Abstract

The ceiling structure in a long-narrow space has a significant impact on the thickness of the fire smoke layer. This paper mainly studies the influence of the height of the ceiling structure on the thickness of the smoke layer before the ceiling structure. Firstly, a theoretical analysis is conducted on the relationship between the critical thickness that affects the smoke flow state and the smoke layer thickness directly below the ceiling structure, and a formula for calculating the smoke layer thickness under gradient flow conditions is derived. Then a small-scale experimental platform was built to study the deviation of actual fire smoke relative to theoretical calculations. Experimental results show that due to the smoke cannot maintain gradient flow when crossing the ceiling structure, there is difference with theoretical calculations in the smoke layer thickness directly below the ceiling structure and some distance before the ceiling structure (which may be of greater concern for personnel evacuation). The gradient flow coefficient and thickness coefficient are defined to represent the above differences. After analysis, it was found that the gradient flow coefficient and thickness coefficient showed different linear variation patterns when the height of the ceiling structure was longer than 35 cm or shorter than 30 cm. Through numerical analysis, this study suggests that the main reason for the change in this linear pattern is whether the potential energy conversed from kinetic energy of the thin layer close to the ceiling structure can directly make the smoke to cross the ceiling structure. The research conclusions of this paper can assist in the engineering design of building smoke control and personnel evacuation.

Similar content being viewed by others

Introduction

Nowadays, smoke screens are often used as dividers for smoke control zones in buildings1. In long-narrow spaces, such as subway stations and tunnels, smoke screens are also often used to confine fire smoke in a limited area for a time2,3,4. However, if the fire could not be suppressed immediately, smoke flow would cross the screens and continue to spread. Although the smoke front has crossed the screen, the smoke screen can continuously affect the smoke flow. Except for smoke screen, structures on the ceiling of long-narrow space, such as crossbeams, affect smoke flow in a similar way. One obvious effect of ceiling structures in long-narrow space is on the thickness of the smoke layer before the structure. The variation of smoke layer thickness affects the clear height of evacuation5, and also affects the state of smoke entrainment and spread speed. Therefore, this paper will focus on the effect of ceiling structures on the thickness of the smoke layer in long-narrow space.

Smoke movement in long—narrow space are studied by researchers for a long time. The classic study is from Thomas and Hinkley6,7,8, which deduced a smoke velocity based on Froude number under the assumption that frictional forces and viscous forces are also determined by Froude number. Kunch9,10 divided the smoke spread process of long-narrow space into 4 regions: rising plume, turning region near the ceiling, radial spreading under the ceiling, transition from radial to one-dimensional flow. Ji Jie11 deduced air entrainment of the 4 regions, and unified mathematical expression forms of the former 3 stages based on Zukoski’s model12. Wang Huan and his coworkers13 pointed out that a smoke screen can shorten the density jump region in Stage 2 and 3 through fire dynamic simulation, which reduces the air entrainment volume. In Wang’s study, the smoke flow pattern is obviously different near the smoke screen, but there was less discuss on the smoke layer thickness when smoke crossing the screen. Huang et al.14 found that as the height of ceiling structure increases, the mass entrainment ratio and the thickness of the smoke layer at the ceiling structure both decrease. Poreh et al.15 suggest that the Froude number of the smoke layer downstream of the ceiling structure of the corridor will be higher than when there is no ceiling structure, and there is a possibility of a sudden density jump. Yang et al.16 studied the density jump characteristics of ceiling structures and pointed out that as the height of the structure increases, the entrainment ratio during the density jump stage first increases and then decreases. According to the characteristics of open channel flow, the density jump after the structure occurs after the density drop when the smoke crosses the structure. Therefore, the thickness of the smoke layer before the structure is related to the density drop and density jump phenomena of the smoke, which is currently lack of quantitative research.

Meng Na and her coworkers17 studied effect of smoke screen on smoke temperature attenuation coefficient through theoretical deduction and experiments of a scale model of subway station. In Wang Huan’s and Meng Na’s study, Under the influence of smoke screens, the relationship between the temperature and thickness of the fire smoke layer changes, and the changing pattern still needs more study. In Meng’s deduction, he put an assumption that smoke screen height is equal to the thickness of smoke layer. However, this is not always true in practice. Chow18 studied the blocking effect of smoke screen in tilted tunnels by scale experimental model. It can be seen from his photo of experiments that the thickness of smoke layer was not always the same as screen height.

