Abstract

Addition and ring-opening metathesis polymerizations of new monomers (Me3Si- and Me3Ge-substituted tricyclononene and tricyclononadienes) were studied. Addition polymerization was carried out on Pd- and Ni-catalyst systems activated by B(C6F5)3 and/or methylalumoxane. New addition polymers were obtained with good yields up to 70% and with molecular weights (Mw) up to 5.6 × 105. Metathesis polymerization was performed using the first-generation Grubbs catalyst. The yields of the first obtained metathesis polymers were higher than 80%, and the Mw values were up to 8.8 × 105. It was revealed that the cyclobutene double bond in the studied tricyclononadienes is inactive in both metathesis and addition polymerizations. The relative activities of the substituted tricyclononene-7 and the corresponding tricyclononadiene-3,7 in the metathesis copolymerization were defined using 1H NMR spectroscopy. It was found that the novel addition polymer poly[(3-trimethylgermyl)tricyclononene-7] possesses high gas-transport parameters (for example, P(O2)=660 Barrers, P(CO2)=3850 Barrers) and solubility-controlled permeation of gaseous hydrocarbons (α (n-C4H10/CH4)=17.3).

Similar content being viewed by others

Introduction

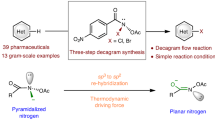

Norbornene is known as a very interesting monomer capable of being polymerized via a variety of methods. The polymerization of norbornene derivatives opens the possibility for the synthesis of a wide range of materials possessing useful properties, such as high optical transparency, excellent permittivity, strong thermal stability and unusual transport properties.1, 2 The introduction of different side-groups into a monomer unit can reveal new properties of polynorbornenes. However, the presence of substituents in norbornene monomers negatively affects their activities in metathesis3 and, especially in addition polymerization.4 The reactivities of endo- and exo-substituted norbornenes in polymerization are usually very different. It was shown that exo-substituted norbornenes are more active in polymerization than endo- ones.4 However, the synthesis methods for norbornene derivatives tend to produce mixtures of isomers with a predominant endo-isomer presence.5 One of the possible ways to synthesize exclusively exo-norbornenes is through the reaction of a [2σ+2σ+2π]-cycloaddition of quadricyclane with olefins (Scheme 1). This reaction results in only exo-tricyclononenes, where the cyclobutane ring is only in the exo-position and the substituents are distanced by one extra C-C bond from the double bond compared with the corresponding norbornenes.6, 7

Tricyclononenes contain a norbornene fragment and can therefore be polymerized according to the typical schemes for norbornenes (Scheme 2).3, 8

The advantages of using exo-tricyclononenes instead of their norbornene analogues in polymerization have been established.9, 10 For example, it has been shown that tricyclononenes with two Me3Si-groups are highly active in addition polymerization due to the absence of an endo-isomer and due to the greater distance between bulky substituents and the double bond,10 whereas norbornenes bearing two bulky Me3Si-groups do not undergo addition polymerization. The obtained addition polytricyclononenes with one or two Me3Si-groups per monomer unit belong to the class of highly permeable polymers and can be considered promising polymer materials for gas separation.8, 10

Although the synthesis of a wide range of tricyclononenes is described in literature,6, 7, 8, 9, 10 their polymerization has been poorly studied. A few examples of the metathesis and addition homo- and copolymerizations of substituted tricyclononenes have been discussed,8, 9, 10, 11, 12, 13, 14, 15, 16 but the addition polymerization of substituted tricyclononadienes has not been published at all. Additionally, the polymerization of Si-substituted tricyclononenes was described for only four monomers (5–8, Figure 1), and there were no data about the polymerization of Ge-containing tricyclononenes/tricyclononadienes.

In this work, we explored for the first time the addition and metathesis polymerizations of the new Me3Si- and Me3Ge-substituted tricyclononene and tricyclononadienes (Figure 1) and studied the properties of the resulting polymers. Additionally, the influence of the second double bond in a monomer was investigated in regard to its behavior during polymerization. The resultant polymers could be of interest for investigating the relations between polymer structures and properties (for example, gas permeability).

