Abstract

This paper presents a successful synthesis of transparent organic–inorganic nanocomposites from poly(arylene ether ketone) (PAEK)-based matrix polymer and BaTiO3 nanoparticles. The dispersibility of nanoparticles was significantly improved by both the introduction of phosphonic acid moiety into the polymer chain and the organic modification of the nanoparticle surface. The structure of phosphonic-acid-modified PAEK polymer was studied by gel permeation chromatography, 31P nuclear magnetic resonance spectroscopy and X-ray fluorescence spectroscopy. Thermal properties of nanocomposites were studied by thermogravimetry and differential scanning calorimetry. Optical clarity of nanocomposites was evaluated by a hazemeter and regular transmittance spectroscopy. Dispersion of nanoparticles was also demonstrated by transmission electron microscopic observation. Fourier transform infrared analysis was carried out to investigate the interaction between the polymer matrix and nanoparticles. Refractive indices of the obtained transparent nanocomposites, which contain up to 44.1 wt% of nanoparticles, were measured. A high refractive index of 1.72 at 589 nm was achieved.

Similar content being viewed by others

Introduction

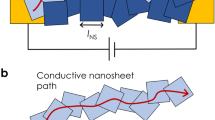

Nanocomposites of organic polymers and inorganic nanoparticles have been actively investigated as a new methodology of material design over the past several decades.1, 2, 3 It is of critical importance to control the dispersion state of nanoparticles to achieve the desired properties. With regard to optical properties, scattering at the interface of different materials, which generally have different refractive indices, causes a loss of transmitted light. Consequently, composites are usually opaque, even when both the matrix and the dispersed materials have no absorption in the visible region. According to Rayleigh's scattering law,4 when the dispersed nanoparticles are of a size sufficiently smaller than the wavelength of visible light, the scattering loss can be reduced and the resulting nanocomposites become transparent. The optical clarity is one of the defining features of nanocomposites over conventional composites. Nanocomposite methodology has been utilized to control the optical properties of polymer-based materials such as refractive index (RI),5, 6, 7, 8, 9, 10, 11 temperature dependence of RI8 or birefringence.12

We have previously reported the synthesis of transparent nanocomposites based on sulfonic-acid-modified poly(bisphenol A carbonate) and TiO2 or ZrO2 nanoparticles.11 Highly transparent nanocomposites were obtained with nanoparticle contents of up to 50 wt%. The resulting nanocomposites showed a high RI, n589 nm>1.7. However, it was found that the thermal degradation temperature severely decreased with increasing nanoparticle contents, which limited further consideration for practical applications. Hydrolytic degradation of poly(bisphenol A carbonate) was considered responsible for the deterioration. In this study, we attempted to synthesize high RI nanocomposites with better thermal stability by using poly(arylene ether ketone) (PAEK) as the matrix polymer. PAEK is an important class of high-performance thermoplastic polymers. Some types of PAEK are transparent in the visible region and have been studied as optical materials.13, 14, 15, 16, 17 PAEK is much more resistant to hydrolytic degradation than is poly(bisphenol A carbonate). Few syntheses of transparent nanocomposites with PAEK matrix have been reported.

BaTiO3 was used as a high RI inorganic material in this study. TiO2 with anatase phase has a higher n589 nm of approximately 2.54, but the photocatalytic activity of anatase may cause the decline of long-term stability of nanocomposite materials for optical applications. BaTiO3 is less photocatalytic than TiO2. In addition, it has an n589 nm of ∼2.40, which is higher than that of ZrO2 (n589 nm≈2.16). For these reasons, BaTiO3 was selected. Transparent nanocomposites were prepared by dispersing surface-modified BaTiO3 nanoparticles into the PAEK-based matrix. Phosphonic acid moiety was introduced into the PAEK chain to improve the dispersibility of nanoparticles. The optical and thermal properties of the resulting nanocomposites were studied.

Experimental procedure

Materials

Titania aqueous sol (STS-100) was purchased from Ishihara Sangyo (Osaka, Japan). Phosphoric acid 2-ethylhexyl ester (mono-, di-ester mixture) (PAEH) was purchased from Tokyo Kasei (Tokyo, Japan). All other chemicals were of reagent grade and used as received without further purification.

