Abstract

The application of dielectric barrier discharge cold plasma (DBD-CP)-treated water as a novel curing process for manufacturing Chinese dried pork loin was investigated. The treatment time of DBD-CP was optimized based on the pH and nitrite level of the plasma-treated water (PTW). PTW treated for 3 min had an alkaline environment and a higher nitrite content than that at the other lengths of treatment time. Pork loins were marinated in control or PTW brine at 4 °C for 24 h and then dry-ripened for 15 days. PTW with a higher treatment voltage significantly decreased lipid oxidation of the products and led to an increased a* value (redness) and an increased residual nitrite content in products that was still within the range of use (all P < 0.05). The contents of each free amino acid increased with increasing treatment intensity (P < 0.05). There were 22 new volatile compounds generated in PTW-cured products, such as 3-methyl-butanol, hexanal and 2,3-octanedione, while six substances were lost, such as 2-pentylfuran, compared with those in the control. This study indicates that using PTW as a curing method can be a potential and effective way of producing dried pork meat products.

Similar content being viewed by others

Introduction

Dielectric barrier discharge cold plasma (DBD-CP) is an emerging technology that has been widely applied for the functionalization and modification of proteins1,2, the elimination of pathogenic and spoilage microorganisms3,4 and the curing process5,6 of meat products. DBD-CP was used for killing microorganisms in fresh pork loin and extending the shelf life of fresh meat7. Lee et al.5 reported that direct DBD-CP treatment can be used as a curing process to produce canned ground ham without undesirable sensory properties due to the generation of nitrite in the meat batter after DBD-CP treatment. For the meat batter, the utilization of direct DBD-CP treatment could increase the a* value and generate nitrites in meat batter without sterilization effects8. Hae et al.9 treated marinated pork with DBD-CP and found that the use of DBD-CP had a bactericidal effect on pork jerky and could improve the formation of a cured color in pork jerk processing. Jung et al.6 processed sausage with DBD-treated water, celery powder and synthetic sodium nitrite and found that PTW could be used as a nitrite source for curing emulsion-type sausage, and PTW-treated sausages had similar sensory properties to sodium nitrite-treated sausages. In addition, PTW could also be applied in manufacturing loin ham as a replacement for sodium nitrite. The residual nitrite content after PTW treatment was significantly lower than that of the sodium nitrite treatment, and the loin ham produced by PTW was proven to not be genotoxic by the Ames test10.

In this study, PTW was formed by dielectric barrier discharge cold plasma (DBD-CP) treatment of water. PTW, which means water containing nitrite11, contains many reactive oxygen and nitrogen species (ROS and RNS, respectively)12. Nitrite has the ability to develop a red color, inhibit lipid oxidation, inactivate spoilage and pathogenic microorganisms, and form a unique flavor in meat products6; thus, PTW has the potential to be a nitrite source for cured meat products.

Currently, consumers are increasingly demanding “chemical-free” meat products. Celery powder has been used in cured meat products to replace synthetic nitrite because of its high nitrate content5,6. Compared with celery powder, PTW is a more welcome alternative due to its low price and short processing time; moreover, the use of celery powder in meat processing could result in an undesirable aroma6.

There are already plenty of meats and meat products processed by DBD-CP, such as canned ground ham5, emulsion-type sausage6, meat batter8, pork jerky9 and loin ham10. Meat can be treated by injecting PTW into the meat or by direct treatment with DBD-CP. However, studies on the volatile and nonvolatile compounds of meat products cured with DBD-CP are very limited, and these compounds can have a great impact on the acceptability of these products by consumers.

To the best of our knowledge, the use of PTW as a curing process has not been evaluated by analysis of the physicochemical properties and flavor of dried pork loin. Furthermore, an increasing number of meat factories use frozen meat as raw material13, and the application of PTW as a simultaneous thawing/curing method would lower the thawing/curing time, reduce the cost and control the quality of the product. The objective of this research was to explore changes in the quality characteristics, lipid oxidation, free amino acid contents and volatile compounds of dried pork loin cured with PTW. The findings of this study will be very useful for the development of meat products in the future.