Experimental Procedure

Materials

All manipulations involving air- and moisture-sensitive compounds were carried out under dried and purified argon using standard Schlenk and vacuum-line techniques. Toluene and C6D6 were dried over sodium metal and then distilled under argon. All monomers were stored under argon. Pd(OAc)2 was received from Fluka (Buchs, Switzerland) and B(C6F5)3 was purchased from Sigma-Aldrich (Schnelldorf, Germany) as individual powders and were then used as toluene solutions (0.007 and 0.1 M, respectively). Nf2Ni was received from a Synthetic Rubber plant in Yefremov (Russia) and was used as a 0.04 M toluene solution. Methylalumoxane (MAO) (Sigma-Aldrich) was used as a commercial 1.4 M solution in toluene. The Grubbs first-generation catalyst was received from Sigma-Aldrich and was used as a 0.004 M solution in toluene. 2,2′-Methylenebis(6-tert-butyl-4-methylphenol) was received from Sigma-Aldrich and was used without any purification. 3-Trimethylsilyltricyclononene-7 (5),10 3,4-bis(trimethylsilyl)tricyclononene-7 (Gringolts et al.9) and monomers 1–4 (Bulgakov et al.18) were obtained as described earlier.

Methods of polymer characterization

NMR spectra were recorded on a Bruker MSL-300 spectrometer (Bruker AXS GmbH, Karlsruhe, Germany) operating at 300 MHz for 1H and on a Varian Unity Inova AS500 spectrometer (Varian, Palo Alto, CA, USA) operating at 125 MHz for 13C. Each polymer sample was dissolved in CDCl3 up to a concentration of 10%. For high-resolution solid-state 13C measurements, conventional CP/MAS 13C NMR was performed at 125 MHz and at 25 °C using a Varian Unity Inova AS500 spectrometer equipped with a solid-state high-resolution apparatus. The rotors that contained the polymer samples were spun at ∼15 kHz and the 90° pulse, the contact and repetition times were 3.5 μs, 2 ms and 2 s. 13C chemical shifts were calibrated using the carbonyl carbon resonance of glycine at 176.03 p.p.m. as an external reference and converted to the values for tetramethylsilane. Gel-permeation chromatography analysis of the polymers was performed on a Waters system with a differential refractometer (Waters, Milford, MA, USA) (Chromatopack Microgel-5, toluene as the eluent, flow rate of 1 ml min−1). The molecular weight and polydispersity were calculated using the standard procedure relative to monodispersed polystyrene standards. Differential scanning calorimetry was performed on a Mettler TA4000 system (Mettler, Schwerzenbach, Switzerland) with a heating rate of 20 °C per minute. Thermal gravimetric measurements (TGA) were carried out using a Perkin-Elmer TGA-7 instrument (Perkin-Elmer, Waltham, MA, USA). A wide-angle X-ray scattering (WAXS) study was carried out using an instrument with a two-coordinate AXS detector (Bruker) and the Cu KR line (wavelength of 0.154 nm). The residual metal content in the polymers was determined by Inductively Coupled Plasma Atomic Emission.

Film casting

Films of the studied polymers were cast from 1.5–2 weight % solution in toluene. The solution was poured into a steel cylinder with a stretched cellophane base. The solvent was allowed to evaporate slowly, yielding the desired polymer film. After the film’s formation, the cellophane was wetted to detach the film from it. Before testing, the films were kept under reduced pressure until they reached a constant weight (∼1 week). The thicknesses of the films were in the range of 80–100 μm.

Gas-permeation measurements

The permeability coefficients of the polymers were determined using the gas chromatographic method. A steady stream of penetrant gases under atmospheric pressure flew across the upstream part of the film, whereas the downstream part was flown over by a gas-carrier, that is, helium or nitrogen (the latter for the measurement of the permeation rate of H2 and He). The permeability coefficients were determined by measuring the penetrant concentration in the gas-carrier and the total flow of this mixture. The partial pressure of the penetrants was 1 atm in the upstream part of the cell and close to zero in the downstream part. The temperature in the cell was 20–22 °C.

Metathesis polymerization

In the typical procedure (the example given is for the ratio of monomer 1/catalyst=3000/1), the monomer (0.41 g, 2.16 mmol), toluene (1.5 ml) and 0.004 M toluene solution of the first-generation Grubbs catalyst (0.18 ml, 7.2 × 10−4 mmol) were charged into a round-bottomed glass ampoule (10 ml) equipped with a magnetic stirrer under an inert atmosphere. The polymerization was stopped by the addition of 0.05 ml of ethylvinyl ether after 2 h. The polymers were precipitated in a 0.1% ethanol solution of an antioxidant (2,2′-methylenebis(6-tert-butyl-4-methylphenol)), decanted, washed with several portions of the same solution and dried under reduced pressure. The polymer was twice reprecipitated in ethanol from a toluene solution and dried under reduced pressure at 50 °C until it reached a constant weight. The yield was 92%, Mw=8.8 × 105 and Mw/Mn=1.7.

