Abstract

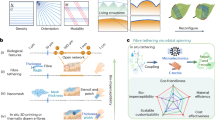

Soft fibres can be used to make smart textiles for use in energy, sensing and therapeutic applications. However, the fabrication of functional fibres is difficult compared with the fabrication of two-dimensional films and three-dimensional monoliths, and current methods typically require high temperatures, high volumes of solvents or complex systems. Here we report a spinning approach to fabricate functional fibres, which is based on spontaneous phase separation and is inspired by the silk-spinning processes of spiders. The silk-spinning process is mimicked by creating a spinning solution of polyacrylonitrile and silver ions, which forms an elastic supramolecular network with silver coordination complexes and in situ reduced silver nanoparticles. This approach, which operates at ambient pressure and temperature, can be used to make soft functional fibres that are mechanically stretchable (more than 500% strain), strong (more than 6 MPa) and electrically conductive (around 1.82 S m−1). To illustrate the capabilities of the technique, we use the fibres to create a sensing glove and a smart face mask.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Shi, X. et al. Large-area display textiles integrated with functional systems. Nature 591, 240–245 (2021).

Zhou, Z. et al. Sign-to-speech translation using machine-learning-assisted stretchable sensor arrays. Nat. Electron. 3, 571–578 (2020).

Loke, G. et al. Digital electronics in fibres enable fabric-based machine-learning inference. Nat. Commun. 12, 3317 (2021).

Zhang, S. et al. Leveraging triboelectric nanogenerators for bioengineering. Matter 4, 845–887 (2021).

Chen, G., Li, Y., Bick, M. & Chen, J. Smart textiles for electricity generation. Chem. Rev. 120, 3668–3720 (2020).

Chen, G. et al. Electronic textiles for wearable point-of-care systems. Chem. Rev. 122, 3259–3291 (2022).

Libanori, A., Chen, G., Zhao, X., Zhou, Y. & Chen, J. Smart textiles for personalized healthcare. Nat. Electron. 5, 142–156 (2022).

Loke, G., Yan, W., Khudiyev, T., Noel, G. & Fink, Y. Recent progress and perspectives of thermally drawn multimaterial fiber electronics. Adv. Mater. 32, 1904911 (2020).

Xu, J. et al. Highly stretchable polymer semiconductor films through the nanoconfinement effect. Science 355, 59–64 (2017).

Zhang, M. et al. Printable smart pattern for multifunctional energy-management e-textile. Matter 1, 168–179 (2019).

Yuk, H. et al. 3D printing of conducting polymers. Nat. Commun. 11, 1604 (2020).

Kanik, M. et al. Strain-programmable fiber-based artificial muscle. Science 365, 145–150 (2019).

Eom, W. et al. Large-scale wet-spinning of highly electroconductive MXene fibers. Nat. Commun. 11, 2825 (2020).

Xin, G. et al. Highly thermally conductive and mechanically strong graphene fibers. Science 349, 1083–1087 (2015).

Yu, D. et al. Scalable synthesis of hierarchically structured carbon nanotube–graphene fibres for capacitive energy storage. Nat. Nanotechnol. 9, 555–562 (2014).

Bai, H., Ju, J., Zheng, Y. & Jiang, L. Functional fibers with unique wettability inspired by spider silks. Adv. Mater. 24, 2786–2791 (2012).

Zheng, Y. et al. Directional water collection on wetted spider silk. Nature 463, 640–643 (2010).

Omenetto, F. G. & Kaplan, D. L. New opportunities for an ancient material. Science 329, 528–531 (2010).

Malay, A. D. et al. Spider silk self-assembly via modular liquid-liquid phase separation and nanofibrillation. Sci. Adv. 6, eabb6030 (2020).

Vollrath, F. & Knight, D. P. Liquid crystalline spinning of spider silk. Nature 410, 541–548 (2001).

Wu, Y. et al. Bioinspired supramolecular fibers drawn from a multiphase self-assembled hydrogel. Proc. Natl Acad. Sci. USA 114, 8163–8168 (2017).

Zhao, X. et al. Bioinspired ultra-stretchable and anti-freezing conductive hydrogel fibers with ordered and reversible polymer chain alignment. Nat. Commun. 9, 3579 (2018).

Sun, W. et al. Molecular engineering of metal coordination interactions for strong, tough, and fast-recovery hydrogels. Sci. Adv. 6, eaaz9531 (2020).

Filippidi, E. et al. Toughening elastomers using mussel-inspired iron-catechol complexes. Science 358, 502–505 (2017).

Zhang, S. et al. Strong, compressible, and ultrafast self-recovery organogel with in situ electrical conductivity improvement. Adv. Funct. Mater. 33, 2209129 (2023).

Pastoriza-Santos, I. & Liz-Marzán, L. M. Synthesis of silver nanoprisms in DMF. Nano Lett. 2, 903–905 (2002).

Pastoriza-Santos, I. & Liz-Marzán, L. M. N. N-dimethylformamide as a reaction medium for metal nanoparticle synthesis. Adv. Funct. Mater. 19, 679–688 (2009).

