Abstract

Safe and powerful energy storage devices are becoming increasingly important. Charging times of seconds to minutes, with power densities exceeding those of batteries, can in principle be provided by electrochemical capacitors—in particular, pseudocapacitors1,2. Recent research has focused mainly on improving the gravimetric performance of the electrodes of such systems, but for portable electronics and vehicles volume is at a premium3. The best volumetric capacitances of carbon-based electrodes are around 300 farads per cubic centimetre4,5; hydrated ruthenium oxide can reach capacitances of 1,000 to 1,500 farads per cubic centimetre with great cyclability, but only in thin films6. Recently, electrodes made of two-dimensional titanium carbide (Ti3C2, a member of the ‘MXene’ family), produced by etching aluminium from titanium aluminium carbide (Ti3AlC2, a ‘MAX’ phase) in concentrated hydrofluoric acid, have been shown to have volumetric capacitances of over 300 farads per cubic centimetre7,8. Here we report a method of producing this material using a solution of lithium fluoride and hydrochloric acid. The resulting hydrophilic material swells in volume when hydrated, and can be shaped like clay and dried into a highly conductive solid or rolled into films tens of micrometres thick. Additive-free films of this titanium carbide ‘clay’ have volumetric capacitances of up to 900 farads per cubic centimetre, with excellent cyclability and rate performances. This capacitance is almost twice that of our previous report8, and our synthetic method also offers a much faster route to film production as well as the avoidance of handling hazardous concentrated hydrofluoric acid.

Similar content being viewed by others

Main

In the search for new electrode materials, two-dimensional solids are of particular interest owing to their large electrochemically active surfaces9. For example, activated graphene electrodes have capacitances of 200–350 F cm−3 compared to 60–100 F cm−3 for activated porous carbons10,11. Yet graphene is limited to the chemistry of carbon, does not tap into metal redox reactions as in ruthenium oxide (RuO2) (ref. 6), and its conductivity is substantially decreased by the addition of redox-active functional groups12. MXenes (of the formula Mn + 1XnTx, where M is a transition metal, X is C and/or N, and Tx denotes surface functionalization) are a relatively young class of two-dimensional solids, produced by the selective etching of the A-group (generally group IIIA and IVA elements) layers from the MAX phases, which comprise a >70-member family of layered, hexagonal early-transition-metal carbides and nitrides13. To date, all MXenes have been produced by etching MAX phases in concentrated hydrofluoric acid (HF)14,15,16.

MXenes have already proved to be promising candidates for electrodes in lithium (Li)-ion batteries17,18 and supercapacitors8, exhibiting volumetric capacitances that exceed most previously reported materials. However, the path to electrode manufacturing required the handling of concentrated HF and a laborious multi-step procedure. Here we sought a safer route by exploiting the reaction between common, inexpensive hydrochloric acid (HCl) and fluoride salts, leading to dissolution of aluminium and the extraction of two-dimensional carbide layers. Furthermore, given the ability of MXenes to preferentially intercalate cations (post-synthesis)8, a related question was whether etching and intercalation might be achieved in a single step, as was observed for etching of thin Ti3AlC2 films with ammonium bifluoride19. The change in MXene properties upon intercalation and the compositional variability of fluoride salts suggested the possibility of a one-step procedure for the synthesis of many MXenes, with tunable structures and properties.

The MXenes reported in this study were prepared by dissolving LiF in 6 M HCl, followed by the slow addition of Ti3AlC2 powders and heating of the mixture at 40° C for 45 h. After etching, the resulting sediments were washed to remove the reaction products and raise the pH (several cycles of water addition, centrifugation and decanting). The resulting sediment formed a clay-like paste that could be rolled, when wet (Fig. 1a), between water-permeable membranes in a roller mill to produce flexible, free-standing films (Fig. 1c) in a matter of minutes, in contrast to those previously produced by the laborious technique of intercalation, delamination, and filtration18.

a, MAX phase is etched in a solution of acid and fluoride salt (step 1), then washed with water to remove reaction products and raise the pH towards neutral (step 2). The resulting sediment behaves like a clay; it can be rolled to produce flexible, freestanding films (step 3), moulded and dried to yield conducting objects of desired shape (step 4), or diluted and painted onto a substrate to yield a conductive coating (step 5). b, When dried samples (left, showing cross-section and top view) are hydrated (right) they swell; upon drying, they shrink. c, Image of a rolled film. d, ‘Clay’ shaped into the letter M (∼1 cm) and dried, yielding a conductive solid (labelled with the experimental conductivity of ‘clay’ rolled to 5 µm thickness). The etched material is referred to as Ti3C2Tx, where the T denotes surface terminations, such as OH, O and F.

