Abstract

A theoretical study of urethane formation through the reaction of phenyl isocyanate and butan-1-ol was carried out, without and in the presence of morpholine, and 4-methylmorpholine catalysts. The reaction with and without catalysts was studied at BHandHLYP/6-31G(d) and G3MP2BHandHLYP levels of theories. The reaction mechanism in the presence of catalysts differs significantly from the catalyst-free case and includes seven steps. The catalyst-free system was investigated along with the catalytic process, the geometries were optimized, and the corresponding thermodynamic properties were calculated. Calculated reactant complexes were compared with crystal structures of morpholine, and 4-methylmorpholine complexed with diols found in the literature. The structures were strikingly similar and thus, the validity of the proposed and studied general organocatalytic reaction mechanism was partially verified. Meanwhile, an irregularity in the energy profile occurred due to the zwitterionic nature of an intermediate. To handle the irregularity, a correction was implemented which handles the appearance of a zwitterionic structure and the corresponding energetic properties. The results showed that morpholine is less effective catalyst compared to 4-methylmorpholine, which can be associated with the difference in their PA (1523.95 and 963.07 kJ/mol, respectively). The current results prove the important role of amine catalysts in urethane synthesis which can be applied in polyurethane catalyst design and development.

Similar content being viewed by others

Introduction

The first polyurethane (PU) which was capable of competing with nylon was developed by Otto Bayer1. This invention is one of the most significant advances in polymer science. Polyurethanes are one of the most versatile and unique polymers utilized in industrial manufacturing2. Flexible and rigid foam, paint, coating, adhesive, packaging, insulation, clothing yarn, and synthetic fiber are all PU applications3,4,5. More than two million tonnes of PU is synthesized each year only in the European Union6. Polyurethane is a segmented polymer containing soft and hard segments. The flexibility is offered by the soft segments, while the hard segments offer strength7,8. PUs are formed by reactions between isocyanate and polyol9,10,11,12,13. Catalysts can be considered as one of the most important components of the reaction system besides the starting materials14. Amines, inorganic salts, organophosphorus and organometallic catalysts are used for the synthesis of polyurethane15,16. However, amine catalysts are the most widely used in the production of polyurethane and its raw materials17,18,19. Especially secondary-amine-containing and tertiary-amine-containing structures are used as catalysts in polyurethane synthesis20. Therefore, extensive research there is aimed to understand catalytic PU formation by using both theoretical and kinetic methods21,22. Mechanisms of the amine-catalyzed isocyanate–alcohol reactions have been the subject of previous research20,22,23,24. The reaction of phenyl isocyanate (PhNCO) with methanol (MeOH) in acetonitrile, using the computational methods of BHandHLYP/6-31G(d) and G3MP2BHandHLYP, combined with the SMD implicit solvent model was examined without and in the presence of eight different catalysts20,22. The result demonstrates the important effect of the studied catalysts on the formation of urethane20,22. The catalytic effect of triethylamine on polythiourethane synthesis was also studied and an enhancement in the reaction rate with the increase in the catalyst concentration was experienced25. Meanwhile, the reaction of phenyl isocyanate (PhNCO) and stoichiometric butan-1-ol (BuOH) in acetonitrile was also explored in the presence of different aliphatic tertiary amine species by using both experimental and theoretical tools26. The computed thermodynamic properties of the reaction are in excellent agreement with the experimentally determined ones. The difference is less than 2 kJ/mol in each catalytic system26.

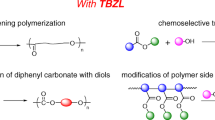

Although several previous studies were conducted, urethane formation is still a hot topic due to its importance in polyurethane production. The further understanding of the catalytic process is inevitable to achieve more environmentally friendly processes and thus, in this research, the reaction between PhNCO and BuOH is studied in the presence of two different cyclic amine catalysts (Fig. 1). These two cataysts, morpholine, and 4-methylmorpholine are synthetic organic liquids used mainly as an intermediate in the production of rubber chemicals, corrosion inhibitors, waxes and polishes, and optical brighteners. Due to their advantageous physicochemical, biological, and metabolic properties, as well as facile synthetic routes. The morpholine ring is a versatile and readily accessible synthetic building block, it is easily introduced as an amine reagent or can be built according to a variety of available synthetic methodologies27.

