Abstract

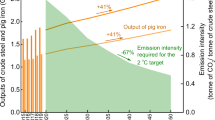

Hard-to-abate sectors emitted ~30% of global CO2 emissions in 2018. As the world’s largest producer of chemicals and steel, China’s mitigation efforts in these sectors are crucial. Here we examine the greenhouse gas mitigation and costs of co-producing steel and chemicals in China by extracting H2 and CO from steelmaking off-gas for chemical production and using a customized optimization model with a life-cycle assessment. Without carbon pricing, co-production reduces greenhouse gas emissions by 36 MtCO2eq yr−1 (−7%) and costs by 1.5 billion CNY per year (−1%) relative to independent production. A carbon price of 350 CNY per tCO2 enhances emissions and cost reductions to 113 MtCO2eq yr−1 (−22%) and 25.5 billion CNY per year (−10%), respectively. Furthermore, 60% of total emissions and cost reductions can be achieved via 24% of connections, ~50% of which are in Hebei, Henan, Shanxi and Shandong provinces. This study demonstrates the cost-effectiveness of using co-production to mitigate these hard-to-abate emissions and the importance of targeting critical connections to obtain the majority of reductions.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All data and parameters used for this study are provided in Source data and Supplementary Information.

Code availability

Each component of our model is detailed in Supplementary Information with parameterizations provided for each step. The codes for the optimization algorithms and mapping of grid boxes are available via GitHub at https://github.com/indsyn/Steel-chemical (ref. 43).

Change history

03 May 2024

In the version of the article initially published, the graphical abstract was missing and has now been added.

References

Novak, D. R. Getting from hard-to-abate to a low-carbon future. Deloitte https://www.deloitte.com/conf/modern/settings/wcm/templates/modern–di-research-template/initial.html (2021).

The challenge of reaching zero emissions in heavy industry—analysis. IEA https://www.iea.org/articles/the-challenge-of-reaching-zero-emissions-in-heavy-industry (2020).

World steel in figures 2022. World Steel Association https://worldsteel.org/steel-topics/statistics/world-steel-in-figures-2022/

Li, S., Xue, Y. & Wang, P. Transforming China’s chemicals industry: pathways and outlook under the carbon neutrality goal. Rocky Mountain Institute https://www.energy-transitions.org/wp-content/uploads/2022/05/transforming_china_chemicals_industry_report.pdf (2022).

Jin, L. et al. Pathway of carbon emissions peak of China’s coal chemical industry. Res. Environ. Sci. 35, 368–376 (2022).

Guo, Y., Peng, L., Tian, J. & Mauzerall, D. L. Deploying green hydrogen to decarbonize China’s coal chemical sector. Nat. Commun. 14, 8104 (2023).

Wang, X. et al. China’s iron and steel industry carbon emissions peak pathways. Res. Environ. Sci. 35, 339–346 (2022).

Hasanbeigi, A., Lu, H. & Zhou, N. Net-Zero Roadmap for China’s Steel Industry (LBNL, 2023).

14th five-year plan for modern energy system. National Development and Reform Commission https://www.ndrc.gov.cn/xxgk/zcfb/ghwb/202203/t20220322_1320016.html (2022).

Choi, W. & Kang, S. Greenhouse gas reduction and economic cost of technologies using green hydrogen in the steel industry. J. Environ. Manage. 335, 117569 (2023).

Cai, B., Li, Q. & Zhang, X. China carbon dioxide capture, utilization, and storage (CCUS) annual report. Chinese Academy of Environmental Planning, Institute of Rock and Soil Mechanics of Chinese Academy of Sciences, and the Administrative Center for China‘s Agenda 21 https://beipa.org.cn/filedownload/387544 (2021).

Guo, Y. & Zhou, J. Current situation and future outlook of steel chemical co-production in China. China Metall. 30, 5–10 (2020).

Zhang, Q., Xiang, T. & Tian, S. Construction and development trend of steel–chemical cogeneration system in future. J. Iron Steel Res. 35, 375–384 (2023).

Li, L. Coal chemical industry helps the steel industry utilize off-gas cleanly. China Energy News http://paper.people.com.cn/zgnyb/html/2019-08/05/content_1940059.htm (2019).

Shangguan, F. et al. Analysis and case on material conversion utilization of by-product gases in steel industry. Iron Steel 54, 114–120 (2019).

Li, L. & Huang, S. A technology for coke oven gas efficient polyregeneration. Fuel Chem. Process. 49, 46–49 (2018).

Accelerate energy-saving and carbon-reducing renovations and upgrades, and promote the green, low-carbon, high-quality development of the coking industry. National Development and Reform Commission https://www.ndrc.gov.cn/xwdt/ztzl/ghnhyjnjdgzsj/zjgd/202203/t20220323_1320107.html (2023).

Mao, Y. Analysis on the collaborative development trend of coal chemical industry and steel industry. Henan Chem. Ind. 38, 4–7 (2021).

Action plans for peaking carbon emissions before 2030. The State Council of the People’s Republic of China https://www.gov.cn/zhengce/content/2021-10/26/content_5644984.htm (2021).

Ramaswami, A. et al. Urban cross-sector actions for carbon mitigation with local health co-benefits in China. Nat. Clim. Change 7, 736–742 (2017).

Zhang, Q. et al. Co-benefits analysis of industrial symbiosis in China’s key industries: case of steel, cement, and power industries. J. Ind. Ecol. 26, 1714–1727 (2022).

Cao, X., Wen, Z., Zhao, X., Wang, Y. & Zhang, H. Quantitative assessment of energy conservation and emission reduction effects of nationwide industrial symbiosis in China. Sci. Total Environ. 717, 137114 (2020).

