Abstract

In this report, we introduce a novel and commercially viable method to recover renewable hydrogen and carbon nanotubes from waste glycerol produced in the biodiesel process. Gas-phase catalytic reforming converts glycerol to clean hydrogen fuel and by replacing the problematical coke formed on the catalyst with high value carbon nanotubes, added value can be realised. Additional benefits of around 2.8 kg CNTs from the reforming of 1 tonne of glycerol and the production of 500 Nm3 H2 could have a considerable impact on the economics of glycerol utilization. Thereby, the contribution of this research will be a significant step forward in solving a current major technical and economic challenge faced by the biofuels industry.

Similar content being viewed by others

Introduction

Rising energy prices and increasing dependence on energy imports jeopardise the security and competitiveness for many countries e.g. EU Member States which are heavily dependent on importing fossil fuels. “An EU Strategy for Biofuels” has been implemented to fight climate change and energy security1. The EU is the one of the world's leading regions for biodiesel production with an estimated potential production capacity of 23.5 million tonnes (2012)2.

However, one challenge for the further development of the biodiesel industry is the large amount of by-product glycerol produced, with around 10% of the weight of the feedstock3,4 with about 0.96 million tonnes of waste glycerol generated in the European in 2010. The surplus of glycerol not only causes storage and waste treatment problems but also substantially influences the glycerol price and biodiesel industry. For example, the glycerol price dropped from a price of 1000–1300 € t−1 between 2000 and 2003 to between 500–700 € t−1 in 2004–20064 and has a current value of around 275–400 € t−1. The price of glycerol may fall to even lower levels with the increase of biodiesel production and thus the economic viability of biodiesel production will be reduced; this has already limited the development of the biodiesel industry2. Making profit from biodiesel by-product-glycerol will be an important route to solve the economic and environmental challenges of biofuels production. This has attracted extensive research interest5,6,7, with efforts focused on production of valuable products from glycerol8.

A number of processes have been explored for converting glycerol to chemicals such as selective oxidation, reforming, esterification, dehydration, fermentation etc.4,9. Among them, recovery of renewable and clean fuel hydrogen from glycerol reforming is a promising route for glycerol utilisation10,11. For aqueous phase reforming of glycerol, less catalyst deactivation, lower reforming temperature and lower levels of CO concentration have been reported5,12,13,14. However, classic gas phase reforming of glycerol provides a comparatively high H2 selectivity using conventional reaction systems under more safe atmospheric pressures and is closer to commercialization6,15,16.

During glycerol gas reforming, Pt-based catalysts have been primarily used to promote hydrogen production6,10. Lately, relatively low-cost Ni-catalysts have been introduced into the reforming process17. While carbon deposition on the catalyst is unavoidable18,19, there has been much effort to reduce coke formation. Recently, we reported a process to turn ‘negative’ coke deposition on catalysts to the ‘positive’ of carbon material production20. A process that could replace the conventional removal of coke by combustion which adds to the atmospheric burden of CO2.

In this paper, the production of renewable H2 together with high quality carbon nanotubes (CNTs) were generated during the reforming of pure glycerol, which was selected to simplify the investigation. Crude glycerol contains a number of impurities, including spent and excess alkali metal catalysts, salts, excess methanol and unrecovered biodiesel compounds (fatty acid methyl esters). Hydrogen and CNT's production from real-world crude glycerol would require future extensive investigation. The process conditions which influence the quality and quantity of H2 and CNTs have been preliminarily investigated by using a two-stage fixed-bed reaction system in the presence of Ni-based catalyst (Schematic diagram of reactor is shown in Supplementary Fig. S1). CNTs have a promising market future because of their special physical and chemical properties and there are many applications in electronics, energy storage and composites21,22,23,24. Currently, CNTs are regarded as high value products25,26, which will significantly increase the economic benefit of the glycerol reforming process which initially only produces hydrogen at relatively lower value27. Thereby, the innovative process described here will make biodiesel production more economically feasible, environmental friendly and resource sustainable.