Methods

Calculations on the studied systems have been carried out by applying density functional theory and composite methods (BHandHLYP/6-31G(d) and G3MP2BHandHLYP)28,29 and using the Gaussian 09 program package30. The effect of acetonitrile (MeCN, εr = 35.688) has also been considered by employing SMD polarizable continuum model to evaluate the effect of the surrounding solvent31. Gas phase calculations and other solvents for selected species were also considered using the same solvent model. Furthermore, frequency calculations have also been performed to determine the thermodynamic properties of the species studied and to verify the nature of the stationary points on the potential energy surface. To achieve the G3MP2BHandHLYP energy, geometry optimization, and frequency calculation were performed at the BHandHLYP/6-31G(d) theoretical level. Furthermore, on the optimized structures, two single-point energy calculations were performed on the QCISD(T)/6-31G(d) and MP2/GTMP2Large theoretical levels and the previously determined composite scheme was applied32. Meanwhile, an irregularity in the energy profile was identified, where an intermediate (IM) was higher in energy compared to the following transitiona state (TS2). To handle the irregularity in the potential energy surface, a correction of − 24.9 kJ/mol was used which is corresponding to the experimental reaction Gibbs free energy of the appearance of a zwitterionic structure starting from a neutral species in acetonitrile33,34. Similar approach was previously applied successfully33,34.

Results and discussion

The formation of the urethane linkage has been studied by using the butan-1-ol and phenyl isocyanate as reference models. Urethane formation without and in the presence of amine catalysts were studied compared by considering the previously proposed general mechanisms20 (Scheme 1). The catalyst-free system was investigated along with the catalytic process, the geometries were optimized, and the corresponding thermodynamic properties were calculated, and based on these the reactions were characterized.

The catalyst-free formation of urethane bonds goes through a concerted mechanism (Scheme 1, and Fig. S1) as it was described before. First, the complex will formed (RC, PhNCO–BuOH) and the next step is the formation of the product (P) through a transition state (TS) (Fig. S1).

In the transition state the proton transfer from the hydroxyl group of butan-1-ol to the nitrogen of the isocyanate occurs, and bond is formed between the oxygen of the former and the carbon of the latter. The distances of N–H and C–O within the TS are 1.387 Å and 1.494 Å, respectively. The relative Gibbs free energy which needs to be overcomed in order to obtain the product is 170.05 kJ/mol (Table 1).

Several additional steps will occur in the case of the mechanism of the phenyl isocyanate – butan-1-ol reaction in the presence of amine catalysts compared to the catalyst-free pathway (Scheme 1) which was proposed before20. In this case, the first step will be the formation of the bimolecular reactant complex (RC1), and then a trimolecular complex will emerge (RC2). Hydrogen bond between BuOH and the catalytic amine is formed, and the corresponding N–H* distance is 1.889 Å in case of morpholine and a bit elongated to 1.906 Å when 4-methylmorpholine is considered (Table 2, Fig. 2, and Table S1).

Optimised structures along the reaction pathway between phenyl isocyanate and butan-1-ol in the presence of catalysts: (a) morpholine, and (b) 4-methylmorpholine calculated at the BHandHLYP/6-31G (d) level of theory in acetonitrile. RC—reactant complex; TS—transition state; IM—intermediate; PC—product complex.

To verify the proposed mechanism and the potential formation of the reactant complexes or intermediates, an extensive search for crystal structures in the Cambridge Structural Database (CSD)36 was carried out. Crystal structures including morpholine and 4-methylmorpholine complexed with hydroquinone (Fig. 3 “a”) were found37. It can be seen that the interaction (−OH–N–, hydrogen bond) between morpholine and the corresponding hydroxyl group in the crystal structure and in the case of the optimized reactant complex (RC1) is very similar to each other and the difference between the length of the hydrogen bonds is only 0.048 Å, while in the case of 4-methylmorpholine it is even smaller 0.031 Å. These promising similarities between the crystal structures and the computed reaction complexes further support the previously proposed complex 7-step mechanism.

