Abstract

Enhanced bio-hydrogen production from protein wastewater by altering protein structure and amino acids acidification type via pH control was investigated. The hydrogen production reached 205.2 mL/g-protein when protein wastewater was pretreated at pH 12 and then fermented at pH 10. The mechanism studies showed that pH 12 pretreatment significantly enhanced protein bio-hydrolysis during the subsequent fermentation stage as it caused the unfolding of protein, damaged the protein hydrogen bonding networks and destroyed the disulfide bridges, which increased the susceptibility of protein to protease. Moreover, pH 10 fermentation produced more acetic but less propionic acid during the anaerobic fermentation of amino acids, which was consistent with the theory of fermentation type affecting hydrogen production. Further analyses of the critical enzymes, genes and microorganisms indicated that the activity and abundance of hydrogen producing bacteria in the pH 10 fermentation reactor were greater than those in the control.

Similar content being viewed by others

Introduction

Hydrogen has been deemed the future energy carrier due to its high energy content and the lack of a greenhouse effect. The use of biotechnology to produce hydrogen is becoming an important strategy and attracting the attention of many researchers as it is a sustainable alternative compared to conventional hydrogen production methods1,2. Bio-hydrogen production by dark fermentation is a process in which anaerobic bacteria use organic wastes to produce hydrogen in the absence of a light source3. This process has several benefits with respect to the environment such as energy recover and resource reuse4. Additionally, it has a high hydrogen production rate with a simple reactor configuration5.

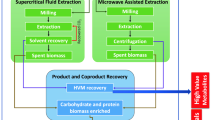

Dark fermentative hydrogen can be produced from many organic wastes, such as wastewater. Carbohydrate in wastewater often accounts for the majority of the organic load to produce bio-hydrogen in the literature6. Nevertheless, protein is also the main organic substrate in some wastewaters. For example, the wastewaters generated during the productions of abattoir, whey, cheese, casein, fish and silk usually contain significant amount of protein7,8. As seen in Figure 1 during anaerobic fermentation protein is firstly hydrolyzed to peptides and amino acids by extracellular enzyme (step-I) and then fermented to volatile fatty acids and hydrogen (step-II). Unlike carbohydrates, protein has a unique three-dimensional structure. Usually, the step-I is very slow as protein is unsusceptible to protease cleavage in its native folded conformation9,10. Thus, hydrolysis is the rate-limiting step during hydrogen production from protein wastewater.

Although it has been reported that bio-hydrogen can be produced from protein wastewater via anaerobic dark fermentation at neutral pH, the reported maximal hydrogen yield is less than 20 mL/g-protein at a protein concentration of 2 g/L211,12. Moreover, in all these studies the hydrogen-producing substrate was peptone, which was formed during partial hydrolysis of protein and was distinguished from protein on the basis of size and three-dimensional structure. The hydrolysis rate of protein could be accelerated by the change of its folded structure, which however, has never been documented in previous studies. In addition, previous studies found that the fermentation pH is an important factor affecting bio-hydrogen production and the optimal pH for bio-hydrogen production from protein-rich waste (such as sewage sludge) is alkaline pH (about 8.5–10) owing to the improved solubilization of sludge organic matters and the inhibitory effect on hydrogen consuming microorganisms2,13, but the impacts of pH on protein structure and protein hydrolyzate (amino acids) conversion involved in step-II during hydrogen production from protein wastewater have seldom been investigated.

In this study a new method (i.e., pretreating protein wastewater at pH 12 and then fermenting it at pH 10) for enhancing bio-hydrogen production from protein wastewater by altering protein structure and amino acids acidification type was reported. Firstly, the effects of different pretreatment and fermentation pH values on the production of bio-hydrogen from protein wastewater were studied. Then, the reasons for pH 12 pretreatment and pH 10 fermentation showing significantly higher hydrogen production were explored by advanced analytical techniques from the aspects of protein unfolding, protein hydrogen bonding networks damage, disulfide bridge breakage, the reactions of amino acids fermentation type, critical enzyme activity and genes and key microbes.

Results

Effects of pretreatment and fermentation pH on bio-hydrogen production

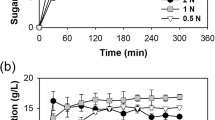

In this study the influence of pretreatment pH on fermentative hydrogen production was investigated firstly. It was observed that the hydrogen production from synthetic protein wastewater was increased with fermentation time between 12 and 72 h (Figure 2A), which, however, was not significantly enhanced when the time was further prolonged to 84 h (p > 0.05). The comparison of pretreatment pH values affecting hydrogen production was therefore made at fermentation time of 72 h. It can be seen from Figure 2A that pH 12 or pH 12.5 pretreatments resulted in a much higher hydrogen production than other pHs and the control (pH 7) at a fermentation time of 72 h. Nevertheless, there was no significant difference in the hydrogen production between pH 12 and pH 12.5 pretreatments (p > 0.05). Thus, the optimal pretreatment pH was 12 under the condition of fermentation pH 7.

