Abstract

Due to the high versatility of chiral cyanohydrins, the catalytic asymmetric cyanation reaction of carbonyl compounds has attracted widespread interest. However, efficient protocols that function at a preparative scale with low catalyst loading are still rare. Here, asymmetric counteranion-directed Lewis acid organocatalysis proves to be remarkably successful in addressing this problem and enabled a molar-scale cyanosilylation in quantitative yield and with excellent enantioselectivity. Also, the catalyst loading could be lowered to a part-per-million level (50 ppm: 0.005 mol%). A readily accessible chiral disulfonimide was used, which in combination with trimethylsilyl cyanide, turned into the active silylium Lewis acid organocatalyst. The nature of a peculiar phenomenon referred to as a “dormant period”, which is mainly induced by water, was systematically investigated by means of in situ Fourier transform infrared analysis.

Similar content being viewed by others

Introduction

As a remarkably efficient approach to obtain enantioenriched organic compounds, asymmetric catalysis has attracted significant attention1,2. In particular, asymmetric organocatalysis, which is an effective complement to well-established methods such as biocatalysis and transition metal catalysis, has emerged as a powerful tool3,4,5,6,7. While metal-based Lewis acids have been intensively studied in asymmetric catalysis8,9, the complementary metal-free Lewis acid organocatalysts have been rarely explored. Our research group has recently developed chiral disulfonimides as efficient Brønsted acid organocatalysts10,11, which can conveniently be utilized as precursors for silylium-mediated Lewis acid organocatalysts, when combined with silicon containing organic nucleophiles11,12,13. This catalytic system afforded remarkably high enantioselection, by pairing a silylium ion equivalent with a chiral enantiopure counteranion, exploiting the concept of asymmetric counteranion-directed catalysis14. This strategy recently led to a number of applications involving several different silicon-containing nucleophiles, for example, silyl ketene acetals13,15,16, Danishefsky-type dienes17, allylsilanes18,19 and silyl phosphites20.

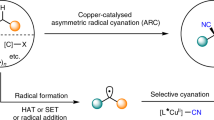

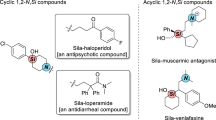

The catalytic asymmetric cyanation of carbonyl compounds (for example, aldehydes and ketones) is an attractive protocol to obtain chiral cyanohydrin derivatives21. This methodology offers a convenient access to a variety of valuable chiral building blocks, as well as biologically active compounds, such as α-hydroxy acids, β-amino alcohols and α-amino acids22,23,24,25. After the initial report on the enantioselective addition of hydrogen cyanide to benzaldehyde in the presence of an extract of almonds as catalyst26, numerous enzymatic27,28 and metal-based Lewis acid catalytic systems29,30,31,32,33,34,35,36 have been investigated for the synthesis of enantioenriched cyanohydrins. A few efficient metal-free, hydrogen bonding or boron promoted protocols have also been reported.37,38,39,40,41,42,43 However, the use of asymmetric counteranion-directed catalysis towards this goal remained unprecedented.

Herein we disclose an asymmetric Lewis acid organocatalysis approach for the cyanosilylation of wide range of aldehydes (2) with trimethylsilyl cyanide (TMSCN, 3), which utilizes a chiral disulfonimide (1) as pre-catalyst (Fig. 1). The developed catalytic system proved to be highly active and scalable, enabling a cyanohydrin synthesis at a scale of greater than 150 g in the presence of merely 0.05 mol% of the catalyst. Moreover, the catalyst loading could be reduced to as little as 0.005 mol% (50 ppm). Furthermore, we observed an interesting phenomenon referred to as dormant period, during which the catalyst is completely inactive and which is reversibly induced by water. This phenomenon was systematically investigated by means of in situ Fourier transform infrared (FT-IR) analysis, providing important mechanistic insight into the pre-catalytic cycle.

