Direct air capture technology from Kanazawa University sucks up ambient CO2 from the atmosphere.

Japan has a huge unharnessed energy source in the form of moderately hot exhaust fumes that could help industry power its own carbon capture technology and clean up its act, says environmental technologist, Akio Kodama.

Already exhaust fumes hotter than 500°C from industrial activities — including melting and processing metals, and operating transport machinery — are sometimes repurposed for uses such as electricity generation, explains Kodama, who is based at the Institute for Frontier Science Initiative at Kanazawa University. But the heat from cooler exhaust fumes typically goes to waste.

“Nearly 80% of exhaust heat produced in Japan is under 200°C, and the current use of this heat is limited to making hot water,” he says. “That’s a significant source to be unlocked.”

Kodama is pioneering a method for extracting waste CO2 using relatively low heat fumes and absorbent materials.

His team leverages ‘temperature swing adsorption’, an established technique for purifying gases, in which adsorbents with small pores capture and release CO2, depending on the temperature. In this process, the release stage is maneuvered so that the CO2 can be extracted by vacuum pumps.

Concentrated effort

The current issue with many carbon-capture and sequestration technologies is that they require huge amounts of energy to power them, meaning that more carbon is generated than they can suck up from the environment. “High-energy-input carbon capture machinery only makes sense where a good renewable energy source is readily available, such as geothermal energy in Iceland. It has been a challenging balancing act in other parts of the world,” explains Kodama.

One problem is that at low temperatures, traditional temperature swing adsorption requires numerous hot air currents to warm adsorbents, releasing captured CO2, but the air tends to dilute the released CO2 so that the concentrations extracted are too small.

In response, Kodama created an alternative heat exchange mechanism to air currents composed of zeolite or activated carbon placed within an adsorption tower1. Waste heat in the 200°C range should be able to fuel this process, but the goal is to get this working at temperatures of 80°C or less.

“The places where we find this type of exhaust heat are also in many cases major CO2 emission sources. How good would it be if industrial plants could use the heat that they are wasting to help reduce their CO2 emissions?” says Kodama.

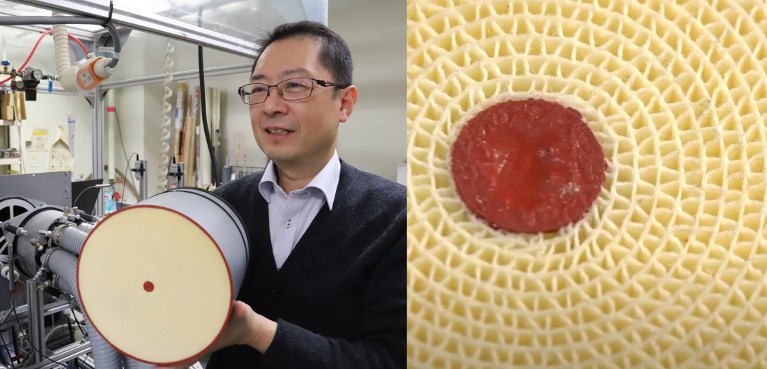

(Left) Akio Kodama is pioneering a method for extracting waste CO2 using the energy of relatively-low-heat fumes. (Right) Honeycomb-like lattices of amine-based adsorbents on rotors help absorb and concentrate CO2 for sequestration.

Direct air capture

Kodama and his team are also hoping to use rotors fitted with honeycomb-like lattices for ‘direct air capture’, which sucks up ambient carbon dioxide from the atmosphere. For this, they are employing amine-based adsorbents being developed by The Research Institute of Innovative Technology for the Earth, based in Kyoto. In future, they intend to integrate these rotors and the heat exchangers.

To make the rotor technology workable, Kodama says the plan is to use it in tandem with other processes that can capture enough carbon to outweigh the energy emissions required to power the technology. “Other techniques can achieve high concentrations of CO2, but need extensive energy and massive equipment, such as large vacuum pumps,” says Kodama. “By adding a rough concentration increasing process as a first step, we’re trying to drastically reduce the amount of air that needs to be processed. This means the machinery can be more compact, with a small vacuum pump.”

This project has been selected for the New Energy and Industrial Technology Development Organization Moonshot Research and Development Program, a Japanese government initiative supporting ambitious projects tackling major societal issues. The eventual plan is for sequestered CO2 to be converted into liquid hydrocarbon to fuel cars, recyclings the CO2.

Finding a new use for currently wasted industrial exhaust heat is also very attractive, says Kodama. “Even as the world moves towards carbon-free energy sources, we will likely still produce significant waste heat beyond 2050,” meaning this potential energy source for carbon capture is here for the foreseeable future.

Nature Index Japan 2023

Nature Index Japan 2023