Abstract

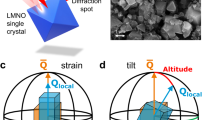

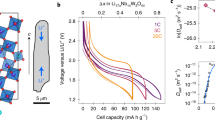

Lithium-ion batteries are yet to realize their full promise because of challenges in the design and construction of electrode architectures that allow for their entire interior volumes to be reversibly accessible for ion storage. Electrodes constructed from the same material and with the same specifications, which differ only in terms of dimensions and geometries of the constituent particles, can show surprising differences in polarization, stress accumulation and capacity fade. Here, using operando synchrotron X-ray diffraction and energy dispersive X-ray diffraction (EDXRD), we probe the mechanistic origins of the remarkable particle geometry-dependent modification of lithiation-induced phase transformations in V2O5 as a model phase-transforming cathode. A pronounced modulation of phase coexistence regimes is observed as a function of particle geometry. Specifically, a metastable phase is stabilized for nanometre-sized spherical V2O5 particles, to circumvent the formation of large misfit strains. Spatially resolved EDXRD measurements demonstrate that particle geometries strongly modify the tortuosity of the porous cathode architecture. Greater ion-transport limitations in electrode architectures comprising micrometre-sized platelets result in considerable lithiation heterogeneities across the thickness of the electrode. These insights establish particle geometry-dependent modification of metastable phase regimes and electrode tortuosity as key design principles for realizing the promise of intercalation cathodes.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information. Source data are provided with this paper. Any other data are available from the corresponding author on reasonable request.

Code availability

All original code scripts have been provided and are freely available.

References

Abakumov, A. M., Fedotov, S. S., Antipov, E. V. & Tarascon, J. M. Solid state chemistry for developing better metal-ion batteries. Nat. Commun. 11, 4976 (2020).

Manthiram, A. A reflection on lithium-ion battery cathode chemistry. Nat. Commun. 11, 1550 (2020).

Xie, J. & Lu, Y. C. A retrospective on lithium-ion batteries. Nat. Commun. 11, 2499 (2020).

Goodenough, J. B. & Park, K. S. The li-ion rechargeable battery: a perspective. J. Am. Chem. Soc. 135, 1167–1176 (2013).

Boebinger, M. G. et al. Spontaneous and reversible hollowing of alloy anode nanocrystals for stable battery cycling. Nat. Nanotechnol. 15, 475–481 (2020).

Mistry, A., Usseglio-Viretta, F. L. E., Colclasure, A., Smith, K. & Mukherjee, P. P. Fingerprinting redox heterogeneity in electrodes during extreme fast charging. J. Electrochem. Soc. 167, 90542 (2020).

Lim, J. et al. Origin and hysteresis of lithium compositional spatiodynamics within battery primary particles. Science 353, 566–571 (2016).

Andrews, J. L. et al. Curvature-induced modification of mechano-electrochemical coupling and nucleation kinetics in a cathode material. Matter 3, 1754–1773 (2020).

Fraggedakis, D. et al. A scaling law to determine phase morphologies during ion intercalation. Energy Environ. Sci. 13, 2142–2152 (2020).

Zheng, H. et al. Quantitative characterization of the surface evolution for LiNi0.5Co0.2Mn0.3O2/graphite cell during long-term cycling. ACS Appl. Mater. Interfaces 9, 12445–12452 (2017).

Bazak, J. D., Allen, J. P., Krachkovskiy, S. A. & Goward, G. R. Mapping of lithium-ion battery electrolyte transport properties and limiting currents with in situ MRI. J. Electrochem. Soc. 167, 140518 (2020).

Siu, C. et al. Enhanced high-rate performance of nanosized single crystal ε-VOPO4 with niobium substitution for lithium-ion batteries. J. Electrochem. Soc. 168, 060519 (2021).

Wong, A. A., Rubinstein, S. M. & Aziz, M. J. Direct visualization of electrochemical reactions and heterogeneous transport within porous electrodes in operando by fluorescence microscopy. Cell Rep. Phys. Sci. 2, 100388 (2021).