A graphical depiction of the processing is provided in Extended Data Fig. 1. Further, scaling was not limited to the size of the filtration apparatus; films of any dimensions could readily be produced. Additionally, when wet, the ‘clay’ could be moulded and dried to yield various shapes that were highly conductive (Fig. 1d). Diluted, it could also be used as an ink to deposit (print) MXene on various substrates. Like clay, the material could be rehydrated, swelling in volume, and shrinking when dried (Fig. 1b).

Energy-dispersive spectroscopy confirmed that aluminium (Al) was removed, and X-ray diffraction (XRD) revealed the disappearance of Ti3AlC2 peaks (traces can be seen in the case of incomplete transformation). Multilayer particles did not show the accordion-like morphology seen in HF-etched MXenes reported to date14,20; rather, particles appeared tightly stacked, presumably as a result of water and/or cationic intercalation (see Extended Data Fig. 2a). Fluorine and oxygen were observed in energy-dispersive spectroscopy; this, coupled with X-ray photoelectron spectroscopy showing evidence of Ti–F and Ti–O bonding, suggests O- and F-containing surface terminations, as has been discussed at length for HF-produced MXenes14,21. The yield of MXene after etching, calculated as described previously14, is around 100%, which is comparable with the HF-etching method. Our new method thus does not lead to material losses, although an accurate yield determination is difficult owing to the variability of surface groups and amount of intercalated water.

XRD patterns of the etched material, in its air-dried multilayered state, showed a remarkable increase in the intensity and sharpness of the (000l) peaks (Fig. 2a, pink); in some cases the full width at half maximum (FWHM) was as small as 0.188°, as opposed to the broad peaks typical of HF-etched MXene7, and more typical of intercalated MXenes18. Further, compared to a lattice parameter of c ≈ 20 Å for HF-produced Ti3C2Tx, the corresponding value in this work was 27–28 Å. XRD patterns of still-hydrated sediment showed shifts to even higher spacings: lattice parameters as high as c ≈ 40 Å have been measured. These large shifts are suggestive of the presence of water, and possibly cations, between the hydrophilic and negatively charged MXene sheets. From these substantial increases in c and the clay-like properties (see below), it is reasonable to assume that—as in clays22,23—the swelling is due to the intercalation of multiple layers of water and possibly cations between the MXene sheets. Interfacial water has a more structured hydrogen-bonding network than bulk H2O (ref. 24). The MXene surface, holding a negative electric charge, may act to align the dipoles of water molecules between MXene layers.

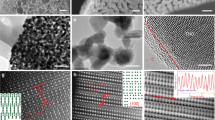

a, XRD patterns of samples produced by etching in LiF + HCl solution. The pink trace is for multilayer Ti3C2Tx, showing a sharp, intense peak (0002) and higher-order (000l) peaks, corresponding to a c lattice parameter of 28 Å and high order in the c direction. The blue trace is for the same sample after rolling into an approximately 40-µm-thick film; c-direction peaks are preserved, but the prominent (110) peak is no longer observed, showing substantial reduction of order in non-basal directions. In both cases, traces of Ti3AlC2 are still present (red diamonds). The MXene (0002) peak is at a much lower angle than that typical of MXene produced by HF (green star). b, TEM image of several flakes, showing lateral sizes up to a few hundred nanometres. Few defective areas are present. The inset shows the overall selected area electron diffraction pattern. c, d, TEM images of single- and double-layer flakes, respectively. Insets show sketches of these layers. e, SEM image of a fracture surface of a ∼4-µm-thick film produced by rolling, showing shearing of layers; the flexibility of the film is demonstrated in the inset. f, Fracture surface of a thicker rolled film (∼30 µm), showing poorer overall alignment of flakes in the interior of the film.