Materials and Methods

Preparation of PTW

As demonstrated in Fig. 1, DBD-CP treatment was carried out using the same system as described by Huang et al.7. In our DBD system, the output voltage was determined by a high-voltage probe (Tektronix Inc., P6015A, USA) and a digital oscilloscope (Tektronix Inc., 2024C, USA). The discharge current was implemented using a conventional current monitor (Pearson Electronics, 2877, USA). The peak output power (P) was calculated by the following formula: P = V × I, where V is the output voltage and I is the discharge current. When the output voltage was 50, 60 and 70 kV, the current was 0.7, 0.8 and 0.9 mA, respectively, so the power was 35, 48 and 63 W, respectively. The operating frequency of our DBD system was 50 Hz. All treatments were carried out using ambient air without air circulation or supplementation with any other particular gas in an atmospheric pressure environment. The distance between the ground electrode and the water sample was adjusted to 2 mm, and the gap between the water surface and the top electrode was fixed at 10 mm during DBD-CP treatments. Distilled water with 0.5% sodium pyrophosphate (w/v) was added to a polypropylene box (178 × 126 × 35 mm), which was then sealed with a laminated barrier film made of polyamide/polyethylene. The box with distilled water was put in the center of two cyclic aluminum annular electrodes (150 mm diameter) between two polypropylene layers above and below the box, which were used as dielectric barriers and were placed at a distance of 40 mm. Afterwards, the box was subjected to DBD-CP treatment at 50, 60, and 70 kV, representing low power, medium power, and high power, respectively. The treatment voltage in this study was used according to the Paschen curves for air breakdown, our DBD-CP system and previously published studies14,15,16. Our preliminary experiments found that there was no significant difference in physicochemical properties between the treated and untreated products when the treatment voltage was below 50 kV. In addition, when the treatment voltage exceeded 75 kV, it resulted in frequent electric arcing with our DBD-CP system and induced excessive protein oxidation, which could lead to bad flavor and adverse effects on meat quality, so we selected 50, 60, and 70 kV as the treatment voltages.

Schematic diagram of dielectric barrier discharges cold plasma (DBD-CP) system. The plasma discharge was generated under the following conditions: operating frequency, 50 kHz; the output voltages were 50, 60 and 70 kV; the current were 0.7, 0.8 and 0.9 mA, respectively, the power were 35, 48 and 63 w, respectively. All the treatments were carried out using ambient air without air circulation or supplementation with any other particular gas at an atmospheric pressure environment. The distance between the ground electrode and the water sample was adjusted to 2 mm, the gap between water surface and the top electrode was fixed at 10 mm during DBD-CP treatments.

Each level of plasma treatment intensity was performed for 1, 2, 3, 4, 5 and 6 min. To ensure the consistency of liquid samples and prevent the interference of the detection reactions with dissolved salt components, PTW was produced using distilled water containing 0.5% sodium pyrophosphate (w/v) under various DBD-CP treatment times and voltages. After each treatment, sodium chloride (NaCl) was added to the PTW to prepare PTW brine solutions, and the concentration of NaCl in all PTW brine solutions was maintained at 6%. Sodium pyrophosphate was used to maintain an alkaline environment. All treatments were conducted under 40 ± 5% relative humidity (RH) and 20 ± 2 °C. At the end of all treatments, the PTW temperature did not exceed 35 °C. Each treatment was carried out in triplicate.

Physiochemical properties of PTW

As soon as each DBD-CP treatment was completed, 50 mL of PTW was collected for analysis of nitrite content and pH. A pH meter (Testo 230, Testo AG Lenzkirch, Germany) was used to determine the pH of the PTW brine. The nitrite content in PTW was measured by spectrophotometry according to Tian et al.17. After each DBD-CP treatment, 10 mL of PTW was added to 100 mL of 10 g/L sulfanilamide at room temperature for 2 min and then mixed with 100 mL of 1.0 g/L N-(1-naphthyl)-ethylenediamine hydrochloride for 20 min. The concentration of nitrite was determined by measuring the absorbance at 540 nm. The diazotizing reagent and coupling reagent were sulfanilamide and N-(1-naphthyl)-ethylenediamine hydrochloride, respectively.

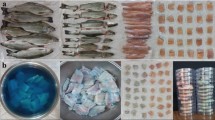

Manufacturing and sample collection of chinese dried pork loins

Pork loins (lumbar longissimus muscle) of Taihu black pigs were obtained from a local market (Nanjing city, Jiangsu Province, China). Taihu black pigs are rich in lean meat with a fresh meat flavor. Pork loins were sliced to a 10-mm thickness and a size of 10 × 10 cm2, randomly divided into four groups, and subsequently vacuum packed and refrigerated at 4 °C before use. One group of samples was prepared as a control (n = 10), and the others used PTW brine as the curing process (n = 100). Figure 2 shows the experimental flow chart. At first, each pork loin was marinated at 4 °C for 24 h. After marinating, the samples were removed from the treatment tank and dry-ripened for 15 days. According to our preliminary experiment18 with slight modification, the temperature was gradually increased from 12 °C to 37 °C at 2 °C per day; simultaneously, the RH progressively decreased from 80% to 65% at 2% per day during the ripening period. For physiochemical properties and volatile analysis, three ripened dried pork loin samples (approximately 50 g each) were randomly taken from each treatment, and all samples were vacuum-packed and stored at −40 °C.

pH measurement

Samples of ripened dried pork loin (5 g) were homogenized with 5 volumes of distilled water at 10,000 rpm for 1 min using a homogenizer model T18 (IKA- Werke GmbH& Co., Staufen, KG, Germany). A pH meter (Testo 230, Testo AG Lenzkirch, Germany) was used to measure the pH value of the homogenates.

Color measurement

CIE L* (lightness), a* (redness) and b* (yellowness) values of dried pork loin were assessed using a colorimeter (Model CR-400; Konica Minolta, Osaka, Japan) with a 30 mm diameter measurement area, an Illuminant D65, and a 0° observer angle. The surface sample color was measured perpendicularly at three different sites. The instrument was calibrated to standard white and black tiles before analysis.