Results

Hydrogen production

The production of hydrogen from the reforming of glycerol was significantly increased with the introduction of a Ni-Mg-Al catalyst and also increasing reforming temperature. As shown in Fig. 1, hydrogen production was increased from 0.02 to 0.51 m3 kg−1 glycerol with increasing reforming temperatures from 500 to 700°C. At the same time, the liquid yield was decreased from 90.5 to 15.2 wt.% at the higher reforming temperature. The addition of steam to glycerol reforming at 600°C (water/glycerol ratio: 0.08 g/g) (Fig. 1) showed only a slight influence on the production of hydrogen (from 0.11 to 0.13 m3 kg−1 glycerol) and concentrations of H2 (from 34.9 to 37 Vol.%). With the increase of reforming temperature from 600 to 700°C in the presence of steam and catalyst, the concentration of CO2 was decreased from 10.7 to 7.5 Vol.% and CH4 concentration was increased from 3.8 to 5.3 Vol.%, other C2-C4 hydrocarbon gas concentrations decreased from 4.5 to 3.4 Vol.% (gas concentration reported as N2 free (results not shown here)).

Mass balance and hydrogen production from catalytic reforming of glycerol.

The presence of Ni-Mg-Al catalyst or sand, reforming temperature and steam addition are marked in the Figure. Hydrogen production is calculated by the volume of hydrogen divided by the mass of total glycerol sample; gas and liquid yield was obtained from weight of gas and liquid related to the weight of total glycerol sample, respectively. Gas concentrations are nitrogen free. Hydrogen production and gas yield is increased with the increase of temperature for glycerol reforming. The presence of steam shows a slight influence on hydrogen production.

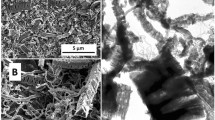

SEM and TEM analysis

Scanning electron microscopy (SEM) images shown in Fig. 2 clearly show well distributed filamentous carbons on the surface of the Ni-Mg-Al catalyst after glycerol reforming at 600°C. These filamentous carbons could hardly be observed on the catalyst surface at the lower reforming temperature of 500°C as shown in Supplementary Fig. S2. Reforming temperatures higher than 500°C were required for the production of both filamentous carbon and hydrogen. The amount of filamentous carbons was clearly increased as H2 yield increased from 0.02 to 0.13 and 0.51 m3 kg−1 glycerol when reforming temperatures were increased from 500 to 600 and 700°C, respectively, in the presence of the Ni-Mg-Al catalyst and steam. Most of these filamentous carbons were in fact tubular multi-walled carbon nanotubes (MWCNTs) which were confirmed by transmission electron microscopy (TEM) in Fig. 3, where CNTs were found with thick walls (~10 nm) (Fig. S2 (c)). In addition to the production of CNTs, TEM analysis (Fig. 3) also confirms the presence of carbon nanofibres, which are also important materials for various applications e.g. hydrogen storage28 or electrochemical capacitors29. However, the majority of filamentous carbons produced from glycerol reforming are suggested to be CNTs as shown in Fig. S2 (d). In addition, uniform CNTs with lengths of up to 50 μm and diameters of around 20 nm were observed from SEM and TEM analysis (Fig. 2, Fig. S2 (b) and (d)). Ni particles can be clearly detected at the tip of the CNTs, as shown in Fig. S3(d).

SEM of reacted Ni-Mg-Al (1:1:1) catalyst from reforming of glycerol at 600°C in the presence of steam.

Filamentous carbons with length more than 10 μm were clearly obtained. Reforming temperature higher than 500°C is required for the glycerol reforming, as filamentous carbons are barely observed after 500°C reforming.

Temperature programmed oxidation (TPO)

TPO was used to quantitatively evaluate the CNT production on the catalyst surface: CNTs oxidation occurred at ca. 650°C and the oxidation of amorphous carbons at a lower temperature of around 550°C20. As shown in Fig. 4, differential thermo-gravimetry (DTG)-TPO confirmed the production of CNTs by showing oxidation peaks at around 650°C for all the reacted catalysts derived from various reforming conditions. CNTs were mostly produced from the reforming of glycerol at 700°C (Fig. 4 (d) and (e)) compared with other reforming temperatures, due to the dominant peak for CNT oxidation shown by the DTG-TPO results at this temperature. Especially for the glycerol reforming temperature of 500°C, TPO peak for oxidation of CNTs was barely observed, which is consistent with the SEM analysis, where almost no CNTs were observed in Fig. S2 (a).

DTG-TPO results of reacted catalysts from various reaction conditions with the Ni-Mg-Al (1:1:1) catalyst.

