Abstract

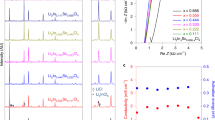

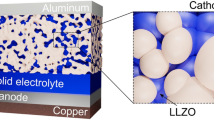

The dominant chemistries of lithium-ion batteries on the market today still rely on flammable organic liquid electrolytes and cathodes containing scarce metals, such as cobalt or nickel, raising safety, cost and environmental concerns. Here we show a FeCl3 cathode that costs as little as 1% of the cost of a LiCoO2 cathode or 2% of a LiFePO4 cathode. Once coupled with a solid halide electrolyte and a lithium-indium (Li–In) alloy anode, it enables all-solid-state lithium-ion batteries without any liquid components. Notably, FeCl3 exhibits two flat voltage plateaux between 3.5 and 3.8 V versus Li+/Li, and the solid cell retains 83% of its initial capacity after 1,000 cycles with an average Coulombic efficiency of 99.95%. Combined neutron diffraction and X-ray absorption spectroscopy characterizations reveal a Li-ion (de)intercalation mechanism together with a Fe2+/Fe3+ redox process. Our work provides a promising avenue for developing sustainable battery technologies with a favourable balance of performance, cost and safety.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data in this work are available in the text and Supplementary Information. Source data are provided with this paper.

References

Janek, J. & Zeier, W. G. A solid future for battery development. Nat. Energy 1, 16141 (2016).

Lu, J., Wu, T. & Amine, K. State-of-the-art characterization techniques for advanced lithium-ion batteries. Nat. Energy 2, 17011 (2017).

Yang, Z., Huang, H. & Lin, F. Sustainable electric vehicle batteries for a sustainable world: perspectives on battery cathodes, environment, supply chain, manufacturing, life cycle, and policy. Adv. Energy Mater. 12, 2200383 (2022).

Zhang, Z.-j et al. Polypyrrole-coated α-LiFeO2 nanocomposite with enhanced electrochemical properties for lithium-ion batteries. Electrochim. Acta 108, 820–826 (2013).

Chung, S.-Y., Bloking, J. T. & Chiang, Y.-M. Electronically conductive phospho-olivines as lithium storage electrodes. Nat. Mater. 1, 123–128 (2002).

Kang, B. & Ceder, G. Battery materials for ultrafast charging and discharging. Nature 458, 190–193 (2009).

Fang, S., Bresser, D. & Passerini, S. Transition metal oxide anodes for electrochemical energy storage in lithium- and sodium-ion batteries. Adv. Energy Mater. 10, 1902485 (2020).

Zhong, K. et al. Investigation on porous MnO microsphere anode for lithium ion batteries. J. Power Sources 196, 6802–6808 (2011).

He, K. et al. Transitions from near-surface to interior redox upon lithiation in conversion electrode materials. Nano Lett. 15, 1437–1444 (2015).

Hua, X. et al. Comprehensive study of the CuF2 conversion reaction mechanism in a lithium ion battery. J. Phys. Chem. C 118, 15169–15184 (2014).

Liu, J.-L., Cui, W.-J., Wang, C.-X. & Xia, Y.-Y. Electrochemical reaction of lithium with CoCl2 in nonaqueous electrolyte. Electrochem. Commun. 13, 269–271 (2011).

Xiao, A. W. et al. Understanding the conversion mechanism and performance of monodisperse FeF2 nanocrystal cathodes. Nat. Mater. 19, 644–654 (2020).

Li, T., Chen, Z. X., Cao, Y. L., Ai, X. P. & Yang, H. X. Transition-metal chlorides as conversion cathode materials for Li-ion batteries. Electrochim. Acta 68, 202–205 (2012).

Karki, K. et al. Revisiting conversion reaction mechanisms in lithium batteries: lithiation-driven topotactic transformation in FeF2. J. Am. Chem. Soc. 140, 17915–17922 (2018).

Wu, F. et al. Metal–organic framework-derived nanoconfinements of CoF2 and mixed-conducting wiring for high-performance metal fluoride-lithium battery. ACS Nano 15, 1509–1518 (2021).

Chang, D., Chen, M.-H. & Van der Ven, A. Factors contributing to path hysteresis of displacement and conversion reactions in Li ion batteries. Chem. Mater. 27, 7593–7600 (2015).

Cabana, J., Monconduit, L., Larcher, D. & Palacín, M. R. Beyond intercalation-based Li-ion batteries: the state of the art and challenges of electrode materials reacting through conversion reactions. Adv. Mater. 22, E170–E192 (2010).

Wang, F. et al. Tracking lithium transport and electrochemical reactions in nanoparticles. Nat. Commun. 3, 1201 (2012).

