Abstract

Biological living materials, such as animal bones and plant stems, are able to self-heal, regenerate, adapt and make decisions under environmental pressures. Despite recent successful efforts to imbue synthetic materials with some of these remarkable functionalities, many emerging properties of complex adaptive systems found in biology remain unexplored in engineered living materials. Here, we describe a three-dimensional printing approach that harnesses the emerging properties of fungal mycelia to create living complex materials that self-repair, regenerate and adapt to the environment while fulfilling an engineering function. Hydrogels loaded with the fungus Ganoderma lucidum are three-dimensionally printed into lattice architectures to enable mycelial growth in a balanced exploration and exploitation pattern that simultaneously promotes colonization of the gel and bridging of air gaps. To illustrate the potential of such mycelium-based living complex materials, we three-dimensionally print a robotic skin that is mechanically robust, self-cleaning and able to autonomously regenerate after damage.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data generated or analysed during this study are available at Zenodo: https://doi.org/10.5281/zenodo.7212419. Further data are available from the corresponding authors upon request. Source data are provided with this paper.

Code availability

The Grasshopper files for print path generation are available at Zenodo: https://doi.org/10.5281/zenodo.7212419.

References

Speck, T. & Burgert, I. Plant stems: functional design and mechanics. Annu. Rev. Mater. Res. 41, 169–193 (2011).

Florea, M. et al. Engineering control of bacterial cellulose production using a genetic toolkit and a new cellulose-producing strain. Proc. Natl Acad. Sci. USA 113, E3431–E3440 (2016).

Di Giacomo, R., Daraio, C. & Maresca, B. Plant nanobionic materials with a giant temperature response mediated by pectin-Ca2+. Proc. Natl Acad. Sci. USA 112, 4541–4545 (2015).

Jonkers, H. M. in Self Healing Materials: an Alternative Approach to 20 Centuries of Materials Science (ed. van der Zwaag, S.) 195–204 (Springer Netherlands, 2007).

Gilbert, C. et al. Living materials with programmable functionalities grown from engineered microbial co-cultures. Nat. Mater. 20, 691–700 (2021).

Gerber, L. C., Koehler, F. M., Grass, R. N. & Stark, W. J. Incorporating microorganisms into polymer layers provides bioinspired functional living materials. Proc. Natl Acad. Sci. USA 109, 90–94 (2012).

Liu, X. et al. 3D printing of living responsive materials and devices. Adv. Mater. 30, 1704821 (2018).

Duraj-Thatte, A. M. et al. Genetically programmable self-regenerating bacterial hydrogels. Adv. Mater. 31, e1901826 (2019).

Schaffner, M., Ruhs, P. A., Coulter, F., Kilcher, S. & Studart, A. R. 3D printing of bacteria into functional complex materials. Sci. Adv. 3, eaao6804 (2017).

Joshi, S., Cook, E. & Mannoor, M. S. Bacterial nanobionics via 3D printing. Nano Lett. 18, 7448–7456 (2018).

Heveran, C. M. et al. Biomineralization and successive regeneration of engineered living building materials. Matter 2, 481–494 (2020).

Lehner, B. A. E., Schmieden, D. T. & Meyer, A. S. A straightforward approach for 3D bacterial printing. ACS Synth. Biol. 6, 1124–1130 (2017).

Kriegman, S., Blackiston, D., Levin, M. & Bongard, J. A scalable pipeline for designing reconfigurable organisms. Proc. Natl Acad. Sci. USA 117, 1853–1859 (2020).

The Royal Society. Animate materials. https://royalsociety.org/topics-policy/projects/animate-materials/ (2021).

Nguyen, P. Q., Courchesne, N. M. D., Duraj-Thatte, A., Praveschotinunt, P. & Joshi, N. S. Engineered living materials: prospects and challenges for using biological systems to direct the assembly of smart materials. Adv. Mater. 30, e1704847 (2018).

Mitchell, M. Complexity: A Guided Tour (Oxford Univ. Press, 2009).

Gow, N. A. & Gadd, G. M. Growing Fungus (Springer, 1995).

Andrews, J. H. Comparative Ecology of Microorganisms and Macroorganisms (Springer-Verlag, 2017).

Aleklett, K., Ohlsson, P., Bengtsson, M. & Hammer, E. C. Fungal foraging behaviour and hyphal space exploration in micro-structured Soil Chips. ISME J. 5, 1782–1793 (2021).

Wösten, H. A. B. et al. How a fungus escapes the water to grow into the air. Curr. Biol. 9, 85–88 (1999).

Holt, G. A. et al. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy 6, 431–439 (2012).

Heisel, F. et al. Design, cultivation and application of load-bearing mycelium components: the MycoTree at the 2017 Seoul Biennale of Architecture and Urbanism. Int. J. Sustain. Energy Dev. https://doi.org/10.20533/ijsed.2046.3707.2017.0039 (2017/18).

Haneef, M. et al. Advanced materials from fungal mycelium: fabrication and tuning of physical properties. Sci. Rep. 7, 41292 (2017).