Results

Optimization of the reaction conditions

We commenced our study by carrying out the asymmetric cyanosilylation of 2-naphthaldehyde (2a) with TMSCN (3) as a model reaction to afford chiral cyanohydrin 4a. After screening a wide variety of solvents in the presence of disulfonimide catalyst 1a (3 mol%), diethyl ether (Et2O) was identified as the most efficient reaction medium in terms of enantioselectivity (Supplementary Table 1). Next, several chiral disulfonimide catalysts 1a–1f were screened to elucidate the relationship between the catalyst’s structure and the reaction outcome (Fig. 2). The performance of screened catalysts, regarding enantioselectivity was highly dependent on the steric demand of the aryl substituents. To our delight, disulfonimide catalyst 1b, which incorporated a larger perfluoroisopropyl substituent gave an excellent enantiomeric ratio of 98:2 e.r.

Conditions: aldehyde 2a (0.05 mmol), TMSCN 3 (0.1 mmol) and catalyst 1 (3 mol%) in Et2O (0.16 M) at –30 °C for 4 days unless noted otherwise. Isolated yields were determined after converting to the corresponding acetate 5a. The e.r. of acetates 5a was determined by HPLC on a chiral stationary phase.

Substrate scope of the reaction

Under optimized reaction conditions, a variety of aldehydes 2 were subjected to this protocol. As shown in Fig. 3, several aryl aldehydes 2b–2l were smoothly converted into the corresponding chiral cyanohydrins 4b–4l with excellent to quantitative yields (90-99%) and excellent enantiomeric ratios (96:4 to 99:1). An alkenyl substrate, α-bromocinnamaldehyde 2m, was also smoothly converted to the desired product 4m in good yield with excellent enantiomeric ratio (82%, 96.5:3.5 e.r.). Furthermore, heteroaromatic aldehydes 2n and 2o also successfully afforded enantioenriched products 4n and 4o (97 and 98%, 93.5:6.5 e.r. and 94.5:5.5 e.r. respectively). The primary alkyl substrate hydrocinnamaldehyde (2p) gave product 4p with moderate yield (45%) and essentially no enantioselection.

Conditions: aldehyde 2 (0.05 mmol), TMSCN (0.1 mmol) and catalyst 1b (3 mol%) in Et2O (0.16 M) at –30 °C for 4 days unless noted otherwise. Isolated yields were determined after converting to the corresponding acetate 5. The e.r. of acetates 5 was determined by HPLC on a chiral stationary phase. [a] –50 °C, 7 days. [b] 7 days. [c] –10 °C, 7 days.

Scale-up syntheses and part-per-million level catalysis

To demonstrate the practicability of the developed protocol, preparative scale syntheses were conducted. At the beginning, a cyanosilylation with 1.00 g scale (0.006 mol) of aldehyde 2b in the presence of 0.10 mol% of disulfonimide catalyst 1b was carried out (Fig. 4a). The reaction proceeded smoothly and gave the desired product 4b in >99% conversion (1H NMR) and with an excellent enantiomeric ratio (97:3 e.r.). Next, a significantly increased scale was chosen and the catalytic cyanosilylation starting with 156 g (1.00 mol) of aldehyde 2a was conducted (Fig. 4b). It is noteworthy that a catalyst loading of merely 0.05 mol% was sufficient to achieve almost full conversion with excellent enantioselection (Fig. 4c left, 97% 1H NMR conversion, 96:4 e.r.) The obtained cyanohydrin 4a was directly hydrolysed under acidic conditions and a subsequent recrystallization provided 183 g (91% yield) of enantiomerically pure (>99:1 e.r.) (S)-2-hydroxy-2-(naphthalen-2-yl)acetamide 6 (Fig. 4c right). In addition, ca. 80% of catalyst 1b was recovered by chromatographic purification in high purity (see Supplementary Methods for details).

An even further reduced catalyst loading of only 0.005 mol% (50 ppm) of catalyst 1b could be successfully utilized to catalyse the reaction of aldehyde 2b to give cyanohydrin 4b, in excellent conversion (92%, turnover number=18,400) and with 88.5:11.5 e.r. Enantioselective organocatalytic C-C bond forming reactions with such low catalyst loadings have been extremely rare44 (see Supplementary Methods for details).

