Abstract

Until now, conventional nanogenerators could only produce electric pulses with relatively low-power densities. Herein, we invent a novel controllable growth technique for two-dimensional (2-D) cuprous oxide (p-Cu2O) single-crystal films, and on this basis, a new concept of 2-D single-crystal film flexoelectric nanogenerators (FENGs) are rationally designed and constructed for the first time, which has the characteristics of long-range order lattice, few grain boundaries and defects. More importantly, the accumulated built-in polarization potential in the bent 2-D p-Cu2O single-crystal film FENGs is in the same orientation as the output electricity, resulting in the first nanogenerator that can output continuous and stable electric signals with high voltage (Voc of 2.8 V), current (Jsc of 11.5 μA·cm−2) and power density (14.4 μW·cm−2), exhibiting great practical application potential for power generation and motion capture. This research breaks new ground and establishes a precedent for high-performance and continuous-output nanogenerators, as well as smart wearable sensors.

Similar content being viewed by others

Introduction

Conventional nanogenerators based on ferroelectric materials typically exhibit a coupling effect of piezoelectricity and flexoelectricity. Professor Zhonglin Wang, for example, pioneered the use of an atomic force microscope (AFM) tip to bend zinc oxide (ZnO) nanowires to construct piezoelectric nanogenerators (PENGs) that also accompanied by the flexoelectric effect1. Piezoelectric effect is to use the asymmetric structure of material crystal to generate dipole moment and polarization near the interface2. Whereas, flexoelectric effect is the electric polarization response generated under the mechanical strain gradient, including interface and bulk polarization3,4. The piezoelectric effect only exists in non-centrosymmetric crystal structures while the flexoelectric effect exists in almost all dielectric materials, thus the concept of flexoelectronics is a great extension of piezoelectronics, which can realize polarization in centrosymmetric crystals, expanding the nanogenerators from the conventional piezoelectric materials to flexoelectric semiconductors5,6. However, at present, the vast majority of the nanogenerators under stress are currently PENGs, while flexoelectricity is still in the stage of theoretical research, and there is little work on pure flexoelectric nanogenerators (FENGs)7.

In addition, the traditional nanogenerators also have some technical bottlenecks that need to be broken through. First, the working principle of the traditional nanogenerators is similar to a capacitor, which leads to the output of only instantaneous pulsed electrical signals8,9,10,11. The traditional nanogenerators present a pulse width of about 1–2 ms, which can be employed in some intermittent power supply scenarios, but are inappropriate for continuous output or monitoring. Unfortunately, at present, there is no nanogenerator that can output continuously for an extended period of time.

On the other hand, the current configurations of nanogenerators are still largely dependent on one-dimensional (1-D) nanowires (arrays)12,13,14, 1-D nanowire braids15,16,17, and 2-D nanosheets (arrays)18,19,20. These configurations are composed of countless crystals of varying orientations that are randomly organized, with enormous gaps between them, lacking overall single-crystallinity (long-range order) and continuity. Therefore, it is found that the output performance of the traditional nanogenerators is very limited. For example, a single ZnO nanowire output an extremely weak current (50 mV, 750 pA)21, and it is still inaccessible to get a high current after building up arrays (28 nA, 70 nW·cm−2)22. Although 2-D monolayer nanogenerators, such as MoS2 (30 pA, 0.6 μW·cm−2)23 and MXene (0.3 nA, 0.65 μW·cm−2)24, have also been studied, we can see that the output voltage, current and power values are still at a low level, due to the crystal dimensions and volumes are too small. However, no work has been reported on large-scale 2-D single-crystal film nanogenerators so far.

The previous research experience told us that single-crystal semiconductor films usually have better properties than polycrystalline and amorphous films, such as carrier concentration, conductivity and mobility25,26,27. The single-crystal films are extremely orderly in crystal arrangement, with few defects and grain boundaries, which have inherent advantages in the field of energy conversion28. The most typical example is that in the field of photovoltaics, the efficiencies of monocrystalline silicon (m-Si) are better than those of polycrystalline silicon (p-Si) and amorphous silicon (a-Si)29. Meanwhile, the advantages of single-crystal films are also reflected in the field of superconducting and graphene materials30,31. Hence, it is not difficult to associate that the performance of 2-D single-crystal film nanogenerators would probably be better than that of 1-D or 2-D polycrystalline nanogenerators theoretically.