The hydrogen production was also observed to be significantly affected by fermentation pH. With the use of pH 12 pretreated wastewater as the substrate the time courses of hydrogen production being affected by fermentation pH are shown in Figure 2B. There was no detectable hydrogen produced at fermentation pH 4 and pH 11. Although bio-hydrogen was produced between pH 5 and pH 10, the maximal hydrogen production and suitable fermentation time were different. In the pH range of 6–10 the optimal fermentation time was 72 h, whereas it was 96 h at pH 5 (statistical analysis is shown in Table S1). The hydrogen production at optimal fermentation time was respectively 155.6 (pH 5), 155.7 (pH 6), 117.1 (pH 7), 96.2 (pH 8), 162.8 (pH 9) and 205.2 (pH 10) mL/g-protein. Obviously, the maximal hydrogen production from pH 12 pretreated synthetic protein wastewater occurred at fermentation pH 10.

Effects of pH 12 pretreatment on the characters of protein wastewater

During pH 12 pretreatment there was no significant change in the concentration of protein (p > 0.05) and no hydrogen was generated. However, pH 12 pretreatment significantly changed the characters of protein wastewater. In this study the influence of pH 12 pretreatment on the α-helix content of protein molecule was firstly investigated by circular dichroism. Compared with the control, as seen in Figure 3A, pH 12 pretreatment induced a significant decrease in the α-helix content of protein from 69.1% to 42.4%. The effect of pH 12 pretreatment on the hydrodynamic diameter of protein was further investigated with BSA as a model protein. The data in Figure 3B showed that the average hydrodynamic diameter of BSA was 8.0 nm in the control (pH 7 pretreatment), while it was increased to 12.3 nm after pH 12 pretreatment.

Protein has endogenous fluorescence since it contains aromatic amino residues and the numbers of tryptophan, tyrosine and phenylalanine residues in the BSA molecule are 2, 21 and 26, respectively14. The effect of pH 12 pretreatment on the changes of protein structure was further assayed by EEM fluorescence spectroscopy, which had been applied as a useful and powerful methodology to extract information about the structural features of protein15. As seen in Figure 4 the fluorescence maximum peak intensity of BSA in the control test was 5.18 × 106 a.u., which was sharply dropped to 1.79 × 106 a.u. after pH 12 pretreatment. Obviously, pH 12 pretreatment caused considerable decrease in the fluorescence intensity of protein. At the same time the maximum excitation and emission wavelengths of protein were shifted after pH 12 pretreatment, i.e., the excitation was 272 nm and emission was 350 nm in the control, while the corresponding data were 278 nm and 340 nm for the pH 12 pretreated protein. It implied that the main reason for pH 12 pretreatment resulting in the decrease of fluorescence intensity was due to the quenching of aromatic residues fluorescence since there was a significant shift in the fluorescence maximum16.

Protein structure is influenced and stabilized to a great extent by disulfide bridges. Raman spectroscopy has been employed extensively to probe the conformation of disulfide bridges in protein because the frequency of S-S stretching mode of the disulfide bridge is sensitive to its conformation17. Raman spectra of the control and pH 12 pretreated BSA in the 200–1800 cm−1 region after being normalized against the phenylalanine band at 1004 cm−1 are shown in Figure S1 (Supplementary information). The region of 500–550 cm−1 in the Raman spectrum belongs to the stretching vibration mode of S-S bridges and the peaks appearing around 500–510, 515–525 and 535–545 cm−1 are the features of the gauche-gauche-gauche (ggg), gauche-gauche-trans (ggt) and trans-gauche-trans (tgt) conformation, respectively17,18. According to the curve fitting of the band, the conformations of 17 disulfide bridges in BSA can be determined. The analyses of S-S Raman bands of BSA before and after pH 12 pretreatment are illustrated in Figure 5. The main conformation of BSA in the control was ggg (506 cm−1, Figure 5A). pH 12 pretreatment decreased the relative intensity of S-S Raman bands and meanwhile induced a prominent increase of ggt conformation of disulfide bridges (Figures 5B). Figure 5C shows the composition of the S-S bridge conformations of BSA after pH 12 pretreatment. There were respectively 11, 3 and 3 out of 17 disulfide bridges of BSA with the ggg, ggt and tgt conformations in the control, which were 3, 6 and 2 after pH 12 pretreatment.

Effects of pH 12 pretreatment on the susceptibility of protein to protease and protein hydrolysis efficiency

To investigate the effects of pH 12 pretreatment on the susceptibility of protein to protease, the protein enzyme hydrolysis experiments were conducted and the protein enzymolysis efficiency was used to express the susceptibility of protein to protease. As seen in Figure 6A the protein enzymolysis efficiency of synthetic protein wastewater was significantly affected by pH 12 pretreatment. After enzymolysis for 1 h, the protein enzymolysis efficiency with the pH 7 pretreated wastewater was only 39.9%, whereas it was significantly increased to 71.9% with the pH 12 pretreated one.