Activity measurement in metathesis copolymerization

Equal amounts of monomers 1 (40.1 mg, 0.21 mmol) and 5 (40.1 mg, 0.21 mmol) and 0.50 ml of C6D6 were placed into a Young NMR tube. The mixture was degassed three times before the solution of the Grubbs first-generation catalyst in C6D6 (4.0 mM, 0.2 ml) was quickly added to the frozen reaction mixture. The mixture was melted, mixed and immediately put into the NMR-spectrometer. The monomers’ activities were established by comparing the integrations of the resonances corresponding to the protons of the monomers’ double bonds.

Poly[3-(trimethylsilyl)tricyclononadiene-3,7]

1H NMR δ (300 MHz, CDCl3): 6.56–6.42 (m, 1H, C(4)H), 5.42–5.14 (m, 2H, C(7)H, C(8)H), 3.18–2.93 (m, 2H), 2.80–2.64 (m, 0.7H), 2.44–2.17 (m, 2.3H), 1.68–1.47 (m, 1H) 0.04 (broaded singlet (br. s), 9H, Si(CH3)3). 13C NMR δ (125 MHz, CDCl3): 157.56 (C(3)), 150.16 (C(4)), 133.58 (C(7), C(8)), 56.98, 55.58 (C(1), C(6)), 43.65–40.00 (C(2), C(5)), 37.99, (C(9)), –1.74, (Si(CH3)3). Analysis calculated for (C12H18Si): C 75.71%, H 9.53%. Found: C 76.01%, H 9.82%.

Poly[3-(trimethylgermyl)tricyclononadiene-3,7]

1H NMR δ (300 MHz, CDCl3): 6.48–6.31 (m, 1H, C(4)H), 5.40–5.18 (m, 2H, C(7)H, C(8)H), 3.22–2.98 (m, 2H), 2.78–2.63 (m, 0.7H), 2.47–2.15 (m, 2.3H) 0.17 (br. s, 9H, Ge(CH3)3). Analysis calculated for (C12H18Ge): C 61.36%, H 7.72%. Found: C 61.80%, H 7.61%.

Poly[3,4-bis(trimethylsilyl)tricyclononadiene-3,7]

1H NMR δ (300 MHz, CDCl3): 5.38–5.11 (m, 2H, C(7)H, C(8)H), 3.14–2.90 (m, 2H), 2.81–2.61 (m, 0.5H), 2.45–2.07 (m, 2.5H), 1.54 (1H), 0.06 (br. s, 18H, Si(CH3)3). 13C NMR δ (125 MHz, CDCl3): 169.90–169.17 (C(3), C(4)), 133.65–132.84 (C(7), C(8)), 58.26–57.50, 44.29–41.63 ((C(1), C(6)), C(2), C(5)), 38.76 (C(9)), –0.65, (Si(CH3)3). Analysis calculated for (C15H26Si2): C 68.62%, H 9.98%. Found: C 68.12%, H 10.11%.

Addition polymerization

In the typical procedure (the given example is for the ratio of monomer 3/Pd(OAc)2/B(C6F5)3/MAO=3000/1/150/400), the 0.007 M toluene solution of Pd(OAc)2 (0.14 ml, 9.7 × 10−4 mmol) and monomer (0.69 g, 2.91 mmol) were charged into a round-bottomed glass ampoule (10 ml) equipped with a magnetic stirrer under an inert atmosphere. The polymerization was initiated by the addition of the 0.1 M toluene solution of B(C6F5)3 (1.5 ml, 0.15 mmol) and MAO (1.4 M solution, 0.28 ml, 0.39 mmol). The reaction mixture was continuously stirred for 12 h at ambient temperature. The polymers were precipitated in acidic ethanol (ethanol:HCl=10:1), separated, washed with several portions of ethanol and dried under reduced pressure. The polymer was twice reprecipitated in ethanol from a toluene solution and dried under reduced pressure at 80 °C until it reached a constant weight. For the other catalytic systems, the typical procedure was similar with the relevant catalyst replacement. The yield was 68%, Mw=5.6 × 105 and Mw/Mn=2.6.

