Abstract

Bacterial contaminations in yeast fermentation tanks are a recurring problem for the bioethanol production industry. Lactic acid bacteria (LAB), particularly of the genus Lactobacillus, are the most common contaminants. Their proliferation can reduce fermentation efficiency or even impose premature shutdown for cleaning. We have previously reported that laboratory yeast strains naturally excrete amino acids via transporters of the Drug: H+ Antiporter-1 (DHA1) family. This excretion allows yeast to cross-feed LAB, which are most often unable to grow without an external amino acid supply. Whether industrial yeast strains used in bioethanol production likewise promote LAB proliferation through cross-feeding has not been investigated. In this study, we first show that the yeast strain Ethanol Red used in ethanol production supports growth of Lactobacillus fermentum in an amino-acid-free synthetic medium. This effect was markedly reduced upon homozygous deletion of the QDR3 gene encoding a DHA1-family amino acid exporter. We further show that cultivation of Ethanol Red in a nonsterile sugarcane-molasses-based medium is associated with an increase in lactic acid due to LAB growth. When Ethanol Red lacked the QDR1, QDR2, and QDR3 genes, this lactic acid production was not observed and ethanol production was not significantly reduced. Our results indicate that Ethanol Red cultivated in synthetic or molasses medium sustains LAB proliferation in a manner that depends on its ability to excrete amino acids via Qdr transporters. They further suggest that using mutant industrial yeast derivatives lacking DHA1-family amino acid exporters may be a way to reduce the risk of bacterial contaminations during fermentation.

Similar content being viewed by others

Introduction

Bioethanol is the biofuel most used worldwide in the transportation sector, its production having increased regularly since the early nineties1. In 2020, the USA and Brazil accounted, respectively, for 53% and 30% of global biofuel production2. Bioethanol is produced from a wide variety of renewable resources (feedstocks), and the yeast Saccharomyces cerevisiae is by far the microorganism most frequently used to carry out the biological process exploited in industrial-scale ethanol production, thanks to its unmatched ethanol yield (> 90%), productivity (> 1 g.L−1.h−1), and tolerance (> 40 g.L−1) and its ability to ferment a wide range of sugars1. In Brazil, bioethanol is produced from sugarcane molasses by high-cell-density fed-batch fermentation, in volumes reaching half a million liters. The elevated cell densities reached in this process (10% wet weight per volume) allow 6–12-h fermentations followed by recycling of the yeast biomass throughout the production season3. As this process is operated under non-sterile conditions, bacterial contamination occurs at high frequency3. Contaminants negatively impact yeast fermentation through competition for scarce nutrients and release of growth inhibitors. This generates considerable economic losses, mostly due to a reduced ethanol production efficiency and also, if the contamination is uncontrolled, to fermenter shutdown for cleaning4,5.

In nature, yeasts and lactic acid bacteria (LAB) are often encountered together, and metabolite exchanges between them have been reported6,7. Sometimes this cohabitation is desirable, as during production of fermented products such as kefir8 or kimchi9. Yet LAB are also the most common and troublesome bacterial contaminants found in ethanol production facilities, because they grow rapidly and tolerate high temperatures and low pH10. Besides competing with yeast for essential nutrients, LAB produce many compounds that inhibit yeast growth, including lactic acid, acetic acid, caproic acid, carbon dioxide, diacetyl, hydrogen peroxide, reuterin, phenyllactic acid, 3-carboxylic fatty acids, and cyclic peptides11. Historically, several methods have been applied to prevent their undesirable growth in yeast fermentation processes. In general, bacterial infections are easily controlled with antibiotics, acid treatments, ammonia, and urea-hydrogen peroxide4,12. Antimicrobial compounds such as c-hydroxycinnamates, organic acids, and membrane-active antimicrobial peptides13 have also been used, with varying degrees of success. These methods, however, pose a potential biological and environmental hazard if waste is not properly disposed of. Furthermore, some of these treatments are quite costly14. Hence, novel strategies are needed to decrease LAB proliferation in industrial bioethanol production plants.