Steinrück, H.-G. et al. Concentration and velocity profiles in a polymeric lithium-ion battery electrolyte. Energy Environ. Sci. 13, 4312–4321 (2020).

Zhao, Y. et al. A review on modeling of electro-chemo-mechanics in lithium-ion batteries. J. Power Sources 413, 259–283 (2019).

McDowell, M. T., Cortes, F. J. Q., Thenuwara, A. C. & Lewis, J. A. Toward high-capacity battery anode materials: chemistry and mechanics intertwined. Chem. Mater. 32, 8755–8771 (2020).

Heenan, T. M. M. et al. Identifying the origins of microstructural defects such as cracking within Ni-rich NMC811 cathode particles for lithium-ion batteries. Adv. Energy Mater. 10, 2002655 (2020).

Ferraro, M. E., Trembacki, B. L., Brunini, V. E., Noble, D. R. & Roberts, S. A. Electrode mesoscale as a collection of particles: coupled electrochemical and mechanical analysis of NMC cathodes. J. Electrochem. Soc. 167, 13543 (2020).

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 104, 4271–4301 (2004).

Yu, Y.-S. et al. Three-dimensional localization of nanoscale battery reactions using soft X-ray tomography. Nat. Commun. 9, 921 (2018).

De Jesus, L. R., Andrews, J. L., Parija, A. & Banerjee, S. Defining diffusion pathways in intercalation cathode materials: some lessons from V2O5 on directing cation traffic. ACS Energy Lett. 3, 915–931 (2018).

Santos, D. A. et al. Bending good beats breaking bad: phase separation patterns in individual cathode particles upon lithiation and delithiation. Mater. Horiz. 7, 3275–3290 (2020).

Yao, K. P. C., Okasinski, J. S., Kalaga, K., Almer, J. D. & Abraham, D. P. Operando quantification of (de)lithiation behavior of silicon–graphite blended electrodes for lithium-ion batteries. Adv. Energy Mater. 9, 1803380 (2019).

Yao, K. P. C., Okasinski, J. S., Kalaga, K., Shkrob, I. A. & Abraham, D. P. Quantifying lithium concentration gradients in the graphite electrode of Li-ion cells using operando energy dispersive X-ray diffraction. Energy Environ. Sci. 12, 656–665 (2019).

Bai, Y., Zhao, K., Liu, Y., Stein, P. & Xu, B.-X. A chemo-mechanical grain boundary model and its application to understand the damage of Li-ion battery materials. Scr. Mater. 183, 45–49 (2020).

Luo, Y. et al. Roadblocks in cation diffusion pathways: implications of phase boundaries for Li-ion diffusivity in an intercalation cathode material. ACS Appl. Mater. Interfaces 10, acsami.8b10604 (2018).

Pan, A., Wu, H. Bin., Yu, L., & Lou, X. W. Template-free synthesis of VO2 hollow microspheres with various interiors and their conversion into V2O5 for lithium-ion batteries. Angew. Chem. Int. Ed. Engl. 52, 2226–2230 (2013).

Hu, Y.-S. et al. Synthesis and electrode performance of nanostructured V2O5 by using a carbon tube-in-tube as a nanoreactor and an efficient mixed-conducting network. Angew. Chem. Int. Ed. Engl. 48, 210–214 (2009).

Horrocks, G. A., Likely, M. F., Velazquez, J. M. & Banerjee, S. Finite size effects on the structural progression induced by lithiation of V2O5: a combined diffraction and Raman spectroscopy study. J. Mater. Chem. A 1, 15265–15277 (2013).

Rozier, P. et al. ε-LixV2O5 bronzes (0.33 ≤ x ≤ 0.64) a joint study by X-ray powder diffraction and 6Li, 7Li MAS NMR. Eur. J. Solid State Inorg. Chem. 33, 1–13 (1996).

Murphy, D. W., Christian, P. A., DiSalvo, F. J. & Waszczak, J. V. Lithium incorporation by vanadium pentoxide. Inorg. Chem. 18, 2800–2803 (1979).