Determination of nitrosoheme pigment and nitrite concentration

Nitrosoheme pigment extraction and determination were performed by method published in previous paper19. Acetone solution (80%) was prepared to extract the pigments in dried pork loins; the solutions were then filtered through Whatman 40 filter papers (Whatman PLC., Maidstone, UK). The concentration of nitrosoheme pigment (ppm of hematin) was calculated as A540 × 290 after measuring the absorbance at 540 nm with a spectrophotometer (UV-2450, Shimadzu Co., Kyoto, Japan). Residual nitrite content in dried pork loin was determined based on the Association of Official Analytical Chemists method NO. 973.3120.

Determination of 2-thiobarbituric acid reactive substances (TBARS)

The extent of lipid oxidation, as measured by the level of 2-thiobarbituric acid reactive substances (TBARS), was determined according to a previously published method with some modifications21. Ten grams of dried pork loin samples was homogenized with 30 mL of a 25% trichloroacetic acid (TCA) solution containing 2% TBA at 10,000 rpm for 1 min and then filtered. Ten milliliters of 20 mM TCA was mixed with 10 mL filtrate for 2 min. The solution was heated in a water bath at 80 °C for 30 min and then cooled with flowing water for 10 min before centrifugation at 10,000 × g for 5 min (4 °C). The absorbance of supernatants was recorded at 532 nm. The determination of malondialdehyde (MDA) was based on a standard curve constructed using 1,1,3,3-tetraethoxypropane. The TBARS value was expressed as mg MDA/kg of sample.

Free amino acid analysis

The free amino acids (FAAs) were extracted from the biceps femoris muscle of dried pork loin according to the method described by Lorenzo et al.22 with some modifications. In general, 2 g of each sample was homogenized with 25 mL of TCA and incubated for 1 h before 5 mL of the solution was filtered through a 0.45-μm membrane. Afterwards, the filtrate was identified and quantified by an automated amino acid analyzer (L-8900; Hitachi, Tokyo, Japan). FAAs were determined for each sample in triplicate. The concentration of FAAs was expressed as mg/100 g of dry matter.

Volatile compound analysis

The determination of the volatile compounds in the pork loin samples was performed using a previously published method with slight modifications23. Samples of 5.0 ± 0.3 g were put into a 20 mL headspace sample vial and sealed with a PTFE-faced silicone rubber septum. The vial was equilibrated at 40 °C in a water bath. Solid-phase microextraction (SPME) and gas chromatography-mass spectrometry (GC/MS) (Agilent 7890) analysis were applied to determine the headspace aroma compounds. After incubating, a 75 μm Carboxen/poly (dimethylsiloxane) (CAR/PDMS) fiber (Supelco, Bellefonte, PA, USA) was inserted into the vial to absorb the aroma compounds at 30 °C for 30 min. Then, the fiber was injected into the GC to desorb at 220 °C for 5 min in splitless mode. The temperature of the GC oven began at 35 °C for 3 min and then was raised to 80 °C at 5 °C/min; the oven temperature was then raised at 8 °C/min to 150 °C, and finally, the temperature was raised to 220 °C at 10 °C/min and held for 10 min. The detector temperature was set at 240 °C. The volatile compounds were separated on a DB5MS capillary column (60 m × 0.32 mm × 1.8 μm film thickness) (Sigma, USA) using helium as the carrier gas. The mass spectra were obtained using a mass selective detector after ionization by electronic impact ionization (70 eV). The detector voltage was 350 V with a scan range between 30 and 450 m/z at a rate of 6.34 scans/s over the range. Data were expressed as the percentage of the total area of identified peaks and identified by comparing their mass spectra with those in the databases of NISTDEMO and the WILEY library.

Statistical analysis

Three samples were randomly taken from ripened Chinese dried pork loin for each treatment, and each sample was analyzed in triplicate for individual parameters. All data were analyzed by one-way analysis of variance (ANOVA) using SPSS version 19.0 (SPSS Inc., Chicago, USA). Significant differences (P < 0.05) among means were identified by Duncan’s new multiple range tests.

Results and Discussion

Physiochemical properties of PTW

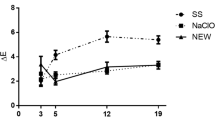

The nitrite concentration and pH value of PTW were analyzed as soon as each DBD-CP treatment was completed. The physiochemical properties of the PTW brine treated with different voltage intensities and time are shown in Fig. 3. Clearly, after treatment at all the intensities, the nitrite level of the brine increased significantly up to 3 min of treatment and then began to decline with increasing treatment time, which was similar to the previous results12,24,25. We speculated that the rise in the nitrite level during the first 3 min of treatment was attributed to the nitrogen oxides generated by ionization of atmospheric oxygen and nitrogen molecules5, such as NO, NO2, N2O4, and N2O3, which are known to form nitric and nitrous acids after reacting with H2O12:

With a similar DBD system6, Ercan et al.24 have reported that the nitrite concentration in the liquid increased after plasma treatment.

