Abstract

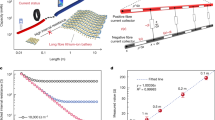

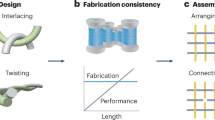

Fibre batteries are of significant interest because they can be woven into flexible textiles to form compact, wearable and light-weight power solutions1,2. However, current methods adapted from planar batteries through layer-by-layer coating processes can only make fibre batteries with low production rates, which fail to meet the requirements for real applications2. Here, we present a new and general solution-extrusion method that can produce continuous fibre batteries in a single step at industrial scale. Our three-channel industrial spinneret simultaneously extrudes and combines electrodes and electrolyte of fibre battery at high production rates. The laminar flow between functional components guarantees their seamless interfaces during extrusion. Our method yields 1,500 km of continuous fibre batteries for every spinneret unit, that is, more than three orders of magnitude longer fibres than previously reported1,2. Finally, we show a proof-of-principle for roughly 10 m2 of woven textile for smart tent applications, with a battery with energy density of 550 mWh m−2.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the Supplementary Information or the corresponding authors on request. Source data are provided with this paper.

References

Sun, H., Zhang, Y., Zhang, J., Sun, X. & Peng, H. Energy harvesting and storage in 1D devices. Nat. Rev. Mater. 2, 17023 (2017).

Wang, L. et al. Application challenges in fiber and textile electronics. Adv. Mater. 32, 1901971 (2020).

Park, S. et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 561, 516–521 (2018).

Pomerantseva, E., Bonaccorso, F., Feng, X., Cui, Y. & Gogotsi, Y. Energy storage: the future enabled by nanomaterials. Science 366, eaan8285 (2019).

Wang, S. et al. Skin electronics from scalable fabrication of an intrinsically stretchable transistor array. Nature 555, 83–88 (2018).

Mo, F. et al. An overview of fiber-shaped batteries with a focus on multifunctionality, scalability, and technical difficulties. Adv. Mater. 32, 1902151 (2020).

Chen, J. et al. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat. Energy 1, 16138 (2016).

He, J. et al. Scalable production of high-performing woven lithium-ion fibre batteries. Nature 597, 57–63 (2021).

Zhu, Y. H., Yang, X. Y., Liu, T. & Zhang, X. B. Flexible 1D batteries: recent progress and prospects. Adv. Mater. 32, 1901961 (2020).

Mackanic, D. G., Kao, M. & Bao, Z. Enabling deformable and stretchable batteries. Adv. Energy Mater. 10, 2001424 (2020).

Kwon, Y. H. et al. Cable-type flexible lithium ion battery based on hollow multi-helix electrodes. Adv. Mater. 24, 5192–5197 (2012).

Ren, J. et al. Twisting carbon nanotube fibers for both wire-shaped micro-supercapacitor and micro-battery. Adv. Mater. 25, 1155–1159 (2013).

Guo, Z. et al. Multi-functional flexible aqueous sodium-ion batteries with high safety. Chem 3, 348–362 (2017).

Yang, H. S. et al. Electrochemical wet-spinning process for fabricating strong PAN fibers via an in situ induced plasticizing effect. Polymer 202, 122641 (2020).

Kinloch, I. A., Suhr, J., Lou, J., Young, R. J. & Ajayan, P. M. Composites with carbon nanotubes and graphene: an outlook. Science 362, 547–553 (2018).

Li, P. et al. Highly crystalline graphene fibers with superior strength and conductivities by plasticization spinning. Adv. Funct. Mater. 30, 2006584 (2020).

Wang, Y. et al. 3D-printed all-fiber Li-ion battery toward wearable energy storage. Adv. Funct. Mater. 27, 1703140 (2017).

Rao, R. B., Krafcik, K. L., Morales, A. M. & Lewis, J. A. Microfabricated deposition nozzles for direct-write assembly of three-dimensional periodic structures. Adv. Mater. 17, 289–293 (2005).

Kaufman, J. J. et al. Structured spheres generated by an in-fibre fluid instability. Nature 487, 463–467 (2012).

Zhang, Y. et al. A fiber-shaped aqueous lithium ion battery with high power density. J. Mater. Chem. A. 4, 9002–9008 (2016).