Cocciantelli, J. M. et al. On the δ→γ irreversible transformation in Li//V2O5 secondary batteries. Solid State Ion. 78, 143–150 (1995).

Meulenkamp, E. A., Van Klinken, W. & Schlatmann, A. R. In-situ X-ray diffraction of Li intercalation in sol-gel V2O5 films. Solid State Ion. 126, 235–244 (1999).

Li, Y. et al. Fluid-enhanced surface diffusion controls intraparticle phase transformations. Nat. Mater. 17, 915–922 (2018).

De Jesus, L. R. et al. Lithiation across interconnected V2O5 nanoparticle networks. J. Mater. Chem. A 5, 20141–20152 (2017).

Danner, T. et al. Thick electrodes for Li-ion batteries: a model based analysis. J. Power Sources 334, 191–201 (2016).

Mistry, A. N. & Mukherjee, P. P. Probing spatial coupling of resistive modes in porous intercalation electrodes through impedance spectroscopy. Phys. Chem. Chem. Phys. 21, 3805–3813 (2019).

Gao, H. et al. Revealing the rate-limiting Li-ion diffusion pathway in ultrathick electrodes for Li-ion batteries. J. Phys. Chem. Lett. 9, 5100–5104 (2018).

Mistry, A. N., Smith, K. & Mukherjee, P. P. Electrochemistry coupled mesoscale complexations in electrodes lead to thermo-electrochemical extremes. ACS Appl. Mater. Interfaces 10, 28644–28655 (2018).

Pietsch, P., Ebner, M., Marone, F., Stampanoni, M. & Wood, V. Determining the uncertainty in microstructural parameters extracted from tomographic data. Sustain. Energy Fuels 2, 598–605 (2018).

Ebner, M., Chung, D.-W., García, R. E. & Wood, V. Tortuosity anisotropy in lithium-ion battery electrodes. Adv. Energy Mater. 4, 1301278 (2014).

Usseglio-Viretta, F. L. E. et al. Resolving the discrepancy in tortuosity factor estimation for Li-ion battery electrodes through micro-macro modeling and experiment. J. Electrochem. Soc. 165, A3403–A3426 (2018).

Wang, W., Juarez-Robles, D. & Mukherjee, P. P. Electroanalytical quantification of electrolyte transport resistance in porous electrodes. J. Electrochem. Soc. 167, 80510 (2020).

Stoney, G. G. The tension of metallic films deposited by electrolysis. Proc. R. Soc. Lond. A 82, 172–175 (1909).

Nix, W. D. Mechanical properties of thin films. Metall. Trans. A 20, 2217 (1989).

Borkiewicz, O. J. et al. The AMPIX electrochemical cell: a versatile apparatus for in situ X-ray scattering and spectroscopic measurements. J. Appl. Crystallogr. 45, 1261–1269 (2012).

Liu, H. et al. Intergranular cracking as a major cause of long-term capacity fading of layered cathodes. Nano Lett. 17, 3452–3457 (2017).

Horrocks, G. A. ; et al. Vanadium K-edge X-ray absorption spectroscopy as a probe of the heterogeneous lithiation of V2O5: first-principles modeling and principal component analysis. J. Phys. Chem. C 120, 23922–23932 (2016).

Borkiewicz, O. J., Wiaderek, K. M., Chupas, P. J. & Chapman, K. W. Best practices for operando battery experiments: influences of X-ray experiment design on observed electrochemical reactivity. J. Phys. Chem. Lett. 6, 2081–2085 (2015).

Toby, B. H. & Von Dreele, R. B. GSAS-II: the genesis of a modern open-source all purpose crystallography software package. J. Appl. Crystallogr. 46, 544–549 (2013).

Stein, P. & Xu, B. 3D isogeometric analysis of intercalation-induced stresses in Li-ion battery electrode particles. Comput. Methods Appl. Mech. Eng. 268, 225–244 (2014).