When the ‘clay’ was rolled into freestanding films, XRD patterns again showed strong ordering in the c direction (Fig. 2a, blue). Films, ranging in thicknesses from submicrometre to about 100 μm, were readily produced by this method. The most compelling evidence for particle shearing is the marked intensity decrease of the (110) peak around 61°, indicating a reduction of ordering in the non-basal directions while order in the c direction was maintained (see blue XRD pattern in Fig. 2a and scanning electron microscopy (SEM) image in Extended Data Fig. 2b). Morphologically, the thinner films showed more overall shearing of the multilayer particles when viewed in cross-section (Fig. 2e, f) and exhibited substantial flexibility, even when allowed to dry thoroughly (inset to Fig. 2e). The contact angle of water on the rolled MXene film was measured as 21.5°, confirming its hydrophilic nature (Extended Data Fig. 3). Attempts to hydrate and roll HF-produced MXene were unsuccessful; we propose that the intercalated water acts as a lubricant that allows facile shearing.

The c parameter expansion also resulted in the weakening of interactions between the MXene layers, as evidenced by the easy delamination of multilayered particles by sonication, as is done for van der Waals solids9. In our previous work, typical sonication times for delamination (after post-synthesis intercalation with dimethyl sulphoxide) were of the order of 4 h (ref. 18). Here, sonication times of the order of 30–60 min resulted in stable suspensions with concentrations as high as 2 g per litre, higher than observed previously. Remarkably, the yield from multilayer to dispersed flakes was about 45% by mass. Freestanding films were also readily fabricated by filtering these suspensions, as reported previously8.

The fact that the LiF + HCl etchant was much milder than HF resulted in flakes with larger lateral dimensions (Fig. 2b) that did not contain the nanometre-size defects frequently observed in HF-etched samples25. Transmission electron microscopy (TEM) analysis showed that, of 321 flakes analysed, over 70% had dimensions of 0.5–1.5 μm (Extended Data Fig. 4a, b). Single layers about 10 Å thick were imaged using TEM (Fig. 2c, d), confirming that the material is indeed two-dimensional. Analysis of 332 flakes suggested that roughly 70% of the flakes were 1–2 layers thick (Extended Data Fig. 4c–f). We note that, since the restacking or folding of flakes can lead to higher apparent thicknesses (Extended Data Fig. 5), the 70% estimate is conservative. Thus, using this method, large fractions of single-layered MXene flakes with high yields, large lateral sizes, and good quality can be readily produced. The flake lateral sizes reported here are larger than those reported for HF-etched Ti3AlC2 (ref. 18); the milder delamination conditions may be partially responsible for this.

Previously we have shown that MXene ‘paper’—made by filtration of solutions containing delaminated Ti3C2Tx flakes—exhibited volumetric capacitances of ∼350 F cm−3 at 20 mV s−1 (and 450 F cm−3 at 2 mV s−1) in potassium hydroxide (KOH) electrolyte8. For comparison, we characterized the electrochemical performances of rolled, freestanding Ti3C2Tx films in 1 M sulphuric acid (H2SO4). The advantages of acidic electrolytes include not only their excellent conductivities but also that protons, being the smallest cations, are known to allow for surface redox reactions in transition-metal oxide electrodes, such as RuO2, MnO2 and some others, and may contribute to the capacitance via fast surface redox1,26.

At a scan rate of 2 mV s−1, capacitance values reached 900 F cm−3 (Fig. 3a) and a good rate handling ability was observed (Fig. 3b). The results—summarized and compared with previous work8 in Fig. 3b—clearly show that rolled Ti3C2Tx clay electrodes show outstanding capacitive performance, not only volumetrically but gravimetrically as well, achieving 245 F g−1 at 2 mV s−1. This can be ascribed to the smaller size of H+ compared to other intercalating cations, surface redox processes, and improved accessibility of interlayer spacing in LiF + HCl-etched MXene owing to pre-intercalated water, compared to the previously studied HF-etched samples. It is worth noting that a similar positive role of structural water for capacitive performance in acidic electrolytes was observed for hydrated ruthenium oxide27. The electrodes showed no measurable capacitance losses even after 10,000 cycles (Fig. 3c). Coulombic efficiency is close to 100% (inset in Fig. 3c), confirming that the outstanding performance is not due to parasitic reactions.