Synthesis of surface-modified BaTiO3 nanoparticles

Highly crystalline BaTiO3 nanoparticles were synthesized using a continuous-flow supercritical hydrothermal reactor. Details of the apparatus, reaction conditions and characterization of products were described elsewhere.18 Briefly, the reactant solution of 0.05 mol dm−3 titania aqueous sol and 0.06 mol dm−3 aqueous barium hydroxide was used as the starting material, which was treated in a flow-type reactor at 400 °C and 30 MPa for 7.8 ms. An aqueous dispersion of crystalline BaTiO3 nanoparticles with a mean diameter of 11 nm was obtained.

A 12-ml sample of aqueous dispersion of BaTiO3 nanoparticles was centrifuged at 1500 × g for 10 min. The same centrifugation condition was used thereafter. The precipitate was dispersed in acetone by ultrasonication and centrifuged, and the resulting precipitate was then re-dispersed into ethanol by ultrasonication. PAEH (0.12 ml) was added to the ethanol dispersion and agitated at 40 °C for 20 min, followed by centrifugation. The precipitate was dispersed into dichloromethane by ultrasonication. The centrifugation of the dichloromethane dispersion gave a small amount of precipitates, and the turbid supernatant was used for the following nanocomposite synthesis. The concentration of BaTiO3 nanoparticles in the supernatant dichloromethane was 2.9 w/v%.

Synthesis of phosphonic-acid-modified poly(arylene ether ketone)s

A solution was prepared of 19.8 mmol 2,2-bis(4-hydroxyphenyl)propane, 0.40 mmol 4-cumylphenol and 20.0 mmol 4,4′-difluorobenzophenone in 40 ml of N,N-dimethylacetamide under a dry N2 atmosphere. Next, 25.0 mmol of anhydrous potassium carbonate and 12 ml of toluene were added to the solution, and the mixture was then heated to azeotropically remove the remaining water. The resulting mixture was then maintained at 160 °C for 4 h. After being cooled to room temperature, the mixture was poured into acidified methanol. The precipitated product was collected by suction filtration, washed well with water and methanol and then dried under a vacuum. PAEK was obtained quantitatively.

PAEK (4 g) was dissolved in 28 ml of dichloroethane under a dry N2 atmosphere. Subsequently, 0.26 g of dimethoxymethane, 0.33 g of thionyl chloride and 20 μl of anhydrous tin(IV) chloride were added to the solution. The resulting mixture was stirred at 60 °C for 2 h. The solution was then poured into methanol, and the precipitated product was collected by suction filtration, washed well with methanol and then dried under a vacuum.

A solution was prepared by dissolving 3.4 g of the obtained partially chloromethylated PAEK in 20 ml of N,N-dimethylacetamide. To the solution was added 1.94 g of triethyl phosphite with stirring at 150 °C for 15 h. After being cooled to room temperature, the solution was poured into methanol, and the precipitated product was collected by suction filtration, washed well with methanol and then dried under a vacuum.

The resulting partially diethyl-phosphonomethylated PAEK was refluxed in concentrated aqueous HCl for 15 h. After being cooled to room temperature, the solution was poured into methanol, and the precipitated product was collected by suction filtration, washed well with deionized water and methanol and then dried under a vacuum.

Synthesis of nanocomposites

A certain amount of PAEK or phosphonic-acid-modified PAEK (PAEK-PA) was dissolved in the dichloromethane dispersion of PAEH-modified BaTiO3. The resulting mixture was cast onto a glass plate using a bar-coater and the solvent was allowed to evaporate. Nanocomposite films were peeled off from the glass plate and dried under a vacuum at 100 °C for 2 h.