The reduced nitrite level from 3 to 6 min of treatment could be explained by the decrease in pH. As the pH dropped below 7, nitrite could be decomposed into nitrate and NO (Reaction 6)26. After DBD-CP treatment, the decrease in pH could also be related to H2O dissociation, thus increasing the H+ concentration27. In addition, H2O2 generated in air or liquid after treatment could lead to the formation of H3O+ ions in PTW2.

Due to the strong oxidative characteristic of PTW, which is due to the generation of ROS12, NO can be irreversibly oxidized to NO2, resulting in the decline of nitrous acid and nitrite contents over time.

As reported28, the decomposition of nitrite generated by plasma treatment would be inhibited under alkaline conditions. Hence, we added sodium pyrophosphate into distilled water to create an alkaline environment. The treatment time of PTW was optimized based on the pH and nitrite contents of PTW. PTW with 3 min of treatment had the most nitrite content and could maintain an alkaline environment at each treatment voltage.

Color and nitrosoheme pigment

The L* values of dried pork loins were not influenced by PTW treatment (P > 0.05, Table 1), which agreed with the previous results4,29.

As shown in Table 1, with the treatment voltages of 50, 60, and 70 kV, the a* values of the products cured with PTW brine increased by 28%, 34% and 42%, respectively, compared with those of the control. We speculated that marination in PTW brine caused the infusion of nitrite into the pork loin, which can significantly increase the a* values of meat products compared with the control30. Honikel28 reported that the redness of cured meat products was attributed to nitrosoheme pigments generated by the reaction of myoglobin and nitric oxide:

The nitric oxide came from the decomposition of nitrite. During high-temperature ripening, nitrosomyoglobin degraded into nitrosylmyochromogen, which could maintain a red color31. Pork loin cured with PTW had enough nitrite to induce the reaction between myoglobin and NO.

Brewer32 found that the increased b* values could be related to the formation of metmyoglobin in the meat. We hypothesized that nitrite generated during plasma treatment could oxidize myoglobin into metmyoglobin, which could lead to the promotion of yellowness in color7.

Residual nitrite content and pH

Compared with the control, the residual nitrite contents in all products processed with PTW brine were significantly increased (P < 0.05) (Table 2). The results demonstrated that the nitrite content of dried pork loins was significantly increased during the treatments from 50 to 70 kV (P < 0.05). Similarly, Jung et al.8 reported that an increased plasma treatment intensity led to an increased nitrite content in meat samples. Importantly, the nitrite concentration in each product treated with PTW brine was below 20 mg/kg, which is lower than the maximum allowable content of residual nitrite in meat products of 100 mg/kg28.

The pH of the dried pork loins made with untreated brine and PTW brine at 50, 60 and 70 kV were 6.28, 5.92, 5.87 and 5.75, respectively. As reported3, the pH of pork loins dropped significantly after DBD-CP treatment because of the NOx molecules produced by DBD-CP and the increased residual nitrite level in the final products.

Lipid oxidation

The TBARS values of dried pork loin processed with different curing methods are shown in Table 2. Generally, reactive species such as RNS and ROS generated during DBD-CP treatment can induce lipid oxidation33. However, in our research, the TBARS value of the dried pork loins cured with PTW brine was significantly lower (P < 0.05) than that of the control. The TBARS values of products cured with PTW brine at 50, 60 and 70 kV were 0.33, 0.25 and 0.22, respectively. Lee et al.5 and Jung et al.8 found that meat batters treated with DBD-CP did not exhibit increased lipid oxidation. Previous studies have demonstrated that nitrite addition could inhibit lipid oxidation in meat products30,34. Nitrite can react with the iron ions of myoglobin to form nitrosylmyoglobin, resulting in the reduction of free iron, which is an accelerator of lipid oxidation, thus preventing lipid oxidation6. Additionally, previous studies revealed that DBD-CP treatment of water could produce hydrogen peroxide, which could react with free iron ions in meat products to form hydroxyl radicals, resulting in the loss of iron ions24,25. The TBARS value of each treatment was below 0.5 mg MDA/kg, which indicated that the lipid oxidation of the products may not influence the oxidized flavor between PTW-treated loin and the control based on a study by Greene35, who found that the oxidized flavor of meat products would not change with TBARS values under 1.0 mg MDA/kg.

