Abstract

The nature of reverse leakage current characteristics in InGaN/GaN blue light emitting diodes (LEDs) on freestanding GaN crystals detached from a Si substrate is investigated for the first time, using temperature-dependent current-voltage (T-I-V) measurement. It is found that the Si-based homoepitaxial InGaN/GaN LEDs exhibit a significant suppression of the reverse leakage current without any additional processes. Their conduction mechanism can be divided into variable-range hopping and nearest neighbor hopping (NNH) around 360 K, which is enhanced by Poole-Frenkel emission. The analysis of T-I-V curves of the homoepitaxial LEDs yields an activation energy of carriers of 35 meV at −10 V, about 50% higher than that of the conventional ones (Ea = 21 meV at −10 V). This suggests that our homoepitaxial InGaN/GaN LEDs bears the high activation energy as well as low threading dislocation density (about 1 × 106/cm2), effectively suppressing the reverse leakage current. We expect that this study will shed a light on the high reliability and carrier tunneling characteristics of the homoepitaxial InGaN/GaN blue LEDs produced from a Si substrate and also envision a promising future for their successful adoption by LED community via cost-effective homoepitaxial fabrication of LEDs.

Similar content being viewed by others

Introduction

Significant development of high luminescence efficiency in InGaN/GaN light emitting diodes (LEDs) has offered new futuristic applications such as automotive headlamps, traffic signals, displays, and general lighting1,2,3. Due to the absence of natural GaN materials, conventional InGaN/GaN LEDs were fabricated on foreign substrates, such as sapphire (Al2O3), Si, and SiC4,5,6. This, however, generates high dislocation densities (108–1010/cm2) due to significant lattice mismatch and thermal expansion coefficient difference between substrates and films, thus deteriorating the device performances7. Even though InGaN/GaN LEDs using freestanding (FS) GaN wafers have been expected to open a promising way to overcome the degraded device characteristics, the fabrication cost and size limitation of conventional FS-GaN have hindered their successful adoptions in industry8.

Recently, we successfully demonstrated homoepitaxial InGaN/GaN blue LEDs on FS-GaN substrate, which was grown and detached from a Si substrate9. In spite of using a Si substrate as the support, the InGaN/GaN LEDs showed excellent optoelectronic properties, and a possibility to achieve high device performance with cost-competitiveness and large diameter scale. Although the demonstration of the InGaN/GaN LEDs on FS-GaN extracted from a Si substrate is considered the remarkable implications for new opportunities in the field of InGaN/GaN LEDs, little about their leakage current characteristics has been investigated so far. Since a leakage current determines the device lifetime, luminescence efficiency, and electrostatic discharge sensitivity10,11,12, a great number of attempts has been employed to suppress a reverse leakage current characteristics in InGaN/GaN LEDs using complicated processes such as a design of electron blocking layer (EBL), and surface passivation13,14.

In this paper, we performed temperature-dependent reverse leakage current measurement of InGaN/GaN LEDs using FS-GaN extracted from a Si substrate to investigate their transport mechanism in a reverse bias regime and introduce the nature of their remarkable reverse leakage current characteristics, which was achieved without any external processes. We expect that this will provide the LED community with the valuable and promising information regarding the device performances of the homoepitaxial InGaN/GaN LEDs.

Experimental

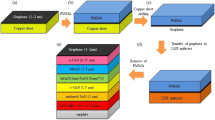

InGaN/GaN multi quantum well (MQW) LEDs with peak emission wavelength of ~440 nm were grown using MOCVD (Aixtron G3 2600) on 2-inch HVPE FS-GaN extracted from a Si substrate (LED I). The device structures and fabrication procedures were detailed in Fig. 1 and ref.9. The epitaxial structure comprised a 3.5-µm-thick n-type GaN grown at 1020 °C, 4 pair multi quantum well active layers (MQWs) consisting of InGaN well (3 nm) and GaN barrier (10 nm), grown at 820 °C, and 150 nm-thick p-type GaN grown at 1020 °C. To compare the reverse leakage current characteristics in InGaN/GaN LEDs fabricated using FS-GaN grown from a Si substrate, conventional InGaN/GaN LEDs with corresponding structures and the peak emission wavelength were fabricated on 2-inch Al2O3 substrate (LED II). All the LED structures were fabricated with conventional lateral chip using conventional photolithography, dry etching, and metallization, which defined 350 µm × 350 µm chip size. Reverse leakage current for both LEDs were measured at reverse voltage of −15 V to 0 V in the temperature range of 80–400 K. The defect densities of LED I and LED II were estimated to be 1 × 106 cm−2 and 5 × 108 cm−2, respectively, which was confirmed by micro photoluminescence (PL) mapping. (Not shown in this paper).