Characterizations

Thermogravimetry (TG) was performed on a thermal analysis system (TAS200 TG8101D, Rigaku, Tokyo, Japan). Samples of approximately 10 mg were heated up to 800 °C at a rate of 10 °C min−1 under a dry air-flow of 100 ml min−1. Differential scanning calorimetry was performed on an Exstar DSC-6200 (Seiko Instruments, Chiba, Japan). Two heating and cooling cycles between 25 and 200 °C were recorded at a rate of 20 °C min−1 under a flow of N2 gas at 50 ml min−1. The second heating scan was used for the analysis of glass transition temperature. Fourier transform infrared (FT-IR) spectra were recorded on a Nicolet NEXUS470 spectrometer (Nicolet, Yokohama, Japan). Gel permeation chromatography was carried out on a Tosoh HLC-8220GPC (Tosoh, Tokyo, Japan) (TSKgel SuperHM-M column × 2) using chloroform as an eluent after calibration with standard polystyrene. 31P Nuclear magnetic resonance (31P NMR) spectra were recorded using a Bruker DSX300 (7.05 T) (Bruker, Yokohama, Japan). CDCl3 was used as the solvent, and H3PO4 in D2O was used as an external standard at 0 p.p.m. The concentration of phosphorus was determined using an X-ray fluorescent element analyzer (MESA-500, Horiba, Kyoto, Japan). Total luminous transmittance and haze values of nanocomposite films were measured using a haze turbidimeter (NDH2000, Nippon Denshoku Industries, Tokyo, Japan). Regular transmittance spectra of the nanocomposite films were measured on a JASCO V-570 spectrophotometer (Jasco, Tokyo, Japan) with an attached FLH-467 film holder. Ultrathin sections of the nanocomposite sample were cut using a Reichert-Nissei Ultracut N ultramicrotome (Reichert-Nissei, Tokyo, Japan) with a diamond knife and were observed on a transmission electron microscopy (JEOL 2000FX, Jeol, Tokyo, Japan) at an accelerating voltage of 100 kV. Refractive indices at 589 nm were measured using a multiwavelength Abbe refractometer (DR-M4, Atago, Tokyo, Japan).

Results and Discussion

Surface modification of BaTiO3 nanoparticles

Highly crystalline BaTiO3 nanoparticles with a mean diameter of 11 nm were used in this study. The details of the synthetic process using a continuous-flow supercritical hydrothermal reactor and the characterization of nanoparticles are documented elsewhere.18 The surface modification of BaTiO3 nanoparticles was carried out to improve dispersibility into polymeric matrices. In this study, PAEH was used as a surface-modifying agent. PAEH is a partial ester of phosphoric acid and can be expected to adsorb onto BaTiO3 through the phosphoric acid moiety. Adsorption of PAEH will render the BaTiO3 surface organophilic and thus improve compatibility with the hydrophobic PAEK matrix.

Phosphoric acid 2-ethylhexyl ester (mono-, di-ester mixture)-treated BaTiO3 nanoparticles could be stably dispersed in dichloromethane. No sedimentation was observed over several weeks. Dried powder was further analyzed by FT-IR and TG. The FT-IR spectra are shown in Figure 1. After modification, C–H stretching absorption peaks appeared in the 2800–3000 cm−1 region, indicating the adsorption of alkyl groups on nanoparticles. In addition, a shift was observed for the stretching vibration absorption of the P=O double bond in the 1000–1200 cm−1 region. The chemical environment of the phosphoric acid group was changed by the adsorption. These results suggest the adsorption of PAEH molecules onto the nanoparticle surface through phosphoric acid moiety.

The amount of adsorbed PAEH was estimated from TG analysis. Thermal weight loss of the PAEH-modified BaTiO3 was 8.3 wt%. Pure PAEH had a 7 wt% residue under the same TG conditions. Here, it was assumed that the percentage of residue from PAEH molecules adsorbed on the nanoparticle was the same as that of pure PAEH. Thus, the weight ratio of PAEH on PAEH-modified BaTiO3 was estimated to be 8.9 wt%. From this value, the average surface area occupied by a single PAEH molecule was calculated to be 0.41 nm2. This value suggests that the surface of nanoparticles was almost fully covered with a monolayer of PAEH.19