LAB are typically auxotrophic for several amino acids and thus depend, for growth, on an external amino acid supply. Importantly, yeast cells grown in defined media have been found to excrete amino acids which can be used by LAB for growth6,7. Hence, an important and still open question is whether such cross-feeding contributes to propagation of contaminating LAB in bioethanol production systems. In yeast, excretion of amino acids is mediated by proteins of Drug:H+ Antiporter family 1 (DHA1), such as Aqr1, Qdr2, and Qdr315,16. Importantly, we have recently demonstrated that deleting these three genes in a laboratory strain reduces the yeast’s ability to cross-feed Lactobacillus fermentum16, a LAB commonly found among contaminating bacteria in bioethanol production facilities. This observation suggests that cultivation of a bioethanol-producing yeast strain lacking specific DHA1-family transporters might be a way to reduce LAB contamination.

In this study we show that in a sterile minimal medium, the industrial yeast strain Ethanol Red, selected for ethanol production, sustains growth of co-cultivated Lactobacillus fermentum much more efficiently than a mutant derivative lacking the QDR3 gene. We next show that growth of Ethanol Red on a nonsterile sugarcane-molasses-based medium is accompanied by an increase in lactic acid, and that this increase is no longer observed when the strain lacks the QDR1, QDR2, and QDR3 genes. These results suggest that using industrial yeast strains with mutations in QDR genes may be a good way to reduce LAB contaminations in bioethanol-production fermentations tanks.

Results

The bioethanol-producing yeast strain Ethanol Red cross-feeds Lactobacillus fermentum

Laboratory strains of S. cerevisiae have been reported to naturally excrete amino acids which can be used by co-cultivated lactic acid bacteria (LAB) unable to grow without an external amino acid supply6,7,16. This cross-feeding can be visualized in experiments where the two microorganisms are co-cultivated in an appropriate amino-acid-free medium. For instance, we have previously reported that L. fermentum can grow in a MES-buffered glucose minimal medium (code number 169) containing NH4+ as sole nitrogen source, and thus in the absence of any external amino acid supply, when it is co-cultivated with a laboratory yeast strain16. We sought to determine whether an industrial yeast strain selected for high-efficiency ethanol production could also cross-feed L. fermentum. We chose the strain Ethanol Red, a standard in industrial biofuel production. This industrial strain was compared with our haploid wild-type reference strain 23344c (derived from the Σ1278b wild-type laboratory strain17), whose unique ura3 auxotrophy was complemented by a plasmid-borne URA3 gene. We first compared the growth of the Ethanol Red and 23344c strains on the MES-buffered NH4+ medium containing glucose or ethanol as carbon source. While the two strains displayed similar growth on glucose, Ethanol Red grew much more slowly on ethanol (Fig. S1A), in keeping with a previous study18. We then cultivated the cells in wells filled with buffered glucose NH4+ medium and subdivided into two compartments separated by a solute-permeable membrane (Fig. 1A). One compartment was inoculated with the 23344c or Ethanol Red strain and the other with L. fermentum. Just after inoculation and after two days of growth, culture samples were withdrawn and yeast and L. fermentum cell densities were quantified by counting the number of colony-forming units (CFU/ml) obtained after plating culture samples on appropriate solid rich media. After two days of cultivation, 23344c and Ethanol Red were found to have proliferated similarly (Fig. 1B). L. fermentum had also proliferated when co-cultivated with either 23344c or Ethanol Red strains (Fig. 1C, D). That this growth of L. fermentum was due to cross-feeding by yeast cells excreting amino acids was confirmed in control experiments: the bacterium failed to grow when placed alone in the MES-buffered glucose NH4+ medium, but proliferated well if the medium was supplemented with a mix of the twenty proteinaceous amino acids (Fig. 1C). This result indicates that the Ethanol Red industrial yeast strain can excrete amino acids and cross-feed L. fermentum.