Matsuyama, H., Teramoto, M., Nakatani, R. & Maki, T. Membrane formation via phase separation induced by penetration of nonsolvent from vapor phase. I. Phase diagram and mass transfer process. J. Appl. Polym. Sci. 74, 159–170 (1999).

Yasuda, K., Armstrong, R. & Cohen, R. Shear flow properties of concentrated solutions of linear and star branched polystyrenes. Rheol. Acta 20, 163–178 (1981).

Hackley, V. A. & Ferraris, C. F. The Use of Nomenclature in Dispersion Science and Technology (NIST Special Publication, 2001).

Breslauer, D. N., Lee, L. P. & Muller, S. J. Simulation of flow in the silk gland. Biomacromolecules 10, 49–57 (2009).

Hashimoto, K. & Imae, T. Rheological properties of aqueous solutions of alkyl- and oleyldimethylamine oxides. Spinnability and viscoelasticity. Langmuir 7, 1734–1741 (1991).

Knight, D. P., Knight, M. M. & Vollrath, F. Beta transition and stress-induced phase separation in the spinning of spider dragline silk. Int. J. Biol. Macromol. 27, 205–210 (2000).

Oliveira, M. S. N. & McKinley, G. H. Iterated stretching and multiple beads-on-a-string phenomena in dilute solutions of highly extensible flexible polymers. Phys. Fluids 17, 071704 (2005).

Tripathi, A., Rutkevičius, M., Bose, A., Rojas, O. J. & Khan, S. A. Experimental and predictive description of the morphology of wet-spun fibers. ACS Appl. Polym. Mater. 1, 1280–1290 (2019).

Kojic, N., Kojic, M., Gudlavalleti, S. & McKinley, G. Solvent removal during synthetic and Nephila fiber spinning. Biomacromolecules 5, 1698–1707 (2004).

Vollrath, F., Knight, D. P. & Hu, X. W. Silk production in a spider involves acid bath treatment. Proc. R. Soc. Lond. B 265, 817–820 (1998).

Zhang, S., Hao, A., Liu, Z., Park, J. G. & Liang, R. A highly stretchable polyacrylonitrile elastomer with nanoreservoirs of lubricant using cyano-silver complexes. Nano Lett. 19, 3871–3877 (2019).

Acknowledgements

S.Z. acknowledges Y. Zhang at the Singapore Management University (SMU) for substantial support and assistance on data visualization and representation. J.C. acknowledges the Henry Samueli School of Engineering and Applied Science and the Department of Bioengineering at the University of California, Los Angeles, for the startup support. J.C. also acknowledges the Hellman Fellows Research Grant, the UCLA Pandemic Resources Program Research Award, the Research Recovery Grant by the UCLA Academic Senate, the Brain & Behavior Research Foundation Young Investigator Grant (grant no. 30944 to J.C.) and the Catalyzing Pediatric Innovation Grant (grant no. 47744 to J.C.) from the West Coast Consortium for Technology & Innovation in Pediatrics, Children’s Hospital Los Angeles. S.C.T. acknowledges the Ministry of Education Singapore Academic Research Fund (Tier 2 grant no. A-0005415-01-00).

Author information

Authors and Affiliations

Contributions

S.Z. conceived the idea, performed most of the experiments and analysed the data. S.C.T., J.C. and Y.-L.Z. supervised the project. Y.Z., A.L. and X.Z. assisted on the data interpretation and writing. Y.D. and P.Z. conducted the AFM–SMFS tests. M.L. assisted on the sensing glove design and execution. M.Z. assisted on proposing the fibre formation mechanism. H.Q. assisted on the car remote control demonstration. Y.-L.Z. performed the simulation. S.Z. wrote the initial manuscript. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

A provisional patent application has been filed by the National University of Singapore (ILO ref: 2023-010 filed on 16 January 2023).

Peer review

Peer review information

Nature Electronics thanks Meifang Zhu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Texts 1–4, Figs. 1–51, Tables 1–5, Methods and references.

Supplementary Video 1

Effect of curing time on spinnability.

Supplementary Video 2

Fibre thinning under ambient conditions.

Supplementary Video 3

CG-MD simulation of the stretching–releasing results at a molecular level.

Supplementary Video 4

Fibre formation under ambient conditions via spontaneous phase separation.

Supplementary Video 5

Removing solvent droplets from fibres.

Supplementary Video 6

Phase separation of PAN and PANSion solution droplets under ambient conditions.

Supplementary Video 7

CG-MD simulation of phase separation (PSEA spinning and WS).

Supplementary Video 8

CG-MD simulation of mass transfer.

Supplementary Video 9

Demonstrations of the electronic applications of PANSion fibres.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, S., Zhou, Y., Libanori, A. et al. Biomimetic spinning of soft functional fibres via spontaneous phase separation. Nat Electron 6, 338–348 (2023). https://doi.org/10.1038/s41928-023-00960-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-023-00960-w

This article is cited by

-

Washable and Multifunctional Electronic Textiles Via In Situ Lamination for Personal Health Care

Advanced Fiber Materials (2024)

-

Ambient-conditions spinning of functional soft fibers via engineering molecular chain networks and phase separation

Nature Communications (2023)