Phosphonic-acid-modified PAEK

Phosphoric acid 2-ethylhexyl ester (mono-, di-ester mixture) was synthesized by the polycondensation of difluorobenzophenone and 2,2-bis(4-hydroxyphenyl)propane. The number-average and weight-average molecular weights of the prepared PAEK were 78 700 and 143 000, respectively. To improve the interaction between nanoparticles and polymer matrix, phosphonic acid functionalities were introduced into the PAEK chain. The reaction scheme is depicted in Figure 2. First, the chloromethylation of PAEK was carried out by the reaction with in situ-generated chloromethylmethylether catalyzed by a Lewis acid.20 Next, the Arbusov reaction21 with triethyl phosphite and the subsequent hydrolysis resulted in PAEK-PA. The 31P NMR spectrum of PAEK-PA showed a single peak at 22.8 p.p.m., confirming the introduction of phosphonic acid moiety into the PAEK chain. However, the degree of introduction could not be determined from 1H or 13C NMR measurements because of the very low concentration. Phosphorus concentration was then measured by X-ray fluorescence to estimate the degree of introduction. The concentration of phosphorus atom in PAEK-PA was 0.16 wt%. The phosphonic-acid-equivalent molecular weight was calculated to be 19 800 g mol−1 phosphonic acid.

Compositions and thermal properties of nanocomposites

Nanocomposite films with different nanoparticle contents were prepared by the casting method from PAEH-modified BaTiO3 nanoparticles and PAEK-PA. Composite films with unmodified PAEK were prepared by the same method for comparison.

Thermogravimetry profiles of prepared samples are shown in Figure 3. Compositions of prepared films were calculated from the TG results and are summarized in Table 1. Temperatures of 5 wt% degradation (T5) are also listed. The addition of nanoparticles up to approximately 10 wt% increased the T5 temperature compared with the matrix polymer. However, nanoparticle contents of more than several tens of wt% caused a decrease in T5. The same trends were seen for both PAEK and PAEK-PA matrices. Although the detailed mechanism of thermal degradation is not currently clear, there is an optimal amount of nanoparticles from the viewpoint of T5.

Glass transition temperatures (Tg) were measured by differential scanning calorimetry and are also listed in Table 1. Tg values of nanocomposites using PAEK-PA decreased slightly with increasing amounts of nanoparticles. It has been reported that the addition of nanomaterials can induce either an increase or a decrease in Tg, depending on other factors such as the interaction between polymers and nanomaterials and the dispersion state.22, 23, 24, 25 The reduced Tg in the current system suggests that the interaction between the main chain of PAEK-PA and PAEH-modified BaTiO3 is not attractive and that their interface behaves in a manner similar to that of a free surface.22 Conversely, Tg values of composites using PAEK did not show such a decline. Nanoparticles were severely aggregated in the PAEK matrix, as discussed in the next section. The interface area between the polymer matrix and nanoparticles is small compared with the well-dispersed PAEK-PA nanocomposites. Therefore, the mobility of the polymer chain was not affected by nanoparticles.

Dispersibility of nanoparticles and optical properties of nanocomposites

The dispersibility of nanoparticles in the polymer matrix was evaluated in terms of the transparency of nanocomposite films with thicknesses of approximately 50 μm. A photograph of the representative samples is shown in Figure 4, which indicates that both samples were macroscopically homogeneous. PAEK-PA-based nanocomposites (NC3) were totally transparent, whereas PAEK-based composites (C2) were translucent. Quantitative evaluations of the transparency of samples were carried out using a hazemeter. The observed total luminous transmittance and haze values are plotted in Figure 5. When the unmodified PAEK was used as the matrix polymer, the clarity of composite films drastically deteriorated even with the small amount of nanoparticles, as indicated by the large decrease in total luminous transmittance and increase in haze values. It is believed that aggregated nanoparticles induce the substantial scattering loss of the transmitting visible light.

In contrast, transparent nanocomposite films were obtained with PAEK-PA. Relatively high total luminous transmittance and low haze values were maintained up to 44 wt% of nanoparticle contents. Introduction of phosphonic acid moiety significantly improved the dispersibility of BaTiO3 nanoparticles into the PAEK-based matrix polymer. However, transparency gradually decreased with larger amounts of nanoparticles. Therefore, optical clarity of PAEK-PA-based nanocomposites was also examined by regular transmission spectroscopy (Figure 6). Regular transmittance of nanocomposites decreased almost uniformly over the entire range of the visible region compared with PAEK-PA. This indicates that the decrease in transparency with increased nanoparticle contents is the result of scattering loss.