In recent years, research on the smoke blocking effect of tunnel ceiling structures has gradually received attention. Chaabat19 and his coworkers studied the effect of barriers and blocks on critical wind velocity of smoke backflow. Their experimental results showed that smoke screen height mainly affects critical velocity, and Ri number affects little. Taher Halawa and Hesham Safwat20 affirmed the positive role of the ceiling structures in smoke suppression and pointed out that after using the ceiling structure, the thickness and temperature of the smoke layer in some areas have increased. Other researchers explored different forms of ceiling structures such as L-shaped21, inclined22, and multi smoke barriers23 combinations for smoke suppression. However, research on the effect of ceiling structures on smoke flow has paid less attention to the influence of structures on the thickness of the smoke layer, especially lacking quantitative research.

In summary, the effect of smoke screen on smoke movement in long-narrow space still needs more study. Some problems are unsolved: (1) Most researchers studied corridors with two openings24, ceiling structures in corridors with one opening still needs systematically study; (2) The pattern of smoke flow crossing screen, especially the thickness of smoke layer needs to be study which is the base of theoretical models and a key factor that affects evacuation. Therefore, this paper mainly focuses on the relationship of smoke layer thickness and screen height when crossing a screen in corridors with one opening.

Theoretical analysis of critical smoke thickness direct below ceiling structures

When the smoke celling jet in the long-narrow space encounters the obstruction of a ceiling structure, the kinetic energy of the jet will be converted into potential energy, causing the velocity of the smoke front to slow down and the thickness to increase. When the thickness of the smoke layer exceeds the ceiling structure, it will "overflow" into the other side of the structure. During this process, the conversion of kinetic and potential energy is the main factor causing changes in the thickness of the smoke layer. Although the presence of ceiling structures affects flow resistance, the increase in smoke flow resistance is not the main factor causing changes in smoke layer thickness.

Under the condition of constant smoke flow rate, the Froude number with smoke thickness as the characteristic length is a function only related to the thickness of the smoke layer, and its formula is as follows.

where, Fr is Froude number; v is the average velocity of the smoke; h is the thickness of the smoke layer; L is the volume flow rate of smoke; and b is the width of a long-narrow space. g’ is buoyancy acceleration25 and

where, g is the gravitational acceleration.

According to previous literature8, in the absence of ceiling structures, the Froude number is less than 1. Before the smoke crosses the ceiling structure, the thickness of the smoke layer is greater than the layer without the structure, thus, the Froude number is also less than 1. After crossing the ceiling structure and before touching the ceiling, due to a sudden lack of flow restrictions, the flow speed of smoke is faster than the one without a structure, and the Froude number is greater than 1. Due to that the thickness and velocity of the smoke cannot undergo absolute sudden changes, during the process of the smoke crossing the ceiling structure, the Froude number continuously changes from less than 1 to greater than 1, and there must be an instantaneous Froude number equal to 1. This process is caused by the ceiling structure, so it can be inferred that the Froude number should be equal to 1 at the moment when the smoke crosses the ceiling structure. Therefore, if the thickness when the Froude number is 1 is called the critical thickness, after the smoke flow stabilizes, the thickness of the smoke layer directly below the ceiling structure is the critical thickness. The calculation formula of critical thickness is as follows.

where, hc is the critical thickness; k1 is the kinetic energy correction factor.

Assuming that the cross-sectional energy e of the smoke refers to the sum of the kinetic energy and potential energy of the smoke per unit volume at a certain cross-section of the smoke layer:

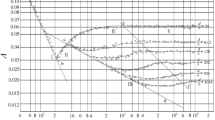

Equation (4) provides quantitative description of the relationship between the thickness of the smoke layer and its energy. It should be noted that e is the total mechanical energy of the smoke with the ceiling as the reference plane. Since the height of the reference plane of e is not necessarily constant, e does not always gradually decrease with the flow of smoke, but is affected by changes in the height of the ceiling. At the moment when smoke crosses the ceiling structure, the reference plane should be the lower edge of the structure, and e will undergo a significant change. From Eq. (4), it can be seen that when the smoke flow rate, corridor width, and smoke density is relatively constant (when the main factor affecting the thickness of the smoke layer is the height of ceiling structure), the energy e of the smoke cross-section is mainly changed with the thickness of the smoke layer, which is like the Froude number. Therefore, it is possible to plot the variation of cross-sectional energy of smoke with the thickness of the smoke layer (Fig. 1).