The bioethanol-producing yeast strain Ethanol Red cross-feeds Lactobacillus fermentum. (A) Schematic representation of the co-culture system. The yeast cell suspension is placed in the well and the insert prefilled with the L. fermentum cell suspension is placed on top of it. The arrows represent solute diffusion across the membrane separating the two cultures. (B) The density of yeast cells in cultures of the wild-type laboratory strain 23344c or the industrial strain Ethanol Red (E⋅RED) were monitored by counting colony-forming units (CFUs) just after inoculation (0 h) and after 48 h of co-culture. (C) L. fermentum cell density was monitored by counting CFUs in co-cultures with the 23344c wild-type or the Ethanol Red (E⋅RED) yeast strain, just after inoculation (0 h) and after 48 h of co-culture. In a control experiment, L. fermentum cell density was assessed after cultivation, in the absence of yeast, in the presence or absence of all 20 amino acids. (D) The values presented in (B and C) were used to calculate the cell propagation ratio of L. fermentum co-cultivated with 23344c or E⋅RED. Bars represent averages of minimum three independent experiments ± standard deviation (SD). * indicates a statistically significant difference as determined with the unpaired t test. * P < 0.034; *** P < 0.0002; **** P < 0.0001.

To determine which amino acid auxotrophies of L. fermentum are efficiently compensated by co-culture with yeast, we used the MES-buffered glucose NH4+ medium containing all twenty amino acids as a positive control and tested how omitting each amino acid individually affected L. fermentum growth. The bacterium was found to grow normally in the absence of alanine, asparagine, proline, glutamate, or serine (Fig. S1B), but it failed to grow in the absence of threonine, phenylalanine, methionine, glutamine, histidine, arginine, cysteine, tyrosine, leucine, lysine, tryptophan, isoleucine, or valine. In the absence of glycine or aspartate, its growth was reduced but detectable. These results indicate that both Ethanol Red and 23344c excrete sufficient amounts of each of the thirteen above-listed essential amino acids to support growth of L. fermentum.

In the Ethanol Red strain, the Qdr3 amino-acid exporter contributes importantly to cross-feeding of Lactobacillus fermentum

In a recent study using strain 23344c as a reference wild type, we found the DHA1-family membrane transporters Aqr1, Qdr2, and Qdr3 to contribute to amino-acid excretion and cross-feeding of L. fermentum during growth in the MES-buffered glucose NH4+ medium16. To determine if this holds true for the Ethanol Red strain, we used CRISPR-Cas919 and adapted transformation protocols to first produce a mutant derivative lacking the QDR3 gene. We obtained many clones with heterozygous deletion of QDR3 and a single homozygous qdr3Δ mutant. When we co-cultivated this mutant with L. fermentum in the MES-buffered glucose NH4+ medium without any added amino acid, the qdr3Δ strain was found to support growth of L. fermentum, though less efficiently than the original Ethanol Red strain (Fig. 2A and Fig. S2). To ascertain that this phenotype was due to the qdr3Δ mutation, we transformed the mutant with a plasmid bearing the QDR3 gene, using as a selection marker a resistance gene for the antibiotic geneticin. The transformed strain was initially cultured in the presence of geneticin and then cells were collected, washed, and used to inoculate antibiotic-free minimal medium. After 48 h of co-culture with L. fermentum and CFU counting, the plasmid-transformed qdr3Δ mutant was found to support growth of the bacterium as efficiently as the Ethanol Red strain (Fig. 2A). Furthermore, whether transformed or not with the QDR3-bearing plasmid, the qdr3Δ mutant proliferated as well as Ethanol Red (Fig. S2A). In a parallel experiment, the qdr3Δ mutant isolated from strain 23344c likewise proliferated as well as its parental wild-type (Fig. S2B), but in keeping with previous observations16, the two strains showed a similar ability to support growth of L. fermentum (Fig. 2A). These observations thus show, unexpectedly, that Qdr3 contributes more importantly in Ethanol Red than in 23344c to excretion of one or several amino acids essential to growth of L. fermentum. It thus seems that in 23344c, other amino acid exporters can efficiently perform this excretion.

Role of Qdr amino-acid exporters in cross-feeding of Lactobacillus fermentum. (A) The values presented in Figure S2 were used to calculate the relative propagation of L. fermentum co-cultivated with either Ethanol Red (E⋅RED), its qdr3Δ mutant derivative, or the same mutant transformed with a plasmid carrying the QDR3 gene from strain 23344c (right). The same experiment was performed to compare strain 23344c (w–t) with its qdr3Δ derivative mutant (left). (B) Same as in A, except that the values in Figure S3 were used to compare L. fermentum propagation when co-cultivated with Ethanol Red (E⋅RED) or its qdr1Δ qdr2Δ qdr3Δ mutant derivative (right). The same experiment was performed to compare strain 23344c (w–t) with its qdr1Δ qdr2Δ qdr3Δ derivative mutant (left). Bars represent averages of minimum three independent experiments ± standard deviation (SD). * indicates a statistically significant difference as determined with the unpaired t test. **** P < 0.0001; ns: not significant, P > 0.05.