Therefore, for rationally designing the next-generation of 2-D nanogenerators, we propose several important requirements that should be met. Firstly, they should meet the single-crystal characteristics in the whole structure, which grow in directional and orderly manners to avoid grain boundaries and gaps; Secondly, they need to reach certain volume requirements, that is, the appropriate cross-sectional area and the quantity of crystal cells are guaranteed to produce high polarization voltages and currents; Thirdly, they should remain flexible and not easy to break, damage or oxidize in the process of long-term deformation; Fourthly, the signal width of the 2-D nanogenerators needs to be extended, and constant output is preferable.

In this work, we propose and fabricate a new concept of 2-D FENGs based on the controllably grown flexible cuprous oxide (p-Cu2O) single-crystal films, which meet all the above requirements. Under asymmetrical bending, the 2-D single-crystal film FENGs form a directional built-in polarization potential, which has the same orientation as the output electricity, very different from the traditional PENGs. Thereafter, for the first time, the innovative nanogenerators could output continuous and stable voltage and current signals, and also possess obvious advantages in terms of durability and application potential. Meanwhile, the output power density is higher than that of any other reported single-component nanogenerators. Consequently, this strategy greatly broadens the research horizon and application field of nanogenerators to realize powerful, continuous and renewable electrical energy.

Results and discussion

Principles and mechanism

Look beyond appearance for the essence, what the nanogenerators do is to deform the crystal lattices by external force, so as to trigger polarization and dipoles inside the crystals. At the same time, as much as possible to maintain the directional movement of carriers driven by the polarization potentials (Work). Figure 1 shows the different behavior between 1-D single-crystal nanowires and 2-D single-crystal thin films under flexural deformation. When bending the 1-D single-crystal nanowires, the stress concentrates in the fixed end (nanowire roots), which can be observed from Fig. 1a that in the strain region, the tensile side (red area) and the compression side (blue area) with the largest shape variables are formed along the radial direction. Obviously, the component of piezoelectric/flexoelectric field (E) in c-axis direction is much larger than that in a-axis direction.

In the course of implementation, however, it is hard to deposit electrodes along the radial direction, especially in dense 1-D nanowire arrays, thus 1-D nanowire PENGs/FENGs are difficult to derive piezoelectric/flexoelectric output from c-axis direction, instead, electrodes are easily deposited from both ends of the 1-D single-crystal nanowires (a-axis direction), causing the piezoelectric/flexoelectric field direction (black arrow) to be inconsistent with the current output direction (white arrow). On the contrary, it is very convenient to deposit electrodes on both sides (c-axis direction) of 2-D single-crystal films. It can be observed from Fig. 1b that when the 2-D single-crystal films are bent, the piezoelectric/flexoelectric field direction (black arrow) and output direction (white arrow) are in the same direction, both along c-axis.

As we know that at absolute zero (0 K) electrons in semiconductors are firmly bound to the valence band, so that there are no free charge carriers in the conduction band32. At this point, the semiconductors behave as insulators and cannot form electric current even if it bends to produce internal polarization fields. At room temperature (~300 K), a number of carriers are thermally excited. At this time, the generation and recombination of carriers exist at the same time, and a dynamic equilibrium is achieved. As shown in the enlarged diagram of Fig. 1a, when 1-D nanowires are bent, the carriers migrate under the influence of piezoelectric/flexoelectric field, and heterogeneous charges gather on both sides along the c-axis. Once grounded or connected with external circuit, the external carriers will enter in attempts to balance the polarization potential. This transition from one initial state to another equilibrium state generates instantaneous pulse signals, similar to the charging process of a “capacitor”.

On the other hand, as shown in the enlarged diagram of Fig. 1b, curved 2-D single-crystal films also gather unlike charges on both sides along the c-axis. Different from 1-D nanowires, carriers in 2-D single-crystal films can be exported directly along the c-axis. Thus, carriers can output continuous (square) signals driven by the accelerating electric field (polarization potential). To sum up, we can find that 2-D single-crystal film PENGs/FENGs have two obvious advantages over 1-D single-crystal nanowire PENGs/FENGs: (1) The largest component of piezoelectric/flexoelectric field intensity along the output direction; (2) The shortest carrier transfer distance and the smallest resistance.