From Fig. 1, it can be seen that there is a critical thickness hc that minimizes the unit cross-sectional energy e of the smoke. Taking the derivative of Eq. (4) over h yields the following equation:

According to Eq. (5), when the Froude number is equal to 1, the unit cross-sectional energy e of smoke is the lowest. Therefore, hc is not only the critical thickness for Fr = 1, but also the critical thickness for the transition of energy change per unit cross-section of smoke.

According to the theory of open channel flow, when the thickness of the smoke layer changes from less than hc to greater than hc, the trend of the cross-sectional energy e changes (shown in Fig. 1), the unit cross-sectional kinetic energy is converted into potential energy, and the flow present different flow states: the flow state changes from rapid flow to slow flow, which is the density jump phenomenon.

To calculate the amount of smoke, Ji Jie's model is selected which is derived from the classic plume flow model Zukoski model12. Due to the fact that Ji Jie et al. derived the plume flow model in a long-narrow space, it is more suitable for the research in this paper. According to Ji Jie’s study11, the mass flow of smoke entrainment in the first three regions can be expressed as the same form like formula (6)

where, C1 is a comprehensive dimensionless coefficients for the first three regions, It should be pointed out that the coefficient C1 in the Ji Jie’s model were indeed experimentally obtained without a smoke screen; m′, Q′ and z′ are the dimensionless form of smoke mass flow, heat release rate and the height of the smoke layer to the ground. They are expressed as:

where, m is the mass flow of smoke; H is the height of the corridor; Q is the heat release rate of the fire; cp is the specific heat capacity of gas at constant pressure; T0 is the ambient temperature; z is the height of the smoke layer to the ground.

Therefore, Calculating the mass flow rate of smoke using Eqs. (6)–(10), and substitute the mass flow rate into Eq. (3) can calculate the critical thickness. The comprehensive calculation formula is shown in Eq. (11).

In the above derivation, the smoke flow should be in an ideal state of uniform or nearly uniform flow (gradually varied flow), and the velocity direction should be parallel to the corridor direction. However, as shown in Fig. 2, during the process of smoke crossing the ceiling structure, the direction of smoke flow can undergo significant changes, and the flow state is significantly different from uniform flow. Therefore, the calculation of the thickness of the smoke layer directly below the ceiling structure needs to be supplemented by experimental research.

Experimental study

Experimental model

A 1:5 corridor model with regular cross-section was established for the experiments. The length of the model is 3.2 m, the width is 0.4 m and the height is 0.8 m (Fig. 3).

In Fig. 3, the right end of the model was closed, and the left end was open. A small pool fire was set at the bottom of the model 0.3 m to the right end. The fuel is ethanol. Smoke cake was set above the pool fire to produce smoke. The diameter of the smoke cake is about 7 cm and the thickness is about 1.5 cm. The smoke production process of the smoke cake is continuous. The time for producing high concentration smoke can last for about 1 min, which can continue until the smoke flow is stable. An electronic balance was put under the pool fire to measure mass loss rate that is used to calculate heat release rate. The pool fire is 10 cm × 10 cm, the heat release rate keeps 1.485 kW (calculated by the mass loss rate). Smoke screen was set on the ceiling of the model 1.75 m to the right end. A set of thermocouples is right below the smoke screen of vertical interval 5 cm for auxiliary measurement of smoke layer thickness and smoke density calculation. High temperature resistant anemometer is used to measure the velocity of smoke 5 cm below the ceiling. The environment temperature is 20 °C. The experiment parameter table is shown as Table 1.

Experimental results of smoke general pattern with a ceiling structure

The general flow patterns of smoke with and without smoke screen are shown in Fig. 4. In Fig. 4a, when there is no ceiling structure (smoke screen), the smoke layer keeps almost the same thickness through the experimental device. The thickness of the smoke layer is 0.25 m. However, in Fig. 4b, when a 20 cm smoke screen was on the ceiling, the smoke layer before smoke screen is much thicker than screen height. In addition, the smoke layer before the smoke screen is a little thicker (the position of the edge is lower) than the one directly below the structure. The smoke layer thickness can keep stable within a range exceeding 50 cm before the structure. The smoke layer after the ceiling structure becomes thinner first and gradually recovers to the same thickness as the one without ceiling structure. The thinnest point indicates a density jump (Froude number changed from greater than 1 to less than 1) after smoke flow crossing the screen.

Photos of experiments with/without ceiling structure (the brightness and contrast of the image have been adjusted to increase the visible effect of light smoke). (a) Photo of smoke stable state the experiment without ceiling structure and (b) Photo of smoke stable state of the experiment with 20 cm smoke screen.