In situ FT-IR study on the dormant period

Despite the fact that in most cases full conversions with excellent enantioselectivities were achieved using our disulfonimide catalyst, rather long reaction times (3–7 days) were usually required. While investigating this particular issue, an interesting phenomenon was observed. When the reaction progress was monitored in the early stage of the reaction using thin layer chromatography and 1H NMR spectroscopy, absolutely no conversion to product was detected. However, at some point in time, the reaction suddenly proceeded very rapidly and was soon found to be completed. In order to gain insight into the details of this unusual phenomenon, we decided to follow the reaction progress by means of in situ FT-IR spectroscopic analysis. This method was chosen, as it allows investigating the actual course of the reaction in real time, without requiring taking aliquots from the reaction mixture. The stretching vibration of the carbonyl group of an aldehyde gives a strong and distinctive infrared band, which is well suited for the in situ FT-IR measurement. Commercially available disulfonimide catalyst 1a12 was selected for this mechanistic study.

As displayed in Fig. 5, the absorption peak of the carbonyl group of aldehyde 2a at 1703, cm−1 was monitored during the progress of the catalytic cyanosilylation and an interesting trend was observed. After dissolving aldehyde 2a, catalyst 1a and TMSCN (3) in Et2O, no conversion was detected in the first 110 min. Surprisingly, after this initial dormant period, the reaction abruptly proceeded and reached >99% conversion (by 1H NMR) within 30 min (Table 1, entry 1). We hypothesized that this reluctance in the early stage was derived mainly from water present in the reaction mixture and thus decided to conduct further control experiments by deliberately adding varied amounts of water. After the initiation of the reaction (step A) and 118 min of the initial dormant period, which results from humidity that is not deliberately added, 1 mol% of water (0.2 μl) was added (step B) when the amount of remaining aldehyde 2a had reached 52%. Here, consistent with our expectation, the reaction was immediately suspended and an induced dormant period was observed, which lasted for 17 min. After this period, the reaction restarted automatically and aldehyde 2a was gradually consumed within the next 20 min (Table 1, entry 2). Using a higher loading of water led to an approximately linear correlation with the length of the induced dormant period. Accordingly, induced dormant periods of 80 and 170 min respectively were observed, when 5 mol% (0.9 μl) and 10 mol% (1.8 μl) of water were added (Table 1, entries 3 and 4). These control experiments clearly indicate that water can induce the dormant period, presumably by hydrolysing the catalytically active species (1a-TMS), which prevents efficient catalysis (see Supplementary Figs. 1–4 for details).

Conditions of step A: aldehyde 2a (0.10 mmol), TMSCN 3 (2.0 equiv.) and catalyst 1a (2 mol%) in Et2O (5.0 ml) at 25 °C. Water (1–10 mol%) was added at the marked time point (step B). (a) Three-dimensional stack plot of the IR spectra (10 mol% water). (b) Plot of conversion of 2a versus time (1–10 mol% water). See Table 1 for the length of dormant periods.

In contrast to the above findings, in our previous in situ FT-IR study on the disulfonimide 1a catalysed Mukaiyama aldol reaction of silyl ketene acetal with aldehyde 2h, the reaction started immediately and no dormant period was observed45. This might be due to the high reactivity of the silyl ketene acetal with the pre-catalyst 1a, which instantaneously (re-)generates the active Lewis acid organocatalyst. Based on this knowledge, we hypothesized that the utilization of a catalytic amount of silyl ketene acetal as an activator, such as for example methyl trimethylsilyl dimethylketene acetal 7a, might shorten or avoid the dormant period. In this context, we implemented an experiment regarding pre-activation of 1a to 1a-TMS by the treatment of 5 mol% of silyl ketene acetal 7a (step A), then successive addition of aldehyde 2a (step B) and TMSCN 3 (step C) as depicted in Fig. 6. To our delight, the dormant period was avoided. The reaction started immediately and reached full conversion to product 4a within less than 1 h with formation of only 0.9 mol% of the Mukaiyama aldol product 8 (see Supplementary Fig. 5 for details).