Design and fabrication

In order to verify the above analysis and theory, we designed and implemented the conceptual prototypes of the 2-D FENGs based on p-Cu2O single-crystal films. p-Cu2O is an inorganic oxide with p-type semiconductor characteristics, benefiting from its internal natural copper ion vacancies33, which has been extensively exploited in the fields of photovoltaic cell25,34, photocatalytic material35, photoelectrode36,37, electric ignition semiconductor ceramic material, and so on38,39,40. In this work, we have developed a controllable growth technology for p-Cu2O single-crystal thin films for the first time, which can produce two kinds of p-Cu2O single-crystal films with artificially selected growth orientations. Briefly, we realized the transformation of growth direction and crystal property selection of the p-Cu2O single-crystal films by adjusting the growth environment, as shown in Fig. 2a. Specifically, by fixing the pH value between 7.5 and 8.5, the p-Cu2O single-crystal films grow parallel to the (100) crystal plane (a-b plane), on the contrary, under the condition of strong alkaline solution with pH > 12, the as-fabricated p-Cu2O single-crystal films grow along the (111) crystal plane (a-b plane).

a Controllable growth of the 2-D p-Cu2O single-crystal films along the specific orientations of (111) and (100). b Configuration and microscopy images of the controllable growth of the p-Cu2O single-crystal films along (111) direction. c Configuration and microscopy images of the controllable growth of the p-Cu2O single-crystal films along (100) direction.

The controllable growth direction adjustment can be confirmed by the single-crystal diffraction peaks in the XRD spectra, as shown in Fig. 2a, the single-crystal films grown along the (100) direction only have a single diffraction peak at 42.6°, while the single-crystal films grown along the (111) direction only display a single diffraction peak at 37.0°. It should be noted that the p-Cu2O single-crystal films belong to the cubic crystal system (Pn-3m 224) with center symmetry. As a result, the p-Cu2O single-crystal films showed a piezoelectric coefficient d33 ≈ 2 pC·N−1 by the d33 meter at the macro level, which is due to the existence of intrinsic crystal defects, such as Cu+ vacancies, slightly destroy the crystal symmetry. In contrast, the flexoelectric coefficient of the p-Cu2O single-crystal films was determined in the order of 1 μC·m−1 by cantilever-based measurement, inferring that the p-Cu2O single-crystal films have a strong potential for flexoelectronics.

On the other hand, although both the films belong to the same crystal form (PDF#34-1354), we found that there are some differences in the band structure between them. As illustrated in Fig. 2b, the p-Cu2O single-crystal films grown along the (111) crystal plane direction possess a bandgap of ~2.0 eV, showing translucent purplish red, while the p-Cu2O single-crystal films grown along the (100) crystal plane direction are translucent yellow-green (Fig. 2c) with a bandgap of ~2.3 eV. The UV-VIS spectra can be found in Supplementary Fig. 1. Ultraviolet photoelectron spectroscopy (UPS) was utilized to determine the valence band maximums (VBM) and work functions, and the derived band structures are presented in Supplementary Fig. 2 and Supplementary Fig. 3, which is further verified by the density functional theory (DFT) calculations (Supplementary Fig. 4). The Hall effect measurement revealed that the (111) and (100) oriented p-Cu2O single-crystal films possessed the hole mobilities of 2.9 and 6.2 cm2·V−1·s−1, respectively, whose carrier concentrations were both in the order of ~1016 cm−3.

Consistent with the crystal diffraction detection, we can observe from the SEM images in Fig. 2 that all the cross sections presented compact and regular structures, without any discernible defects and grain boundaries. The surface morphologies of the single-crystal films varied with the growth direction, from Fig. 3a, b, we can see that the surfaces were distributed with triangular pyramids and tetrapyramids for the (111) and (100)-oriented single-crystal films, respectively, and that their AFM surface roughness was detected to be ~90 and ~50 nm. The overall thickness of the films can be precisely controlled in the range of 500–5000 nm by manipulating the growth time (Supplementary Fig. 5). Here, 1000 nm-thickness was preferentially selected for the subsequent study. For outputting electricity, we partially covered the surface of the 2-D p-Cu2O single-crystal film FENGs with Pt and copper tape as negative electrodes.