The experimental phenomenon of ceiling structures reflects the density drop and density jump during the smoke flow process. At the moment of crossing the structure, the Froude number of the smoke changes from less than 1 to greater than 1, causing the smoke flow speed to increase and the smoke layer to become thinner, which belongs to the phenomenon of density drop; After the thinnest point after crossing the structure, the Froude number of the smoke changes from greater than 1 to less than 1, and the smoke layer becomes thicker, resulting in a decrease in the flow velocity, which is a density jump phenomenon.

Experimental results of smoke layer thickness with ceiling structures of different heights

Figure 5 demonstrates the smoke layer thickness near the ceiling structure. The analysis of experimental errors can be found in the appendix. From Fig. 5, it can be seen that within the height range of 15–50 cm for the ceiling structure, the variation pattern of the smoke layer thickness before and after crossing the ceiling structure is basically the same. The thickness of the smoke layer before the ceiling structure is relatively large, while the thickness of the smoke layer directly below the structure slightly decreases. The thinnest point of the smoke layer appears after the structure, and then the thickness of the smoke layer gradually increases. As the height of the ceiling structure increases, the thickness of the smoke layer before the structure increases. Due to the increase in the thickness of the smoke layer, the mass flow of smoke entrainment decreases, and the critical thickness of the smoke layer decreases (according to Eq. (3)). Therefore, the thickness of the smoke directly below the structure decreases as the height of the structure increases. Table 2 shows the lower boundary of the smoke layer directly below the smoke screen and at 50 cm before the smoke screen. Meanwhile, Table 2 shows the critical thickness of the smoke layer calculated by Eq. (9) (where the value of C1 is 0.376, and the value of z is height of the lower boundary of the smoke layer directly below the smoke screen). From Table 2, it can be seen that there is a difference between the thickness of the smoke layer directly below the structure and the calculated critical thickness, and their relationship needs further analysis and discussion.

Photos of smoke layer thickness in experiments with smoke screen of different height (the brightness and contrast of the image have been adjusted to increase the visible effect of light smoke). (a) Smoke screen height is 15 cm, (b) Smoke screen height is 20 cm, (c) Smoke screen height is 25 cm, (d) Smoke screen height is 30 cm, (e) Smoke screen height is 35 cm, (f) Smoke screen height is 40 cm and (g) Smoke screen height is 50 cm.

Discussion

Relationship of smoke layer thickness directly below the structure and ceiling structure height

It can be seen from Fig. 4 that the smoke layer thickness directly below the smoke screen was always larger than the smoke screen height, especially when the smoke screen is relatively short. In addition, the smoke layer thickness directly below the smoke screen height (excluding the smoke screen height) decreased with the smoke screen height.

From Table 1 and the above analysis, it can be seen that there is a difference between the thickness of the smoke layer directly below the structure and the calculated critical thickness hc. The reason for the difference is that the smoke crosses the structure as a non-uniform flow with significant changes in flow direction.

In order to explore the relationship between the thickness of the smoke layer and the critical thickness hc, the ratio of the smoke layer thickness directly below the structure in the experiment to the theoretically calculated critical thickness (referred to as the gradient flow coefficient in this article) is shown in Fig. 6. The horizontal axis in the figure represents the height of the ceiling structure.

From the Fig. 6, it can be seen that with a height of 30–35 cm as the turning point, the gradient flow coefficient exhibits two different patterns as the height of the ceiling structure changes. When the height of the ceiling structure is less than or equal to 30 cm, the gradient flow coefficient increases with the height of the structure; When the height of the ceiling structure is greater than or equal to 35 cm, the gradient flow coefficient decreases with the height of the structure. The variation patterns of both are close to linear changes. The linear fitting equation is shown in Fig. 6.

Relationship of smoke layer thickness at 50 cm before the structure and ceiling structure height

It can be seen from Fig. 4 that the smoke layer thickness at 50 cm before the smoke screen was always larger than the one directly below the smoke screen height. In addition, the difference between smoke layer thickness and the smoke screen height decreased with the smoke screen height.

In order to reveal the quantitative relationship between the thickness of the smoke layer and the height of the ceiling structure, this paper examined the ratio of smoke layer thickness directly below the ceiling structure to the thickness of the smoke layer 50 cm before the structure (the part exceeding the height of the structure), based on the bottom edge of the structure in the experiment. Define the above ratio as the thickness coefficient. The results are shown in Fig. 7.