Importantly, after completion of the reaction, the generated active catalyst 1a-TMS remained stable in the absence of humidity and its repeated utilization could be successfully realized. As shown in Fig. 7, one equivalent of each compound 2a and TMSCN (3) was added to the reaction mixture (step B), after the first catalytic reaction (initiated by step A) was completed. Eight further cycles of substrate addition were conducted and the completion of each independent cycle was monitored by in situ FT-IR. Here, no further dormant periods were observed and full conversion to the desired cyanohydrin 2a occurred in each of the overall nine cycles (see Supplementary Fig. 6 for details).

Reaction conditions (first cycle): 1a (0.01 mmol, 1 mol%), 25 °C, Et2O (4.6 ml), 2a (1.0 mmol, 1.0 equiv.), 3 (2.0 mmol, 2.0 equiv.). Reaction conditions (second to ninth cycle): addition of 2a (1.0 mmol, 1.0 equiv.), 3 (2.0 mmol, 2.0 equiv.). The reaction was monitored by means of in situ FT-IR analysis.

Discussion

During the pre-catalytic cycle (dormant period), Brønsted acid 1 slowly reacts with TMSCN (3) to generate the active Lewis acid organocatalyst 1-TMS and HCN. The resulting species 1-TMS is immediately hydrolysed back to the pre-catalyst 1, while water and silanol 9 are being converted to silanol 9 and hexamethyldisiloxane 10, respectively. After water and silanol 9 are completely consumed, the silylated species 1-TMS starts to catalyse the addition of TMSCN (3) to aldehyde 2. Further studies revealed that the addition of trimethylsilanol 9 during the course of the reaction also induces a dormant period, while hexamethyldisiloxane 10 has no influence on the reaction progress (see Supplementary Fig. 7). 1H-29Si-HMBC and 2D-EXSY NMR studies revealed that 1a-TMS exists as a mixture of O- and N-silylated tautomers (see Supplementary Figs. 8, 9 and Supplementary Table 2). The build-up and decay of the silylated species 1a-TMS were also studied by 1H NMR and the results are in accordance with the in situ FT-IR studies regarding the dormant period, which is induced by water addition (see Supplementary Fig. 10). Based on these results, we propose a pre-catalytic cycle (dormant period) as shown in Fig. 8.

In conclusion, we have successfully developed an asymmetric counteranion-directed cyanosilylation promoted by a silylium Lewis acid organocatalyst. In the presence of the highly accessible disulfonimide catalyst 1, a variety of aldehydes were converted into the corresponding cyanohydrins in excellent yields and enantiomeric ratios. The developed protocol is scalable to more than 150 g of substrate. The catalyst loading could be reduced to as little as 0.005 mol% (50 ppm). The reaction is triggered through the formation of active catalyst 1-TMS via a dormant period causing pre-catalytic cycle (see Supplementary Discussion concerning induction period versus dormant period). This phenomenon was shown to be predominantly induced by water, and was systematically studied by means of in situ FT-IR analysis.

Methods

Procedure for the asymmetric cyanosilylation reactions

A dried vial with a Teflon-coated magnetic stirring bar was charged with disulfonimide 1 (0.0015, mmol, 3 mol%), aldehyde 2 (0.05 mmol, 1.0 equiv.) and Et2O (0.31 ml). TMSCN 3 (0.1 mmol, 2.0 equiv.) was added to the reaction mixture via a microlitre syringe and the vial was cooled to –30 °C immediately. The reaction mixture was stirred at –30 °C and the progress of the reaction was monitored by TLC. The reaction was quenched with 2% (v/v) trifluoroacetic acid in CH2Cl2 (0.38 ml) and water (2 μl) after the progress of the reaction was determined to be complete. The reaction mixture was warmed up to room temperature and stirred for 2 h to hydrolyse the TMS-protected cyanohydrin. The solvent and the volatile compounds were evaporated under reduced pressure at ambient temperature. Then CH2Cl2 (1 ml), acetic anhydride (47 μl, 10 equiv.) and pyridine (36 μl, 9 equiv.) were added and the reaction mixture was stirred at room temperature overnight. The solvent and volatile compounds were evaporated under reduced pressure at 40 °C. The residue was purified by column chromatography on silica gel using iso-hexane/ethyl acetate (4:1) as the eluent thus delivering the pure cyanohydrin acetate. The e.r. was determined by HPLC analysis of the cyanohydrin acetate on a chiral stationary phase.