The results presented in Fig. 2A also show that the qdr3Δ mutant isolated from Ethanol Red strain can still support growth of L. fermentum. This suggests that excretion of amino acids required for L. fermentum proliferation is reduced but not abolished when Qdr3 is not functional. We thus examined whether deletion of additional amino acid exporter genes might further reduce the ability of Ethanol Red to cross-feed L. fermentum. Specifically, we applied CRISPR-Cas9 to the qdr3Δ mutant to delete, in a single step, the highly similar and adjacent QDR1 and QDR2 genes. These likely originate from a duplication event, and chromosomal synteny analysis20 suggests that the ancestral QDR1/2 gene is a paralog of the AQR1 gene encoding another DHA1-family amino acid exporter15,16. The derived qdr1Δ qdr2Δ qdr3Δ mutant strain co-cultivated with L. fermentum sustained growth of the bacterium as efficiently as the single qdr3Δ mutant (Fig. 2B and Fig. S3). In contrast, the same QDR1 and QDR2 deletions in the qdr3Δ mutant of strain 23344c resulted in decreased propagation of co-cultivated L. fermentum (Fig. 2B and Fig. S3). In conclusion, under the conditions used here, the Qdr3 amino acid exporter of Ethanol Red plays an important role in cross-feeding L. fermentum. Residual cross-feeding does occur, however, even if Qdr1 and Qdr2 are also lost. In laboratory strain 23344c, Qdr3 does not seem so important in supporting growth of L. fermentum, but additional loss of Qdr1 and Qdr2 considerably reduces cross-feeding. It thus seems that the relative contributions of the Qdr proteins to amino-acid excretion differ significantly between Ethanol Red and 23344c.

The AQR1 gene encodes another well-characterized DHA1-family amino acid exporter15,16. It was not possible to investigate the role of Aqr1 in amino acid excretion by Ethanol Red because homozygous deletion of the AQR1 gene in this strain proved much more difficult than for the QDR genes.

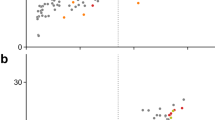

Loss of Qdr amino acid exporters in the Ethanol Red strain prevents an increase in lactic acid during growth on molasses

Nonsterile crop-derived culture media used for industrial production of bioethanol generally contain several LAB species whose propagation during fermentation causes a detectable increase in lactic acid21. To assess the importance of amino-acid excretion by industrial yeast strains in the proliferation of these LAB, flasks containing equal volumes of a nonsterile molasses-based medium were inoculated with equivalent cell samples of the Ethanol Red strain or its qdr3Δ or qdr1Δ qdr2Δ qdr3Δ mutant derivatives. The culture flasks were incubated for 240 h at 30 °C with shaking and their gradual weight loss due to CO2 production was measured. This allowed us to compare the efficiency of glucose fermentation by the three strains, which proved reproducibly similar (Fig. 3A). Accordingly, we observed no significant difference in ethanol concentration, as measured after 240 h in several independent experiments (Fig. 3B). We also measured the lactic acid concentration in the media, before and after yeast cultivation. In cultures of Ethanol Red, we detected an increase in lactic acid, indicating that LAB proliferated to some extent (Fig. 3C, D). A similar increase in lactic acid was observed in cultures of the qdr3Δ mutant, but none was detected in cultures of the qdr1Δ qdr2Δ qdr3Δ mutant (Fig. 3C, D). This shows that lactic acid production was dependent on yeast and its ability to produce functional Qdr proteins. This observation, together with the results of cross-feeding experiments in defined MES-buffered glucose NH4+ medium, shows that Ethanol Red excretes amino acids via the Qdr exporters and that this excretion supports growth of LAB naturally present in molasses. It also suggests that deleting specific QDR genes in bioethanol-producing yeast strains may be a novel strategy for reducing the risk of contamination of bioethanol fermentation tanks with lactic acid bacteria.