From Fig. 7, it can be seen that the thickness coefficient exhibits a clear linear pattern with the height of the ceiling structure. Linear fitting was performed on the thickness coefficients of ceiling structures below 30 cm and above 35 cm, with correlation coefficients R2 = 0.77 and 0.97. 30–35 cm is a turning point, and the thickness coefficient exhibits different linear patterns when the ceiling structure is above 35 cm or below 30 cm.

Reasons for transformation of the variation law of smoke layer thickness

The above research indicates that when the height of the ceiling structure is around 30–35 cm, the gradient flow coefficient and thickness coefficient undergo transitional changes. This paper attempts to explain the difference in smoke flow status between ceiling structures above 35 cm and below 30 cm from the perspective of energy conversion. After the flow of smoke over the ceiling structure stabilizes, the flow speed of smoke before the ceiling structure is relatively slow. At the moment of crossing the structure, due to buoyancy, the velocity of smoke flow suddenly accelerates, and the potential energy of smoke is converted into kinetic energy. The distance of the thinnest point and the smoke screen is varying versus the height of the smoke screen. It can be seen that the distance from the thinnest point to the smoke screen decreased as the height of the smoke screen increased. The larger distance of the thinnest point from the smoke screen indicated a larger velocity of the smoke flow crossing the screen. The velocity of the smoke flow crossing the screen is related to the volume flow rate and the thickness of the smoke layer directly below the screen.

Figure 8 is an instantaneous photo of the smoke flow when the smoke was first visible in the experiment.

From the Fig. 8, it can be seen that after the smoke front collides with the ceiling structure, the kinetic energy of the smoke is converted into potential energy. When the height of the ceiling structure is 20 cm, smoke can directly cross the ceiling structure, as shown in Fig. 8a. After crossing the ceiling structure, the smoke still has a certain amount of kinetic energy, and the boundary of the smoke layer forms an angle with the smoke screen under the combined effect of this kinetic energy and buoyancy. When the height of the ceiling structure is 40 cm, the smoke does not directly cross the structure, but gradually filling the space on one side of the structure, and then overflows the structure, as shown in Fig. 8b. After crossing the ceiling structure, the smoke has almost no kinetic energy, and the boundary of the smoke layer is almost vertical mainly under the action of buoyancy. It is precisely these two different flow states that result in different rates of change in the flow direction of smoke crossing the structure, leading to a turning point change in the gradient flow coefficient and thickness coefficient.

In order to clarify whether the energy conversion process of the ceiling jet is the same as the initial stage in the stable flow of the smoke layer. This paper conducts numerical simulation research. The numerical model is the actual corridor size corresponding to the experimental similarity ratio26. Numerical model was built using FDS shown in Fig. 10. The model is a 16 m long regular corridor with one end open. The height and width (4 m × 2 m) are set based on experiments in this paper. The fire was set at the bottom, 1.5 m to the close end. The ceiling structure was set at 8 m to the right end. 3 sets of longitudinally evenly distributed thermocouples are arranged in front, behind and right below the smoke screen to assist in measuring the thickness of the smoke layer. The walls of the model are adiabatic because the study neglected heat transfer of wall. The fire source power is 83 kW. The grid size is 0.1 m and is encrypted to 0.01 near the smoke screen. The mesh zone is larger than the corridor model. The smoke thickness is detect by the built-in tool in pyrosim according to the concentration of smoke, and thermocouples assist in testing the thickness of the smoke layer by detecting vertical temperature changes. The simulation parameter table is shown in Table 3.

The FDS numerical simulation grid setting needs to be adapted to the fire source characteristic diameter. The calculation method for the characteristic diameter of the fire source is shown in the following equation.

where, D* is the characteristic diameter of the fire source, m; Q is the fire source power, kW; ρ∞ is the density of air, kg/m3; Cp is the specific heat capacity of constant pressure air, J/(kg·°C); T∞ is the ambient temperature, which is set to 293 K; g is gravitational acceleration, m/s2.

It can be calculated that, when the fire power is 83 kW, the characteristic diameter of the fire source in this example is 0.36 m. Based on previous research findings22,27,28, when the characteristic diameter of the fire source is 4–16 times the grid size, the accuracy of the simulation results is acceptable. The grid size should be set as 0.02–0.09 m. when the fire power is 400 kW, the characteristic diameter of the fire source in this example is 0.66 m, and the grid size should be set as 0.04–0.16 m.