Dispersibility of nanoparticles in the PAEK-PA matrix was further confirmed by transmission electron microscopy observation. Figure 7 shows a transmission electron microscopy micrograph of NC3 that contains 44 wt% BaTiO3 nanoparticles in the PAEK-PA matrix. Good dispersion of nanoparticles can be observed.

Fourier transform infrared analysis was attempted to determine the interaction between the polymer matrix and nanoparticles. There was little difference between the FT-IR spectra of PAEK and PAEK-PA (Figures 8a and b). It was difficult to detect bands assignable to the phosphonic acid moiety owing to its very low concentration. In the FT-IR of NC2 (Figure 8c), absorption from BaTiO3 nanoparticles appears in the 400–700 cm−1 region. However, any other changes such as peak shifts or new peaks could not be detected in the 700–1800 cm−1 region, compared with PAEK-PA. No significant interaction exists between the PAEK-PA main chain and surface-modified BaTiO3. This result is consistent with differential scanning calorimetry analysis, as described above. Although it was difficult to obtain direct evidence of a chemical interaction between the phosphonic acid moiety of PAEK-PA and BaTiO3, the improved dispersibility in the PAEK-PA matrix indicates the validity of the introduction of the phosphonic acid moiety.

Measurement of RI was enabled as transparent nanocomposite films were obtained with the PAEK-PA matrix. The RI values of nanocomposites at 589 nm are plotted in Figure 9 as a function of the weight content of nanoparticles. The RI increased with increasing amounts of BaTiO3 and reached a value of 1.72.

Conclusions

Transparent nanocomposites were successfully synthesized from the phosphonic-acid-modified PAEK polymer matrix and surface-modified BaTiO3 nanoparticles. Differential scanning calorimetry and FT-IR analyses indicated that no attractive interaction existed between the PAEK main chain and the surface-modified BaTiO3. Introduction of phosphonic acid moiety into the PAEK chain significantly improved the dispersion of nanoparticles. The obtained nanocomposites showed a high RI of up to 1.72.

References

Mark, J. E. & Pan, S. J. Reinforcement of polydimethylsiloxane networks by in situ precipitation of silica—A new method for preparation of filled elastomers. Makromol. Chem. Rapid Commun. 3, 681–685 (1982).

Chujo, Y. & Saegusa, T. Organic polymer hybrids with silica-gel formed by means of the sol–gel method. Adv. Polym. Sci. 100, 11–29 (1992).

Novak, B. M. Hybrid nanocomposite materials—between inorganic glasses and organic polymers. Adv. Mater. 5, 422–433 (1993).

Bohren, F. B. & Huffman, D. R. Absorption and Scattering of Light by Small Particles (John Wiley & Sons, Inc., New York, USA, 1983).

Pope, E. J. A., Asami, M. & Mackenzie, J. D. Transparent silica gel–PMMA composites. J. Mater. Res. 4, 1018–1026 (1989).

Wang, B. & Wilkes, G. L. New Ti–PTMO and Zr–PTMO ceramer hybrid materials prepared by the sol gel method: synthesis and characterization. J. Polym. Sci.: Part B: Polym. Chem. 29, 905–909 (1991).

Lü, C., Cui, Z., Wang, Y., Li, Z., Guan, C., Yang, B. & Shen, J. Preparation and characterization of ZnS–polymer nanocomposite films with high refractive index. J. Mater. Chem. 13, 2189–2195 (2003).

Mataki, H., Yamaki, S. & Fukui, T. Nanostructured organic/inorganic composites as transparent materials for optical components. Jpn. J. Appl. Phys. 43, 5819–5823 (2004).

Nakayama, N. & Hayashi, T. Preparation and characterization of TiO2–ZrO2 and thiol-acrylate resin nanocomposites with high refractive index via UV-induced crosslinking polymerization. Composites: Part A 38, 1996–2004 (2007).

Liu, J. G., Nakamura, Y., Ogura, T., Shibasaki, Y., Ando, S. & Ueda, M. Optically transparent sulfur-containing polyimide–TiO2 nanocomposite films with high refractive index and negative pattern formation from poly(amic acid)–TiO2 nanocomposite film. Chem. Mater. 20, 273–281 (2008).

Imai, Y., Terahara, A., Hakuta, Y., Matsui, K., Hayashi, H. & Ueno, N. Transparent poly(bisphenol A carbonate)-based nanocomposites with high refractive index nanoparticles. Euro. Polym. J. 45, 630–638 (2009).