Output performance and durability

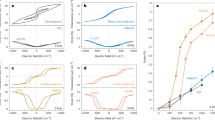

In Fig. 3a we demonstrate the difference in output characteristics between the traditional 1-D ZnO nanowire PENGs and the 2-D p-Cu2O single-crystal film FENGs. As previously stated, when bending the 1-D nanowire, the polarization potential direction is perpendicular to the current output direction, preventing the carriers from moving out continuously and producing a pulse with a signal width of less than 0.3 s. On the contrary, after bending the 2-D p-Cu2O single-crystal films, the polarization potential direction is consistent with the current output direction, then output continuous electricity (square signal), and the signal width has no upper limit during the bending state. Moreover, with the increase of the curvature degree (i.e., crystal structure deformation) of the 2-D single-crystal film FENGs, the flexoelectric field intensity inside the films increases accordingly, as shown in Fig. 3b, when the bending angle of the 2-D single-crystal film DC FENGs gradually increased from 0° to 30°, 60°, and 90°, the Voc also increased from 0 to 0.18, 0.76, and 2.8 V, and generated 1.9, 5.2, and 11.5 μA·cm−2 of Jsc, respectively. The output voltage and current signals vanished as soon as the external force and deformation were canceled. In this situation, the 2-D single-crystal film DC FENGs can be employed not only as power production devices, but also as bending degree sensors.

The spontaneous flexoelectric polarization induced by the strain gradient during the bending operation is responsible for the exceptional performance of the 2-D single-crystal film FENGs. Because all of the crystal lattices in the single-crystal film are aligned in a regular pattern, a high cumulative polarization potential can be created to facilitate the directed separation of positive charges and electrons (Fig. 4a), which is high enough to easily overcome the Schottky barriers formed by the electrodes on both sides. As demonstrated in Fig. 4b, the valence band maximum (VBM) of the 2-D p-Cu2O single-crystal film (0.47 VRHE) is exactly between the Fermi levels of ITO (0.2 VRHE) and Pt (1.15 VRHE), forming two interface Schottky electric fields. The Schottky barriers can effectively block the reverse moving carriers, thus obtaining unidirectional DC output.

a Schematic showing the accumulated flexoelectric built-in electric field formed in the 2-D p-Cu2O single-crystal film FENGs. b Band structure and the Schottky barriers in the (111)-oriented 2-D single-crystal film FENGs. c Durability at bending angle: 30°, 60°, and 90° with interval of 3 s, respectively. Inset: Current density-voltage (J-V) curve and the corresponding power density of the device at bending angle of 90°. d Practical applications of the (111)-oriented 2-D single-crystal film FENGs/sensors as the motion of human joints.

Through J-V curve scanning, the instantaneous output power of different load resistors can be accurately calculated. As plotted in the inset of Fig. 4c, with a load resistance of ~220 kΩ, the output power density reached the peak value of ~14.4 μW·cm−2, which is several orders of magnitude higher than those of traditional 1-D PENGs. Table 1 compares this work with other one-component PENGs in previous publications. It is not difficult to see that the 2-D p-Cu2O single-crystal thin film DC FENGs possess the longest signal width and the highest power density so far. On this basis, we believe that realizing 2-D monocrystallization of the nanogenerators is the trend and effective solution to derive better performance in future research. On the other hand, we also found that the performance is orientation-dependent. The (111)-oriented single-crystal film FENGs were superior to the (100)-oriented single-crystal film FENGs in the responses of c-AFM (Supplementary Fig. 6), KPFM (Supplementary Fig. 7), and output characteristics (Supplementary Table 1).