Jones, M., Gandia, A., John, S. & Bismarck, A. Leather-like material biofabrication using fungi. Nat. Sustain. 4, 9–16 (2021).

Antinori, M. E. et al. Advanced mycelium materials as potential self-growing biomedical scaffolds. Sci. Rep. 11, 12630 (2021).

Bigall, N. C. et al. Fungal templates for noble-metal nanoparticles and their application in catalysis. Angew. Chem. Int. Ed. 47, 7876–7879 (2008).

Mizzi, L. et al. Assessing the individual microbial inhibitory capacity of different sugars against pathogens commonly found in food systems. Lett. Appl. Microbiol. 71, 251–258 (2020).

Maurice, S. et al. Modelling the effect of temperature, water activity and pH on the growth of Serpula lacrymans. J. Appl. Microbiol. 111, 1436–1446 (2011).

Fricker, M. D., Heaton, L. L. M., Jones, N. S. & Boddy, L. The mycelium as a network. Microbiol. Spectr. https://doi.org/10.1128/microbiolspec.FUNK-0033-2017 (2017).

O’Loughlin, P. F. et al. Selection and development of preclinical models in fracture-healing research. J. Bone Jt Surg. 90, 79–84 (2008).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Coulter, F. B. et al. Bioinspired heart valve prosthesis made by silicone additive manufacturing. Matter 1, 266–279 (2019).

Acknowledgements

We thank the Swiss Competence Center for Energy Research for funding in Capacity Area A3 on the minimization of energy demand (K.M. and A.R.S.). We are greateful for Swiss National Science Foundation Consolidator grant BSCGIO_157696 (S.G., F.B.C. and A.R.S.). We thank the Swiss National Science Foundation for funding within the framework of the National Center of Competence in Research for Bio-Inspired Materials (P.A.R. and A.R.S.).

Author information

Authors and Affiliations

Contributions

The conceptualization was by S.G., P.A.R., K.M. and A.R.S. The methodology was by S.G., E.C., J.K., E.T., F.B.C., K.M. and P.A.R. The software was by S.G. and F.B.C. The investigation was by S.G., E.C., J.K., E.T., F.B.C., K.M. and P.A.R. The visualization was by S.G., E.C. and J.K. Funding acquisition was by A.R.S. Project administration was by S.G. Supervision was by S.G., K.M., P.A.R. and A.R.S. Writing the original draught was done by S.G. and A.R.S. Reviewing and editing the paper was done by S.G., K.M., P.A.R., F.B.C. and A.R.S.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Athanassia Athanassiou, Alexander Bismarck, Wil Srubar III and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

Extended Data Fig. 1 Mycelium growth within hydrogel grid.

(A, B) Optical microscopy images of a cross-sectional cut of a 3D grid printed from an ink containing 10% malt extract concentration. The images show the mycelium growth on the surface of the ink. (C) Estimated volume of the mycelium layer grown on agar hydrogels. The volume was calculated from the radius and thickness of the grown mycelium network (Fig. 2B). (D) Scanning electron microscopy images showing the freeze-dried structure of mycelium grown on a printed hydrogel filament. The images shown in (A,B,D) are representatives of a series of 3 equal experiments.

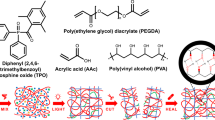

Extended Data Fig. 2 Rheological properties and printability of mycelium inks.

(A) Apparent viscosity of hydrogel inks measured under steady shear conditions, indicating the shear thinning behaviour of inks containing varying concentrations of malt extract. (B) Storage (G’) and loss (G’) moduli of inks before and after inoculation obtained from oscillatory rheological measurements at increasing applied frequency. The data show that the printed inks are predominantly elastic over the entire range of probed frequencies. (C) Rheological response of inks under printing simulation conditions. The alternating oscillatory (grey area) and steady-state (white area) measurements show quick recovery of the storage modulus of the ink upon cessation of shear. (D) 3D printed grids obtain from inks with increasing yield strength of approximately 100 Pa (left) 400 Pa (middle) and >1000 Pa (right). The images indicate filament sagging and flowing for inks with low yield stress, whereas high-yield-stress inks lead to fragile and brittle grids. Optimal print results are achieved with inks at intermediate yield stress level. (E) Effect of height and line gap spacing on the minimum yield stress required to print hydrogel grids that resist gravity-induced distortion. LD and DN correspond to the line spacing and the filament diameter, respectively.

Extended Data Fig. 3 3D printed mycelium grid structures.

(A-C) Photographs of grids after 10 days of growth for structures printed with varying (A) line gaps, (B) nozzle diameters, and (C) malt extract concentrations.

Extended Data Fig. 4 Mycelium grid structure during compression testing.

Snapshots taken at distinct compressive strains show the changing internal structure of the material. The grids were printed from inks containing 10 % malt extract with a line gap of 1.2 mm and nozzle diameter of 0.84 mm.

Extended Data Fig. 5 Long-term resilience and biological viability of mycelia-based structures.

Printed living grids that were maintained hydrated (upper row) or dried (lower row) for 8 months are able to re-grow the mycelial network after culturing on malt extract growth plates. Both samples quickly regenerated new mycelium and colonized the plates within 7 days of growth.