Tagaya, A., Ohkita, H., Mukoh, M., Sakaguchi, R. & Koike, Y. Compensation of the birefringence of a polymer by a birefringent crystal. Science 301, 812–814 (2003).

Li, X. D., Zhong, Z. X., Kim, J. J. & Lee, M. H. Novel photosensitive fluorinated poly(arylene ether) having zero birefringence. Macromol. Rapid Commun. 25, 1090–1094 (2004).

Qi, Y., Ding, J., Day, M., Jiang, J. & Callender, C. L. Cross-linkable highly fluorinated poly(arylene ether ketones/sulfones) for optical waveguiding applications. Chem. Mater. 17, 676–682 (2005).

Seesukphronrarak, S., Kawasaki, S., Kobori, K. & Takata, T. Synthesis of fluorene-based high performance polymers. I. Poly(arylene thioether)s with excellent solubility and high refractive index. J. Polym. Sci.: Part A: Polym. Chem. 45, 3073–3082 (2007).

Berti, C., Celli, A., Marianucci, E. & Vannini, M. Preparation and characterisation of novel random copoly(arylene ether–thioether ketone)s containing 2,2-bis(4-phenylene)propane units. Euro. Polym. J. 43, 2453–2461 (2007).

Ding, J., Jiang, J., Blanchetière, C. & Callender, C. L. Highly fluorinated aromatic–aliphatic copolyethers. Macromolecules 41, 758–763 (2008).

Matsui, K., Noguchi, T., Islam, N. M., Hakuta, Y. & Hayashi, H. Rapid synthesis of BaTiO3 nanoparticles in supercritical water by continuous hydrothermal flow reaction system. J. Cryst. Growth 310, 2584–2589 (2008).

Guerrero, G., Mutin, P. H. & Vioux, A. Anchoring of phosphonate and phosphinate coupling molecules on titania particles. Chem. Mater. 13, 4367–4373 (2001).

Wright, M. E., Toplikar, E. G. & Svejda, S. A. Details concerning the chloromethylation of soluble high molecular weight polystyrene using dimethoxymethane, thionyl chloride, and a Lewis acid: a full analysis. Macromolecules 24, 5879–5880 (1991).

Bhattacharya, A. K. & Thyagarajan, G. The Michaelis–Arbuzov rearrangement. Chem. Rev. 81, 415–430 (1981).

Rittigstein, P. & Torkelson, J. M. Polymer–Nanoparticle interfacial interactions in polymer nanocomposites: confinement effects on glass transition temperature and suppression of physical aging. J. Polym. Sci.: Part B: Polym. Phys. 44, 2935–2943 (2006).

Ash, B. J., Siegel, R. W. & Schadler, L. S. Glass-transition temperature behavior of alumina/PMMA nanocomposites. J. Polym. Sci.: Part B: Polym. Phys. 42, 4371–4383 (2004).

Arrighi, V., McEwen, I. J., Qian, H. & Serrano Prieto, M. B. The glass transition and interfacial layer in styrene-butadiene rubber containing silica nanofiller. Polymer 44, 6259–6266 (2003).

Grady, B. P., Paul, A., Peters, J. E. & Ford, W. T. Glass transition behavior of single-walled carbon nanotube-polystyrene composites. Macromolecules 42, 6152–6158 (2009).

Acknowledgements

Transmission electron microscopy observation of nanocomposite samples was carried out by Dr Keiko Nishikubo at National Institute of Advanced Industrial Science and Technology. Experimental support by Ms Ryoko Tsuru and Ms Reiko Hayashi is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Imai, Y., Terahara, A., Hakuta, Y. et al. Synthesis and characterization of high refractive index nanoparticle/poly(arylene ether ketone) nanocomposites. Polym J 42, 179–184 (2010). https://doi.org/10.1038/pj.2009.322

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2009.322

Keywords

This article is cited by

-

Cellulose derivative/barium titanate composites with high refractive index, conductivity and energy density

Cellulose (2022)

-

High refractive index and dielectric properties of BaTiO3 nanocube/polymer composite films

Journal of Nanoparticle Research (2020)