We conduct simulations when the smoke screen height is 2 m, under the conditions that the grid size is 0.04 m, 0.08 m, 0.1 m and 0.15 m. The simulations concern on the smoke layer thickness before the smoke screen. The results is shown in Fig. 9. From Fig. 9, when the grid size is between 0.06 and 0.2, there is not much difference in the height change of the smoke layer. Especially within the range after 40 s, the difference is even smaller. Only when the grid size is 0.2, the height of the smoke layer is slightly lower. Considering that the simulation needs to adapt to two types of fire source power, a 0.1 m grid can balance simulation accuracy and running speed. Considering the smoke screen size in this paper, the grid is encrypted to 0.01 near the smoke screen (Fig. 10).

The ceiling structure in the middle of the model was set to 1.25 m and 2 m for two simulations. The velocity vector diagram (side view) of smoke flow is shown in Fig. 11.

When observing the numerical simulation results in Fig. 11, and comparing them with thermocouple data, it can be found that when the height of the smoke screen is 1 m, the thickness of the smoke layer directly below it is about 80 cm; When the height of the smoke screen is 2 m, the thickness of the smoke layer directly below it is about 55 cm. Comparing experimental data with a 1:5 similarity ratio, when the height of the smoke screen is 0.2 m, the thickness of the smoke layer directly below it is about 23 cm; When the height of the smoke screen is 0.4 m, the thickness of the smoke layer directly below it is about 12 cm. The ratio of the thickness of the smoke layer directly below the smoke screen in the experimental and simulation results is also about 1:5. In terms of the smoke layer thickness in key areas, the simulation and experimental results are in good agreement.

From Fig. 10, it can be seen that after the smoke flow stabilizes, there is still layered flows within the smoke layer, and even opposite flow directions may occur at backward flowing layers. The fastest flow rate is the thin layer of smoke near the ceiling, which is about 30–40 cm. When the ceiling structure is 1 m, the thin layer of smoke can directly cross the structure. When the ceiling structure is 2 m, the thin layer is difficult to directly cross the ceiling structure. And a noticeable reflux phenomenon occurred. Therefore, whether the kinetic energy of thin layer can directly cross the ceiling structure after being converted into potential energy is also a critical condition that affects the variation of the gradient flow coefficient and thickness coefficient of smoke.

In order to compare the flow velocity of the thin layer with that of the smoke layer without a smoke screen, this paper conducted numerical simulations of the smoke layer without a smoke screen. The simulation results are shown in Fig. 12. The main flow velocity of the smoke layer in Fig. 12 is around 1 m/s, which is equivalent to the thin layer flow velocity in Fig. 11.

According to the experimental results of the hot wire anemometer, it can be reckoned that the turning point of the gradient flow coefficient and thickness coefficient is related to the conversion of smoke kinetic energy and potential energy. The smoke flow velocity without a smoke screen can be used as a reference for the thin layer flow velocity. For example, When there is no ceiling structure, as shown in Fig. 13, the flow velocity of the thin layer is about 0.27 m/s.

It is calculated by Eq. (12) that the conversion of kinetic energy into potential energy can increase the thickness of the smoke layer by 4.6 cm (based on the smoke temperature 318 K, the density is approximately 1.11 kg/m3).

where, Δh is the height that come from potential energy conversed of kinetic; v is the velocity of smoke.

Compared to the ceiling structure without a ceiling structure (the thickness of the smoke layer is about 25 cm), the total thickness of 29.6 cm is very close to the critical smoke screen height of 30–35 cm obtained from the experiment.

Applicability different fire power

To demonstrate the applicability of the conclusions of this paper under different fire source power conditions, we conducted simulations of 83 kW and 400 kW fire source power using the numerical model mentioned in this paper. The linear fitting graph of the gradient flow coefficient and thickness coefficient obtained from the simulations is shown in Fig. 14. Although there are differences in the correlation of linear fitting it can be seen from Fig. 14, that the fitting laws of the gradient flow coefficient and thickness coefficient still exhibit two different patterns with the height of the smoke screen. As the power of the fire source increases, the turning point of the pattern also moves towards higher areas.

Conclusions

This paper investigates the influence of ceiling structures on the thickness of smoke layers during the spread of fire smoke through long-narrow spaces. Through theoretical deduction, the critical thickness of the flow state change during the process of smoke crossing the ceiling structure was analyzed. We built an experimental platform and studied the relationship between the critical thickness and the thickness of the smoke layer directly below the ceiling structure, as well as the thickness of the smoke layer before the ceiling structure. Numerical simulation was conducted to obtain the velocity field of smoke flow, and the variation patterns of gradient flow coefficient and thickness coefficient were explained. The main conclusions are as follows:

-

1.