Free amino acid analysis

Table 3 shows the FAA content of dried pork loins under different treatments. Compared with those in the control, the content of each FAA significantly decreased (P < 0.05) after 50 kV treatment and increased in the 60 kV and 70 kV treatments with increasing treatment voltage, which indicated that the 60 kV and 70 kV treatments may accelerate some protein degradation into free amino acids and have no negative effect on the flavor of the products. The main FFAs were alanine, glutamic acid, proline, histidine, lysine, and glycine. Some FAAs have a significant relationship with taste36, and some of them are the precursors of flavor compounds for dry-cured meat products37. For instance, a sweet flavor is related to the contents of alanine, serine, proline, threonine, and glycine; a bitter flavor is attributed to leucine, valine, isoleucine, and methionine; phenylalanine, histidine, glutamic and aspartic acid are helpful for forming acidic tastes; lysine, tyrosine, and aspartic acid are connected with an aged flavor. Therefore, the accumulation of FAAs has a great influence on the sensory quality of dried pork loins. The arginine content increased with increasing treatment intensity, and its concentration was significantly higher (P < 0.05) in all PTW treatments than that in the control. It has been proven that, as one of the umami-related amino acids, arginine is important for developing the characteristic flavor of dry-cured meat products38. The cysteine concentration of the control was significantly lower (P < 0.05) than that in the 60 kV and 70 kV treatments, which could be related to the higher TBARS values of the control since cysteine was particularly sensitive to oxidative treatment39. Compared with the other FAAs, the relatively low concentration of cysteine was due to its involvement in the Maillard reaction40 and the dehydrogenation of the thiol group in the cysteine branched chain7. Therefore, the low amount of cysteine seen in the 50 kV treatment may be related to the low content of 3-methyl-butanal in the 50 kV treatment that underwent the Maillard reaction.

Volatile compound analysis

In total, 54 volatile compounds were found in four groups of Chinese dried pork loin by GC/MS (Table 4). The volatile compounds were classified as ten aldehydes, five esters, five alcohols, six ketones, one acid, and twenty-seven hydrocarbons. Figure 4 shows that PTW used as a curing process could significantly (P < 0.05) affect the formation of volatile compounds in dried pork loin. To date, there is limited literature on the flavor of dried pork loin manufactured by PTW brine. It is well known that most of the volatile compounds generated from lipid oxidation and protein degradation, in addition Strecker degradation and the Maillard reaction contributed to the formation of flavor41. In this study, 3-methyl-butanol, 1-hexanol and 1-heptanol were only detected in the PTW treatment. 1-Octen-3-ol was the most abundant alcohol and is an unsaturated alcohol produced by linoleic acid β-oxidation that contributes a mushroom flavor34. Garcia-Gonzalez et al.42 found that 1-octen-3-ol contributed to the flavor of cured meat products since it has a low threshold value. In this study, lipid oxidation was prevented by PTW treatment, causing the decline of 1-octen-3-ol compared with that in the untreated control. 3-Methyl-butanol also had a low threshold, which came from the reduction of 3-methyl-butanal and the Strecker reaction41.

Aldehydes have an important impact on the overall flavor of cured meat products due to their low perception threshold43. Among the straight chain aldehydes detected in all four treatments, nonanal was the most abundant compound, except in the 60 kV treatment, which showed a significantly higher (P < 0.05) nonanal concentration in the control than that in the PTW treatments. This result was consistent with the TBARS results since nonanal is generally considered a product of lipid oxidation44. However, we found that the results of hexanal were in contradiction with the TBARS values, which could be attributed to the difference in sources of hexanal and MDA and various rates of generation; in addition, further reactions with other substances between hexanal and MDA could cause this result as well21. The significantly lower (P < 0.05) levels of heptanal and decanal in the 60 kV and 70 kV treatments than those in the other two treatments are in agreement with a lower level of lipid oxidation in the 60 kV and 70 kV treatments.

The ripening temperature used in this study was shown to be high enough for initiating the Maillard reaction and Strecker degradation in the meat process45. Hence, the lowest amount of 3-methyl-butanal in the 50 kV treatment among that in all treatments could be explained by the lowest content of FAAs being exhibited in the 50 kV treatments since 3-methyl-butanal is related to branched amino acids involved in the Maillard reaction and Strecker degradation46. The higher benzaldehyde content in the control compared with that in the PTW treatments was related to the higher TBARS values in the control since benzaldehyde is produced by the decomposition of α-linolenic acid47.

2,3-Octanedione and 2,3-hydroxy-butanone formed from carbohydrate fermentation46 were only found in the PTW treatments. 2-Heptanone and 2-nonanone are the products of lipid oxidation with ethereal, butter, or spicy flavors43, which were significantly higher in the control. The esters could be generated by the esterification reactions between acids and alcohols47. Two more ester compounds were found in PTW-processed dried pork loin, which may be due to the increased amount of alcohols in the PTW-treated products. Only one acid was detected, which may be related to the shorter processing time compared to that of other meat products. 3-Methyl-butanoic acid with a unique cheese flavor could be formed by the oxidation of 3-methyl-butanal48. Due to the high threshold value of straight chain hydrocarbons, even the high content of straight chain hydrocarbons had no significant impact on the flavor of cured meat products41. Aromatic hydrocarbons, such as d-limonene, came from the animal diet, while p-xylene, o-xylene, and 1,2,4-trimethylbenzene are benzene derivatives47. 2-Pentylfuran derived from linoleic acid and other n-6 fatty acids were not found in the PTW-treated products. Pyrazine compounds belonging to nitrogen-containing heterocyclic compounds with a roasted aroma were found in all treatments. Kim, et al.3 had demonstrated that there were no significant sensory property differences between cooked pork loins treated with DBD-CP and the untreated control.