Poly[3-(trimethylgermyl)tricyclononene-7]

1H NMR δ (300 MHz, CDCl3): 3.25–0.60 (m, 11H, C(1)H, C(2)H, C(3)H, C(4)H, C(5)H, C(6)H2, C(7)H, C(8)H, C(9)H2), 0.10 (br. s, 9H, Ge(CH3)3). 13C NMR δ (125 MHz, CDCl3): 60.00–40.00, 33.00–20.00 (C(1), C(2), C(3), C(4), C(5), C(6), C(9)), −1.60, −4.21 (Ge(CH3)3). Analysis calculated for (C12H20Ge): C 60.84%, H 8.51%. Found: C 60.69%, H 8.75%.

Poly[3-(trimethylsilyl)tricyclononadiene-3,7]

1H NMR δ (300 MHz, CDCl3): 6.50–6.20 (m, 1H, C(4)H), 2.99–0.69 (m, 9H, C(1)H, C(2)H, C(3)H, C(4)H, C(5)H, C(6)H2, C(7)H, C(8)H, C(9)H2), 0.10 (br. s., 9H, Si(CH3)3).

Poly[3,4-bis(trimethylsilyl)tricyclononadiene-3,7]

1H NMR δ (300 MHz, CDCl3): 2.98–0.62 (m, 8H, C(1)H, C(2)H, C(3)H, C(4)H, C(5)H, C(6)H2, C(7)H, C(8)H, C(9)H2), 0.07 (br. s., 18H, Si(CH3)3).

Poly[(3,4-bis(trimethylsilyl))tricyclononadiene-3,7]

Obtained using (Pd(OAc)2/B(C6F5)3/MAO).

13C NMR (CP/MAS, δ): 168.2 (s, C(3), C(4)), 57.68–29.46 (m, C(1), C(2), C(5), C(6), C(7), C(8), C(9)), −0.33 (s, Si(CH3)3).

Results and Discussion

Metathesis polymerization

Ring-opening metathesis polymerizations (ROMP) of the monomers mentioned above (1–4, Figure 1) was performed using the Grubbs first-generation catalyst. All monomers appeared to be active during ROMP and the corresponding polymers were obtained for the first time. High yields (80–94%) and high molecular weights (Mw), up to 8.8 × 105, were achieved (Scheme 3, Table 1).

It is notable that in the case of tricyclononadienes, as we found in this work, only the norbornene double bond was active during ROMP, while the substituted double bond of the strained cyclobutene ring remained unchanged, as confirmed by 1H NMR (Figure 2). Soluble ROMP polymers containing additional double bonds not in the main chains were thus obtained.

The synthesized ROMP polytricyclononenes and polytricyclononadienes, containing the same number of Me3Si-groups per monomer unit, had similar glass transition temperatures (Tg), Table 1. The introduction of the second double bond in the tricycle fragment had little effect on the polymer chain flexibility. Additionally, the Tg of the synthesized poly(tricyclononadienes) were a little bit lower than those of the analogous poly(norbornadienes) described earlier15 (Tg=99 and 108 °C for mono-substituted). A similar difference between the Tg was observed for Me3Si-substituted polytricyclononenes and polynorbornenes (Tg=129°C and 167°C for vicinal bis-substituted monomers).8

It was also interesting to compare the relative activities of substituted tricyclononadienes with those of the similar tricyclononenes in ROMP copolymerization. For 3-trimethylsilyltricyclononene-7 (5) and 3-trimethylsilyltricyclononadiene-3,7 (1), the measurements of the relative activities in ROMP was performed using 1H NMR spectroscopy. The study showed that tricyclononene 5 was more active in copolymerization than tricyclononadiene 1 in the presence of the first-generation Grubbs catalyst (Figure 3). Bis-substituted tricyclononadiene (2) and the corresponding 3,4-bis(trimethylsilyl)tricyclononene (6) appeared to have similar reactivities during ROMP copolymerization. Such differences could be explained by the decreasing influence of the cyclobutene double bond on activity in ROMP due to shielding by the two Me3Si-groups. For the other monomers considered here, such experiments were impossible to perform because of overlapping signals between the protons in the monomers and the copolymer.