a, Cyclic voltammetry profiles at different scan rates for a 5-µm-thick electrode in 1 M H2SO4. b, Comparison of rate performances reported in this work and previously for HF-produced MXene8. c, Capacitance retention test of a 5-µm-thick rolled electrode in 1 M H2SO4. Inset shows galvanostatic cycling data collected at 10 A g−1. d, Cyclic voltammetry profiles collected at 2 mV s−1 and 20 mV s−1 with hatched portions of the contributions of the processes not limited by diffusion, that is, capacitive (‘C-’); vertical lines limit the cyclic voltammetry area used in calculations. e, f, Rate performance (e) and electrochemical impedance spectroscopy data (f) of 5-µm-thick (red stars), 30-µm-thick (black circles) and 75-µm-thick (olive triangles) rolled electrodes. The inset in f shows the magnified high-frequency region.

To quantify the capacitive and diffusion limited contributions to the total capacitances, we used the approach of ref. 28. The results of this analysis—summarized in Fig. 3d—show that, at scan rates below 20 mV s−1, there is a noticeable, yet not prevailing, contribution of diffusion-limited processes to the total capacitance. At scan rates of 20 mV s−1 and higher, the response is not diffusion-controlled but is rather due to surface capacitive effects, whether electrostatic or pseudocapacitive. This observation is in agreement with the conjecture of Levi et al.29 about the presence of shallow- and deep-trap sites in MXene structures. Further, if there are also redox contributions from changes in the oxidation states of surface Ti atoms28, the redox processes are not diffusion-limited, and thus represent ‘intrinsic’ capacitive behaviour30.

When the electrochemical responses of three rolled clay electrodes (5 µm thick, 30 µm thick and 75 µm thick) were compared (Fig. 3e, f), not surprisingly, the volumetric capacitances decreased with increased thickness. These thickness-dependent differences can be partially traced to the electrode morphologies. As noted above, electrodes thinner than 10 µm showed good flake alignment (Fig. 2e) with typical densities of 3.6–3.8 g cm−3. At 2.2–2.8 g cm−3, the densities of the thicker (15 µm and larger) rolled electrodes were lower, which is a reflection of the fact that their core seemed to be more open (Fig. 2f). And while the lower densities led to lower volumetric capacitances, their more open structure ensured accessibility to ions and thus similar rate performances as their thinner counterparts (Fig. 3e, f). The lower densities also ensured that the drop in gravimetric capacitances with thickness (see Extended Data Fig. 6) was not substantial. A summary of key mass- and volume-normalized capacitance values as a function of electrode thickness is provided in Extended Data Table 1. Although the voltage window used for testing is relatively narrow, it can be expanded by conducting tests in other types of electrolytes, such as neutral aqueous and organic electrolytes, or using MXenes as negative electrodes in asymmetric cell configurations.

The good capacitive rate performance of the 75-µm-thick electrodes (Fig. 3e) is noteworthy, however, and demonstrates scalability and huge promise of MXenes for application as negative electrodes of hybrid large-scale energy storage devices. Electrodes of that thickness cannot be produced by filtration and the MXene clay-like characteristics add important versatility to electrode manufacturing, allowing films of the required thicknesses to be rolled. Note that the capacitance values reported herein are still preliminary. As better understanding of how the films’ morphologies affect their capacitances is gained, enhancements in the latter should ensue.

In terms of versatility, the LiF + HCl solution was also capable of etching other MAX phases, for example, Nb2AlC and Ti2AlC. In the case of Ti2AlC, we delaminated the multilayer powders in a similar fashion to Ti3C2Tx to produce suspensions of Ti2CTx flakes, as well as Ti2CTx ‘paper’, which had not been previously reported. These considerations hint at the potential of this new etching method for the synthesis of other MXenes, which will be explored in future studies.

This method of MXene production was successful to varying degrees for other fluoride salts, such as NaF, KF, CsF, tetrabutylammonium fluoride, and CaF2 in HCl, all of which showed similar etching behaviour. When H2SO4 was used instead of HCl, MXenes were still obtained. We note here that these systems are options and merit further study; the ability to fine tune the reaction based on reagents used will indubitably lead to potentially useful variations in compositions and properties, especially since it is reasonable to assume that different acids and salts should modify the surface chemistries and pre-intercalate different ions.