(a) Reforming temperature of 500°C with water addition; major oxidation peak is around 500°C, assigned to amorphous carbons, which supports the SEM analysis where no filamentous carbons were observed. (b) Reforming temperature of 600°C without water addition. (c) Reforming temperature of 600°C with water; the majority of carbon oxidation for the reacted catalyst at 600°C reforming temperature is around 500°C for the TPO results indicating that a large amount of amorphous carbons were present at this reforming temperature. (d) Reforming temperature of 700°C without water addition. (e) Reforming temperature of 700°C with water; Major oxidation peak for carbons is around 650°C indicating that filamentous CNT carbons are dominant for the reforming process at temperature of 700°C; the addition of water in the reforming process has reduced the total amount of coke deposition due to the effect of water etching reaction.

Introduction of water (steam) to the glycerol reforming process showed little influence on the distribution of oxidation peaks from the DTG-TPO results (Fig. 4). However, the total amount of carbon obtained on the surface of the catalyst was reduced with the introduction of water injection. For example carbon formation was reduced from 21.5 to 7.5 wt.% (weight of carbon divided by weight of catalyst) when water was introduced for glycerol reforming at 700°C (Supplementary Fig. S3 (d) and (e)).

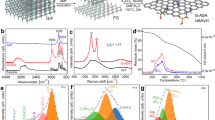

Raman spectroscopy analysis

Production of CNTs from glycerol reforming has been confirmed by Raman analysis of the reacted catalysts (Fig. 5). The D band at around 1345 cm−1 is due to disordered amorphous carbon structures, while the G band at about 1568 cm−1 corresponds to tangential vibrations of the graphite carbons (i.e. crystallinity)30. The second order Raman spectrum G' band at around 2684 cm−1 is ascribed to the two-photon elastic scattering process31. The intensity of the D band normalized to the G band (ID/IG) is used to evaluate the degree of graphitization of CNTs30. More amorphous carbons and impurities, due to higher intensity of the D band (ID/IG of 1.12) was observed for the reacted Ni-Mg-Al catalyst from glycerol reforming at 700°C without water addition.

Raman analysis to the reacted Ni-Mg-Al catalyst.

(a) Reforming temperature of 600°C with water addition. (b) Reforming temperature of 600°C without water. (c) Reforming temperature of 700°C without water. (d) Reforming temperature of 700°C with water. Higher purity of CNTs was obtained at a reforming temperature of 700°C compared with 600°C, as a lower intensity of D peak was obtained. The addition of water in the glycerol reforming process resulted in the reduction of intensity ratio (ID/IG) indicating the improvement of CNT purity.

The addition of water injection in the glycerol reforming process resulted in a higher purity of CNTs formed on the surface of the reacted Ni-Mg-Al catalyst (Fig. 5 (d) with a lower ID/IG ratio (0.80) for the reforming temperature of 700°C. In addition, the addition of water for the glycerol reforming at 600°C also resulted in higher quality CNTs (a lower ID/IG ratio was obtained for Fig. 5 (a) compared with Fig. 5 (b). The higher purity of CNTs obtained on the reacted Ni-Mg-Al catalyst was also produced at a reforming temperature of 700°C (Fig. 5 (d) with ID/IG ratio of 0.80) compared with 600°C (Fig. 5 (a) with ID/IG ratio of 0.77) in the presence of water; this is consistent with the observation of TPO analysis, where the intensity of CNT oxidation was higher for 700°C (Fig. 4).

Discussion

CNTs were produced and, confirmed by TEM and Raman analysis, with a quantity of around 10 wt.% of the weight of the Ni-Mg-Al catalyst, when glycerol was reformed with a feeding rate of 18 g h−1 for 1 h at the reforming temperature of 700°C. From the hydrogen production results (Fig. 1) and Raman analysis (Fig. 4), it is proposed that higher reforming temperatures (> 500°C) should be used for higher yields of hydrogen and CNTs production.

Raman analysis showed that the purity of CNTs was improved by the addition of water to the reforming process; however, the quantity of CNTs produced was reduced (TPO analysis shown in Supplementary Fig. S3, e.g. reduced from 21.5 to 7.5 wt.% at a reforming temperature of 700°C), while the hydrogen production was only slightly changed. This is ascribed to the etching effect of steam on carbons32 formed during glycerol steam reforming. Therefore, the production yield and quality of CNTs can be tuned within the glycerol reforming process by controlling the water content, thereby producing different types of CNTs according to application specifications and end-markets.