Addition polymerization

In our previous work,9, 10 we have developed some efficient Pd-containing catalyst systems for the addition polymerization of Si-substituted tricyclononenes. To carry out the addition polymerization of 1–4, we have used four catalyst systems: Nf2Ni/B(C6F5)3/MAO, Pd(OAc)2/B(C6F5)3, Pd(OAc)2/B(C6F5)3/MAO and Pd(OAc)2/MAO.

As shown before, the Ni-based catalyst systems did not appear to be as good for the polymerization of substituted tricyclononenes as they were for 5-(trimethylsilyl)norbornene.19 The most efficient catalyst for the addition polymerization of Me3Si-substituted tricyclononenes was Pd(OAc)2/B(C6F5)3.10 Previously, this catalyst enabled us to obtain high molecular weight polymers with good yields from mono- and bis(trimethylsilyl)tricyclononenes10 (Table 2). However, the catalyst system Pd/B(C6F5)3 appeared to not be sufficiently active in the addition polymerizations of tricyclononene 3 and tricyclononadienes 1, 2 and 4, which were studied for the first time in this work. Therefore, we combined this catalyst system with MAO, a third component. This improvement allowed us to obtain new high molecular weight addition polymers based on monomers 1–4 (Scheme 4). The summary of the polymerization data is presented in Table 2.

The data presented in Table 2 demonstrated that not only substituted tricyclononenes can be involved in addition polymerization but also that the considered tricyclononadienes can be involved as well. This polymerization is also interesting because the corresponding norbornadienes did not polymerize but only dimerized under the conditions of the addition polymerization.9

Substituted tricyclononenes turned out to be more active addition polymerization than the corresponding tricyclononadienes (Table 2). All of the obtained polymers had high molecular weights and had no Tg until the decomposition temperature.

For 3,4-bis(trimethylsilyl)tricyclononadiene-3,7, in the presence of catalyst systems containing B(C6F5)3, insoluble polymers were formed. The solid-state 13C NMR spectra of the prepared polymers confirmed the addition type structures (Figure 4); the signals of the norbornene double bond disappeared (140–130 p.p.m.). According to the WAXS data, the prepared polymers were amorphous (Figure 5, Table 3), and the WAXS patterns exhibited four peaks, in contrast with poly-6a, which only exhibited two peaks.10 The insolubility (in toluene, hexane, THF, chloroform, o-xylene) of poly-2a can be explained by the high density in the polymer molecular packaging caused by a high level of intermolecular order.

Polymerization of 2 using Pd(OAc)2/MAO resulted in a soluble addition polymer of low molecular weight with low yields. Individual B(C6F5)3 did not cause the polymerization of 2 or any transformations at all.

Literature concerning the synthesis and properties of polynorbornenes containing Ge-substituents is extremely limited,20 and there are no data on the synthesis of a Ge-containing addition polynorbornene. In this work, the detailed study of the properties of addition poly-3a was undertaken.

The addition poly-3a was amorphous (Figure 5b and Table 3). It gave a WAXS pattern with one peak, which is specific to conventional glassy polymers, for example, polysulfones.21 It is interesting to note that two peaks were observed for poly-5a(the Si-analogue of poly-3a), and the maximum of the poly-5a peaks was located at a smaller angle, indicating a larger intersegmental d-spacing (Table 3). Poly-3a demonstrated high thermal stability (Figure 6). The TGA studies showed that the decomposition of the polymer started at 270 °C in air and at ∼325 °C under inert atmosphere (Ar) (Figure 6a). The greater amount of residue after heating in air (7.6%) in comparison with the same process under argon (1.2%) can be explained by the formation of nonvolatile germanium compounds in the presence of oxygen. Poly-3a films had a very high transparency; this parameter was ∼90% in the 300- to 800-nm wavelength range and is comparable to the transparency of the industrial material TOPAS made by Celanese (Summit, NJ, USA) AG 92–94%.22

Membrane properties of the polymers

Saturated addition polynorbornenes are more attractive than their unsaturated metathesis analogues as materials for gas separation membranes. Moreover, the permeability of the former extremely exceeds that of the latter.8 The gas-permeation properties of the novel saturated addition poly-3a demonstrated relatively high permeability coefficients, though they are somewhat lower than the Pi values for its Me3Si analogue (Table 4). Conversely, the separation factors are higher (Table 5).