Comparison of morpholine and 4-methylmorpholine complexes: (a) crystal structures37; (b) optimized structures.

Another interaction was established between the carbon of isocyanate and hydroxyl oxygen of BuOH. The corresponding C–O distance is 3.044 Å and 3.055 Å in case of morpholine and 4-methylmorpholine, respectively (Fig. 2). After the reactant complex formation, proton transfer occurs in TS1 from the hydroxyl group to the nitrogen of both morpholine and 4-methylmorpholine, and thus, the corresponding N–H* distances reduced to 1.674 Å and 1.689 Å, respectively (Fig. 2).

The relative energy of TS1 is the lowest 97.42 kJ/mol when 4-methylmorpholine is considered, while in case of morpholine a slight increase of ~ 1 kJ/mol is experienced (Fig. 4). However, in both cases the relative energy of the transition state significantly reduced compared to catalyst-free process.

Relative Gibbs free energy (∆rG) profile of the studied catalysed urethane formation reactions in the presence of morpholine, or 4-methylmorpholine calculated at the G3PMP2BHandHLYP level of theory in acetonitrile using the SMD implicit solvent model at 298.15 K and 1 atm, respectively. *Corrected relative Gibbs free energies of IM calculated according to Ref.35.

The catalysts are mixed first with the polyol in the experimental preparation steps and thus, RC1 is formed. Thereafter, the trimolecular complex is evolved by adding the isocyanate and the reaction proceeds. Therefore, to compute the barrier height for the first reaction step, the relative energy between TS1 and RC1 has to be computed. In the presence of morpholine and 4-methylmorpholine (Table 1). In previous studies, kinetic experiments of urethane formation were carried out23,26,38. The results showed that in the case of cyclic catalysts the activation energy (Ea) cover a wider range between 24.8 and 51.8 kJ/mol, while in the case of linear catalysts it is around 23.9–25.5 kJ/mol. In the current work, the studied catalysts are cyclic structures and the calculated activation energies are 29.7 and 26.6 kJ/mol, for morpholine and 4-methylmorpholine, respectively, which is in good agreement with previous experimental data for similar catalysts. This indicates that morpholine is a bit less effective to prepare urethane compared to its methylated counterpart. A zwitterionic intermediate structure (IM) will form after TS1 within which a new bond will develop between the isocyanate’s carbon and butan-1-ol. The corresponding relative Gibbs free energies of the IMs are 12.79 and 8.77 kJ/mol, for the morpholine and 4-methylmorpholine catalyzed reaction, respectively (Table 1).

The second transition state (TS2) will form where the proton transfer from the catalyst to the product occurs. In TS2, the distance between N–H** decreased, while the distance between N–H* increased compared to IM (Table 2, Fig. 2), and the relative energies are differed by ~ 10 kJ/mol in case of morpholine and 4-methylmorpholine. The TS2 structures including morpholine and 4-methylmorpholine have a relative energy of 5.46 kJ/mol and − 2.68 kJ/mol, respectively.

It seems that IM is higher in energy than TS2, ΔΔrG_TS2-IM = − 7.32 kJ/mol and − 11.45 kJ/mol in case of morpholine and 4-methylmorpholine, respectively (Table 1), which needs to be explained. The most straightforward explanation is the solvent effect, which is caused by the zwitterionic nature of the intermediate. Despite numerous attempts, IM was not located in the gas phase, which is also related to its zwitterionic nature. Furthermore, calculations were also carried out in different solvents and it was found that by changing solvent the relative energy of TS2 and IM is also changing (Table S3) similarly in the literature35, but the IM remained higher than the corresponding transition state. Thus, the applied method is not suitable to handle the solvent effect precisely in case of the zwitterionic intermediate. Therefore, a correction was applied which was previously successfully used in the literature to handle a system within which zwitterionic structure is formed in case of an amino acid34. To balance the effect of the formation of the zwitterionic IM, − 24.9 kJ/mol33 was added to the relative Gibbs free energy which shifted the uncorrected ΔΔrG_TS2-IM from − 7.32 kJ/mol and − 11.45 kJ/mol to 17.58 and 13.45 kJ/mol in case of the morpholine and 4-methylmorpholine catalyzed process, respectively. By applying the correction, the IM became lower in energy than TS2, and thus, the previous irregularity in the energy profile has been handled.

