garrahan, J. P. & Chandler, D. Dynamic order-disorder in atomistic models of structural glass formers. Science 323, 1309–1313 (2009).

Li, M.-X. et al. High-temperature bulk metallic glasses developed by combinatorial methods. Nature 569, 99–103 (2019).

Lakeland, D. L., Rechenmacher, A. & Ghanem, R. Towards a complete model of soil liquefaction: the importance of fluid flow and grain motion. Proc. R. Soc. A 470, 20130453 (2014).

Liu, Y. H. et al. Deposition of multicomponent metallic glass films by single-target magnetron sputtering. Intermetallics 21, 105–114 (2012).

Yang, R. Q., Fan, J. T., Li, S. X. & Zhang, Z. F. Fracture behavior of Zr55Cu30Al10Ni5 bulk metallic glass under quasi-static and dynamic compression. J. Mater. Res. 23, 1744–1750 (2008).

Oliver, W. C. & Pharr, G. M. An improved technique for determining hardness and elastic-modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992).

Poisl, W. H., Oliver, W. C. & Fabes, B. D. The relationship between indentation and uniaxial creep in amorphous selenium. J. Mater. Res. 10, 2024–2032 (1995).

Weihs, T. P., Hong, S., Bravman, J. C. & Nix, W. D. Mechanical deflection of cantilever microbeams: a new technique for testing the mechanical properties of thin films. J. Mater. Res. 3, 931–942 (1988).

Acknowledgements

S.S. is supported by the National Natural Science Foundation of China (grant no. 51821001) and MOST 973 of China (grant no. 2015CB856800). M.C. is supported by the National Science Foundation (NSF DMR-1804320) with J. Yang as the programme director. F.Z. is sponsored by the Shanghai Pujiang Program under grant no. 21PJ1401800. We also thank the staff from the Shanghai Key Laboratory of Advanced High-Temperature Materials and Precision Forming for assistance during data collection.

Author information

Authors and Affiliations

Contributions

S.S. designed and performed the broadband stress relaxation experiments and data processing; F.Z. prepared the MG samples and conducted the microstructure characterization; and S.S. and M.C. analysed the data, developed the models and wrote the paper. M.C. conceived and supervised the project.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Jean Marc Pelletier and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–8, Tables 1–3 and notes.

Source data

Source Data Fig. 1

Source data for Fig. 1b,c.

Rights and permissions

About this article

Cite this article

Song, S., Zhu, F. & Chen, M. Universal scaling law of glass rheology. Nat. Mater. 21, 404–409 (2022). https://doi.org/10.1038/s41563-021-01185-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01185-y

This article is cited by

-

Strain-driven Kovacs-like memory effect in glasses

Nature Communications (2023)

-

Uncovering the flow of metallic glass

Nature Materials (2022)