Effects of pH 12 pretreatment on the susceptibility of protein to protease (A) and the protein hydrolysis efficiency during protein wastewater anaerobic fermentation for hydrogen production at pH 7 for 72 h (B).

The concentration of pronase E in the synthetic protein wastewater was 50 mg/L and the enzymolysis time was 1 h. Error bars represent standard deviations of triplicate tests.

As seen in Figure 6B the hydrolysis of protein during anaerobic hydrogen production was significantly affected by pH 12 pretreatment. The hydrolysis efficiency in the control (pH 7 pretreatment) was only 28.8%, whereas it bacame 86.7% after the wastewater was pretreated at pH 12. Further investigation showed that during fermentation for hydrogen production the activity of protease was also remarkably improved after the protein wastewater was pretreated by pH 12 (Figure 6B).

Effects of pH 10 fermentation on amino acids conversion

From the proposed metabolic pathway illustrated in Figure 1 it can be seen that the hydrogen production from protein wastewater comes from the conversion of amino acids to volatile fatty acids. Thus, the synthetic amino acids wastewater was used to further investigate the influence of pH 10 fermentation on bio-hydrogen production. As shown in Figure S2A (Supplementary information) the hydrogen generation in the pH 7 (control) fermentation test of synthetic amino acids wastewater was much lower than that in the pH 10 one (63.1 versus 139.9 mL/g-amino acids). The data in Figure S2A indicated that the concentration of VFA at fermentation pH 7 test was slightly higher than that at fermentation pH 10 (2166.8 versus 1836.4 mg COD/L). However, the concentration and percentage of acetic acid in pH 10 reactor were significantly greater than those in pH 7 reactor (940.0 against 572.0 mg COD/L and 51.2% versus 26.4%) and the opposite observations were made with propionic acid (207.0 against 632.8 mg COD/L and 11.3% versus 29.2%, see Figure S2B).

Effects of pH 12 pretreatment plus pH 10 fermentation on the activities of key enzymes and microorganisms during hydrogen production

According to the supposed metabolic pathway for bio-hydrogen production from protein (Figure 1), the NADH-Fd reductase and hydrogenase are the key metalloenzyme responsible for hydrogen formation. To recycle NAD+, NADH is oxidized by NADH-Fd reductase, while hydrogenase oxidizes reduced ferredoxin to produce molecular hydrogen19,20. Oxaloacetate transcarboxylase (OAATC) is a key enzyme involved in propionic acid synthesis and NADH consumption21. As illustrated in Figure 7A the relative activity of NADH-Fd reductase and hydrogenase was improved by 34% and 71% when the wastewater fermentation pH changed from pH 7 to pH 10. The OAATC, however, was significantly restrained to 58.5% of the control at fermentation pH 10. Then the real-time polymerase chain reaction (PCR) analysis (see Supplementary information of “Real-time PCR” and Table S2) was conducted to explore the intrinsic reason. As seen in Figure 7B the expression of Fd (ferredoxin) gene in the pH 10 fermentation reactor was about 1.44- fold of that in the control reactor. The same observation was made with the expression of hydA (Fe-hydrogenase) gene, which was 1.85-fold of the control when the anaerobic fermentation pH was 10. The fluorescence in situ hybridization (FISH) assay was conducted to investigate the influences of pH 10 on the abundance of hydrogen producing bacteria (see Supplementary information of “Fluorescence in situ hybridization”). The images are shown in Figure 8. Further images analysis indicated that the abundance of hydrogen producing bacteria in pH 7 and pH 10 fermentation reactors was 24.5% and 32.1%, respectively.

Microscopy of sludge from the hydrogen production reactor of fermentation pH 7 and fermentation pH 10 at the time of 72 h by FISH (×10).

Hydrogen producing bacteria were labeled with HEX (yellow, A1 for pH 7 and A2 for pH 10) and domain bacteria were labeled with FITC (green, B1 for pH 7 and B2 for pH 10).

Hydrogen production from real protein wastewater enhanced by pH 12 pretreatment and pH 10 fermentation

The examination of applying pH 12 pretreatment plus pH 10 fermentation to enhance hydrogen production from whey protein wastewater, a real high protein content organic wastewater, was conducted. As seen in Figure S3A (Supplementary information) no matter whether the hydrogen production from whey protein wastewater pretreated or not was increased with fermentation time, the accumulative hydrogen production of control (pH 7 pretreatment and pH 7 fermentation) was only 44.8 mL/g-COD at fermentation time of 72 h, while it was significantly improved to 106.9 mL/g-COD after the whey protein wastewater was pretreated at pH 12 and fermented at pH 10. The same observations were made with the protein utilization efficiency and VFA production, which was increased respectively by 154% and 67% compared with the control (Figure S3B, Supplementary information).