Procedure for the in situ study monitored by in situ FT-IR

Disulfonimide 1a (8.2 mg, 0.010 mmol) and Et2O (4.54 ml) were placed in a pre-dried newly designed reactor (see Supplementary Fig. 11) equipped with a Teflon-coated magnetic stirring bar and thermometer under argon. A probe rod of ReactIR 15 (Mettler Toledo) was inserted into the solution, the reactor was connected with a high performance cryostat and the temperature was set to be 20 °C. The scanning (interval: 1 min) was started and 2-naphthaldehyde 2a (156.2 mg, 1.000 mmol) was added to the mixture after a few minutes. The stretching vibration absorption of the carbonyl group (1703, cm−1) in 2a was monitored. TMSCN (250 μl, 2.00 mmol) was added to the reaction mixture after 5 min and the reaction profile (IR versus time) was recorded. The reaction was quenched with water (10 μl) after most of the aldehyde 2a had been converted to the product. The conversion of 2a was determined by 1H NMR.

Other detailed experimental procedures and characterization data for all the new compounds are given in Supplementary Methods. For NMR and HPLC analysis of the compounds in this article, see Supplementary Figs. 12–45.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and its Supplementary Information files.

Additional information

How to cite this article: Zhang Z. et al. Asymmetric counteranion-directed Lewis acid organocatalysis for the scalable cyanosilylation of aldehydes. Nat. Commun. 7:12478 doi: 10.1038/ncomms12478 (2016).

References

Mikami, K. & Lautens, M. New Frontiers in Asymmetric Catalysis John Wiley & Sons (2007).

Gruttadauria, M. & Giacalone, F. Catalytic Methods in Asymmetric Synthesis: Advanced Materials, Techniques, and Applications John Wiley & Sons (2011).

Movassaghi, M. & Jacobsen, E. N. The simplest "enzyme". Science 298, 1904–1905 (2002).

List, B. & Yang, J. W. The organic approach to asymmetric catalysis. Science 313, 1584–1586 (2006).

MacMillan, D. W. C. The advent and development of organocatalysis. Nature 455, 304–308 (2008).

List, B. Asymmetric Organocatalysis, Topics in Current Chemistry Vol. 291 (Springer (2009).

List, B. & Maruoka, K. Science of Synthesis: Asymmetric Organocatalysis Vols. 1-2 (Georg Thieme Verlag (2012).

Yamamoto, H. Lewis Acids in Organic Synthesis Wiley-VCH (2000).

Yamamoto, H. & Ishihara, K. Acid Catalysis in Modern Organic Synthesis Vols. 1-2 (, Wiley-VCH (2008).

Akiyama, T. & Mori, K. Stronger Brønsted acids: recent progress. Chem. Rev. 115, 9277–9306 (2015).

James, T., van Gemmeren, M. & List, B. Development and applications of disulfonimides in enantioselective organocatalysis. Chem. Rev. 115, 9388–9409 (2015).

van Gemmeren, M., Lay, F. & List, B. Asymmetric catalysis using chiral, enantiopure disulfonimides. Aldrichim. Acta 47, 3–13 (2014).

García-García, P., Lay, F., García-García, P., Rabalakos, C. & List, B. A powerful chiral counteranion motif for asymmetric catalysis. Angew. Chem. Int. Ed. 48, 4363–4366 (2009).

Mahlau, M. & List, B. Asymmetric counteranion-directed catalysis: concept, definition, and applications. Angew. Chem. Int. Ed. 52, 518–533 (2013).

Ratjen, L., García-García, P., Lay, F., Beck, M. E. & List, B. Disulfonimide-catalyzed asymmetric vinylogous and bisvinylogous Mukaiyama aldol reactions. Angew. Chem. Int. Ed. 50, 754–758 (2011).