Extended Data Fig. 6 Self-healing of cuts made in the printed mycelium grids.

(A) A 3D printed grid was intentionally cut and imaged for a duration of 7 days. After this time period, the cross-section image of the sample shows that the cut is fully healed through the growth of mycelia across the open space. (B) Setup comprising metal frame and wood chip substrate used to evaluate the tensile mechanical properties and self-healing ability of printed mycelium grids.

Extended Data Fig. 7 Strategy to fabricate the mycelium-based skin for the robotic gripper.

From left to right: non-planar 3D printed half of the robotic skin after 7 days of growth. Counterpart flipped to show the bottom side of the printed structure. The two halves put together ready to mount onto the mechanical actuators. Final mycelium-based skin assembled around the gripper after an additional 3 days of growth to fuse the individual parts together.

Extended Data Fig. 8 Sample holder used for bridging experiments and 3D printing setup.

(A) 3D representation indicating the air gap that was changed to create a distance for the mycelium to bridge. (B,C) Drawings displaying different cross-sections of the sample holder. (D) Custom-built syringe pump mounted on a fused filament fabrication printer (Ultimaker 2+) to create the direct ink writing setup (DIW). (E) DIW of the mycelium ink into a grid structure.

Extended Data Fig. 9 Surface hydrophobicity of printed structures.

(A) Contact angle measurement on a mycelium-covered surface. (B) Colored water droplets on a plate covered with mycelium.

Extended Data Fig. 10 Effect of nozzle diameter on the dry biomass and stiffness of mycelium grids.

Apparent mechanical stiffness and biomass content of mycelia-laden grids printed with varying nozzle diameters. The line distance and the malt extract concentration were kept constant at 2 mm and 10%, respectively. The apparent stiffness values reported correspond to the instantaneous elastic modulus at a strain value of 25%. The data represent the mean values and the standard deviation obtained from 5 measurements of distinct samples at each data point.

Supplementary information

Supplementary Information

Supplementary Video Legends 1–5, note and references.

Supplementary Video 1

Mechanical robustness of mycelium-based living objects. The video shows the deformation of mycelium-covered objects under tensile forces, under a compressive load and under the action of a cutting wire. The wire cutting experiment demonstrates the toughness of the mycelium skin grown around the printed grids. The compression tests are also performed on samples with cut sides to reveal the deformation of the interior of the structure during mechanical loading.

Supplementary Video 2

Growth of mycelia between printed filaments. The video shows a sequence of confocal microscopy images during the growth of mycelia between two printed filaments over a time window of five days. A 3D representation of the mycelial network is shown at the top, whereas the bottom displays a projection of the confocal images along the out-of-plane z axis.

Supplementary Video 3

Tensile testing of self-healing mycelium-covered structures. The video displays the deformation of sample A (Fig. 4e) when subjected to tensile loading. The first part shows the intact sample deformed until the first fracture event. The second part depicts the fracture of the same sample after self-healing.

Supplementary Video 4

Fabrication and testing of mycelium-based skin for a rolling robot. The footage first shows the deposition of the mycelium ink onto half-spherical mandrels using a five-axis printer, followed by the growth of the mycelia to generate the living robotic skin. The video then displays the robustness of the skin and its ability to protect the robot from harsh environments, such as gravel, rocks and water.

Supplementary Video 5

Fabrication and testing of mycelium-based skin for a robotic gripper. The video illustrates the 3D printing of non-planar grid structures onto a mandrel with the shape of a robotic finger. After growth, assembly and fusion steps, the mycelium-covered gripper is used to deposit the rolling robot into a water bath. The robotic gripper retrieves the rolling robot again from the water after a short period of underwater motion. The hydrophobic skin covering the rolling robot and the gripper protects them against damage in water.

Source data

Source Data Fig. 2

Statistical source data tabulated for Fig. 2b–f.

Source Data Fig. 3

Statistical source data tabulated for Fig. 3c–g.

Source Data Fig. 4

Statistical source data tabulated for Fig. 4b–d.

Source Data Extended Data Fig. 1

Statistical source data tabulated for Extended Data Fig. 1c.

Source Data Extended Data Fig. 2

Statistical source data tabulated for Extended Data Fig. 2a–c,e.

Source Data Extended Data Fig. 10

Statistical source data tabulated for Extended Data Fig. 10.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gantenbein, S., Colucci, E., Käch, J. et al. Three-dimensional printing of mycelium hydrogels into living complex materials. Nat. Mater. 22, 128–134 (2023). https://doi.org/10.1038/s41563-022-01429-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-022-01429-5

This article is cited by

-

Biocomposite thermoplastic polyurethanes containing evolved bacterial spores as living fillers to facilitate polymer disintegration

Nature Communications (2024)

-

Gradient matters via filament diameter-adjustable 3D printing

Nature Communications (2024)

-

Structural engineered living materials

Nano Research (2024)

-

Current trends, limitations and future research in the fungi?

Fungal Diversity (2024)

-

Impact of malt concentration in solid substrate on mycelial growth and network connectivity in Ganoderma species

Scientific Reports (2023)