Conclusion

In summary, we prepared Chinese dried pork loin using PTW brine as a novel curing process. The results showed that compared with the traditional method, dried pork loins made by treatment with PTW had no undesirable properties according to the analysis of physicochemical properties and volatile compounds. Thus, we concluded that PTW brine could be a potentially safe curing process for meat products. The physicochemical properties of the PTW - treated and untreated products in this study were mainly concentrated on regarding the impacts on color, lipid oxidation and FAA of PTW. The significantly higher a* value in the 70 kV treatment than those in the other treatments provided the characteristic cured color to the meat products, which is important for consumers. According to our DBD-CP system, the 70 kV treatment could result in significant increases in the accumulation of FAA, which has a great influence on the specific taste. Moreover, the TBARS values in the 70 kV treatment were markedly lower than those in the control, suggesting that the 70 kV treatment could increase the oxidative stability of meat products. Hence, based on these analyses, it is recommended to use 70 kV in the treatment of PTW for curing meat products. However, even though PTW is already proven to be a purified water without chemical additives, the safety of meat products processed with PTW warrants further research to satisfy authorities and consumers.

References

Ekezie, F. C., Cheng, J. H. & Sun, D. W. Effects of atmospheric pressure plasma jet on the conformation and physicochemical properties of myofibrillar proteins from king prawn (Litopenaeus vannamei). Food Chemistry 276, 147–156, https://doi.org/10.1016/j.foodchem.2018.09.113 (2019).

Sharifian, A., Soltanizadeh, N. & Abbaszadeh, R. Effects of dielectric barrier discharge plasma on the physicochemical and functional properties of myofibrillar proteins. Innovative Food Science & Emerging Technologies 54, 1–8, https://doi.org/10.1016/j.ifset.2019.03.006 (2019).

Kim, H. J., Yong, H. I., Park, S., Choe, W. & Jo, C. Effects of dielectric barrier discharge plasma on pathogen inactivation and the physicochemical and sensory characteristics of pork loin. Current Applied Physics 13, 1420–1425, https://doi.org/10.1016/j.cap.2013.04.021 (2013).

Kim, B. et al. Effect of atmospheric pressure plasma on inactivation of pathogens inoculated onto bacon using two different gas compositions. Food Microbiology 28, 9–13, https://doi.org/10.1016/j.fm.2010.07.022 (2011).

Lee, J. et al. The use of atmospheric pressure plasma as a curing process for canned ground ham. Food Chemistry 240, 430–436, https://doi.org/10.1016/j.foodchem.2017.07.148 (2018).

Jung, S. et al. The use of atmospheric pressure plasma-treated water as a source of nitrite for emulsion-type sausage. Meat Science 108, 132–137, https://doi.org/10.1016/j.meatsci.2015.06.009 (2015).

Huang, M. et al. Effect of in-package high voltage dielectric barrier discharge on microbiological, color and oxidation properties of pork in modified atmosphere packaging during storage. Meat Science 149, 107–113, https://doi.org/10.1016/j.meatsci.2018.11.016 (2019).

Jung, S. et al. Direct infusion of nitrite into meat batter by atmospheric pressure plasma treatment. Innovative Food Science & Emerging Technologies 39, 113–118, https://doi.org/10.1016/j.ifset.2016.11.010 (2017).

Hae, I. Y. et al. Color development, physiochemical properties, and microbiological safety of pork jerky processed with atmospheric pressure plasma. Innovative Food Science and Emerging Technologies, https://doi.org/10.1016/j.ifset.2017.09.005 (2017).

Yong, H. I. et al. An innovative curing process with plasma-treated water for production of loin ham and for its quality and safety. Plasma Processes and Polymers 15, https://doi.org/10.1002/ppap.201700050 (2018).

Foster, J., Sommers, B. S., Gucker, S. N., Blankson, I. M. & Adamovsky, G. Perspectives on the Interaction of Plasmas With Liquid Water for Water Purification. IEEE Transactions on Plasma Science 40, 1311–1323, https://doi.org/10.1109/tps.2011.2180028 (2012).

Oehmigen, K. et al. The Role of Acidification for Antimicrobial Activity of Atmospheric Pressure Plasma in Liquids. Plasma Processes and Polymers 7, 250–257, https://doi.org/10.1002/ppap.200900077 (2010).

Grau, R., Albarracín, W., Trinidad Pérez, M., Antequera, T. & Barat, J. M. Use of simultaneous brine thawing/salting in dry-cured Iberian ham production. Journal of Food Engineering 104, 316–321, https://doi.org/10.1016/j.jfoodeng.2010.12.023 (2011).

Yang, R. et al. Effect of atmospheric cold plasma on structure, activity, and reversible assembly of the phytoferritin. Food Chemistry 264, 41–48, https://doi.org/10.1016/j.foodchem.2018.04.049 (2018).