Discussion

In the literature protein wastewater is directly fermented at approximately pH 7 to produce hydrogen without any pretreatment and the hydrogen yield is less than 20 mL/g-protein at a protein concentration of around 2.0 g/L2,11. The data in Figure 2A indicated that if the protein wastewater was unpretreated and directly fermented at pH 7 (control) the bio-hydrogen production was 39.0 mL/g-protein, which was higher than the results of some previous studies because the the activity of homoacetogenesis was inhibited by CHCl3 in the current study. However, the hydrogen production was significantly increaed to 205.2 mL/g-protein when the protein wastewater was pretreated at pH 12 and then fermented at pH 10, which was more than 5-fold of the control. The reasons for pH 12 pretreatment plus pH 10 fermentation showing significantly higher bio-hydrogen production were explored and discussed next.

It is well known that under anaerobic fermentation conditions protein is firstly hydrolyzed to peptides and amino acids and then fermented to volatile fatty acids and hydrogen (Figure 1). As the generation of hydrogen is relevant to the metabolism of protein, the influence of pH 12 pretreatment on protein hydrolysis is investigated firstly. In this study it was observed that during pH 12 pretreatment there was no significant change in the concentration of protein, which suggested that pH 12 pretreatment did not directly cause the hydrolysis of protein.

The bio-hydrolysis behavior of protein has been reported to be affected by the changes of its secondary structure10,22. The α-helix and β-sheet are the two main shapes in the secondary structure of protein and the native BSA is dominated by α-helix without β-sheet23. The decrease in α-helix content of protein indicates the breakage of hydrogen bonding networks, which has been reported to be positively consistent with the degradation of protein24,25. In this study pH 12 pretreatment induced a significant decrease in the α-helix content of protein from 69.1% to 42.4% (Figure 3A), which was consistent with the results of protein hydrolysis efficiency during anaerobic fermentation (Figure 6B).

The unfolding of protein is often a prerequisite for its bio-hydrolysis9. Dynamic light scattering can probe the unfolding of protein by giving the size properties of protein in a three-dimensional structure26. The unfolding of protein has been reported to play a critically important role in protein bio-hydrolysis by ATP-dependent protease as it influences the susceptibility of protein to proteases27. The data in Figure 3B showed that pH 12 pretreatment unfolded BSA from 8.0 nm to 12.3 nm. The unfolding of protein would change the microenvironment of tryptophan, which could decrease protein fluorescence intensity and shift the fluorescence maximum15,28. This observation consistented with the changes of protein fluorescence after pH 12 pretreatment (Figure 4). Then the unfolding of protein enhanced susceptibility of protein to proteases (Figure 6A) and the protease activity was therefore increased by almost 28% compared with the control (Figure 6B). Further investigation indicated that pretreating wastewater at pH 12 not only destroyed the disulfide bridges of protein but changed their conformations (Figure 5). Thus the hydrolysis of protein during anaerobic fermentation was significantly increaced from 28.8% to 86.7% after the wastewater was pretreated at pH 12. Since more protein was bio-hydrolyzed, more amino acids were provided for hydrogen producers and the hydrogen production was increased.

As stated above, there was no hydrogen produced during pH 12 pretreatment and pH 12 pretreatment did not cause protein hydrolysis directly. However, it significantly altered protein structure and the alteration remained stable when the pH was adjusted to pH 10 for bio-hydrogen production (see Table S3 for details). But it should be emphasized that during protein wastewater fermentation the hydrogen is generated in the process of amino acids being bio-converted to volatile fatty acids and there is no hydrogen generated when protein is hydrolyzed to amino acids. In this study the maximal hydrogen production from protein wastewater occurred at fermentation pH 10 and the dynamic of hydrogen (Figure 2) was in line with that of ammonia (Figure S4), which was generated during the conversion of amino acids to volatile fatty acids by the reaction of deamination. The amino acids synthetic wastewater was further used to investigate the influence of pH 10 fermentation on bio-hydrogen production. The data in Figure S2A showed that the hydrogen generation from amino acids wastewater in the pH 7 (control) fermentation test was much lower than that in the pH 10 one, which consistented with the result of higher hydrogen production at fermentation pH 10 observed in Figure 2B. At the same time, as illustrated in Figure S2A the concentration of volatile fatty acids produced from amino acids at fermentation pH 7 and pH 10 was 2166.8 and 1836.4 mg COD/L, respectively. It implied that the difference of hydrogen production from amino acids at fermentation pH 7 and pH 10 was not owing to the utilization efficiency of substrate but to the different anaerobic biochemical reactions.