In summary, a new high-yield method for MXene synthesis that is safer, easier, and provides a faster route to delaminated flakes has been detailed. This method yields a clay-like material (for a discussion of the effect of experimental conditions on properties, see Methods), which can be shaped to give conductive solids of desired forms, or rolled into thin sheets, for a host of applications. When the rolled films were used as supercapacitor electrodes in a H2SO4 electrolyte, the performances were extraordinary, with volumetric capacitances up to 900 F cm−3 or 245 F g−1. When it is further appreciated that these numbers are ‘first-generation’ numbers that will no doubt increase as we better understand the underlying processes and modify the material structure and chemistry, the potential of these non-oxide two-dimensional materials to push electrochemical energy storage to new heights is clear.

Methods

Synthesis of Ti3AlC2

The MAX phase used as precursor for MXene synthesis herein—Ti3AlC2—was prepared by mixing commercial Ti2AlC powders (Kanthal, Sweden) with TiC in a 1:1 molar ratio (after adjusting for the ∼12 wt% Ti3AlC2 already present in the commercial powder), followed by ball milling for 18 h. The mixture was then heated at 5 °C min−1, under flowing argon (Ar) in a tube furnace for 2 h at 1,350 °C. The resulting lightly sintered brick was ground with a TiN-coated milling bit and sieved through a 400 mesh sieve producing powder with particle size less than 38 μm.

Synthesis of Ti3C2Tx MXene

Concentrated HCl (Fisher, technical grade), was added to distilled water to prepare a 6 M solution (30 ml total). 1.98 g (5 molar equivalents) of LiF (Alfa Aesar, 98+%) was added to this solution. The mixture was stirred for 5 min with a magnetic Teflon stir bar to dissolve the salt.

Three grams of Ti3AlC2 powders were carefully added over the course of 10 min to avoid initial overheating of the solution as a result of the exothermic nature of the reactions. The reaction mixture was then held at 40 °C for 45 h, after which the mixture was washed through ∼5 cycles of distilled water addition, centrifugation (3,500 r.p.m. × 5 min for each cycle), and decanting, until the supernatant reached a pH of approximately 6. The final product, with a small amount of water, was filtered on cellulose nitrate (0.22 μm pore size). At this stage, the filtrate exhibited clay-like properties and could be directly processed into films by rolling.

Preparation of Ti3C2Tx ‘paper’

The Ti3C2Tx flakes were dispersed in distilled water (2 g MXene per 0.5 litre of water), deaerated with Ar, followed by sonication for 1 h. The mixture was then centrifuged for 1 h at 3,500 r.p.m., and the supernatant, which was dark green in colour, was collected. This dispersion was filtered using a membrane (3501 Coated PP, Celgard, USA) to yield flexible, freestanding Ti3C2Tx paper. The weight percentage of MXene delaminated into stable suspension in this case was around 45 wt%.

Ti3C2Tx clay electrodes

Preparation of the clay electrodes is depicted step-by-step in Extended Data Fig. 1. The dried and crushed Ti3C2Tx powder is hydrated to the consistency of a thick paste, roughly two parts powder to one part water (Extended Data Fig. 1a–c), which turns it into a plastic, clay-like state, that can be formed and moulded. The ‘clay’ is then rolled using a roller mill with water-permeable Celgard sheets (Extended Data Fig. 1d) on either side, resulting in the formation of a freestanding film (Extended Data Fig. 1e), which was readily lifted off the membrane upon drying (Extended Data Fig. 1f).

Activated carbon electrodes

The activated carbon electrodes were prepared by mechanical processing of a pre-mixed slurry, containing ethanol (190 proof, Decon Laboratories), YP-50 activated carbon powder (Kuraray, Japan), and polytetrafluoroethynene (PTFE) binder (60 wt% in H2O, Sigma Aldrich). The resulting composition of the activated carbon electrodes was 95 wt% activated carbon and 5 wt% PTFE. They had thicknesses that varied between 100 µm and 150 µm; the mass densities per unit area were in the 10–25 mg cm−2 range.