Sarangapani, C., Ryan Keogh, D., Dunne, J., Bourke, P. & Cullen, P. J. Characterisation of cold plasma treated beef and dairy lipids using spectroscopic and chromatographic methods. Food Chemistry 235, 324–333, https://doi.org/10.1016/j.foodchem.2017.05.016 (2017).

Wang, J. M., Zhuang, H., Lawrence, K. & Zhang, J. H. Disinfection of chicken fillets in packages with atmospheric cold plasma: effects of treatment voltage and time. Journal of Applied Microbiology 124, 1212–1219, https://doi.org/10.1111/jam.13637 (2018).

Tian, Y. et al. Assessment of the Physicochemical Properties and Biological Effects of Water Activated by Non-thermal Plasma Above and Beneath the Water Surface. Plasma Processes and Polymers 12, 439–449, https://doi.org/10.1002/ppap.201400082 (2015).

Jin, G. et al. Lipolysis and lipid oxidation in bacon during curing and drying–ripening. Food Chemistry 123, 465–471, https://doi.org/10.1016/j.foodchem.2010.05.031 (2010).

Hunt, M. C. et al. AMSA meat color measurement guidelines. Vol. 61 (American Meat Science Association, 2012).

AOAC, Association of Official Analytical Chemists Nitrites in cured meats Official Method 973.31. Official methods of analysis (15th ed.). Arlington, VA: AOAC (1990).

Wang, J., Jin, G., Zhang, W., Ahn, D. U. & Zhang, J. Effect of curing salt content on lipid oxidation and volatile flavour compounds of dry-cured turkey ham. LWT - Food Science and Technology 48, 102–106, https://doi.org/10.1016/j.lwt.2012.02.020 (2012).

Lorenzo, J. M., Cittadini, A., Bermúdez, R., Munekata, P. E. & Domínguez, R. Influence of partial replacement of NaCl with KCl, CaCl 2 and MgCl 2 on proteolysis, lipolysis and sensory properties during the manufacture of dry-cured lacón. Food Control 55, 90–96, https://doi.org/10.1016/j.foodcont.2015.02.035 (2015).

Marusic, R. N., Vidacek, S., Janci, T. & Medic, H. Characterization of volatile compounds, physico-chemical and sensory characteristics of smoked dry-cured ham. Journal of Food Science and Technology 53, 4093–4105, https://doi.org/10.1007/s13197-016-2418-2 (2016).

Ercan, U. K., Smith, J., Ji, H. F., Brooks, A. D. & Joshi, S. G. Chemical Changes in Nonthermal Plasma-Treated N-Acetylcysteine (NAC) Solution and Their Contribution to Bacterial Inactivation. Scientific reports 6, 20365, https://doi.org/10.1038/srep20365 (2016).

Arben, K. et al. Chemistry for Antimicrobial Properties of Water Treated With Non-Equilibrium Plasma. Journal of Nanomedicine & Biotherapeutic Discovery 04, https://doi.org/10.4172/2155-983x.1000120 (2014).

Alahakoon, A. U., Jayasena, D. D., Ramachandra, S. & Jo, C. Alternatives to nitrite in processed meat: Up to date. Trends in Food Science &. Technology 45, 37–49, https://doi.org/10.1016/j.tifs.2015.05.008 (2015).

Korachi, M., Gurol, C. & Aslan, N. Atmospheric plasma discharge sterilization effects on whole cell fatty acid profiles of Escherichia coli and Staphylococcus aureus. Journal of Electrostatics 68, 508–512, https://doi.org/10.1016/j.elstat.2010.06.014 (2010).

Honikel, K. O. The use and control of nitrate and nitrite for the processing of meat products. Meat Science 78, 68–76, https://doi.org/10.1016/j.meatsci.2007.05.030 (2008).

Jayasena, D. D. et al. Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: effects on pathogen inactivation and meat-quality attributes. Food Microbiology 46, 51–57, https://doi.org/10.1016/j.fm.2014.07.009 (2015).

Tsoukalas, D. S., Katsanidis, E., Marantidou, S. & Bloukas, J. G. Effect of freeze-dried leek powder (FDLP) and nitrite level on processing and quality characteristics of fermented sausages. Meat Science 87, 140–145, https://doi.org/10.1016/j.meatsci.2010.10.003 (2011).

Sebranek, J. G. Basic curing ingredients. Ingredients in meat products (pp. 1–23). New York: Springer (2009).

Brewer, S. Irradiation effects on meat color - a review. Meat Science 68, 1–17, https://doi.org/10.1016/j.meatsci.2004.02.007 (2004).

Xiang, Q. et al. Influences of cold atmospheric plasma on microbial safety, physicochemical and sensorial qualities of meat products. Journal of Food Science and Technology 55, 846–857, https://doi.org/10.1007/s13197-017-3020-y (2018).

Lee, J. H., Alford, L., Kannan, G. & Kouakou, B. Curing properties of sodium nitrite in restructured goat meat (chevon) jerky. International Journal of Food Properties 20, 526–537, https://doi.org/10.1080/10942912.2016.1168833 (2016).