This novel polymer also displays so-called solubility-controlled permeation; its P(n-C4H10) value is higher than its P(CH4) value. Accordingly, the ideal separation factor α(n-C4H10/CH4) is much higher than the value observed for its Si-containing analogue. In fact, the observed value of 17.3 is among the highest reported for such permselectivity of polyacetylenes23 and addition polynorbornenes.8

Conclusions

The work reported the addition polymerization and ROMP of new trimethylsilyl- and trimethylgermyl-substituted tricyclononenes and tricyclononadienes. The studied monomers demonstrated high activity in polymerizations. The corresponding polymers were obtained with good yields and high molecular weights. The gas-permeation properties of the new addition poly[3-(trimethylgermyl)tricyclononene-7] were studied. It was found that this polymer possesses high permeability and permselectivity coefficients and belongs to the group of polymers with the highest permeability.

[2σ+2σ+2π]-cycloaddition of quadricyclane with olefins.

Polymerization of tricyclononenes.

ROMP polymerization of 3-(trimethylsilyl)tricyclononadiene-7.

The addition polymerization of 3-trimethylgermyltricyclononene (3).

References

Haselwander, T. F. A., Heitz, W., Krugel, S. A. & Wendorff, J. H. Polynorbornene: synthesis, properties and simulations. Marcomol. Chem. Phys. 197, 3435–3453 (1996).

Haselwander, Th. F. A., Heitz, W., Krugel, S. A. & Wendorff, J. H. Rigid random coils: rotationally confined chain molecules. Marcomolecules 30, 5345–5353 (1997).

Ivin, K. J. & Mol, J. C. Olefin Metathesis and Metathesis Polymerization 472 (Academic Press, London, 1997).

Hennis, A. D., Polley, J. D., Long, G. S., Sen, A., Yandulov, D., Lipian, J., Benedict, G. M., Rhodes, L. F. & Huffman, J. Novel, efficient, palladium-based system for the polymerization of norbornene derivatives: scope and mechanism. Organometallics 20, 2802–2812 (2001).

Kagan, H. B. & Riant, O. Catalytic asymmetric Diels-Alder reactions. Chem. Rev. 92, 1007–1019 (1992).

Tabushi, I., Yamamura, K. & Yoshida, Z. Regio- and stereospecific [2.pi.+2.sigma.+2.sigma.] cycloaddition reaction of quadricyclane. J. Am. Chem. Soc. 94, 787–792 (1972).

Petrov, V. A. & Vasil’ev, N. V. Synthetic chemistry of quadricyclane. Curr. Org. Synth. 3, 175–213 (2006).

Finkelshtein, E. Sh., Bermeshev, M. V., Grongolts, M. L., Starannikova, L. E. & Yampolskii, Yu. P. Substituted polynorbornenes as promising materials for gas separation membranes. Russ. Chem. Rev. 80, 341–361 (2011).

Gringolts, M. L., Bermeshev, M. V., Makovetsky, K. L. & Finkelshtein, E. Sh. Effect of substituents on addition polymerization of norbornene derivatives with two Me3Si-groups using Ni(II)/MAO catalyst. Eur. Polym. J. 45, 2142–2149 (2009).

Gringolts, M., Bermeshev, M., Yampolskii, Yu., Starannikova, L., Shantarovich, V. & Finkelshtein, E. New high permeable addition poly(tricyclononenes) with Si(CH3)3 side groups. synthesis, gas permeation parameters, and free volume. Macromolecules 43, 7165–7172 (2010).

Feiring, A. E., Crawford, M. K., Farnham, W. B., French, R. H., Leffew, K. W., Petrov, V. A., Schadt, F. L., Tran, H. V. & Zumsteg, F. C. Bis(fluoroalcohol) monomers and polymers: improved transparency fluoropolymer photoresists for semiconductor photolithography at 157 nm. Macromolecules 39, 1443–1448 (2006).

Feiring, A. E., Crawford, M. K., Farnham, W. B., Feldman, J., French, R. H., Junk, C. P., Leffew, K. W., Petrov, V. A., Qiu, Weiming, Schadt, F. L., Tran, H. V. & Zumsteg, F. C. New amorphous fluoropolymers of tetrafluoroethylene with fluorinated and non-fluorinated tricyclononenes. Semiconductor photoresists for imaging at 157 and 193 nm. Macromolecules 39, 3252–3261 (2006).