Since the catalytic mechanism includes proton transfers proton affinities (PAs) for the active nitrogens of the catalysts are also calculated (Fig. 1, Table 3). It was found that morpholine is better proton acceptor, as it had higher proton affinity (1523.95 kJ/mol). While, 4-methylmorpholine has a lower proton affinity (963.07 kJ/mol), after protonation, it is more prone to donate the proton.

The formation of the product complex (PC) is the penultimate step of the reaction, it is a bimolecular compound of the catalyst and product (Fig. 2). In the last step, the catalyst is separated from the product. The reaction is significantly changed in the presence of catalysts compared to the case of catalyst-free system (Fig. 4). The product forms in multiple steps and the relative energy is significantly reduced in case of the organocatalytic reaction. The proton affinity of the catalytic site affects the relative energy of the reaction steps (e.g., TS1, IM, TS2) and by increasing proton affinity the corresponding relative energy is also increasing and thus, the lower proton affinitiy can be associated with better catalytic effect. Considering the studied catalysts, 4-methylmorpholine is more effective to promote urethane formation than morpholine.

Conclusions

The reaction mechanism of the urethane formation from phenyl isocyanate and butan-1-ol without and in the presence of morpholine and 4-methylmorpholine catalysts was determined using computational chemistry tools including both density functional theory (BHandHLYP/6-31G(d)) and composite (G3MP2BHandHLYP) methods. The proposed mechanism for urethane formation in the presence of morpholine or 4-methylmorpholine catalyst contains seven steps compared to the catalyst-free reaction mechanism. To verify the proposed mechanism crystal structures of morpholine, and 4-methylmorpholine complexed with diols found in the literature were compared with calculated reactant complexes. Based on the structural similarity the proposed and studied general organocatalytic reaction mechanism was partially verified. In terms of the catalytic activity, morpholine is a bit less effective to promote urethane formation compared to its methylated counterpart. The relative energy of the TS1 is lower (97.42 kJ/mol) when 4-methylmorpholine is considered, while in the case of morpholine an increase of ~ 1 kJ/mol is experienced. However, in both cases, the relative energy of the transition state was significantly reduced compared to the catalyst-free process. An irregularity in the energy profiles was found, where the IM is higher in energy compared to the TS2, ∆∆rG_TS2-IM = − 7.32 kJ/mol and − 11.45 kJ/mol in the case of morpholine and 4-methylmorpholine catalyzed process, respectively. This irregularity was successfully explained and a correction was applied to balance the effect of the formation of the zwitterionic IM, which shifted the uncorrected difference (∆∆rG_TS2-IM) to 17.58 and 13.45 kJ/mol for the morpholine and 4-methylmorpholine containing system, respectively. By applying the correction, the IM is lower in energy than TS2, and thus, the irregularity in the energy profile has been handled. Meanwhile, as the proposed catalytic mechanism contains protonation steps, therefore the corresponding PA values (1523.95 and 963.07 kJ/mol, for morpholine and 4-methyl morpholine, respectively) have been calculated. The PA of the catalytic site affects the relative energy of the reaction steps (e.g., TS1, IM, TS2) and by increasing proton affinity the corresponding relative energy is also increasing and thus, the lower proton affinity can be associated with better catalytic effect. Based on the results it was found that the studied cyclic catalysts can be effectively applied in organocatalytic urethane synthesis.

References

Yanping, Y. The development of polyurethane. Mater. Sci. Mater. Rev. 1, 1–8 (2018).

Cavaco, L. I. Polyurethanes Properies, Structure and Applicatiovs (Nova Science Publishers, Inc., 2012).