The output persistence was investigated by tracking the maximum power point of the 2-D single-crystal film DC FENGs under the condition of repeated strain durability, both the strain holding time and the interval time were 3 s during one cycle with different bending angles (30°, 60°, and 90°), which can continuously export 0.14, 1.2, and 14.4 μW·cm−2, respectively, in a total test of 3000 s (Fig. 4c). The chemical and mechanical durability of the 2-D single-crystal film DC FENGs was confirmed by the stable output signals within a narrow fluctuation range (±5%) and the intact film structures (Supplementary Fig. 8). Furthermore, the flexoelectric response tests with extended strain holding times of 50 and 100 s are presented in Supplementary Fig. 9, indicating that the output signals still maintain good continuity and intensity. Finally, we verified the practical application potential of the 2-D p-Cu2O single-crystal film FENGs, as illustrated in Fig. 4d, the FENGs can not only drive low-power electrical appliances, but can also detect joint movement and generate electrical waveforms in proportion to joint curvature. Apparently, the FENGs can be used as nanogenerators, as well as motion sensors.

In conclusion, we developed a controllable 2-D single-crystal film growth technique for p-Cu2O, followed by constructing the first 2-D single-crystal film FENGs. This work breaks through the traditional cognition and reveals that polarization field direction is closely related to the output characteristics, especially the signal continuity. The accumulated flexoelectric built-in electric field formed in the 2-D p-Cu2O single-crystal film FENGs is consistent with the output direction in the curved state, leading to a continuous, stable and high-power density of 14.4 μW·cm−2. Based on our results, the concept for the constant power FENGs has been methodically established. The comparative analysis demonstrates that the 2-D p-Cu2O single-crystal film FENGs can not only outperform conventional single-component PENGs but also offer substantial application potentials in the development of continuous power generators and motion behavior tracers.

Methods

Preparation

The newly designed 2-D single-crystal film DC FENGs use 125 μm-thick PET as the flexible substrate with ITO (5 Ω/sq) as the conductive layer on one side. The growth technology of the single-crystal films can refer to our previous research papers. In brief, after polishing and cleaning the conductive substrates, the directionally grown p-Cu2O single-crystal films were obtained by in-situ electrochemical deposition method33,34,36,37. Different from the previous studies, we found that the crystal orientations of the single-crystal films can be artificially adjusted under specific growth conditions. For the growth of the (100)-oriented 2-D p-Cu2O single-crystal films, the electrolyte was preferably 0.2 M CuSO4 (ALADDIN), 18 mM sodium tetraborate (MACKLIN) and 1.2 M sodium lactate (ALADDIN) in deionized water, whose pH was adjusted to 8.5 by dropwise adding NaOH (1 M). On the other hand, the (111)-oriented 2-D p-Cu2O single-crystal films were grown in the electrolyte containing 0.2 M CuSO4 (ALADDIN) and 1.2 M sodium lactate (ALADDIN) in deionized water, whose pH was adjusted to 12 by dropwise adding NaOH (1 M). As the temperature has a great influence on the crystal growth, constant temperature water bath was used to control the growth temperature to 20 °C under real-time monitoring. After washing, the as-fabricated devices were rapidly dried in high-pressure Argon flow and transferred into a desiccator. Afterwards, the metal electrodes were deposited with a DC magnetron sputtering machine (Remoulded HM-MS200) using ∅50 mm Pt target (purity: 99.9%). The vacuum chamber was pre-pumped to a base pressure of 1.0 × 10−4 Pa before deposition. Followed by charging high-purity Argon as working gas and keeping a constant working pressure of 0.3–0.5 Pa. The dimension of the as-fabricated 2-D p-Cu2O single-crystal film FENGs was 2 × 2 cm. Before encapsulation, the conductive copper tapes were partially pasted on the Pt electrode surface to draw out the voltage and current signals. In the end, the 2-D p-Cu2O single-crystal film FENGs were encapsulated with Kafuter genuine K-705 RTV silicone rubber electronic glue sealant transparent organosilicon in the atmospheric environment.