Under anaerobic conditions the evolution of hydrogen through a NADH pathway is driven by the necessity of reoxidizing the residual NADH of metabolic reactions as NADH + H+ → NAD+ + H229. As shown in Figure 1, there is 1, −2 and 0 molecules residual NADH produced when one molecule pyruvate is respectively converted to acetic, propionic and butyric acid, which indicates that higher hydrogen production corresponds to greater acetic acid but less propionic acid generation. It should be noted that the generation of butyric acid has no connection with the production of hydrogen but only contributes to reoxidation of NADH. There was no detectable ethanol and lactic acid produced in the current study. As seen in Figure S2B, the percentage of acetic acid in the pH 10 fermentation reactor was significantly greater than that in the pH 7 reactor (51.2% versus 26.4%), but the opposite observations was made with propionic acid (11.3% versus 29.2%). Obviously, the result was in line with the theory of fermentation type affecting hydrogen production.

The NADH-Fd reductase and hydrogenase are the key enzymes to oxidize NADH and reduced ferredoxin to produce molecular hydrogen, while OAATC is a key enzyme for propionic acid synthesis19,20,21. As illustrated in Figure 7A pH 10 fermentaion improved the relative activitives of NADH-Fd reductase and hydrogenase, but it restrained the relative activitiy of OAATC compared with pH 7 fermentaion. The real-time PCR further indicated that the expressions of Fd (ferredoxin) and hydA (Fe-hydrogenase) genes both were improved in the pH 10 fermentation reactor (Figure 7B). The same observation was made with the abundance of hydrogen produing bacteria, which was increased from 24.5% (in the control reactor) to 32.1% (in the pH 10 fermentation reactor) according to the FISH results (Figure 8). It can be easily understood therefore that amino acids fermentation at pH 10 had higher hydrogen production than that at pH 7.

In summary, we presented a new strategy to significantly increase bio-hydrogen production from protein wastewater by altering protein structure and amino acids acidification type via pH control. The hydrogen production reached 205.2 mL/g-protein, which was much higher than that reported in the literature2. pH 12 pretreatment induced the unfolding of protein, damaged the protein hydrogen bonding networks, destroyed the disulfide bridges and changed their conformations, which increased the susceptibility of protein to protease and enhanced the hydrolysis of protein9. Moreover, when the fermentation pH varied from pH 7 to pH 10 the anaerobic metabolic reaction of amino acids shifted from propionic acid to acetic acid and the critical enzyme activities and abundance of hydrogen producing bacteria were improved, which resulted in higher hydrogen yield in the fermentative reactor of pH 10. Finally, the application of 12 pretreatment and pH 10 fermentation to enhance bio-hydrogen evolution from real protein wastewater was testified to be feasible.

Methods

Experiments of pretreatment pH affecting hydrogen production from protein wastewater

The synthetic protein wastewater used in this study for bio-hydrogen production was prepared with bovine serum albumin (BSA, diagnostic grade power of BAH 68, obtained from Equitech-Bio) as carbon source and its concentration was maintained at 2.0 g/L. The pretreatment was conducted in 12 identical reactors, each with working volume of 600 mL, outside diameter of 85 mm, height of 180 mm and cap of 25 mm. For each reactor 300 mL protein wastewater was added and the pH value was adjusted to 2, 3, 4, 5, 6, 7 (control), 8, 9, 10, 11, 12, 12.5, respectively, by adding 6 M hydrochloric acid (HCl) or 6 M sodium hydroxide (NaOH) and maintained in an air-bath shaker (100 rpm) with temperature of 21 ± 1°C for 24 h. There was no microorganism during the pretreatment of protein wastewater. After pretreatment, 1.0 g NaHCO3 (buffer salt), 35 mg K2HPO4·3H2O (phosphorus source), 1 mL trace element solution and 30 mL seed microorganism (see Supplementary Information for details) were added to each reactor. The mixture was then anaerobically fermented to produce hydrogen after its pH value was adjusted to 7 by adding 6 M HCl or 6 M NaOH. According to the literature 60 ul CHCl3 (0.02%, V/V) was added to the mixture to inhibit homoacetogenesis30. After being flushed with nitrogen gas for 2 min to remove oxygen, all reactors were capped with rubber stoppers, sealed and placed in an air-bath shaker (140 rpm) with the temperature of 36 ± 1°C. The total gas volume was measured by releasing the pressure in the reactor using a glass syringe (100 mL) to equilibrate with the room pressure according to the previous publication13. Gas was sampled with a 5 mL syringe for composition assay. As the pH value of protein wastewater was around 7, the pH 7 pretreated test could be regarded as the un-pretreated one.

Experiments of fermentation pH affecting hydrogen production from pH 12 pretreated protein wastewater

The bio-hydrogen production experiments were conducted in 8 identical reactors with the pH 12 pretreated protein wastewater as substrate. The fermentation pH in these 8 reactors was respectively 4, 5, 6, 7, 8, 9, 10 and 11 and was kept constant by adding 6 M HCl or 6 M NaOH during the entire fermentation process. All other operations were the same as described above.