Chen, L. et al. Enabling safe aqueous lithium ion open batteries by suppressing oxygen reduction reaction. Nat. Commun. 11, 2638 (2020).

Yang, C. et al. Aqueous Li-ion battery enabled by halogen conversion–intercalation chemistry in graphite. Nature 569, 245–250 (2019).

Zhao, C. et al. Layered nanocomposites by shear-flow-induced alignment of nanosheets. Nature 580, 210–215 (2020).

Liu, L. et al. Aligned, high-density semiconducting carbon nanotube arrays for high-performance electronics. Science 368, 850–856 (2020).

Zhu, C., Usiskin, R. E., Yu, Y. & Maier, J. The nanoscale circuitry of battery electrodes. Science 358, eaao2808 (2017).

Zhu, M. & Schmidt, O. G. Tiny robots and sensors need tiny batteries—here’s how to do it. Nature 589, 195–197 (2021).

Bin, D. et al. Progress in aqueous rechargeable sodium-ion batteries. Adv. Energy Mater. 8, 1703008 (2018).

Suo, L. et al. ‘Water-in-salt’ electrolyte makes aqueous sodium-ion battery safe, green, and long-lasting. Adv. Energy Mater. 7, 1701189 (2017).

Acknowledgements

This work was supported by the Ministry of Science and Technology of the People’s Republic of China (grant no. 2016YFA0203302 to H.P.), National Natural Science Foundation of China (grant nos. 21634003 to H.P., 22075050 to X. Sun, 21805044 to P.C.), Science and Technology Commission of Shanghai Municipality (grant nos. 20JC1414902 to H.P., 18QA1400700 to B.W., 19QA1400800 to P.C.) and Shanghai Municipal Education Commission (grant no. 2017-01-07-00-07-E00062 to H.P.). We thank A.-L. Chun of Science Storylab for critically reading and editing the manuscript and Y. Zhang for important suggestions.

Author information

Authors and Affiliations

Contributions

H.P. and B.W. conceived and designed the research project. M.L., C.W. and Y.H. performed the experiments on solution-extruded fibre batteries, textile batteries and integration systems, and contributed equally to this work. Y.Z., X.C., H.S. and L.Y. performed electrochemical measurements of functional inks. X.H. performed the simulation. J. Wu, X. Shi and X.Z. performed experiments on the display textile. X.K. performed the experiments on the photovoltaic textile. J. Wang and P.L. analysed the data. X. Sun, P.C., Y.W., Y.X., Y.C. and all other authors discussed the data and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review information

Nature Nanotechnology thanks Sheng Yong, Xinbo Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Materials and Methods, Supplementary Figs. 1–21, Tables 1 and 2, Captions for Videos 1–8 and References.

Supplementary Video 1

Continuous production of fibre batteries.

Supplementary Video 2

FLIB textile charges a phone.

Supplementary Video 3

FLIB textile charges a phone under folding.

Supplementary Video 4

FLIB textile charges a phone when heated by a flame.

Supplementary Video 5

FLIB textile charges a phone when punctured by a blade.

Supplementary Video 6

FLIB textile charges a phone after washing.

Supplementary Video 7

FLIB textile charges a phone when rolled on by a motorbike.

Supplementary Video 8

Weaving the textile display for the smart tent system.

Source data

Source Data Fig. 1

Source data for Fig. 1.

Source Data Fig. 2

Source data for Fig. 1.

Source Data Fig. 3

Source data for Fig. 1.

Rights and permissions

About this article

Cite this article

Liao, M., Wang, C., Hong, Y. et al. Industrial scale production of fibre batteries by a solution-extrusion method. Nat. Nanotechnol. 17, 372–377 (2022). https://doi.org/10.1038/s41565-021-01062-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41565-021-01062-4

This article is cited by

-

Design and fabrication of wearable electronic textiles using twisted fiber-based threads

Nature Protocols (2024)

-

A rechargeable calcium–oxygen battery that operates at room temperature

Nature (2024)

-

Calcium–Oxygen Fiber Batteries for Next-Generation Wearables

Advanced Fiber Materials (2024)

-

Fabricating a smart clothing system based on strain-sensing yarn and novel stitching technology for health monitoring

Science China Technological Sciences (2024)

-

Design, fabrication and assembly considerations for electronic systems made of fibre devices

Nature Reviews Materials (2023)