Loss of Qdr amino acid exporters in the Ethanol Red strain prevents a lactic acid increase during growth on molasses. (A) Wild-type (black), qdr3Δ (orange), and qdr1Δ qdr2Δ qdr3Δ (blue) Ethanol Red cells were grown on nonsterile molasses-based medium and weight loss was monitored along time. Arrow show the end of each fermentation and the sampling timepoint. (B) Ethanol concentration in the medium at the end of each fermentation. (C) Lactic acid concentration at the end of each fermentation. The dotted line corresponds to the lactic acid detected in the medium before inoculation with yeast. (D) Concentrations of lactic acid expressed as percentages of that observed in supernatants of the wild-type cultures. Bars represent averages of three independent experiments ± standard deviation (SD). * indicates a statistically significant difference as determined with the unpaired t test. ** P < 0.0021; ns: not significant, P > 0.05.

Discussion

The proliferation of contaminating LAB in yeast fermentation tanks is a recurring problem causing a significant reduction of bioethanol production yields5,22. To prevent or at least reduce the risk of such contaminations at bioethanol production plants, it is imperative to better understand the factors promoting LAB proliferation in this context. Contaminating LAB are typically auxotrophic for multiple amino acids and thus require an external supply of amino acids in order to proliferate. On the other hand, it is well established that yeast cells naturally excrete several amino acids7,23. We have previously shown that the yeast DHA1-family transporters Aqr1, Qdr2, and Qdr3 contribute to amino acid excretion from cells15,16. Although why this excretion takes place remains unclear, it is known to be favored by conditions such as nitrogen overflow7 and/or a limited supply of other nutrients23,24. We therefore reasoned that this natural excretion of amino acids by yeast might contribute to LAB proliferation in nonsterile media used in industrial fermentations. To test this hypothesis, we introduced homozygous deletions of genes encoding DHA1-family amino-acid exporters into the genome of strain Ethanol Red used in bioethanol production. Our most important observation concerns lactic acid production, indicative of LAB proliferation, in nonsterile molasses-based medium containing either the Ethanol Red strain or its triple mutant lacking the QDR1, QDR2 and QDR3 genes: in contrast to cultures seeded with the parental strain, those containing the triple mutant showed no significant increase in lactic acid over a ten-day growth period. We conclude that LAB proliferation was supported by yeast-excreted amino acids rather than by free amino acids naturally available in the medium or released as a consequence of cell death. Our work further highlights Qdr1, -2, and -3 as three DHA1-family transporters that likely play a particularly important role in LAB-growth-sustaining excretion of amino acids by Ethanol Red (Fig. 4). To our knowledge, this has not been described before. Importantly, the absence of these proteins did not reduce this strain’s ethanol-producing capacity. This opens the prospect of exploiting yeast qdr mutants to reduce or control the risk of LAB contamination during bioethanol production.

A novel strategy for reducing the risk of bacterial contaminations during bioethanol production. (A) The Ethanol strain used in this study excretes multiple amino acids via Qdr amino-acid exporters of the DHA1 family, thereby promoting proliferation of contaminating lactic acid bacteria. (B) Loss of Qdr transporters by means of homozygous mutations reduces amino acid excretion and cross-feeding of lactic acid bacteria, without altering ethanol production.

To further assess the potential of this strategy, it will be useful to conduct further experiments with alternative industrial cultivation media and bioethanol-producing yeast strains. Additional work will also be needed to evaluate the respective contributions of different DHA1-family amino acid exporters to LAB cross-feeding under industrial fermentation conditions. For instance, although we show here that lactic acid was not produced by LAB in sugarcane molasses-based medium seeded with the qdr1Δ qdr2Δ qdr3Δ triple-mutant strain, we cannot rule out the possibility that a qdr1Δ or qdr2Δ single mutant or a qdr1Δ qdr2Δ double mutant might have displayed a similar advantage. This seems unlikely, however, as previous cross-feeding experiments have shown that several DHA1-family genes need to be inactivated in order to markedly reduce excretion of a single amino acid, e.g. threonine or homoserine15,16. Furthermore, in peculiar culture media, deletion of additional DHA1-family genes might be necessary to reduce amino acid excretion. In our laboratory strain, for instance, the Aqr1 transporter plays an important role in amino acid excretion15,16. It will thus be of interest to delete the corresponding gene in Ethanol Red and in its qdr1Δ qdr2Δ qdr3Δ derivative to see if this deletion eliminates the residual cross-feeding of L. fermentum observed with the qdr1Δ qdr2Δ qdr3Δ mutant in synthetic buffered minimal medium. For reasons that remain to be clarified, however, deleting this gene proved particularly difficult and could not be achieved in the framework of this work.