When there is a ceiling structure in a long-narrow space, the smoke layer is thicker than that when there is no ceiling structure, and its thickness exceeds the sum of the height of the ceiling structure and the smoke layer directly below the ceiling structure. After the smoke crosses the ceiling structure, a density drop phenomenon occurs, presenting a brief rapid flow state. Subsequently, a thinnest point appeared in the smoke layer, at which the smoke flow experienced a density jump phenomenon. The smoke after this point is in a slow flow state again. The thickness of the slow flow smoke layer is equivalent to that without a ceiling structure.

-

2.

The slow and rapid flow of smoke in long-narrow spaces is related to the thickness of the smoke layer. There exists a critical thickness hc, and when the thickness of the smoke layer is greater than hc, the smoke is in a slow flow state; when the thickness of the smoke layer is less than hc, the smoke is in a rapid flow state. The critical thickness of smoke flow essentially reflects the magnitude of cross-sectional energy and is related to the Froude number. According to the relationship of critical thickness and Fr number, considering smoke entrainment pattern, the critical thickness can be calculated by Eq. (11) under the assumption that the smoke flow can keep a gradient flow.

-

3.

In the experiment, density drop occurred when the smoke crossed the ceiling structure. Due to the fact that the smoke flow during this process is not a gradual flow, the thickness of the smoke layer directly below the ceiling structure is slightly larger than the calculated critical thickness. The experimental results indicate that the ratio of the experimental critical thickness to the calculated critical thickness (gradient flow coefficient) is related to the height of the ceiling structure. When the height of the ceiling structure is higher than 35 cm or lower than 30 cm, different linear patterns are observed.

-

4.

In the experiment, the linear pattern of the gradient flow coefficient and thickness coefficient both changed at a height of 30–35 cm of the ceiling structure. The numerical simulation results indicate that even if the thickness of the smoke layer is greater than the height of the ceiling structure, there still exists a thinner ceiling jet inside the smoke layer, similar to the early stages of fire development. After the jet collides with the ceiling structure, the kinetic energy is converted into potential energy. The main reason why the gradient flow coefficient and thickness coefficient exhibit different linear patterns with a certain height of the ceiling structure is whether this potential energy transformed from kinetic energy can allow the smoke to directly cross the ceiling structure.

According to the research results of this paper, when there is a structure on the ceiling, the thickness of the smoke layer will be slightly greater than the height of the structure and can be calculated. The calculation of the thickness of the smoke layer before the ceiling structure have engineering significance for the design of building smoke control and exhaust engineering, as well as the evacuation design of fire scene. The determination of the thickness of the smoke layer is the basis for studying the flow law of smoke, and it has theoretical significance for studying the blockage law of ceiling structures.

Data availability

All data generated or analyzed during this study available from the corresponding author on reasonable request.

References

In GB51251–2017 (ed Ministry of housing and urban rural development of the people's Republic of China) 16–17 (China Planning Press, 2017).

Bettelini, M., Rigert, S., Anagnostou, G. & Ehrbar, H. On the use of flexible devices for controlling smoke propagation in road tunnels—Perspectives and limitations. Undergr. Way Future. 321–328 (2013).

Wang, Z. S., Ni, Z. P., Lu, S. C. International Forum on Energy, Environment Science and Materials.

Lou, Z. et al. Plugging methods for underground gas extraction boreholes in coal seams: A review of processes, challenges and strategies. Gas Sci. Eng. https://doi.org/10.1016/j.jgsce.2024.205225 (2024).

Seike, M., Kawabata, N., Hasegawa, M. & Kobayashi, T. The retarding effect of fixed barriers on smoke propagation in tunnel fires. Tunn. Undergr. Space Technol. 85, 100–113. https://doi.org/10.1016/j.tust.2018.12.007 (2019).

Thomas, P. H. The Movement of Buoyant Fluid Against a Stream and the Venting of Underground Fires (England Fire Research Station, 1958).

Thomas, P. H. The Movement of Smoke in Horizontal Passages Against an Air Flow (England Fire Research Station, 1968).

Hinkley, P. L. The Flow of Hot Gases Along an Enclosed Shopping Mall a Tentative Theory (England Fire Research Station, 1970).

Kunsch, J. P. Critical velocity and range of a fire-gas plume in a ventilated tunnel. Atmos. Environ. 13 (1999).

Kunsch, J. P. Simple model for control of fire gases in a ventilated tunnel. Fire Saf. J. 37, 67–81 (2002).

Ji, J., Zhang, Y., Zhong, W. & Hu, L. Experimental study on the entrainment mass flow rate across the smoke layer interface during horizontal spread in a long channel. J. Univ. Sci. Technol. China 39, 738–742 (2009).