Wang, Q., Leutzsch, M., van Gemmeren, M. & List, B. Disulfonimide-catalyzed asymmetric synthesis of β3-amino esters directly from N-Boc-Amino sulfones. J. Am. Chem. Soc. 135, 15334–15337 (2013).

Guin, J., Rabalakos, C. & List, B. Highly enantioselective hetero-Diels–Alder reaction of 1,3-bis-(silyloxy)-1,3-dienes with aldehydes catalyzed by chiral disulfonimide. Angew. Chem. Int. Ed. 51, 8859–8863 (2012).

Mahlau, M., García-García, P. & List, B. Asymmetric counteranion-directed catalytic Hosomi–Sakurai reaction. Chem. Eur. J 18, 16283–16287 (2012).

Gandhi, S. & List, B. Catalytic asymmetric three-component synthesis of homoallylic amines. Angew. Chem. Int. Ed. 52, 2573–2576 (2013).

Guin, J., Wang, Q., van Gemmeren, M. & List, B. The catalytic asymmetric Abramov reaction. Angew. Chem. Int. Ed. 54, 355–358 (2015).

Kurono, N. & Ohkuma, T. Catalytic asymmetric cyanation reactions. ACS Catal 6, 989–1023 (2016).

Gregory, R. J. H. Cyanohydrins in nature and the laboratory: biology, preparations, and synthetic applications. Chem. Rev. 99, 3649–3682 (1999).

Brunel, J.-M. & Holmes, I. P. Chemically catalyzed asymmetric cyanohydrin syntheses. Angew. Chem. Int. Ed. 43, 2752–2778 (2004).

North, M. & Murahashi, S.-I. Science of Synthesis Vol. 19, 235–284Georg Thieme Verlag (2004).

North, M., Usanov, D. L. & Young, C. Lewis acid catalyzed asymmetric cyanohydrin synthesis. Chem. Rev. 108, 5146–5226 (2008).

Rosenthaler, L. Durch enzyme bewirkte asymmetrische synthese. Biochem. Z. 14, 238–253 (1908).

Effenberger, F. Enzyme-catalyzed preparation and synthetic applications of optically active cyanohydrins. Chimia 53, 3–10 (1999).

Holt, J. & Hanefeld, U. Enantioselective enzyme-catalysed synthesis of cyanohydrins. Curr. Org. Synth. 6, 15–37 (2009).

Belokon, Y. N. et al. The asymmetric addition of trimethylsilyl cyanide to aldehydes catalyzed by chiral (salen)titanium complexes. J. Am. Chem. Soc. 121, 3968–3973 (1999).

Hamashima, Y., Sawada, D., Kanai, M. & Shibasaki, M. A new bifunctional asymmetric catalysis: an efficient catalytic asymmetric cyanosilylation of aldehydes. J. Am. Chem. Soc. 121, 2641–2642 (1999).

Hamashima, Y., Kanai, M. & Shibasaki, M. Catalytic enantioselective cyanosilylation of ketones. M. J. Am. Chem. Soc. 122, 7412–7413 (2000).

Hatano, M., Ikeno, T., Miyamoto, T. & Ishihara, K. Chiral lithium binaphtholate aqua complex as a highly effective asymmetric catalyst for cyanohydrin synthesis. J. Am. Chem. Soc. 127, 10776–10777 (2005).

Liu, X., Qin, B., Zhou, X., He, B. & Feng, X. Catalytic asymmetric cyanosilylation of ketones by a chiral amino acid salt. J. Am. Chem. Soc. 127, 12224–12225 (2005).

Lundgren, S., Wingstrand, E., Penhoat, M. & Moberg, C. Dual Lewis acid-Lewis base activation in enantioselective cyanation of aldehydes using acetyl cyanide and cyanoformate as cyanide sources. J. Am. Chem. Soc. 127, 11592–11593 (2005).

Kurono, N., Arai, K., Uemura, M. & Ohkuma, T. [Ru(phgly)2(binap)]/Li2CO3 : a highly active, robust, and enantioselective catalyst for the cyanosilylation of aldehydes. Angew. Chem. Int. Ed. 47, 6643–6646 (2008).