Characterization and measurements

X-ray diffraction (XRD) patterns were recorded with a Shimadzu XRD-6000 diffractometer, with a Cu Kα X-Ray source. Surface morphologies were observed with a HITACHI Regulus-8100 field-emission scanning electron microscopy (SEM) at an acceleration voltage of 15 kV. X-ray photoelectron spectroscopy (XPS) and ultraviolet photoelectron spectroscopy (UPS) were acquired by Shimadzu XPS spectrometer (AXIS Ultra DLD), and the XPS spectra were calibrated by using the C 1 s at 284.6 eV, to confirm the chemical states. A He I (21.22 eV) light source was used as the UPS excitation source. UV-Visible-Near infrared (UV-VIS-NIR) absorption spectra were measured with a METASH UV-8000 spectrometer equipped with an integrating sphere. The electrical output characteristics of the devices were measured by using CHI660E workstation (CH Instruments, Inc.) and Keithley 2400 sourcemeter. Hall Measurement System (Ecopia, HMS-3000) was used to determine the carrier concentration and mobility. The atomic force microscope (AFM) images were obtained with tapping mode by CSPM5500A cantilever probe. An NTE-GRA PRIMA (NT-MDT) instrument captured piezoresponse force microscopy (PFM), conductive atomic force microscopy (c-AFM) c-AFM and Kelvin probe force microscope (KPFM) data. The piezoelectric coefficients were measured by a d33 PiezoMeter System (LC2730A). The flexoelectric coefficient measurements were carried out at room temperature by using a home-made cantilever-based experimental apparatus. Strain gradient was generated in the samples along the thickness direction by an automatically slice. A MicroStrain DVRT transducer was used to measure the displacement along the films. The resultant current was monitored by the lock-in amplifier.

Density functional theory (DFT) calculations

To state the electron density property, the periodic DFT calculations were operated using Cambridge Serial Total Energy Package (CASTEP), and some detailed calculation processes can be found in our previous work. The geometry optimization was carried out using Generalized Gradient Approximation (GGA) to describe the exchange and correlation potential implemented by Perdew-Burke-Ernzerhof (PBE). The ultrasoft pseudopotential was used for geometry optimization and properties calculation. The Cu2O {111} and Cu2O {100} layers were completely relaxed when calculating the crystal surface energy band. The electronic configuration of the different components is as follows: Cu: [Ar] 3s23p63d94s2, O: [Ne] 2s22p4. The cutoff energy was set as 400 eV in the calculation. The convergence criteria were selected as follows: 1.0 e−5 eV atom−1 of energy, 0.03 eV Å−1 of force, 0.05 GPa of stress, and 1.0 × 10−3 Å of displacement. A vacuum slab of 20 Å was employed for the structure optimization and properties calculations. The Monkhorst-Pack mesh was optimized by utilizing k-points 3 × 3 × 1 and monitoring the total energy of the system. The top of the valence band of the Cu2O {111} crystal plane and the Cu2O {100} crystal plane is mainly contributed by Cu 3d.

Analysis of deformation and stress

The ANSYS Workbench Static Structural 19.2 was used to illustrate the bending stress and the force-to-strain response of the 1-D nanowires and the 2-D single-crystal films. For the 2-D single-crystal film FENGs, a plate structure model was adopted, and a tetrahedral mesh was applied to the overall structure, adopting adaptive dimension, high smooth quality, fine spanangle center and size resolution of 7. The mesh was optimized by using the element size of 1.0 e−2 cm. The geometric center changes of the positive and negative charges during the deformation of the 1-D and 2-D PENGs/FENGs were analyzed by Creo 4.0. For the 2-D single-crystal film FENGs, the geometric centers of positive and negative charges in the bend state were determined according to the PRT0016 coordinate frame.

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

The codes supporting the results during the current study are available from the corresponding author on reasonable request.

References

Wang, Z. & Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 312, 242–246 (2006).

Shehzad, M., Wang, S. & Wang, Y. Flexible and transparent piezoelectric loudspeaker. npj Flex. Electron. 5, 24 (2021).

Nguyen, T., Mao, S., Yeh, Y.-W., Purohit, P. & McAlpine, M. Nanoscale flexoelectricity. Adv. Mater. 25, 946–974 (2013).

Guo, P. et al. Mechanical modulation of 2D electronic devices at atto-Joule energy via flexotronic effect. Adv. Funct. Mater. 32, 2202779 (2022).

Wang, L. et al. Flexoelectronics of centrosymmetric semiconductors. Nat. Nanotechnol. 15, 661–667 (2020).

Gaur, A., Tiwari, S., Kumar, C. & Maiti, P. Flexible, lead-free nanogenerators using poly(vinylidene fluoride) nanocomposites. Energy Fuels 34, 6239–6244 (2020).