Lundgren, H., Behm, M. & Lindbergh, G. Electrochemical characterization and temperature dependency of mass-transport properties of LiPF6 in EC:DEC. J. Electrochem. Soc. 162, A413–A420 (2014).

Mistry, A. N., Smith, K. & Mukherjee, P. P. Secondary-phase stochastics in lithium-ion battery electrodes. ACS Appl. Mater. Interfaces 10, 6317–6326 (2018).

Landesfeind, J., Hattendorff, J., Ehrl, A., Wall, W. A. & Gasteiger, H. A. Tortuosity determination of battery electrodes and separators by impedance spectroscopy. J. Electrochem. Soc. 163, A1373 (2016).

Acknowledgements

This study is based on work supported by the National Science Foundation (NSF) under DMR 1809866. We also gratefully acknowledge support from award no. A-1978-20190330 from the Welch Foundation. B.-X.X. acknowledges the German Science Foundation (DFG) for funding under project number 398072825. M.P. acknowledges support from NSF under DMR 1944674. K.X. acknowledges X-Grants Initiative at Texas A&M University for support of this work. A.M. gratefully acknowledges support from Argonne National Laboratory. P.P.M. acknowledges financial support in part from the National Science Foundation under grant no. 1805656). This research used resources of the Advanced Photon Source of Argonne National Laboratory under contract no. DE-AC02-06CH11357. Argonne National Laboratory is operated for the US Department of Energy Office of Science by UChicago Argonne. We thank A. Yakovenko for his support at Beamline 17-BM of the APS. We also thank J. Okasinski for his help with experiments at 6-BM of APS. Use of the TAMU Materials Characterization Facility and the Texas A&M Microscopy and Imaging Center is acknowledged.

Author information

Authors and Affiliations

Contributions

Y.L., B.-X.X. and S.B. designed the project. Y.L. performed material synthesis, microscopy experiments, operando X-ray diffraction and EDXRD experiments and data analysis. A.M. designed the mesoscale model. B.-X.X., Y.B. and S.R. contributed to the phase-field simulations. Y.Z. performed MOS experiment and data analysis. K.X., Y.Z. and D.Z. conducted FIB-SEM experiment and 3D reconstruction. S.S. performed EIS fitting and calculated tortuosity. J.V.H. helped with operando X-ray diffraction and EDXRD experiments. A.C.C. helped with operando energy dispersive X-ray diffraction data analysis. L.C. performed TEM measurements. K.W. helped with battery assembly. M.P., P.P.M., B.-X.X. and S.B. supervised the whole project. All authors contributed to writing and editing the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Materials thanks Thomas Heenan and Louis Piper for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–18 and Tables 1–10.

Supplementary Video 1

Operando EDXRD data acquired for layers 3–5 with corresponding first discharge/charge profile for bulk V2O5.

Supplementary Video 2

Operando EDXRD data acquired for layers 3–5 with corresponding first discharge/charge profile for NS V2O5.

Supplementary Video 3

3D reconstruction of bulk V2O5 electrode from FIB-SEM images.

Supplementary Video 4

3D reconstruction of NS V2O5 electrode from FIB-SEM images.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Source Data Fig. 3

Statistical source data.

Source Data Fig. 4

Statistical source data.

Source Data Fig. 5

Statistical source data.

Source Data Fig. 6

Statistical source data.

Rights and permissions

About this article

Cite this article

Luo, Y., Bai, Y., Mistry, A. et al. Effect of crystallite geometries on electrochemical performance of porous intercalation electrodes by multiscale operando investigation. Nat. Mater. 21, 217–227 (2022). https://doi.org/10.1038/s41563-021-01151-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-021-01151-8

This article is cited by

-

Effect of pre-intercalation on Li-ion diffusion mapped by topochemical single-crystal transformation and operando investigation

Nature Materials (2024)

-

A bifunctional nitrile additive for high-performance lithiumoxygen batteries

Nano Research (2024)

-

A deep learned nanowire segmentation model using synthetic data augmentation

npj Computational Materials (2022)