Hua, X. et al. Revisiting metal fluorides as lithium-ion battery cathodes. Nat. Mater. 20, 841–850 (2021).

Liu, P., Vajo, J. J., Wang, J. S., Li, W. & Liu, J. Thermodynamics and kinetics of the Li/FeF3 reaction by electrochemical analysis. J. Phys. Chem. C 116, 6467–6473 (2012).

Fu, W. et al. Iron fluoride–carbon nanocomposite nanofibers as free-standing cathodes for high-energy lithium batteries. Adv. Funct. Mater. 28, 1801711 (2018).

Wiaderek, K. M. et al. Comprehensive insights into the structural and chemical changes in mixed-anion FeOF electrodes by using operando PDF and NMR spectroscopy. J. Am. Chem. Soc. 135, 4070–4078 (2013).

Jung, S.-K. et al. New iron-based intercalation host for lithium-ion batteries. Chem. Mater. 30, 1956–1964 (2018).

Ko, J. K. et al. Transport, phase reactions, and hysteresis of iron fluoride and oxyfluoride conversion electrode materials for lithium batteries. ACS Appl. Mater. Interfaces 6, 10858–10869 (2014).

Kim, T. et al. A cathode material for lithium-ion batteries based on graphitized carbon-wrapped FeF3 nanoparticles prepared by facile polymerization. J. Mater. Chem. A 4, 14857–14864 (2016).

Li, L. et al. Origins of large voltage hysteresis in high-energy-density metal fluoride lithium-ion battery conversion electrodes. J. Am. Chem. Soc. 138, 2838–2848 (2016).

Wu, F. & Yushin, G. Conversion cathodes for rechargeable lithium and lithium-ion batteries. Energy Environ. Sci. 10, 435–459 (2017).

Dubouis, N. et al. Extending insertion electrochemistry to soluble layered halides with superconcentrated electrolytes. Nat. Mater. 20, 1545–1550 (2021).

Asano, T. et al. Solid halide electrolytes with high lithium-ion conductivity for application in 4 V class bulk-type all-solid-state batteries. Adv. Mater. 30, 1803075 (2018).

Park, K.-H. et al. High-voltage superionic halide solid electrolytes for all-solid-state Li-ion batteries. ACS Energy Lett. 5, 533–539 (2020).

Li, X. et al. Air-stable Li3InCl6 electrolyte with high voltage compatibility for all-solid-state batteries. Energy Environ. Sci. 12, 2665–2671 (2019).

Liu, Z. et al. High ionic conductivity achieved in Li3Y(Br3Cl3) mixed halide solid electrolyte via promoted diffusion pathways and enhanced grain boundary. ACS Energy Lett. 6, 298–304 (2021).

Delmas, C., Fouassier, C. & Hagenmuller, P. Structural classification and properties of the layered oxides. Phys. B+C 99, 81–85 (1980).

Helm, B. et al. Exploring aliovalent substitutions in the lithium halide superionic conductor Li3−xIn1−xZrxCl6 (0 ≤ x ≤ 0.5). Chem. Mater. 33, 4773–4782 (2021).

Kwak, H. et al. Li+ conduction in aliovalent-substituted monoclinic Li2ZrCl6 for all-solid-state batteries: Li2+xZr1−xMxCl6 (M = In, Sc). J. Chem. Eng. 437, 135413 (2022).

Kanno, R. et al. Synthesis, structure, and electrochemical properties of a new lithium iron oxide, LiFeO2, with a corrugated layer structure. J. Electrochem. Soc. 143, 2435–2442 (1996).

Kanno, R., Shirane, T., Inaba, Y. & Kawamoto, Y. Synthesis and electrochemical properties of lithium iron oxides with layer-related structures. J. Power Sources 68, 145–152 (1997).

Padhi, A. K., Nanjundaswamy, K. S. & Goodenough, J. B. Phospho-olivines as positive-electrode materials for rechargeable lithium batteries. J. Electrochem. Soc. 144, 1188–1194 (1997).

Sun, X. et al. Operando EDXRD study of all-solid-state lithium batteries coupling thioantimonate superionic conductors with metal sulfide. Adv. Energy Mater. 11, 2002861 (2021).

Soubeyroux, J. L., Cros, C., Gang, W., Kanno, R. & Pouchard, M. Neutron diffraction investigation of the cationic distribution in the structure of the spinel-type solid solutions Li2−2xM1+xCl4 (M = Mg, V): correlation with the ionic conductivity and NMR data. Solid State Ion. 15, 293–300 (1985).

Jiang, M. et al. Materials perspective on new lithium chlorides and bromides: insights into thermo-physical properties. Phys. Chem. Chem. Phys. 22, 22758–22767 (2020).

