Abstract

The nanomechanical properties of thin silicon films will become increasingly critical in semiconductor devices, particularly in the context of substrates that consist of a silicon film on an insulating layer (known as silicon-on-insulator, or SOI, substrates). Here we use very small germanium crystals as a new type of nanomechanical stressor to demonstrate a surprising mechanical behaviour of the thin layer of silicon in SOI substrates, and to show that there is a large local reduction in the viscosity of the oxide on which the silicon layer rests. These findings have implications for the use of SOI substrates in nanoelectronic devices.

Similar content being viewed by others

Main

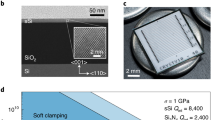

We use SOI substrates consisting of a handle wafer (a thick silicon (Si) layer), a thin oxide (a 400-nm thickness of SiO2) and a very thin (10 nm) template layer of crystalline Si on top of the oxide. The template layer is patterned to form micrometre-sized (5–20 µm) mesas (Fig. 1a). About 10 monolayers of germanium (Ge; total thickness 1.6 nm) are deposited by molecular-beam epitaxy at 700 °C. Germanium has a lattice constant 4% greater than that of silicon.

a, Mesa structures patterned and etched on a SOI substrate wafer. b, Transmission electron microscope image showing a Ge nanocrystal and the bent Si-template layer underneath. The Ge nanocrystals, which grow in register with the Si lattice, have a 4% greater lattice constant than the Si, and thus cause it to bend locally. The local shear stress is sufficient to reduce the viscosity of the oxide underneath the thin Si layer so as to allow the oxide to flow locally. Scale bars, 20 µm (a) and 50 nm (b).

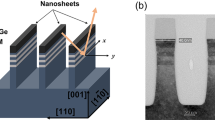

Figure 1b shows the formation of Ge nanocrystals (about 10 nm high, with 100-nm bases) that are crystallographically in register with the Si template, and an anomalous local bending of the Si template layer underneath each individual nanocrystal. The curvature underneath the islands is greater than 0.005 nm−1. This new mode of local bending (Fig. 2a) of a nanometre-scale thin film is different from the commonly observed extended, uniform bending mode (Fig. 2b) that is induced by strained-layer film growth on thick Si(001) (refs 1, 2).

a, Local bending mode that occurs only when the density of nanocrystals (dotted domes) is low. b, Extended bending mode that occurs at high nanocrystal densities. For a thin Si layer, a transition from local to extended bending occurs with increasing nanocrystal density. c, Some parameters used to calculate the bending induced by a pyramidal nanocrystal acting as a local stressor. ti is the thickness of the Ge nanocrystal, ts is the thickness of the Si membrane, I is the base dimension of the nanocrystal, ɛm is the misfit strain in the nanocrystal, Z is the normal to the membrane, and L is the dimension of the bent region of membrane underneath the nanocrystal. d, The calculated bending curvature, K, of a free-standing, 10-nm Si layer as a function of the equivalent film thickness, tGe, normalized to the Si-layer thickness, tSi. Arrow indicates the curvature (local thickness, local bending) that corresponds to the observed 10-nm Ge nanocrystal height; this is consistent with the data in Fig. 1b.

Our calculations show that the local bending curvature depends on the nanocrystal's density and shape (Fig. 2c, d). On a thick substrate, local bending is suppressed3, resulting in an overall extended bending that can be estimated using Stoney's formula4 and which is independent of nanocrystal density and shape, as would be the case in a uniform film of equivalent thickness.

The local bending mode and large bending magnitude indicate that the Si template layer behaves as a 'free-standing' layer during the growth of Ge nanocrystals, an outcome that can be achieved if SiO2 acts as a fluid with substantial viscous flow. The viscosity of SiO2 at 700 °C (the growth temperature) is ordinarily much too great for such a large degree of relaxation to occur. However, this viscosity can decrease almost exponentially with increasing applied shear stress5.

From the bending curvature, and hence the bending stress, we estimate5 that the viscosity of SiO2 can be reduced by three to five orders of magnitude in the regions beneath the bent Si layer below the Ge nanocrystals. The relaxation time for SiO2 flow is then reduced by a few orders of magnitude, to well within the deposition time of about 150 s. Thus, the large bending stress in the Si layer greatly enhances the viscous flow of SiO2, which in turn helps to increase the bending of the Si layer, because the Si film can then behave as a free-standing film.

The local stressor on the thin Si template layer of SOI substrate modifies both the mechanical properties of the Si layer and its electronic properties, providing a unique method for electronic (band) engineering on a nanometre scale. For these reasons, local stressors in SOI substrates could also become a significant issue for the semiconductor industry, which is increasingly using such substrates to manufacture devices.

References

Floro, J. A., Chason, E., Twesten, R. D., Hwang, R. Q. & Freund, L. B. Phys. Rev. Lett. 79, 3946–3949 (1997).

Floro, J. A. et al. Phys. Rev. B 59, 1990–1998 (1999).

Johnson, H. T. & Freund, L. B. J. Appl. Phys. 81, 6081–6090 (1997).

Stoney, G. G. Proc. R. Soc. Lond. A 82, 172–178 (1909).

Rafferty, C. S., Borucki, L. & Dutton, R. W. Appl. Phys. Lett. 54, 1516–1518 (1989).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

About this article

Cite this article

Liu, F., Rugheimer, P., Mateeva, E. et al. Response of a strained semiconductor structure. Nature 416, 498 (2002). https://doi.org/10.1038/416498a

Issue Date:

DOI: https://doi.org/10.1038/416498a

This article is cited by

-

Strain-Dependent Electronic and Magnetic of Mg-Doped Monolayer of WS2

Journal of Superconductivity and Novel Magnetism (2018)

-

Controlling Magnetism of F-Adsorbed BN Nanosheets by Applying Isotropic Strain

Journal of Superconductivity and Novel Magnetism (2018)

-

Effect of Strain on Magnetic Coupling in Ga-Doped WS2 Monolayer: Ab Initio Study

Journal of Superconductivity and Novel Magnetism (2018)

-

Properties of gold nanostructures sputtered on glass

Nanoscale Research Letters (2011)

-

Annealing of sputtered gold nano-structures

Applied Physics A (2011)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.