Experiments of pH 10 affecting hydrogen generation from amino acids fermentation

In this study the comparison of fermentation pH 7 and pH 10 affecting amino acids fermentation was conducted with synthetic amino acids wastewater. The synthetic amino acids wastewater consisted of 0.25 g/L L-leucine, L-lysine, L-glutamic acid, L-alanine, L-aspartic acid, L-valine, L-cysteine and L-threonine, respectively. Batch experiments of bio-hydrogen production from synthetic wastewater were conducted in 2 identical reactors, where fermentation pH was adjusted to 7 and 10, respectively, by adding 6 M HCl or 6 M NaOH. All other operations were the same as described above.

Experiments of hydrogen production from real protein wastewater

The real wastewater containing high concentration of whey protein was obtained from a milk powder processing plant in Hangzhou, Zhejiang Province, China. The main characteristics of whey protein wastewater in experiments are as follows: pH 6.56 ± 0.04, total chemical oxygen demand (TCOD) 3436 ± 80 mg/L, protein 2709 ± 72 mg COD/L and carbohydrate 554 ± 22 mg COD/L. Comparison of bio-hydrogen production from pH 7 and pH 12 pretreated whey protein wastewater was conducted in 2 identical reactors, where fermentation pH was controlled at 7 and 10, respectively, by adding 6 M HCl or 6 M NaOH. All other operations were the same as described above.

Experiments of protein enzyme hydrolysis

To investigate the effects of pH 12 pretreatment on susceptibility of protein to protease, the protein enzyme hydrolysis experiments were conducted and the protein enzymolysis efficiency was used to express the susceptibility of protein to protease. The experiments were conducted in 2 identical reactors with the pH 7 pretreated protein wastewater (control) and pH 12 pretreated protein wastewater as substrate, respectively. The concentration of pronase E (model protease, purchased from Merck) in each reactor was 50 mg/L and the hydrolysis pH was adjusted to 7 by adding 6 M HCl or 6 M NaOH during the entire hydrolysis process. After being flushed with nitrogen gas for 2 min to remove oxygen, both reactors were capped with rubber stoppers, sealed and placed in an air-bath shaker (140 rpm) with the temperature of 36 ± 1°C. At set intervals 5 mL sample was took out and immediately being heat-treated at 100°C for 10 min to inhibit enzyme activity. After cooling down to room temperature the residual protein in sample was precipitated by adding 5 mL 15% trichloroacetic acid (TCA) and the mixture was centrifuged at 4500 rpm for 15 min. The total organic nitrogen concentration in supernatant was determined using a TOC analyzer (TOC-V CPH, Shimadzu, Tokyo, Japan). In this study the enzymolysis efficiency of protein was expressed by the following equation.

where Cinitial and Cremaining is respectively the concentration of protein in wastewater before and after experiment, TN is the concentration of nitrogen in supernatant and 16% is the average value of nitrogen content in protein31.

Circular dichroism spectrum measurement of protein

The circular dichroism (CD) spectrum of protein was measured on a JASCO J-715 automatic recording spectropolarimeter (Tokyo, Japan) controlled by the JASCO software with a 0.1 cm quartz cell at room temperature. The sample was diluted to a concentration of 45 mg BSA/L and transferred to a quartz cell with a 1 cm light-path length. Molecular ellipticity was measured in the range of 190–250 nm with a bandwidth of 1 nm and the scan rate was 50 nm/min. The distilled water was selected as the blank and was automatically subtracted from each spectrum during scanning. The α-helix content of BSA was calculated according to equations (2) and (3)32.

where MRE is the mean residue ellipticity (deg.cm2.dmol−1), CP is the molar concentration of protein, n is the number of amino acid residues (583 for BSA) and L is the path length of the cell (mm).

where MRE208 is the observed MRE at 208 nm, 4000 is the MRE of the β-form and random coil conformation cross at 208 nm and 33000 is the MRE value of a pure α-helix at 208 nm.

Fluorescence spectroscopy analysis of protein

Excitation emission matrix (EEM) fluorescence spectroscopy of protein was obtained with a luminescence spectrometry (Fluoromax-4 Spectrofluorometer, HORIBA Scientific, France). Prior to the EEM test, the sample was filtered through a 0.45 μm hydrophilic filtration membrane and diluted to an approximate concentration. To get the fluorescence of EEM, the excitation and emission wavelengths were gradually increased from 200 to 400 nm at 2 nm increments and 250 to 450 nm at a 5 nm step, respectively.

Raman spectrum analysis of protein

Before Raman measurements, the pH 7 (control) or pH 12 pretreated synthetic protein wasterwaters was frozen at −20°C and then lyophilized. Raman spectrum was recorded on a Dilor-Jobin Yvon-Spex Raman spectrometer equipped with an Olympus BX 40 system microscope with 100× objectives. A He–Ne laser system with excitation line at 632.8 nm and an excitation power of 6 mW was used in the measurements. The recording range was 200–1800 nm with a resolution of 1.2 cm−1 and the spectrum was the accumulated averages of 3 exposures at room temperature (25°C). The average spectrum was smoothed by a 5 cm−1 filter and was corrected by a polynomial baseline using LabSpec (Dilor-Jobin Yvon-Spex, France) software. To calculate the corresponding content of the protein conformation, spectra shown in the main text were normalized against the phenylalanine band at 1004 cm−1 as its intensity (set as 1000) was unaffected by conformational changes in protein according to the leaterature18. The curve fitting of Raman spectrum was made by Origin 8.5 (Origin, USA) using multiple peak fit (Gaussian model).