In addition to the investigation of reforming temperature and water addition, it was also found that the production of CNTs and hydrogen were influenced by the type of catalyst and glycerol/catalyst ratio; higher quantities of CNTs were obtained with a Ni-Al (1:2) catalyst at a reforming temperature of 600°C, while more amorphous carbons were obtained with the Ni-Mg-Al catalyst at this temperature (TPO results from Supplementary Fig. S4, S5). In addition, a higher ratio of glycerol/catalyst during glycerol reforming generated a higher production of carbons; however with a lower production of hydrogen (Fig. S4, S6). Therefore, optimization of glycerol feeding rate and type of catalyst etc. is also believed to generate high quality CNTs and/or high yields of hydrogen.

This work proposes an innovative solution for a problematic waste, glycerol, from biodiesel production. The proposed process provides for production of renewable hydrogen and CNTs having high-end applications such as energy storage and use in fuel cells from the reforming of glycerol; e.g. around 2.8 kg of CNTs and 500 Nm3 H2 could be produced from the reforming of 1 tonne of glycerol at a reforming temperature of 700°C in the presence of a Ni-Mg-Al (1:1:1) catalyst. By controlling processing conditions such as water content and reforming temperature and the type of catalyst, hydrogen production and the quality of CNTs could be potentially manipulated to adjust to the market demands for hydrogen and/or CNTs. Clearly, the CNT's are required to be separated from the catalyst and purified according to the end-use application. Currently, there is intensive work on the separation and purification of CNTs including liquid phase oxidation33, gas phase oxidation34, density differentiation35, DNA sequences36 etc. In this work, we did not separate or purify the CNTs produced from glycerol reforming, but will be a key step in the future development of the process.

The Ni-Mg-Al catalyst, used in this work, has shown good stability in terms of hydrogen production after around 6 hours testing; changes of gas concentration (CH4, CO, CO2 and H2) during glycerol reforming are shown in Fig. S7. It is interesting to point out that the catalyst can regain its activity for hydrogen production after switching off the glycerol injection or reducing the reforming temperature. The catalyst was not deactivated in terms of hydrogen production from the deposition of carbons, which might be attributed to the strong interaction of metal and support. A high reduction temperature (~840°C) was required to reduce the catalyst based on temperature program reduction analysis (Fig. S8 (a)). In addition, metal oxides could be observed from the X-ray analysis of the fresh Ni-Mg-Al catalyst (Fig. S8 (b)) indicating that the Ni has reacted with the support material37. In addition, in this work carbon deposition could not be directly related to hydrogen production (Fig. S7), which may be attributed to the active Ni sites maintaining their availability for catalytic activity for hydrogen production even though carbon deposition had occurred37.

This novel process enables the production of CNTs instead of problematic amorphous carbons formed on the catalyst from catalytic glycerol reforming and to increase economic and environmental value to the reforming process originally only with the purpose of hydrogen production. For example, it is estimated that the reforming of 1 tonne of glycerol would produce ~2.8 kg CNTs in addition to ~500 Nm3 of hydrogen could have a considerable impact on the economics of glycerol utilization. It should also be noted that a cheap Ni-based catalyst was used in this work, the overall cost of the catalyst used could be reduced if the metals could be recycled, while there are potential income streams from production of hydrogen and CNTs. In addition, if CNTs are produced from glycerol, which is a renewable resource regarded as waste, this could potentially bring down the price of CNTs; thus contributing to the development of the emerging CNT industry.

Methods

Glycerol reforming was conducted with a fixed-bed two-stage reaction system (a schematic diagram is shown in Supplementary Fig. S1). Glycerol was fed using a syringe pump with a feeding rate of 18 g h−1 with or without water injection of 1.5 g h−1 and was first pre-heated at around 250°C and reformed in the second stage at the investigated reforming temperatures. The generated non-condensed gas was analysed with gas chromatography.

A high resolution scanning electron microscope (SEM, LEO 1530) and transmission electron microscope (TEM) (Philips CM200) were used to characterize the catalysts. The temperature-programmed oxidation (TPO) was carried out on the reacted catalysts using a Stanton-Redcroft thermogravimetric analyser (TGA and DTG) to determine the oxidation properties of the CNTs deposited on the reacted catalysts. Raman spectra were obtained for the deposited carbons using a Renishaw Invia system at a wavelength of 514 nm.