Engels, H. W. et al. Polyurethanes: Versatile materials and sustainable problem solvers for today’s challenges. Angew. Chem. Int. Ed. 52, 9422–9441 (2013).

Deng, Y. et al. Reviewing the thermo-chemical recycling of waste polyurethane foam. J. Environ. Manage. 278, 111527 (2021).

Mouren, A. & Avérous, L. Sustainable cycloaliphatic polyurethanes: From synthesis to applications. Chem. Soc. Rev. 52, 277–317 (2022).

Global Polyurethane Market to Worth USD 91.2 Billion by. https://www.globenewswire.com/en/news-release/2022/10/05/2528659/0/en/Global-Polyurethane-Market-to-Worth-USD-91-2-Billion-by-2028-China-Produces-32-of-the-Global-Polyurethane-Industry-Vantage-Market-Research.html.

Russo, P. et al. Thermoplastic polyurethane films reinforced with carbon nanotubes: The effect of processing on the structure and mechanical properties. Eur. Polym. J. 49, 379–388 (2013).

Ozaki, S. Recent advances in isocyanate chemistry. J. Synth. Org. Chem. Jpn. 40, 285–295 (1982).

Lu, M. Y., Surányi, A., Viskolcz, B. & Fiser, B. Molecular design of sugar-based polyurethanes. Croat. Chem. Acta 91, 299–307 (2018).

Nwabunma, R. F. G. Polyurethanes Science, Tchnology, Markets, and Trends Vol. 21 (Wiley, 2020).

Peyrton, J. & Avérous, L. Structure-properties relationships of cellular materials from biobased polyurethane foams. Mater. Sci. Eng. R Rep. 145, 100608 (2021).

Ionescu, M. Chemistry and Technology of Polyols for Polyurethane Vol. 2 (Rapra Publishing, 2016).

Bakkali-Hassani, C., Berne, D., Ladmiral, V. & Caillol, S. Transcarbamoylation in polyurethanes: Underestimated exchange reactions?. Macromolecules 55, 7974–7991 (2022).

Suzuki, T. et al. Zero emission polyurethane catalyst. TOSOH Res. Technol. Rev. 57, 13–21 (2013).

Ruiduan, L. et al. Research progress of amine catalysts for polyurethane. New Mater. Intell. Manuf. (NMIM) 1, 54–57 (2018).

Wisniak, J. The history of catalysis. From the beginning to Nobel prizes. Educ. Química 21, 60–69 (2010).

Vratsanos, M. S. Polyurethane catalysts. Polymeric materials encyclopedia. in 6947 (2020).

Fernandes, T. D. A. et al. Bifunctional primary amine 2-aminobenzimidazole organocatalyst anchored to trans-cyclohexane-1,2-diamine in enantioselective conjugate additions of aldehydes. Tetrahedron Asymmetry 27, 118–122 (2016).

Silva, A. L. & Bordado, J. C. Recent developments in polyurethane catalysis: Catalytic mechanisms review. Catal. Rev. Sci. Eng. 46, 31–51 (2004).

Waleed, H. Q. et al. Computational study of catalytic urethane formation. Polymers (Basel) https://doi.org/10.3390/polym14010008 (2022).

Chaffanjon, P., Grisgby, R. A. Jr., Rister, E. L. Jr. & Zimmerman, R. L. Use of real-time FTIR to characterize kinetics of amine catalysts and to develop new grades for various polyurethane applications, including low emission catalysts. J. Cell. Plast. 39(3), 187–210 (2003).

Waleed, H. Q. et al. The catalytic effect of DBU on urethane formation—A computational study. Mater. Sci. Eng. 46, 70–77 (2021).

Waleed, H. Q. et al. Experimental and theoretical study of cyclic amine catalysed urethane formation. Polmers 14, 2859 (2022).

Waleed, H. Q., Viskolcz, B., Fejes, Z. & Fiser, B. Urethane formation in the presence of 2,2-dimorpholinodiethylether ( DMDEE ) and 1,4-dimethylpiperazine ( DMP)—A combined experimental and theoretical study. Comput. Theor. Chem. 1221, 114045 (2023).