Papakyriakou, M. et al. Mechanical behavior of inorganic lithium-conducting solid electrolytes. J. Power Sources 516, 230672 (2021).

Liang, J. et al. Halide layer cathodes for compatible and fast-charged halides-based all-solid-state Li metal batteries. Angew. Chem. Int. Ed. 62, e202217081 (2023).

Wang, K., Gu, Z., Xi, Z., Hu, L. & Ma, C. Li3TiCl6 as ionic conductive and compressible positive electrode active material for all-solid-state lithium-based batteries. Nat. Commun. 14, 1396 (2023).

Fan, X. et al. High energy-density and reversibility of iron fluoride cathode enabled via an intercalation-extrusion reaction. Nat. Commun. 9, 2324 (2018).

Wang, K. et al. A cost-effective and humidity-tolerant chloride solid electrolyte for lithium batteries. Nat. Commun. 12, 4410 (2021).

Kwak, H. et al. Emerging halide superionic conductors for all-solid-state batteries: design, synthesis, and practical applications. ACS Energy Lett. 7, 1776–1805 (2022).

Kwak, H. et al. New cost-effective halide solid electrolytes for all-solid-state batteries: mechanochemically prepared Fe3+-substituted Li2ZrCl6. Adv. Energy Mater. 11, 2003190 (2021).

Wang, C. et al. Solvent-free approach for interweaving freestanding and ultrathin inorganic solid electrolyte membranes. ACS Energy Lett. 7, 410–416 (2022).

Ye, L. & Li, X. A dynamic stability design strategy for lithium metal solid state batteries. Nature 593, 218–222 (2021).

Tan, D. H. S. et al. Carbon-free high-loading silicon anodes enabled by sulfide solid electrolytes. Science 373, 1494–1499 (2021).

Kwak, H. et al. Boosting the interfacial superionic conduction of halide solid electrolytes for all-solid-state batteries. Nat. Commun. 14, 2459 (2023).

Perl, J., Shin, J., Schümann, J., Faddegon, B. & Paganetti, H. TOPAS: an innovative proton Monte Carlo platform for research and clinical applications. Med. Phys. 39, 6818–6837 (2012).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Acknowledgements

Z.L. and H.C. acknowledge financial support from the National Science Foundation (Grant Nos. 1706723 and 2108688) and from the faculty startup fund of Georgia Tech. The Advanced Photon Source at Argonne National Laboratory was made available through the General User Program, which is supported by the US Department of Energy (DOE), Office of Science, Office of Basic Energy Sciences (Contract No. DE-AC02-06CH11357). This research also used the 28ID-2 XPD beamline of the National Synchrotron Light Source II, a DOE, Office of Science user facility operated for the DOE Office of Science by Brookhaven National Laboratory (Contract No. DE-SC0012704). A portion of this research used resources at the Spallation Neutron Source, a DOE Office of Science user facility operated by Oak Ridge National Laboratory. J.L. thanks the DOE, Office of Science, Office of Basic Energy Sciences for funding support (Grant No. DOE-BES-ERKCSNX). S.Z. and Y.T. acknowledge support from the National Science Foundation (Grant No. 1923802) and NASA (Grant No. 80NSSC21K0483). We thank the beamline scientists J. Okasinski, J. Bai and W. Xu for their help with the synchrotron experiments. We thank Z. Fan’s group at the University of Houston for assisting with scanning electron microscopy characterizations.

Author information

Authors and Affiliations

Contributions

Z.L. and H.C. conceived the ideas and designed the experiments. Z.L conducted the synthesis, electrochemical testing and part of the characterizations. J.L. S.Z., S.X., P.B., S.C. and Y.T. contributed to the characterization of materials. J.L. contributed to the structure analysis and wrote part of the manuscript. Z.L., T.Z. and H.C. wrote the manuscript. All authors reviewed and revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

Z.L. and H.C. have filed a US provisional patent application (63/363,875) covering the application of FeCl3 and related compounds as cathode materials in solid-state batteries as described in this paper. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks the anonymous reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–22 and Tables 1–7.

Source data

Source Data Fig. 1

Rietveld refinement results of synchrotron XRD for pristine FeCl3.

Source Data Fig. 2

Electrochemical performance of FeCl3 in solid cells.

Source Data Fig. 3

XANES results of FeCl3 at different discharge and charge stages.

Source Data Fig. 4

Operando EDXRD results of the FeCl3 solid cell and Rietveld refinement results of Li0.8FeCl3.

Source Data Fig. 5

Comparison of costs between FeCl3 and other cathode materials.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Z., Liu, J., Zhao, S. et al. Low-cost iron trichloride cathode for all-solid-state lithium-ion batteries. Nat Sustain (2024). https://doi.org/10.1038/s41893-024-01431-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41893-024-01431-6