Sanders, D. P., Connor, E. F., Grubbs, R. H., Hung, R. J., Osborn, B. P., MacDonald, S. A., Willson, C. G. & Conley, W. Metal-catalyzed addition polymers for 157 nm resist applications. synthesis and polymerization of partially fluorinated, ester-functionalized tricyclo[4.2.1.02,5]non-7-enes. Macromolecules 36, 1534–1542 (2003).

Saunders, R. S. New polymers from ring-opening metathesis polymerization of quadricyclane adducts. Macromolecules 28, 4347–4349 (1995).

Gringol’ts, M. L., Bermeshev, M. V., Syromolotov, A. V., Starannikova, L. E., Filatova, M. P., Makovetskii, K. L. & Finkel’shtein, E. Sh. Highly permeable polymer materials based on silicon-substituted norbornenes. Petrol. Chem. 50, 352–361 (2010).

Gringolts, M. L., Bermeshev, M. V., Starannikova, L. E., Rogan, Yu. V., Yampol’skii, Yu. P. & Finkel’shtein, E.Sh Synthesis and gas separation properties of metathesis polynorbornenes with different positions of one or two SiMe3 groups in a monomer unit. Polym. Sci. Ser. A 51, 1233–1240 (2009).

Bermeshev, M. V., Syromolotov, A. V., Gringolts, M. L., Starannikova, L. E., Yampolskii, Y. P. & Finkelshtein, E. Sh. Synthesis of high molecular weight poly[3-{tris(trimethylsiloxy)silyl}tricyclononenes-7] and their gas permeation properties. Macromolecules 44, 6637–6640 (2011).

Bulgakov, B. A., Bermeshev, M. V., Demchuk, D. V., Lakhtin, V. G., Kazmin, A. G. & Finkelshtein, E. Sh. Synthesis of tricyclononenes and tricyclononadienes containing MX3-groups (M=C, Si, Ge; X=Cl, Me). Tetrahedron 68, 2166–2171 (2012).

Finkelshtein, ESh., Makovetskii, K. L., Gringolts, M. L., Rogan, Y. V., Golenko, T. G., Lakhtin, V. G. & Filatova, M. P. Addition polymerization of silyl-containing norbornenes in the presence of Ni-based catalysts. J. Mol. Catal. A Chem. 257, 9–13 (2006).

Finkelshtein, E. S., Portnykh, E. B., Ushakov, N. V., Gringolts, M. L. & Yampolsky, Yu. P. Synthesis of a new polymer — polycyclopentylenevinylene bearing Ge-containing group. Macromol. Chem. Phys. 198, 1085–1090 (1997).

Pixton, M. R. & Paul, D. R. in Polymeric Gas Separation Membranes (eds Paul D. R., Yampolskii Y. P.,) 83 (CRC Press, Boca Raton, FL, 1994).

Khanarian, G., Hoechst Celanese Optical properties of cyclic olefin copolymers. Opt. Eng. 40, 1024–1029 (2001).

Nagai, K., Masuda, T., Nakagawa, T., Freeman, B. D. & Pinnau, I. Poly[1-(trimethylsilyl)-1-propyne] and related polymers: synthesis, properties and functions. Progr. Polym. Sci. 26, 721–798 (2001).

Acknowledgements

We are grateful for support from the Ministry of Education and Science of the Russian Federation (GK No. 16.120.11.3056-MK, 16.740.11.338) and the Russian Foundation for Basic Research (Grant No. 12–08–00648-a). We thank Dr Boris Shklyaruk for the registration of WAXS and Professor Yuri Yampolskii for useful discussions on the gas-permeability study.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bermeshev, M., Bulgakov, B., Demchuk, D. et al. Metathesis and addition polymerization of novel Me3Si- and Me3Ge-substituted tricyclononenes. Polym J 45, 718–726 (2013). https://doi.org/10.1038/pj.2012.211

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2012.211

Keywords

This article is cited by

-

Metathesis and additive poly(tricyclononenes) with geminal trimethylsilyl side groups: chain rigidity, molecular and thin film properties

Journal of Polymer Research (2018)

-

Experimental and Theoretical Study of [2σ + 2σ + 2π]–Cycloaddition of Quadricyclane and Ethylenes Containing Three Silyl-Groups

Silicon (2015)

-

Structure-Sensitive Maxima in the Absorption Spectra of Polymers in the Terahertz Frequency Range

Radiophysics and Quantum Electronics (2015)