Our study further shows that in a synthetic medium, deletion of QDR3 alone is sufficient to reduce cross-feeding of L. fermentum by the Ethanol Red and that further deletion of QDR1 and QDR2 does not enhance this effect. This contrasts with the results obtained with the same strains grown on the nonsterile molasses-based medium, which likely contains several LAB species: in this case, deletion of QDR3 alone did not significantly reduce lactic acid production. Why these differences exist remains unknown. Perhaps growth on molasses medium alters the expression profile of DHA1-family genes in Ethanol Red, or perhaps the LAB species present in molasses have auxotrophies that differ from those present in L. fermentum. This illustrates the possibility that reducing LAB growth might require introducing different combinations of qdr mutations according to the culture medium used.

Reducing LAB propagation could favor the proliferation of other bacteria, for instance acetic acid bacteria25. In support of this view, we observed a significant increase in acetic acid production in nonsterile molasses cultures inoculated with the qdr1Δ qdr2Δ qdr3Δ triple mutant, as compared with the parental Ethanol Red strain (Fig. S4). Thus, reduced amino acid excretion by yeast might promote growth of acetic acid bacteria by causing lesser proliferation of several LAB species. Interestingly, acetate production was also observed in molasses medium seeded with the qdr3Δ single mutant, although lactic acid production was not reduced (Fig. S4). Perhaps the lack of Qdr3-dependent excretion of specific amino acids prevented proliferation of some but not all LAB species, this being sufficient to allow proliferation of acetic acid bacteria in the available ecological niche. This illustrates the complexity of interactions between microorganisms in co-cultures. Further investigation of these interactions and of the molecular mechanisms underlying them, including cross-feeding, should make it possible to better control bacterial proliferation during bioethanol production.

In conclusion, we report that deletion of QDR genes in the Ethanol Red strain reduces its ability to support propagation of lactic acid bacteria and provides a potentially efficient means of limiting contamination of fermentations by LAB during industrial bioethanol production. This approach can in principle be applied also to second-generation bioethanol production processes relying on nonsterile lignocellulose biomass and to industrial production by yeast of other compounds of interest.

Methods

Strains and growth conditions

The Saccharomyces cerevisiae strains used in this study (Table 1) derive from the laboratory strain Σ1278b17 or from the industrial strain Ethanol Red (Leaf, Lesaffre, Marcq-en-Baroeul, France). Cells of Σ1278b-derived strains were transformed with plasmids (Table 2) as previously described26. The same protocol was used to transform cells of the Ethanol Red strain, except that PEG4000 was replaced with PEG3350 and higher amounts of DNA (10–25 μg) were used. To introduce homozygous gene deletions in the Ethanol Red strain, we applied CRISPR-Cas9 as previously described18. Yeast and Lactobacillus fermentum (strain LMG17551 from the Belgian Coordinated Collections of Microorganisms) were co-cultivated on a MES-buffered, amino acid free minimal medium (code number 169) containing glucose (3%) as a carbon source and ammonium as a nitrogen source added as (NH4)2SO4 (0.5%), as previously described15. For cultures on nonsterile molasses, the growth medium consisted of sugarcane molasses (30%), (NH4)2SO4 (567 mg/L), and a nutrient mix (350 mg/L) (Gusmer Enterprises, LN W148320).

Cross-feeding of L. fermentum by yeast cells

Assays for measuring cross-feeding between yeast and L. fermentum cells were carried out in 6-well plates equipped with ThinCert cell culture inserts (Greiner -657,640), as previously described16.

Fermentation efficiency assay

Yeast cells were first pre-grown in a standard rich medium containing glucose (10%), bactopeptone (2%), and yeast extract (1%). Flasks filled with 60 ml nonsterile sugarcane-molasses-based medium were then inoculated (5⋅106 cells/ml) and incubated at 30 °C with shaking. Weight loss of the flasks due to CO2 production was monitored until it became negligible.