Electrochemical setup

All electrochemical measurements were performed in three-electrode Swagelok cells, in which MXene served as the working electrode, over-capacitive activated carbon films were used as the counter electrode, and Ag/AgCl in 1 M KCl was the reference electrode. Two layers of the Celgard membranes were used as separators. The electrolyte was 1 M H2SO4 (Alfa Aesar, American Chemical Society grade).

Electrochemical measurements

Cyclic voltammetry, electrochemical impedance spectroscopy, and galvanostatic cycling were performed using a VMP3 potentiostat (Biologic, France). Cyclic voltammetry was performed using scan rates that ranged from 1 mV s−1 to 100 mV s−1. Electrochemical impedance spectroscopy was performed at open circuit potential, with a 10-mV amplitude, and frequencies that ranged from 10 mHz to 200 kHz. Galvanostatic cycling was performed at 1 A g−1 and 10 A g−1 between the potential limits of −0.3 V to 0.25 V versus Ag/AgCl. Capacitance data reported in the article were calculated from the slope of the discharge curve.

Characterization of structure and properties

XRD patterns were recorded with a powder diffractometer (Rigaku SmartLab) using Cu Kα radiation (λ = 1.54 Å) with 0.2° 2θ steps and 0.5 s dwelling time.

Scanning electron microscopy was performed on a Zeiss Supra 50VP (Carl Zeiss SMT AG, Oberkochen, Germany) equipped with an energy-dispersive spectroscope (Oxford EDS, with INCA software). Most energy-dispersive spectroscope scans were obtained at low magnification (100× to 200×) at random points of powdered samples.

Transmission electron microscopy of the MXene flakes was performed on a JEM-2100 (JEOL, Japan) using an accelerating voltage of 200 kV. The TEM samples were prepared by dropping two drops of diluted colloidal solution of MXene flakes onto a copper grid and drying in air. The flake size and number of layers per flake distributions were obtained through statistical analysis of more than 300 MXene flakes in the TEM images.

Resistivity measurements were performed with a 4-point probe (ResTest v1, Jandel Engineering, UK). Measured resistivity was automatically multiplied by the proper thickness correction factor given by the Jandel software.

Temperature and time in the MXene synthesis

We found that reaction conditions of 35 °C for 24 h rather than 40 °C for 45 h produced a material with persistent MAX-phase peaks in the XRD patterns, and higher Al content revealed by energy-dispersive spectroscopy, but that gave reliable high yields of delaminated flakes upon sonication. The Ti3AlC2 etched at higher temperatures showed lower Al content but did not always readily delaminate and disperse by sonication.

Capacitance calculations

The volumetric capacitance determined from the cyclic voltammetry data is given by:

and the volumetric capacitance determined from the galvanostatic charge/discharge data is given by:

where C is the normalized capacitance (in units of F cm−3), j is the current density (in A cm−3), s is the rate (in V s−1), V is the voltage (in V), ΔV is the voltage window (in V) and t is time (in s). Calculations of the gravimetric capacitance (in F g−1) were performed using current density per electrode weight (in A g−1).

Analysis of the limiting processes for charge storage

To quantify the diffusion-limited contribution to capacitance, the relationship between the current i(V) (at a given voltage V, in units of mA) and scan rate υ (in units of V s−1), was assumed to be27:

where k1 and k2 are constants. For the cyclic voltammetry experiments, at scan rates from 1 mV s−1 to 20 mV s−1, current values were extracted, and i/υ0.5 versus υ0.5 was plotted at each voltage and linear fitting was performed: i(V)/υ0.5 = k1υ0.5 + k2. The slope k1, for each voltage, describes the contributions of the non-diffusion controlled processes to the overall process.

References

Simon, P. & Gogotsi, Y. Materials for electrochemical capacitors. Nature Mater. 7, 845–854 (2008)

Augustyn, V. et al. High-rate electrochemical energy storage through Li+ intercalation pseudocapacitance. Nature Mater. 12, 518–522 (2013)

Gogotsi, Y. & Simon, P. True performance metrics in electrochemical energy storage. Science 334, 917–918 (2011)

Murali, S. et al. Volumetric capacitance of compressed activated microwave-expanded graphite oxide (a-MEGO) electrodes. Nano Energy 2, 764–768 (2013)