Cetegen, E. E. Z. T. K. B. Entrainment in fire plumes. Fire Saf. J. 3, 107–121 (1980).

Xian, W. H. Q. Q. J. H. Z. X. W. Study on smoke movement characteristics in long—narrow channel with smoke barrier. J. Saf. Sci. Technol. 13, 150–156 (2017).

Huang, J.-L., Zhu, G.-Q., Yu, M.-W. & Gu, S.-N. Effect of smoke barrier in narrow space on smoke flow utilizing CFD. Proc. Eng. 135, 142–150. https://doi.org/10.1016/j.proeng.2016.01.095 (2016).

Poreh, M., Marshall, N. R. & Regev, A. Entrainment by adhered two-dimensional plumes. Fire Saf. J. 43, 344–350. https://doi.org/10.1016/j.firesaf.2007.11.001 (2008).

Tao, Y. D. C. Y. D. Characteristics of fire smoke density jump downstream of ceiling barrier in tunnels. China Saf. Sci. J. 33, 7 (2023).

Meng, N., Hu, L., Zhu, S. & Yang, L. Effect of smoke screen height on smoke flow temperature profile beneath platform ceiling of subway station: An experimental investigation and scaling correlation. Tunn. Undergr. Space Technol. 43, 204–212. https://doi.org/10.1016/j.tust.2014.05.008 (2014).

Chow, W. K., Wong, K. Y. & Chung, W. Y. Longitudinal ventilation for smoke control in a tilted tunnel by scale modeling. Tunn. Undergr. Space Technol. 25, 122–128. https://doi.org/10.1016/j.tust.2009.10.001 (2010).

Chaabat, F. et al. The effects of solid barriers and blocks on the propagation of smoke within longitudinally ventilated tunnels. Build. Environ. https://doi.org/10.1016/j.buildenv.2019.106207 (2019).

Halawa, T. & Safwat, H. Fire-smoke control strategies in road tunnels: The effectiveness of solid barriers. Case Stud. Therm. Eng. https://doi.org/10.1016/j.csite.2021.101260 (2021).

Halawa, T. Enhancement of smoke extraction in tunnels in the case of fire by using L-shape curtain near smoke extraction vents. Case Stud. Therm. Eng. https://doi.org/10.1016/j.csite.2022.101969 (2022).

Zhang, S. et al. Numerical study on lateral centralized smoke extraction in immersed tunnel with a new-style inclined smoke barrier. Case Stud. Therm. Eng. https://doi.org/10.1016/j.csite.2023.102770 (2023).

Jia, J., Tian, X. & Wang, F. Research on smoke control for an underground mall fire, based on smoke barrier and mechanical smoke exhaust system. Sci. Rep. 12, 13071. https://doi.org/10.1038/s41598-022-16067-9 (2022).

Huan, W. Influence of smoke barrier on smoke flow characteristics and smoke exhaust effect in the long and narrow channel. Doctor thesis, Liaoning Technical University (2017).

Alpert, R. L. Calculation of response time of ceiling-mounted fire detectors. Fire Technol. 8, 181–195 (1972).

Chow, W. K. & Lo, H. H. W. Scale modeling on natural smoke filling in an atrium. Heat Transf. Eng. 29, 76–84. https://doi.org/10.1080/09647040701677565 (2010).

Zhong, W., Sun, C., Bian, H., Gao, Z. & Zhao, J. The plug-holing of lateral mechanical exhaust in subway station: Phenomena, analysis, and numerical verification. Tunn. Undergr. Space Technol. https://doi.org/10.1016/j.tust.2021.103914 (2021).

Chen, Z. et al. Research on the effect of ceiling centralized smoke exhaust system with air curtains on heat confinement and plug-holing phenomenon in tunnel fires. Process Saf. Environ. Prot. 169, 646–659. https://doi.org/10.1016/j.psep.2022.11.054 (2023).

Acknowledgements

This work was supported by Henan Science and Technology Research Project (Grant No. 242102320062, 242102321104, 242102321033).

Author information

Authors and Affiliations

Contributions

W.Z. and L.K. wrote the main manuscript text. Y.J. and S.L. conducted the experiments. Q.H. and W.X. provide ideas for data analysis. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wu, Z., Liu, K., Yang, J. et al. Study on the variation law of smoke layer thickness with ceiling structure height in long-narrow space with one end opening. Sci Rep 14, 19567 (2024). https://doi.org/10.1038/s41598-024-70557-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-70557-6

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.