Greene, B. E. & Cumuze, T. H. Relationship Between TBA Numbers and Inexperienced Panelists’Assessments of Oxidized Flavor in Cooked Beef. Journal of Food Science 47, 52–54 (1982).

Jurado, A., Garcia, C., Timon, M. L. & Carrapiso, A. I. Effect of ripening time and rearing system on amino acid-related flavour compounds of Iberian ham. Meat Science 75, 585–594, https://doi.org/10.1016/j.meatsci.2006.09.006 (2007).

Hidalgo, F. J. & Zamora, R. Amino Acid Degradations Produced by Lipid Oxidation Products. Critical Reviews in Food Science and Nutrition 56, 1242–1252, https://doi.org/10.1080/10408398.2012.761173 (2016).

Santos, B. A. D. et al. Impact of sodium chloride replacement by salt substitutes on the proteolysis and rheological properties of dry fermented sausages. Journal of Food Engineering 151, 16–24, https://doi.org/10.1016/j.jfoodeng.2014.11.015 (2015).

Zhou, F., Zhao, M., Cui, C. & Sun, W. Influence of linoleic acid-induced oxidative modifications on physicochemical changes and in vitro digestibility of porcine myofibrillar proteins. LWT - Food Science and Technology 61, 414–421, https://doi.org/10.1016/j.lwt.2014.12.037 (2015).

Pugliese, C., Sirtori, F., Calamai, L. & Franci, O. The evolution of volatile compounds profile of “Toscano” dry-cured ham during ripening as revealed by SPME-GC-MS approach. International Journal of Mass Spectrometry 45, 1056–1064, https://doi.org/10.1002/jms.1805 (2010).

Lorenzo, J. M. & Carballo, J. Changes in physico-chemical properties and volatile compounds throughout the manufacturing process of dry-cured foal loin. Meat Science 99, 44–51, https://doi.org/10.1016/j.meatsci.2014.08.013 (2015).

Garcia-Gonzalez, D. L., Tena, N., Aparicio-Ruiz, R. & Morales, M. T. Relationship between sensory attributes and volatile compounds qualifying dry-cured hams. Meat Science 80, 315–325, https://doi.org/10.1016/j.meatsci.2007.12.015 (2008).

Pateiro, M., Franco, D., Carril, J. A. & Lorenzo, J. M. Changes on physico-chemical properties, lipid oxidation and volatile compounds during the manufacture of celta dry-cured loin. Journal of Food Science and Technology 52, 4808–4818, https://doi.org/10.1007/s13197-014-1561-x (2015).

Purrinos, L., Franco, D., Carballo, J. & Lorenzo, J. M. Influence of the salting time on volatile compounds during the manufacture of dry-cured pork shoulder “lacon”. Meat Science 92, 627–634, https://doi.org/10.1016/j.meatsci.2012.06.010 (2012).

Jiang, J. J., Zeng, Q. X. & Zhu, Z. W. Analysis of Volatile Compounds in Traditional Chinese Fish Sauce (Yu Lu). Food and Bioprocess Technology 4, 266–271, https://doi.org/10.1007/s11947-008-0173-8 (2008).

Wu, H. et al. Influence of partial replacement of NaCl with KCl on profiles of volatile compounds in dry-cured bacon during processing. Food Chemistry 172, 391–399, https://doi.org/10.1016/j.foodchem.2014.09.088 (2015).

Zhao, J. et al. Volatile flavor constituents in the pork broth of black-pig. Food Chemistry 226, 51–60, https://doi.org/10.1016/j.foodchem.2017.01.011 (2017).

Larrouture-Thiveyrat, C., Pepin, M., Leroy-Sétrin, S. & Montel, M. C. Effect of Carnobacterium piscicola on aroma formation in sausage mince. Meat science 63, 423–426 (2003).

Acknowledgements

This work was supported by the Agricultural Innovation Fund Project of Jiangsu Province (No. CX(18)3041) and the National Key Research and Development Program (2018YFD0700802).

Author information

Authors and Affiliations

Contributions

Ji Luo performed all of the experiments, Ji Luo and Jianhao Zhang wrote the main manuscript text and performed the data analysis and interpretation, Wenjing Yan helped in the chemistry experiments and prepared the PTW, and Mustapha Muhammad Nasiru assisted with the discussion and evaluation. Hong Zhuang and Guanghong Zhou contributed substantially to the concept and design of the work. All authors contributed to the manuscript editing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Luo, J., Yan, W., Nasiru, M.M. et al. Evaluation of physicochemical properties and volatile compounds of Chinese dried pork loin curing with plasma-treated water brine. Sci Rep 9, 13793 (2019). https://doi.org/10.1038/s41598-019-50351-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-50351-5

This article is cited by

-

Application of Direct and Indirect Non-thermal Plasma in the Development of Ready-to-Eat Foods

Current Food Science and Technology Reports (2024)

-

New Strategies for the Total/Partial Replacement of Conventional Sodium Nitrite in Meat Products: a Review

Food and Bioprocess Technology (2022)

-

Alternative Curing Methods

Current Clinical Microbiology Reports (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.