Results and Discussion

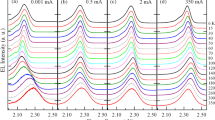

Figure 2 shows the representative temperature-dependent current-voltage (T-I-V) characteristics for LED I (solid), and LED II (dash). Regardless of the substrate materials, the reverse currents of LEDs gradually increase with the reverse voltage and temperature. It is worthy to note that the characteristics of reverse leakage current for LED I is superior to that for LED II in all the temperature ranges. The leakage currents for LED I, and LED II at a reverse voltage of −5 V are −1.5.0 × 10−9 A, and −8.9 × 10−8 A at 300 K, respectively. Obviously, a significant suppression of the reverse leakage current in LED I was observed, compared to that of LED II. In addition, it is essential to note that the reverse leakage current in LED I is reduced more than one or two orders of magnitude with respect to the other results using additional leakage current suppression processes15,16,17. We believe that this is attributed to the reduced dislocation density in LED I. One can clearly observe that the behaviors of the reverse leakage current curves for LED I and LED II appear quite similar in a way that their current under the reverse bias increases sub-linearly. However, their dependence on the temperature and the magnitude of reverse bias demands further detailed investigation. Based on T-I-V measurement results, it can be assumed that they have the same transport mechanisms with different onset points in terms of the temperature and applied reverse bias. It was already reported that the characteristics of the reverse leakage current for both LEDs takes the applied voltage and temperature into the account, suggesting the combination of tunneling current and thermal generation current. At low applied reverse bias, the slope of the reverse I–V curves are significantly dependent upon the temperature, indicative of the presence of thermally activated process18. It is well known that a tunneling through defect sites dominates the conduction mechanism in this regime19. A tunneling in LED I does not seem to dominate by the reverse bias of 8 V, where an abrupt increase in the current occurs. On the contrary, the reverse leakage current in LED II starts to increase at the reverse voltage of about 1 V. Note that the temperature- and field-dependence on the reverse leakage current in LED II appears relatively more severe, compared to that in LED I. We speculate that this is attributed to higher dislocation density in LED II, which can stimulate the field-dependent carrier tunneling at the elevated temperature.

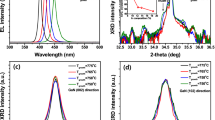

In order to get further insight on the transport mechanism of the reverse leakage current in the InGaN/GaN LEDs, we conducted Arrhenius plots of the reverse leakage current as a function of reciprocal temperature under the reverse bias of −10 V for LED I and LED II, as illustrated in Fig. 3. As seen in the figure, two distinct scaling behaviors are clearly found at low and high temperature regimes in both LED I and LED. It is well known that the drift-diffusion current and Sah-Noyce-Shockley generation-recombination current under reverse bias can be neglected in wide-bandgap GaN-based LEDs20. Hence, main transport mechanisms could be attributed to variable-range hopping (VRH) conduction mechanism and field-enhanced thermionic emission, also known as Poole-Frenkel emission, with different slope regimes20. In region below 320 K, the reverse leakage current in both LEDs appears to be slightly dependent upon the temperature. This implies that the VRH conduction mechanism is responsible for the leakage tunneling characteristics, where the carriers hop from the valence band of p-GaN to the conduction band of n-type GaN via localized deep trap levels21,22. The relationship between current and driving voltage for VRH can be given by23:

where T0 is the characteristic temperature.

(a) Arrhenius plot of the reverse leakage current of LED I and LED II as a function of reciprocal temperature, measured at −10 V. (b) Thermal activation energies (Ea) of LED I and LED II from Arrhenius plots as a function of the square root of the average internal electric field. SQRT implies the square root.

From the fitting (1) onto Fig. 3, LED I and LED II follow a VRH conduction below the temperature of 360 K and 280 K, respectively. VRH conduction mechanism does not fit well anymore over 360 K and 280 K for LED I and LED II, respectively. It is well established in the nearest neighbor hopping (NNH) model that the transport of electrons from valence band of p-GaN to the conduction band of n-GaN occurred through the multistep hopping across the close states in space but far ones in energy at high temperature. This can be enhanced by the Poole-Frenkel emission24. The leakage current increases exponentially as a function of 1/T. The slope indicates the thermal activation energy Ea, implying the energy for those trapped carriers in deep trap levels to escape25. This can be explained by the following equations20,26,27.

where Ea is the thermal activation energy, k is the Boltzmannn constant, ΦPF is the Poole-Frenkel barrier height of carriers trapped in deep trap centers without external electric field, corresponding to extrapolation of Ea at the bias of V = 0 V, βBF is the Poole-Frenkel constant (theoretical value in GaN: 3.28 × 10−4 eV·V−1/2·cm1/2), and F is the local electric field strength exerting on the deep centers. The Poole–Frenkel constant accounts for how the average barrier height of deep centers interacts with the external bias23. Linear fittings by eq. (2) confirm thermal activation energies of 35 meV, and 21 meV for LED I, and LED II, respectively. One can notice that the activation energy for LED I is much higher than that for LED II. We assign that this ascribes lower dislocation density in LED I, notwithstanding the use of a Si substrate as a supporting material. This is in good agreement with the reported results that higher dislocation causes lower thermal activation energy23,28. Furthermore, ΦPF can be extracted to be 0.64 eV, and 0.50 eV for LED I, and LED II from the extrapolation of the thermal activation energy as a function of average internal electric field, F1/2, respectively, as depicted in Fig. 3(b). The average internal electric field can be estimated by F = (Vbi − V)/d, where Vbi is the built-in voltage of the InGaN LEDs, d is the depletion width29. Capacitance-voltage (C-V) measurements were conducted to compute the internal electric field. (Not shown) We can easily notice that the Ea decreases with the increase in the reverse bias. This indicates carriers can escape from localized deep centers more easily at higher reverse voltage, implying participation of escaped carriers into leakage current. Notably, the value of ΦPF for LED I is much higher at any bias than that for LED II. We speculate that the low threading dislocation density of the homoepitaxial LED I contribute to the enhancement of ΦBF. Note that the Poole-Frenkel constant of LED I exhibits on the order of 10−4 eV·V−1/2·cm1/2. It is evident that the electrical characteristics of defects in LED I using a Si substrate as a support seems quite similar to one in LED II using sapphire substrates.