Jiang, X., Huang, W. & Zhang, S. Flexoelectric nano-generator: materials, structures and devices. Nano Energy 2, 1079–1092 (2013).

Cao, X. et al. Piezoelectric nanogenerators derived self-powered sensors for multifunctional applications and artificial intelligence. Adv. Funct. Mater. 31, 2102983 (2021).

Briscoe, J. & Dunn, S. Piezoelectric nanogenerators—a review of nanostructured piezoelectric energy harvesters. Nano Energy 14, 15–29 (2015).

Hu, D. et al. Strategies to achieve high performance piezoelectric nanogenerators. Nano Energy 55, 288–304 (2019).

Rajeevan, S., John, S. & George, S. C. Polyvinylidene fluoride: a multifunctional polymer in supercapacitor applications. J. Power Sources 504, 230037 (2021).

Wang, Y., Zhu, Y., Gu, H. & Wang, X. Enhanced performances of n-ZnO nanowires/p-Si heterojunctioned pyroelectric near-infrared photodetectors via the plasmonic effect. ACS Appl. Mater. Interfaces 13, 57750–57758 (2021).

Cao, X. et al. Piezoelectric nanogenerators derived self‐powered sensors for multifunctional applications and artificial intelligence. Adv. Funct. Mater. 31, 2102983 (2021).

Sengupta, D. et al. Single and bundled carbon nanofibers as ultralightweight and flexible piezoresistive sensors. npj Flex. Electron. 4, 9 (2020).

Kumar, B. et al. Controlled growth of semiconducting nanowire, nanowall, and hybrid nanostructures on graphene for piezoelectric nanogenerators. ACS Nano 5, 4197–4204 (2011).

Bai, S. et al. Two dimensional woven nanogenerator. Nano Energy 2, 749–753 (2013).

Iqbal, S., Mahgoub, I., Du, E., Leavitt, M. & Asghar, W. Advances in healthcare wearable devices. npj Flex. Electron. 5, 9 (2021).

Gupta, M. K., Lee, J. H., Lee, K. Y. & Kim, S. W. Two-dimensional vanadium-doped ZnO nanosheet-based flexible direct current nanogenerator. ACS Nano 7, 8932–8939 (2013).

Kim, K. H. et al. Piezoelectric two-dimensional nanosheets/anionic layer heterojunction for efficient direct current power generation. Sci. Rep. 3, 2017 (2013).

Zelenovskii, P. et al. 2D layered dipeptide crystals for piezoelectric applications. Adv. Funct. Mater. 31, 2102524 (2021).

Yang, R., Qin, Y., Dai, L. & Wang, Z. Power generation with laterally packaged piezoelectric fine wires. Nat. Nanotechnol. 4, 34–39 (2009).

Xu, S. et al. Self-powered nanowire devices. Nat. Nanotechnol. 5, 366–373 (2010).

Kim, S. K. et al. Directional dependent piezoelectric effect in CVD grown monolayer MoS2 for flexible piezoelectric nanogenerators. Nano Energy 22, 483–489 (2016).

Tan, D. et al. Piezoelectricity in monolayer MXene for nanogenerators and piezotronics. Nano Energy 90, 106528 (2021).

Li, Y. et al. Preparation strategies of p-type cuprous oxide and its solar energy conversion performance. Energy Fuels 35, 17334–17352 (2021).

Wang, K., Yang, D., Wu, C., Shapter, J. & Priya, S. Mono-crystalline perovskite photovoltaics toward ultrahigh efficiency? Joule 3, 311–316 (2019).

Jiang, B., Sun, J. & Liu, Z. Synthesis of graphene wafers: from lab to fab. Acta Phys. Chim. Sin. 0, 2007068–2007060 (2020).

Minemawari, H. et al. Inkjet printing of single-crystal films. Nature 475, 364–367 (2011).

De Bastiani, M. et al. Efficient bifacial monolithic perovskite/silicon tandem solar cells via bandgap engineering. Nat. Energy 6, 167–175 (2021).

Vlassiouk, I. V. et al. Evolutionary selection growth of two-dimensional materials on polycrystalline substrates. Nat. Mater. 17, 318–322 (2018).