Zhang, Z., Wang, Z., Zhang, R. & Ding, K. An efficient titanium catalyst for enantioselective cyanation of aldehydes: cooperative catalysis. Angew. Chem. Int. Ed. 49, 6746–6750 (2010).

Oku, J., Ito, N. & Inoue, S. Asymmetric cyanohydrin synthesis catalyzed by synthetic dipeptides, 1. Makromol. Chem 180, 1089–1091 (1979).

Tian, S.-K. & Deng, L. A highly enantioselective chiral Lewis base catalyzed asymmetric cyanation of ketones. J. Am. Chem. Soc. 123, 6195–6196 (2001).

Tian, S.-K., Hong, R. & Deng, L. Catalytic asymmetric cyanosilylation of ketones with chiral Lewis base. J. Am. Chem. Soc. 125, 9900–9901 (2003).

Ryu, D. H. & Corey, E. J. Highly enantioselective cyanosilylation of aldehydes catalyzed by a chiral oxazaborolidinium ion. J. Am. Chem. Soc. 126, 8106–8107 (2004).

Ryu, D. H. & Corey, E. J. Enantioselective cyanosilylation of ketones catalyzed by a chiral oxazaborolidinium ion. J. Am. Chem. Soc. 127, 5384–5387 (2005).

Fuerst, D. E. & Jacobsen, E. N. Thiourea-catalyzed enantioselective cyanosilylation of ketones. J. Am. Chem. Soc. 127, 8964–8965 (2005).

Zuend, S. J. & Jacobsen, E. N. Cooperative catalysis by tertiary aminothioureas: mechanism and basis for enantioselectivity of ketone cyanosilylation. J. Am. Chem. Soc. 129, 15872–15883 (2007).

Giacalone, F., Gruttadauria, M., Agrigento, P. & Noto, R. Low-loading asymmetric organocatalysis. Chem. Soc. Rev. 41, 2407–2447 (2012).

Zhang, Z. & List, B. Kinetics of the chiral disulfonimide-catalyzed Mukaiyama aldol reaction. Asian J. Org. Chem 2, 957–960 (2013).

Acknowledgements

We gratefully acknowledge the Max Planck Society and the European Research Council (Advanced Grant ‘High Performance Lewis Acid Organocatalysis, HIPOCAT’ to B.L.). This work is part of the Cluster of Excellence RESOLV (EXC 1069) funded by the DFG and HYB acknowledges a postdoctoral fellowship from this programme.

Author information

Authors and Affiliations

Contributions

Z.Z. and J.G. developed the reaction conditions and investigated the scope. Z.Z. and H.Y.B. developed the large-scale reactions. C.R. synthesized catalyst 1b and discovered the DSI-catalysed cyanosilylation. Z.Z., H.Y.B., M.vG., M.L. and M.K. conducted the mechanistic investigations. B.L. designed and oversaw the project. Z.Z., M.vG., H.Y.B. and B.L. wrote the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-45, Supplementary Tables 1-2, Supplementary Discussion, Supplementary Methods and Supplementary References (PDF 3693 kb)

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Zhang, Z., Bae, H., Guin, J. et al. Asymmetric counteranion-directed Lewis acid organocatalysis for the scalable cyanosilylation of aldehydes. Nat Commun 7, 12478 (2016). https://doi.org/10.1038/ncomms12478

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms12478

This article is cited by

-

Carbene-catalyzed chemoselective reaction of unsymmetric enedials for access to Furo[2,3-b]pyrroles

Nature Communications (2023)

-

Organocatalytic stereoselective cyanosilylation of small ketones

Nature (2022)

-

Tetramethylguanidine-functionalized melamine as a multifunctional organocatalyst for the expeditious synthesis of 1,2,4-triazoloquinazolinones

Scientific Reports (2021)

-

Approaching sub-ppm-level asymmetric organocatalysis of a highly challenging and scalable carbon–carbon bond forming reaction

Nature Chemistry (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.