Yang, X., Cheng, C., Wang, Y., Qiu, L. & Li, D. Liquid-mediated dense integration of graphene materials for compact capacitive energy storage. Science 341, 534–537 (2013)

Zheng, J. P., Cygan, P. J. & Jow, T. R. Hydrous ruthenium oxide as an electrode material for electrochemical capacitors. J. Electrochem. Soc. 142, 2699–2703 (1995)

Naguib, M. et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2 . Adv. Mater. 23, 4248–4253 (2011)

Lukatskaya, M. R. et al. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science 341, 1502–1505 (2013)

Nicolosi, V., Chhowalla, M., Kanatzidis, M. G., Strano, M. S. & Coleman, J. N. Liquid exfoliation of layered materials. Science 340, 6139 (2013)

Ghaffari, M. et al. High-volumetric performance aligned nano-porous microwave exfoliated graphite oxide-based electrochemical capacitors. Adv. Mater. 25, 4879–4885 (2013)

Tao, Y. et al. Towards ultrahigh volumetric capacitance: graphene derived highly dense but porous carbons for supercapacitors. Sci. Rep. 3, 2975 (2013)

Jung, I., Dikin, D. A., Piner, R. D. & Ruoff, R. S. Tunable electrical conductivity of individual graphene oxide sheets reduced at “low” temperatures. Nano Lett. 8, 4283–4287 (2008)

Barsoum, M. W. MAX Phases: Properties of Machinable Ternary Carbides and Nitrides (John Wiley & Sons, 2013)

Naguib, M., Mochalin, V. N., Barsoum, M. W. & Gogotsi, Y. MXenes: a new family of two-dimensional materials. Adv. Mater. 26, 982 (2014)

Xie, X. et al. Surface Al leached Ti3AlC2 substituting carbon for catalyst support served in a harsh corrosive electrochemical system. Nanoscale 6, 11035–11040 (2014)

Peng, Q. et al. Unique lead adsorption behavior of activated hydroxyl group in two-dimensional titanium carbide. J. Am. Chem. Soc. 136, 4113–4116 (2014)

Tang, Q., Zhou, Z. & Shen, P. Are MXenes promising anode materials for Li ion batteries? computational studies on electronic properties and Li storage capability of Ti3C2 and Ti3C2X2 (X = F, OH) monolayer. J. Am. Chem. Soc. 134, 16909–16916 (2012)

Mashtalir, O. et al. Intercalation and delamination of layered carbides and carbonitrides. Nature Commun. 4, 1716 (2013)

Halim, J. et al. Transparent conductive two-dimensional titanium carbide epitaxial thin films. Chem. Mater. 26, 2374–2381 (2014)

Chang, F., Li, C., Yang, J., Tang, H. & Xue, M. Synthesis of a new graphene-like transition metal carbide by de-intercalating Ti3AlC2 . Mater. Lett. 109, 295–298 (2013)

Enyashin, A. N. & Ivanovskii, A. L. Two-dimensional titanium carbonitrides and their hydroxylated derivatives: structural, electronic properties and stability of MXenes Ti3C2−xNx(OH)2 from DFTB calculations. J. Solid State Chem. 207, 42–48 (2013)

Madsen, F. T. & Müller-Vonmoos, M. The swelling behaviour of clays. Appl. Clay Sci. 4, 143–156 (1989)

Hensen, E. J. & Smit, B. Why clays swell. J. Phys. Chem. B 106, 12664–12667 (2002)

Lis, D., Backus, E. H. G., Hunger, J., Parekh, S. H. & Bonn, M. Liquid flow along a solid surface reversibly alters interfacial chemistry. Science 344, 1138–1142 (2014)

Mashtalir, O., Naguib, M., Dyatkin, B., Gogotsi, Y. & Barsoum, M. W. Kinetics of aluminum extraction from Ti3AlC2 in hydrofluoric acid. Mater. Chem. Phys. 139, 147–152 (2013)

Conway, B. Electrochemical capacitors based on pseudocapacitance. In Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications (Kluwer Academic/Plenum, 1999)

Dmowski, W., Egami, T., Swider-Lyons, K. E., Love, C. T. & Rolison, D. R. Local atomic structure and conduction mechanism of nanocrystalline hydrous RuO2 from X-ray scattering. J. Phys. Chem. B 106, 12677–12683 (2002)