Zhang, R. et al. Wafer-scale epitaxy of flexible nitride films with superior plasmonic and superconducting performance. ACS Appl. Mater. Interfaces 13, 60182–60191 (2021).

Galsin, J. S. Solid State Physics, Ch. 14 (Academic Press, 2019).

Li, Y., Yun, X., Chen, H., Zhang, W. & Li, Y. Facet-selective charge carrier transport, deactivation mechanism and stabilization of a Cu2O photo-electro-catalyst. Phys. Chem. Chem. Phys. 18, 7023–7026 (2016).

Li, Y. et al. A new concept and strategy for photovoltaic and thermoelectric power generation based on anisotropic crystal facet unit. Adv. Funct. Mater. 30, 2002606 (2020).

Li, Y. et al. Cuprous oxide single-crystal film assisted highly efficient solar hydrogen production on large ships for long-term energy storage and zero-emission power generation. J. Power Sources 527, 231133 (2022).

Li, Y., Zhong, X., Luo, K. & Shao, Z. A hydrophobic polymer stabilized p-Cu2O nanocrystal photocathode for highly efficient solar water splitting. J. Mater. Chem. A 7, 15593–15598 (2019).

Li, Y. & Luo, K. Performance improvement of a p-Cu2O nanocrystal photocathode with an ultra-thin silver protective layer. Chem. Commun. 55, 9963–9966 (2019).

Rubino, A., Zanoni, R., Schiavi, P. G., Latini, A. & Pagnanelli, F. Two-dimensional restructuring of Cu2O can improve the performance of nanosized n-TiO2/p-Cu2O photoelectrodes under UV-visible light. ACS Appl. Mater. Interfaces 13, 47932–47944 (2021).

K, K. M. et al. Novel boron-doped p-type Cu2O thin films as a hole-selective contact in c-Si solar cells. ACS Appl. Mater. Interfaces 12, 12972–12981 (2020).

Luo, Z. et al. Cu2O as a promising cathode with high specific capacity for thermal battery. J. Power Sources 448, 227569 (2020).

Lee, Y. et al. Direct-current flexible piezoelectric nanogenerators based on two-dimensional ZnO nanosheet. Appl. Surf. Sci. 509, 145328 (2020).

Wu, W. et al. Piezoelectricity of single-atomic-layer MoS2 for energy conversion and piezotronics. Nature 514, 470–474 (2014).

Han, S. A. et al. Point-defect-passivated MoS2 nanosheet-based high performance piezoelectric nanogenerator. Adv. Mater. 30, 1800342 (2018).

Fuh, Y. K., Kuo, C. C., Huang, Z. M., Li, S. C. & Liu, E. R. A transparent and flexible graphene-piezoelectric fiber generator. Small 12, 1875–1881 (2016).

Zhou, Y.-X. et al. Tungsten disulfide nanosheets for piezoelectric nanogenerator and human-machine interface applications. Nano Energy 97, 107172 (2022).

Khan, H. et al. Liquid metal-based synthesis of high performance monolayer SnS piezoelectric nanogenerators. Nat. Commun. 11, 3449 (2020).

Song, H. et al. Lead iodide nanosheets for piezoelectric energy conversion and strain sensing. Nano Energy 49, 7–13 (2018).

Acknowledgements

This work has been supported by National Natural Science Foundation of China (No. 21606171), China Postdoctoral Science Foundation (No. 2021M691326, 2015M580205, and 2017T100160), Natural Science Foundation of Jiangsu Province (BK20211345), and Independent Innovation Foundation of Tianjin University (1705). We want to particularly thank Prof. Zhonglin Wang for the consultation and guidance by e-mail.

Author information

Authors and Affiliations

Contributions

Y.L. conceived the idea and wrote the manuscript. Q.Z. and J.W. were primarily responsible for the experiments and analyzed the data. W.S. directed the characterization and the DFT calculations. J.X., C.S., and D.C. carried out the experimental guidance and manuscript revision. J.X. and Z.S. supervised this project. All authors discussed the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, Y., Zhou, Q., Wu, J. et al. Controllably grown single-crystal films as flexoelectric nanogenerators for continuous direct current output. npj Flex Electron 6, 88 (2022). https://doi.org/10.1038/s41528-022-00223-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-022-00223-2