Arvola, J., Harkonen, J., Mottonen, M., Haapasalo, H. & Tervonen, P. Combining steel and chemical production to reduce CO2 emissions. Low Carbon Econ. 02, 115 (2011).

Deng, L. & Adams, T. A. II Techno-economic analysis of coke oven gas and blast furnace gas to methanol process with carbon dioxide capture and utilization. Energy Convers. Manag. 204, 112315 (2020).

Ghanbari, H., Saxén, H. & Grossmann, I. E. Optimal design and operation of a steel plant integrated with a polygeneration system. AIChE J. 59, 3659–3670 (2013).

Kang, D. & Han, J. Environmental analysis of methanol production from steel-making offgas. Environ. Technol. Innov. 28, 102694 (2022).

Di Lullo, G. et al. Large-scale long-distance land-based hydrogen transportation systems: a comparative techno-economic and greenhouse gas emission assessment. Int. J. Hydrog. Energy 47, 35293–35319 (2022).

Zhu, Z. et al. Technical and economic analysis on long-distance hydrogen pipeline transportation. Pet. Sci. Bull. 8, 112–124 (2023).

Long, X. & Goulder, L. H. Carbon emission trading systems: a review of systems across the globe and a close look at China’s national approach. China Econ. J. 0, 1–14 (2023).

The overall operation of China’s carbon market is stable and orderly, with trading prices steadily rising. Xinhua http://www.news.cn/2023-07/12/c_1129744679.htm (2023).

Goulder, L. H., Long, X., Qu, C. & Zhang, D. China’s nationwide CO2 emissions trading system: a general equilibrium Assessment. In Proc. 26th Annual Conference on Global Economic Analysis (GTAP, 2023).

Tang, H. Carbon—Introduction of New Chemical Technology (Chemical Industry Press, 2009).

Zhao, J., Zhang, Q. & Zhou, D. Can marketed on-grid price drive the realization of energy transition in China’s power industry under the background of carbon neutrality? Energy 276, 127556 (2023).

China Coal Chemical Industry Projects. AnyChem http://coalchem.anychem.com/project (2023).

Global Steel Plant Tracker. Global Energy Monitor https://globalenergymonitor.org/projects/global-steel-plant-tracker/ (2023).

Baidu map open application programming interface. Baidu https://lbsyun.baidu.com/ (2022).

Notice on publicly soliciting opinions on the China Association for Standardization’s Standard ‘Technical Specifications for Hydrogen Gas Transmission Industrial Pipelines’. China Association for Standardization http://www.china-cas.org/zxdtxhtz/3050.jhtml (2023).

ISO 14040:2006, Environmental management—Life cycle assessment—Principles and framework. International Standardization Organization https://www.iso.org/obp/ui#iso:std:iso:14040:ed-2:v1:en (2006).

Rebitzer, G. et al. Life cycle assessment: part 1: framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 30, 701–720 (2004).

Si, W. & Yu, D. How low can the cost of hydrogen be reduced?—Storage and transportation chapter. Guangzheng Hang Seng http://qccdata.qichacha.com/ReportData/PDF/dfc9713e0408154e2b3f91c2f0e63527.pdf (2019).

National Geographic Fundamental Information Database. National Catalogue Service for Geographic Information http://www.webmap.cn/main.do?method=index (2021).

Climate Change 2013: The Physical Science Basis. IPCC https://www.ipcc.ch/report/ar5/wg1/ (2013).

Steel-chemical. GitHub https://github.com/indsyn/Steel-chemical (2023).

Acknowledgements

The authors thank Princeton University for financial support. Y.G. acknowledges the support from the Schmidt Science Fellows, in partnership with the Rhodes Trust. The funders had no role in study design, data collection and analysis, or decision to publish or preparation of the manuscript.

Author information

Authors and Affiliations

Contributions

Y.G. and D.L.M. conceived the research idea. Y.G., J.L. and D.L.M. designed the study procedures; Y.G. and J.L. compiled the database and configured the scenarios; Y.G. conducted the parameterizations and modeling; Y.G. and J.L. made the figures and tables; J.L., Q.Z., Y.C. and L.C. contributed to parameterizations; Y.G., J.L., Q.Z., Y.C., L.C. and D.L.M. analyzed the results; Y.G., J.L. and D.L.M. wrote the paper with contributions from all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemical Engineering thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–7, Tables 1–11, Figs. 1–4 and References.

Supplementary Data

Source data for supplementary figures and the inventory of steel and coal chemical plants.

Source data

Source Data Fig. 1

Changes in GHG emissions and costs per tonne of H2 or CO used for co-production relative to independent production.

Source Data Fig. 2

Supply of H2 and CO from steel plants and demand for H2 and CO in coal chemical plants in China.

Source Data Fig. 3

GHG mitigation rates and cost reduction rates in co-production relative to independent production across carbon prices and pipeline length limits.

Source Data Fig. 4

Changes in GHG emissions and costs by industrial process in co-production relative to independent production.

Source Data Fig. 5

Cost-effective supply of H2 and CO in the co-production from origin provinces (rows) to destination provinces (columns).

Source Data Fig. 6

Onsite GHG mitigation of H2 and CO connections in co-production relative to independent production.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Y., Lu, J., Zhang, Q. et al. Co-production of steel and chemicals to mitigate hard-to-abate carbon emissions. Nat Chem Eng 1, 365–375 (2024). https://doi.org/10.1038/s44286-024-00061-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s44286-024-00061-1

This article is cited by

-

Integrating industrial sectors in the transition to more sustainable chemicals

Nature Chemical Engineering (2024)