Du, W., Zhang, G., Wang, S., Tan, L. & Chen, H. Cure kinetics of an optical polythiourethane with amine catalyst by IR analysis. Int. J. Polym. Sci. https://doi.org/10.1155/2019/8194379 (2019).

Waleed, H. Q. et al. Aliphatic tertiary amine catalysed urethane formation—A combined experimental and theoretical study. Phys. Chem. Chem. Phys 24, 20538–20545 (2022).

Humans, I. W. G. on the E. of C. R. to. Some Organic Solvents, Resin Monomers and Related Compounds, Pigments and Occupational Exposures in Paint Manufacture and Painting. (1989).

Becke, A. D. A new mixing of Hartree–Fock and local density-functional theories. J. Chem. Phys. 98, 1372–1377 (1993).

Petersson, G. A. et al. A complete basis set model chemistry. I. The total energies of closed-shell atoms and hydrides of the first-row elements. J. Chem. Phys. 89, 2193–2218 (1988).

Frisch, M. J., Trucks, G.W., Schlegel, H.B., Scuseria, G.E., Robb, M.A., Cheeseman, J.R., Scalmani, G., Barone, V., Mennucci, B., Petersson, G. A., et al. Gaussian 09, Revision, E.01; Gaussian, Inc.: Wallingford, CT, USA,. (2009)

Marenich, A. V., Cramer, C. J. & Truhlar, D. G. Universal solvation model based on solute electron density and on a continuum model of the solvent defined by the bulk dielectric constant and atomic surface tensions. J. Phys. Chem. B 113, 6378–6396 (2009).

Curtiss, L. A., Redfern, P. C., Raghavachari, K., Rassolov, V. & Pople, J. A. Gaussian-3 theory using reduced Møller-Plesset order. J. Chem. Phys. 110, 4703–4709 (1999).

Wada, G., Tamura, E., Okina, M. & Nakamura, M. On the ratio of zwitterion form to uncharged form of glycine at equilibrium in various aqueous media. Bull. Chem. Soc. Jpn. 55, 3064–3067 (1982).

Fiser, B. et al. Glutathione as a prebiotic answer to α-peptide based life. J. Phys. Chem. B 119, 3940–3947 (2015).

Emamian, S. R., Domingo, L. R. & Tayyari, S. F. Tautomerism in pyridazin-3(2H)-one: A theoretical study using implicit/explicit solvation models. J. Mol. Graph. Model. 49, 47–54 (2014).

Oswald, I. D. H., Motherwell, W. D. S. & Parsons, S. Acta crystallogr. Sect. B Struct. Sci. 61, 46 (2005).

Mashlyakovskiy, L., Khomko, E., Zaiviy, V. & Tonelli, C. Fluoropolyethers end-capped by polar functional groups. II. Effect of catalyst and reagents concentration, solvent nature, and temperature on reaction kinetics of α, ω-bis(hydroxy)-terminated fluoropolyethers with cycloalyphatic and aromatic diisocyanates. J. Polym. Sci. Part A Polym. Chem. 38, 2579–2602 (2000).

Acknowledgements

This research was supported by the National Research, Development and Innovation Fund (Hungary) within the TKP2021-NVA-14 project. The GITDA (Governmental Information-Technology Development Agency, Hungary) is gratefully acknowledged for allocating the computing resources used in this work.

Funding

Open access funding provided by University of Miskolc.

Author information

Authors and Affiliations

Contributions

B.F. and B.V. conceived the scientific idea. B.F. supervised the work. H.Q.W. and B.F. adminstrated the project. H.Q.W. and R.H. did calculations and curated the data. All authors participated in the formal analysis of data, writing and reviewing of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Waleed, H.Q., Hadjadj, R., Viskolcz, B. et al. Effect of morpholine, and 4-methylmorpholine on urethane formation: a computational study. Sci Rep 13, 17950 (2023). https://doi.org/10.1038/s41598-023-44492-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-44492-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.