Wang, J., Polleux, J., Lim, J. & Dunn, B. Pseudocapacitive contributions to electrochemical energy storage in TiO2 (anatase) nanoparticles. J. Phys. Chem. C 111, 14925–14931 (2007)

Levi, M. D. et al. Solving the capacitive paradox of 2D MXene by electrochemical quartz-crystal admittance and in situ electronic conductance measurements. Adv. Energy Mater. http://dx.doi.org/10.1002/aenm.201400815 (2014)

Simon, P., Gogotsi, Y. & Dunn, B. Where do batteries end and supercapacitors begin? Science 343, 1210–1211 (2014)

Acknowledgements

We thank O. Mashtalir and Z. Ling for help with material characterization. This work was supported by the US National Science Foundation under grant number DMR-1310245. Electrochemical research was supported by the Fluid Interface Reactions, Structures and Transport (FIRST) Center, an Energy Frontier Research Center funded by the US Department of Energy, Office of Science, and Office of Basic Energy Sciences. XRD, X-ray photoelectron spectroscopy, SEM and TEM investigations were performed at the Centralized Research Facilities at Drexel University.

Author information

Authors and Affiliations

Contributions

M.G. conducted material synthesis and XRD analysis. M.R.L. performed electrochemical measurements and SEM analysis. M.-Q.Z. performed TEM analysis. M.W.B. and Y.G. planned and supervised the research. M.R.L., M.G., M.W.B. and Y.G. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Extended data figures and tables

Extended Data Figure 1 Processing of MXene clay.

a, Dried and crushed powder. b, c, Hydrated clay is plastic and can be readily formed and moulded. d, Demonstration of films produced in the roller mill. e, f, Rolled freestanding film being lifted off Celgard membranes.

Extended Data Figure 2 SEM images.

a, Multilayer MXene particle. b, Cross-section of rolled Ti3C2 film, showing shearing that is most probably responsible for the loss of the 60° angle peak in the XRD pattern.

Extended Data Figure 3 Contact angle.

Digital image showing contact angle of a water droplet on rolled MXene film, indicating its hydrophilic surface.

Extended Data Figure 4 TEM characterization of dispersed Ti3C2Tx flakes.

a, Representative TEM image showing the morphology and size of a large single-layer Ti3C2Tx flake. Note folding on all sides of this large flake. b, The lateral size distribution of the dispersed Ti3C2Tx flakes. c–e, Representative TEM images showing single-layer (c), double-layer (d) and triple-layer (e) flakes. f, Statistical analysis of layer number distribution of dispersed Ti3C2Tx flakes. Note that the fractions of double- and few-layer flakes are overestimated owing to inevitable restacking and edge folding of single-layer flakes during preparation of samples for TEM analysis. Edge folding is clearly seen in a. An example of restacking is shown in Extended Data Fig. 5.

Extended Data Figure 6 Gravimetrically normalized capacitance.

Cyclic voltammetry profiles at different scan rates for 5-µm-thick (a), 30-µm-thick (b) and 75-µm-thick (c) electrodes in 1 M H2SO4. d, Gravimetric rate performances of rolled electrodes, 5 µm thick (black squares), 30 µm thick (red circles) and 75 µm thick (blue triangles).

Rights and permissions

About this article

Cite this article

Ghidiu, M., Lukatskaya, M., Zhao, MQ. et al. Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 516, 78–81 (2014). https://doi.org/10.1038/nature13970

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/nature13970

This article is cited by

-

Elastic properties and tensile strength of 2D Ti3C2Tx MXene monolayers

Nature Communications (2024)

-

Self-Assembly of Binderless MXene Aerogel for Multiple-Scenario and Responsive Phase Change Composites with Ultrahigh Thermal Energy Storage Density and Exceptional Electromagnetic Interference Shielding

Nano-Micro Letters (2024)

-

Recent trends in synthesis of 2D MXene-based materials for sustainable environmental applications

Emergent Materials (2024)

-

Recent Progress in Optical Sensors Based on MXenes Quantum Dots and MXenes Nanosheets

Journal of Analysis and Testing (2024)

-

Aqueous electrolyte-mediated Al3+ ion storage in electrochemically treated Ti3AlC2

Bulletin of Materials Science (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.