Other analytical methods

The gas component was measured using a gastight syringe (0.2 mL injection volume) and a gas chromatograph (GC112A, China) equipped with a thermal conductivity detector (TCD) and a 4 mm × 2 m GDX-102 stainless column13. The temperatures of the injection port, column and detector were set at 40, 40 and 80°C, respectively. Nitrogen was used as the carrier gas at a flow rate of 30 mL/min. The pH value was measured by a pH meter. The determinations of protein, SS, VSS and volatile fatty acids (VFA) were the same as those described previously33. The total VFA was calculated as the sum of measured acetic, propionic, n-butyric, iso-butyric, n-valeric and iso-valeric acids. The detailed analytical procedures of fluorescence in situ hybridization (FISH), real-time polymerase chain reaction (PCR), protease, oxaloacetate transcarboxylase (OAATC), NADH-Fd reductase and hydrogenase activities are presented in Supplementary information.

Statistical analysis

All tests were conducted in triplicate and the results were expressed as mean ± standard deviation. An analysis of variance (ANOVA) was used to test the significance of results and p < 0.05 was considered to be statistically significant.

References

Brentner, L. B., Peccia, J. & Zimmerman, J. B. Challenges in Developing Biohydrogen as a Sustainable Energy Source: Implications for a Research Agenda. Environ. Sci. Technol. 44, 2243–2254 (2010).

Xiao, B., Han, Y. & Liu, J. Evaluation of biohydrogen production from glucose and protein at neutral initial pH. Int. J. Hydrog. Energy 35, 6152–6160 (2010).

Zhu, H. & Beland, M. Evaluation of alternative methods of preparing hydrogen producing seeds from digested wastewater sludge. Int. J. Hydrog. Energy 31, 1980–1988 (2006).

Wang, Y., Sheng, G., Shi, B., Li, W. & Yu, H. A Novel Electrochemical Membrane Bioreactor as a Potential Net Energy Producer for Sustainable Wastewater Treatment. Sci. Rep. 3, 1864 (2013).

Lee, H. S., Salerno, M. B. & Rittmann, B. E. Thermodynamic evaluation on H(2) production in glucose fermentation. Environ. Sci. Technol. 42 (2008).

Li, C. L. & Fang, H. H. P. Fermentative hydrogen production from wastewater and solid wastes by mixed cultures. Crit. Rev. Environ. Sci. Technol. 37, 1–39 (2007).

Ramsay, I. R. & Pullammanappallil, P. C. Protein degradation during anaerobic wastewater treatment: derivation of stoichiometry. Biodegradation 12, 247–257 (2001).

Wu, J., Wang, Z. & Xu, S. Preparation and characterization of sericin powder extracted from silk industry wastewater. Food Chem. 103, 1255–1262 (2007).

Herman, R., Gao, Y. & Storer, N. Acid-induced unfolding kinetics in simulated gastric digestion of proteins. Regul. Toxicol. Pharmacol. 46, 93–99 (2006).

Carbonaro, M., Maselli, P. & Nucara, A. Relationship between digestibility and secondary structure of raw and thermally treated legume proteins: a Fourier transform infrared (FT-IR) spectroscopic study. Amino Acids 43, 911–921 (2012).

Bai, M., Cheng, S. & Chao, Y. Effects of substrate components on hydrogen fermentation of multiple substrates. Water Sci. Technol. 50, 209–216 (2004).

Akutsu, Y., Lee, D. Y., Li, Y. Y. & Noike, T. Hydrogen production potentials and fermentative characteristics of various substrates with different heat-pretreated natural microflora. Int. J. Hydrog. Energy 34, 5365–5372 (2009).

Zhao, Y., Chen, Y., Zhang, D. & Zhu, X. Waste Activated Sludge Fermentation for Hydrogen Production Enhanced by Anaerobic Process Improvement and Acetobacteria Inhibition: The Role of Fermentation pH. Environ. Sci. Technol. 44, 3317–3323 (2010).

Friedli, G.-L. Interaction of deamidated soluble wheat protein (SWP) with other food proteins and metals. Doctoral thesis, University of Surrey. 193–199 (1996). http://epubs.surrey.ac.uk/2204/ [2012-8-30].

Bhattacharya, M., Jain, N., Bhasne, K., Kumari, V. & Mukhopadhyay, S. pH-induced Conformational Isomerization of Bovine Serum Albumin Studied by Extrinsic and Intrinsic Protein Fluorescence. J. Fluoresc. 21, 1083–1090 (2011).