Analysis of organic acids and ethanol in culture media

Production of lactic acid and acetic acid was assayed by High Performance Liquid Chromatography (HPLC) with the LCM1 Waters Chromatographic chain (600 Pump, 2487 Absorbance Detector and Degasser, 717 Plus Autosampler) and a column (Aminex HPX-87H, Biorad) thermoregulated at 65 °C. Ethanol production was assayed by headspace Gas Chromatography (GC), with Perkin-Elmer 8000 series 2 GC instrumentation, and HS-40 Automatic Injector, and an Agilent CP- WAX 52 CB WCOT FS 50 mm × 0,32 mm column. The results are given in % ethanol v/v.

Data availability

All data are contained within the manuscript.

Abbreviations

- LAB:

-

Lactic acid bacteria

- DHA1:

-

Drug: H+ Antiporter-1

References

Mohd Azhar, S. H. et al. Yeasts in sustainable bioethanol production: A review. Biochem. Biophys. Rep. 10, 52–61 (2017).

Mueller, L. P., Santos, Md. S. M., Cardoso, C. A. L. & Batistote, M. The effects of thermal and ethanolic stress in industrial strains of Saccharomyces cerevisiae. Res. Soc. Dev. 9, e6819109091 (2020).

Amorim, H. V., Lopes, M. L., de Castro Oliveira, J. V., Buckeridge, M. S. & Goldman, G. H. Scientific challenges of bioethanol production in Brazil. Appl. Microbiol. Biotechnol. 91, 1267–1275 (2011).

Muthaiyan, A. & Ricke, S. C. Current perspectives on detection of microbial contamination in bioethanol fermentors. Bioresour. Technol. 101, 5033–5042 (2010).

Lino, F. S. d. O. et al. (2021) Strain dynamics of specific contaminant bacteria modulate the performance of ethanol biorefineries. bioRxiv, 2021.2002.2007.430133

Challinor, S. W. & Rose, A. H. Interrelationships between a yeast and a bacterium when growing together in defined medium. Nature 174, 877–878 (1954).

Ponomarova, O. et al. Yeast creates a niche for symbiotic lactic acid bacteria through nitrogen overflow. Cell Syst. 5, 345-357.e346 (2017).

Prado, M. R. et al. Milk kefir: Composition, microbial cultures, biological activities, and related products. Front. Microbiol. 6, 1177 (2015).

Lee, M. E. et al. Starter cultures for kimchi fermentation. J. Microbiol. Biotechnol. 25, 559–568 (2015).

Narendranath, N. V., Hynes, S. H., Thomas, K. C. & Ingledew, W. M. Effects of lactobacilli on yeast-catalyzed ethanol fermentations. Appl. Environ. Microbiol. 63, 4158–4163 (1997).

Beckner, M., Ivey, M. L. & Phister, T. G. Microbial contamination of fuel ethanol fermentations. Lett Appl Microbiol 73, 387–394 (2011).

Broda, M. & Grajek, W. Ammonia disinfection of corn grains intended for ethanol fermentation. Acta Sci. Polon. Technol. Aliment. 8(4), 33–38 (2009).

Bom, I. J., Klis, F. M., de Nobel, H. & Brul, S. A new strategy for inhibition of the spoilage yeasts Saccharomyces cerevisiae and Zygosaccharomyces bailii based on combination of a membrane-active peptide with an oligosaccharide that leads to an impaired glycosylphosphatidylinositol (GPI)-dependent yeast wall protein layer. FEMS Yeast Res. 1, 187–194 (2001).

Pimentel, D. Biofuels, solar and wind as renewable energy systems (Springer, 2008).

Velasco, I., Tenreiro, S., Calderon, I. L. & Andre, B. Saccharomyces cerevisiae Aqr1 is an internal-membrane transporter involved in excretion of amino acids. Eukaryot. Cell 3, 1492–1503 (2004).

Kapetanakis, G. C., Gournas, C., Prévost, M., Georis, I. & André, B. Overlapping roles of yeast transporters Aqr1, Qdr2, and Qdr3 in amino acid excretion and cross-feeding of lactic acid bacteria. Front. Microbiol. 12, 3586 (2021).