Ni-Al and Ni-Mg-Al catalysts were prepared by a co-precipitation method. NH4(OH) was added into Ni(NO3)·6H2O and Al(NO3)3·9H2O with or without Mg(NO3)2·6H2O aqueous solutions (200 ml) at 40°C with moderate stirring until the final pH reached was around 8. The precipitates were filtered with water (40°C), followed by drying at 105°C overnight and then were calcined at 750°C for 3 h. Catalyst with particle size between 50 and 220 μm was used for the experiments. Ni-Al catalysts with molar ratio 1:2 and 1:4 were prepared, assigned as Ni-Al (1:2) and Ni-Al (1:4). Ni-Mg-Al with molar ratio 1:1:1 was prepared and assigned as Ni-Mg-Al in this work.

References

EU An EU Strategy for Biofuels. (2006).

EBB The EU biodeisel industry. 2012 (2010).

Coombs, A. Glycerin bioprocessing goes green. Nat Biotech 25, 953–954 (2007).

Behr, A., Eilting, J., Irawadi, K., Leschinski, J. & Lindner, F. Improved utilisation of renewable resources: New important derivatives of glycerol. Green Chemistry 10, 13–30 (2008).

Huber, G. W., Shabaker, J. W. & Dumesic, J. A. Raney Ni-Sn Catalyst for H2 Production from Biomass-Derived Hydrocarbons. Science 300, 2075–2077 (2003).

Simonetti, D. A., Kunkes, E. L. & Dumesic, J. A. Gas-phase conversion of glycerol to synthesis gas over carbon-supported platinum and platinum–rhenium catalysts. Journal of Catalysis 247, 298–306 (2007).

Shabaker, J. W., Simonetti, D. A., Cortright, R. D. & Dumesic, J. A. Sn-modified Ni catalysts for aqueous-phase reforming: Characterization and deactivation studies. Journal of Catalysis 231, 67–76 (2005).

Haas, M. J., McAloon, A. J., Yee, W. C. & Foglia, T. A. A process model to estimate biodiesel production costs. Bioresource Technology 97, 671–678 (2006).

Pagliaro, M., Ciriminna, R., Kimura, H., Rossi, M. & Della Pina, C. From Glycerol to Value-Added Products. Angewandte Chemie International Edition 46, 4434–4440 (2007).

Soares, R. R., Simonetti, D. A. & Dumesic, J. A. Glycerol as a Source for Fuels and Chemicals by Low-Temperature Catalytic Processing. Angewandte Chemie International Edition 45, 3982–3985 (2006).

Jacobsen, H. “Heterogreeneous” Chemistry: Catalysts for Hydrogen Production from Biomass. Angewandte Chemie International Edition 43, 1912–1914 (2004).

Cortright, R. D., Davda, R. R. & Dumesic, J. A. Hydrogen from catalytic reforming of biomass-derived hydrocarbons in liquid water. Nature 418, 964–967 (2002).

Zhang, L. et al. Correlation of Pt-Re surface properties with reaction pathways for the aqueous-phase reforming of glycerol. Journal of Catalysis 287, 37–43 (2012).

Chheda, J. N., Huber, G. W. & Dumesic, J. A. Liquid-Phase Catalytic Processing of Biomass-Derived Oxygenated Hydrocarbons to Fuels and Chemicals. Angewandte Chemie International Edition 46, 7164–7183 (2007).

Hirai, T., Ikenaga, N.-O., Miyake, T. & Suzuki, T. Production of Hydrogen by Steam Reforming of Glycerin on Ruthenium Catalyst. Energy & Fuels 19, 1761–1762 (2005).

Cui, Y., Galvita, V., Rihko-Struckmann, L., Lorenz, H. & Sundmacher, K. Steam reforming of glycerol: The experimental activity of La1−xCexNiO3 catalyst in comparison to the thermodynamic reaction equilibrium. Applied Catalysis B: Environmental 90, 29–37 (2009).

Kim, S. M. & Woo, S. I. Sustainable Production of Syngas from Biomass-Derived Glycerol by Steam Reforming over Highly Stable Ni/SiC. ChemSusChem 5, 1513–1522 (2012).

Iriondo, A. et al. Glycerol liquid phase conversion over monometallic and bimetallic catalysts: Effect of metal, support type and reaction temperatures. Applied Catalysis B: Environmental 106, 83–93 (2011).

Huber, G. W., Shabaker, J. W., Evans, S. T. & Dumesic, J. A. Aqueous-phase reforming of ethylene glycol over supported Pt and Pd bimetallic catalysts. Applied Catalysis B: Environmental 62, 226–235 (2006).