Kristo, E., Hazizaj, A. & Corredig, M. Structural changes imposed on whey proteins by UV irradiation in a continuous UV light reactor. J. Agric. Food Chem. 60, 6204–6209 (2012).

Nakamura, K. et al. Conformational changes in seventeen cystine disulfide bridges of bovine serum albumin proved by Raman spectroscopy. Febs Lett. 417, 375–378 (1997).

Li Chan, E. C. Y. The applications of Raman spectroscopy in food science. Trends Food Sci. Technol. 7, 361–370 (1996).

Blusson, Petitdemange & Gay, R. A new, fast and sensitive assay for NADH-ferredoxin oxidoreductase detection in clostridia. Anal. Biochem. 110, 176–181 (1981).

Vignais, P. M., Billoud, B. & Meyer, J. Classification and phylogeny of hydrogenases. Fems Microbiol. Rev. 25, 455–501 (2001).

Wood, H. G., Jacobson, B., Gerwin, B. I. & Northrop, D. B. Oxalacetate transcarboxylase from Propionibacterium. Methods Enzymol. 8, 215–230 (1969).

Yu, P. Q. Protein secondary structures (alpha-helix and beta-sheet) at a cellular level and protein fractions in relation to rumen degradation behaviours of protein: a new approach. Br. J. Nutr. 94, 655–665 (2005).

Carter, D. C. & Ho, J. X. Structure of serum albumin. Adv. Protein Chem. 45, 153–203 (1994).

Shaikh, S. M. T., Seetharamappa, J., Kandagal, P. B., Manjunatha, D. H. & Ashoka, S. Spectroscopic investigations on the mechanism of interaction of bioactive dye with bovine serum albumin. Dyes Pigment. 74, 665–671 (2007).

Li, R. et al. Effect of pH on the gel properties and secondary structure of fish myosin. Food Chem. 121, 196–202 (2010).

Chodankar, S., Aswal, V. K., Kohlbrecher, J., Vavrin, R. & Wagh, A. G. Structural evolution during protein denaturation as induced by different methods. Phys. Rev. E 77 (2008).

Bertrand-Harb, C., Baday, A., Dalgalarrondo, M., Chobert, J. M. & Haertle, T. Thermal modifications of structure and co-denaturation of alpha-lactalbumin and beta-lactoglobulin induce changes of solubility and susceptibility to proteases. Nahrung 46, 283–289 (2002).

Piatkevich, K. D. et al. Extended Stokes Shift in Fluorescent Proteins: Chromophore-Protein Interactions in a Near-Infrared TagRFP675 Variant. Sci. Rep. 3, 1847 (2013).

Tanisho, S., Kuromoto, M. & Kadokura, N. Effect of CO2 removal on hydrogen production by fermentation. Int. J. Hydrog. Energy 23, 559–563 (1998).

Xu, K., Liu, H. & Chen, J. Effect of classic methanogenic inhibitors on the quantity and diversity of archaeal community and the reductive homoacetogenic activity during the process of anaerobic sludge digestion. Bioresour. Technol. 101, 2600–2607 (2010).

Miron, Y., Zeeman, G., Van Lier, J. B. & Lettinga, G. The role of sludge retention time in the hydrolysis and acidification of lipids, carbohydrates and proteins during digestion of primary sludge in CSTR systems. Water Res. 34, 1705–1713 (2000).

Khan, S. N. et al. Interaction of mitoxantrone with human serum albumin: Spectroscopic and molecular modeling studies. Eur. J. Pharm. Sci. 35, 371–382 (2008).

Yuan, H. et al. Improved bioproduction of short-chain fatty acids (SCFAs) from excess sludge under alkaline conditions. Environ. Sci. Technol. 40, 2025–2029 (2006).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51178324 and 51278354) and National Key Technology Research and Development Program of the Ministry of Science and Technology of China (No. 2012BAC11B04).

Author information

Authors and Affiliations

Contributions

N.D.X. carried out the experiments and wrote the paper, Y.G.C. conceived the study design and co-wrote the paper, A.H.C. analyzed the data, L.Y.F. characterized the protein structure. All authors contributed to the scientific planning and discussions.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Xiao, N., Chen, Y., Chen, A. et al. Enhanced Bio-hydrogen Production from Protein Wastewater by Altering Protein Structure and Amino Acids Acidification Type. Sci Rep 4, 3992 (2014). https://doi.org/10.1038/srep03992

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep03992

This article is cited by

-

Modeling anaerobic digestion metabolic pathways for antibiotic-contaminated wastewater treatment

Biodegradation (2020)

-

Simultaneous production of hydrogen and volatile fatty acids from anaerobic digestion of Macrocystis pyrifera biomass residues

Journal of Central South University (2017)

-

New concepts of microbial treatment processes for the nitrogen removal: effect of protein and amino acids degradation

Amino Acids (2016)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.