Bechet, J., Greenson, M. & Wiame, J. M. Mutations affecting the repressibility of arginine biosynthetic enzymes in Saccharomyces cerevisiae. Eur. J. Biochem. 12, 31–39 (1970).

Bruder, S., Reifenrath, M., Thomik, T., Boles, E. & Herzog, K. Parallelised online biomass monitoring in shake flasks enables efficient strain and carbon source dependent growth characterisation of Saccharomyces cerevisiae. Microb. Cell Fact. 15, 127 (2016).

Mans, R. et al. CRISPR/Cas9: A molecular Swiss army knife for simultaneous introduction of multiple genetic modifications in Saccharomyces cerevisiae. FEMS Yeast Res. 15(2), 4 (2015).

Scannell, D. R. & Wolfe, K. H. A burst of protein sequence evolution and a prolonged period of asymmetric evolution follow gene duplication in yeast. Genome Res. 18, 137–147 (2008).

Tian, X., Chen, H., Liu, H. & Chen, J. Recent advances in lactic acid production by lactic acid bacteria. Appl. Biochem. Biotechnol. 193, 4151–4171 (2021).

Lopes, M. L. et al. Ethanol production in Brazil: a bridge between science and industry. Braz. J. Microbiol. 47(Suppl 1), 64–76 (2016).

Grenson, M. Specificity and regulation of the uptake and retention of amino acids and pyrimidines in yeast. In Genet. Ind. Microorg. 2, 179–193s (1973).

Paczia, N. et al. Extensive exometabolome analysis reveals extended overflow metabolism in various microorganisms. Microb. Cell. Fact. 11, 122 (2012).

De Roos, J. & De Vuyst, L. Acetic acid bacteria in fermented foods and beverages. Curr. Opin. Biotechnol. 49, 115–119 (2018).

Gietz, R. D., Schiestl, R. H., Willems, A. R. & Woods, R. A. Studies on the transformation of intact yeast cells by the LiAc/SS-DNA/PEG procedure. Yeast 11, 355–360 (1995).

Bonneaud, N. et al. A family of low and high copy replicative, integrative and single-stranded S. cerevisiae/E. coli shuttle vectors. Yeast 7, 609–615 (1991).

Zhang, G. C. et al. Construction of a quadruple auxotrophic mutant of an industrial polyploid saccharomyces cerevisiae strain by using RNA-guided Cas9 nuclease. Appl. Environ. Microbiol. 80, 7694–7701 (2014).

Acknowledgements

We are grateful to Catherine Jauniaux, Lauranne Rochefort, and Dominique Vinnette for skillful technical assistance. We also thank all lab members, Christos Gournas and Guy Hélin (Syngulon) for fruitful discussions and advices. G. Kapetanakis and L. Sousa are fellows of the Fonds pour la Formation à la Recherche dans l'Industrie et l'Agriculture (FRIA). This research has received funding from the Algotech and Contamibac projects funded by the Walloon Region, the Commission Communautaire Française (COCOF), and the Meurice Research and Development a.s.b.l.

Author information

Authors and Affiliations

Contributions

G.K., I.G., P.G. and B.A. conceived the study. G.K., I.G., L.V.N. and B.A. designed the experiments, G.K., L.S. and C.F. carried out them (G.K. being the main contributor), G.K. prepared the figures. L.V.N., L.S. and L.M. contributed to analysis of specific data. G.K. and I.G. wrote the initial version of manuscript. G.K., I.G., L.V.N, and B.A. finalized and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

B.A. is named co-inventor on a patent (number WO 2021/219558) describing the utilization of yeast mutants lacking DHA1-family genes for reducing contaminations by bacteria. B.A. serves on the Scientific Advisory Board of Syngulon. The other authors declare no competing financial interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kapetanakis, G.C., Sousa, L.S., Felten, C. et al. Deletion of QDR genes in a bioethanol-producing yeast strain reduces propagation of contaminating lactic acid bacteria. Sci Rep 13, 4986 (2023). https://doi.org/10.1038/s41598-023-32062-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-32062-0

This article is cited by

-

Novel endolysin LysMP for control of Limosilactobacillus fermentum contamination in small-scale corn mash fermentation

Biotechnology for Biofuels and Bioproducts (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.