Wu, C., Wang, Z., Wang, L., Williams, P. T. & Huang, J. Sustainable processing of waste plastics to produce high yield hydrogen-rich synthesis gas and high quality carbon nanotubes. RSC Advances 2, 4045–4047 (2012).

Brown, M. Carbon nanotubes for hydrogen storage. Chemistry World 8, 20–20 (2011).

Noked, M., Okashy, S., Zimrin, T. & Aurbach, D. Composite Carbon Nanotube/Carbon Electrodes for Electrical Double-Layer Super Capacitors. Angewandte Chemie-International Edition 51, 1568–1571 (2012).

Baughman, R. H., Zakhidov, A. A. & de Heer, W. A. Carbon Nanotubes--the Route Toward Applications. Science 297, 787–792 (2002).

Fang, W. et al. Ce-Ni mixed oxide as efficient catalyst for H-2 production and nanofibrous carbon material from ethanol in the presence of water. RSC Advances 2, 9626–9634 (2012).

Dasgupta, K., Joshi, J. B. & Banerjee, S. Fluidized bed synthesis of carbon nanotubes – A review. Chemical Engineering Journal 171, 841–869 (2011).

Noorden, R. V. The trials of new carbon. Nature 4569, 14–16 (2011).

Vispute, T. P., Zhang, H., Sanna, A., Xiao, R. & Huber, G. W. Renewable Chemical Commodity Feedstocks from Integrated Catalytic Processing of Pyrolysis Oils. Science 330, 1222–1227 (2010).

Blackman, J. M., Patrick, J. W., Arenillas, A., Shi, W. & Snape, C. E. Activation of carbon nanofibres for hydrogen storage. Carbon 44, 1376–1385 (2006).

Yang, L., Hou, L. R., Zhang, Y. W. & Yuan, C. Z. Facile synthesis of mesoporous carbon nanofibres towards high-performance electrochemical capacitors. Materials Letters 97, 97–99 (2013).

DiLeo, R. A., Landi, B. J. & Raffaelle, R. P. Purity assessment of multiwalled carbon nanotubes by Raman spectroscopy. Journal of Applied Physics 101, 064307–064305 (2007).

Saito, R. et al. Double resonance Raman spectroscopy of single-wall carbon nanotubes. New Journal of Physics 157.151–157.115 (2003).

Hata, K. et al. Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes. Science 306, 1362–1364 (2004).

Monthioux, M. et al. Sensitivity of single-wall carbon nanotubes to chemical processing: An electron microscopy investigation. Carbon 39, 1251–1272 (2001).

Zimmerman, J. L., Bradley, R. K., Huffman, C. B., Hauge, R. H. & Margrave, J. L. Gas-Phase Purification of Single-Wall Carbon Nanotubes. Chemistry of Materials 12, 1361–1366 (2000).

Arnold, M. S., Green, A. A., Hulvat, J. F., Stupp, S. I. & Hersam, M. C. Sorting carbon nanotubes by electronic structure using density differentiation. Nat. Nanotechnol. 1, 60–65 (2006).

Tu, X. M., Manohar, S., Jagota, A. & Zheng, M. DNA sequence motifs for structure-specific recognition and separation of carbon nanotubes. Nature 460, 250–253 (2009).

Rossetti, I. et al. Nickel Catalysts Supported Over TiO2, SiO2 and ZrO2 for the Steam Reforming of Glycerol. ChemCatChem 5, 294–306 (2013).

Acknowledgements

This work was supported by the, International Exchange Scheme from the Royal Society (IE110273) and the Early Career Research Scheme from the University of Sydney. Authors acknowledge Lisha Dong for her assistance during experiments.

Author information

Authors and Affiliations

Contributions

Z.W. and C.W. conducted the experiments. C.W. designed the experiments, analysed the data and wrote the manuscript. J.H. and P.W. supervised the project and contributed to manuscript modification. All authors contributed to the discussions of the results.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivs 3.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-nd/3.0/

About this article

Cite this article

Wu, C., Wang, Z., Williams, P. et al. Renewable hydrogen and carbon nanotubes from biodiesel waste glycerol. Sci Rep 3, 2742 (2013). https://doi.org/10.1038/srep02742

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep02742

This article is cited by

-

Conversion of biomass-derived sorbitol to glycols over carbon-materials supported Ru-based catalysts

Scientific Reports (2015)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.