To visually describe and compare the transport mechanisms of two different LEDs used in this study, we illustrate the schematics of LED structure with different defect density and energy diagrams of the p-i-n junction under reverse bias, as shown in Fig. 4(a,b). As mentioned above, conventional InGaN/GaN LEDs on sapphire substrates bear relatively higher number of threading dislocation density, often resulting in V-shaped pits embedded in InGaN/GaN multiple quantum wells (MQWs). However, the threading dislocation density of LED I is significantly reduced due to the nature of homoepitaxial growth, consequently leading to the reduced density of V-shaped defects in MQW layers as well. Although V-shaped defects exhibit other advantageous effect, it is well known that a threading dislocation behaves as the leakage current path, thus deteriorating the reverse leakage current characteristics of InGaN/GaN LEDs30,31. Figure 4(c,d) illustrate the schematic diagram of the conduction mechanism of LED I and LED II based on an origin of reverse leakage current under the reverse bias, respectively. These figures schematically describes relative higher activation energy of trapped carriers at deep centers for the conduction in homoepitaxial InGaN/GaN LED, compared to one of LED II. One can expect that higher activation energy of trapped carriers in LEDs, lower chance of carriers escaping from the deep traps and also lower leakage current under the reverse bias. Not surprisingly, the magnitude of reverse leakage current in InGaN/GaN LEDs is also associated with the density of threading dislocations in LEDs. As a result, LED II possesses more than 3 orders higher reverse leakage current magnitude, compared to that of LED I over wide range of temperature. This is in good agreement with the recent literature32. Additionally, a reduced density of deep trap levels in the homoepitaxial InGaN/GaN LEDs assist a decrease in a tunneling probability of carriers into the conduction band edge of the p-GaN layers. Besides, the reverse current distribution of LED I in a wafer exhibit much lower values, compared to that of LED II since LED I exhibits much lower dislocation density33.

Conclusions

We report the reverse leakage characteristics of InGaN/GaN LEDs on FS-GaN peeled off from a Si substrate for the first time, using T-I-V measurement. Compared to the reverse leakage current characteristics of conventional LEDs, the Si-based homoepitaxial LED shows significantly suppressed one without any supplementary processes. Additionally, the transport mechanism of the homoepitaxial InGaN/GaN blue LEDs is dominated by VRH and Poole-Frenkel emission, which is similar to that of conventional blue LEDs. The lower reverse leakage current of the homoepitaxial InGaN/GaN LEDs is attributed to a higher thermal activation energy (Ea = 35 meV@ −10 V) and a reduced dislocation density. This study offers strong support for the viability of InGaN/GaN LED on FS-GaN peeled off from a Si substrate to achieve the highly reliable homoepitaxial InGaN/GaN LEDs with high cost-effectiveness and large diameter-scale.

References

Nakamura, S. The roles of structural imperfections in InGaN-based blue light-emitting diodes and laser diodes. Science 281, 956–961 (1998).

Jeong, H. & Jeong, M. S. Confocal electroluminescence investigations of highly efficient green InGaN LED via ZnO nanorods. J. Alloys Compd. 660, 480–485 (2016).

Cai, W. et al. On-chip integration of suspended InGaN/GaN multiple-quantum-well devices with versatile functionalities. Opt. Express 24, 6004–6010 (2016).

Shan, L. et al. Super-aligned carbon nanotubes patterned sapphire substrate to improve quantum efficiency of InGaN/GaN light-emitting diodes. Opt. Express 23, A957–A965 (2015).

Li, J. et al. “W-shaped” injection current dependence of electroluminescence linewidth in green InGaN/GaN-based LED grown on silicon substrate. Opt. Express 25, A871–A879 (2017).

Cheng, C.-H. et al. Growing GaN LEDs on amorphous SiC buffer with variable C/Si compositions. Sci. Rep. 6, 19757 (2016).

Hwang, J.-I., Hashimoto, R., Saito, S. & Nunoue, S. Development of InGaN-based red LED grown on (0001) polar surface. Appl. Phys. Express 7, 071003 (2014).

Jeong, H. et al. Carrier localization in In-rich InGaN/GaN multiple quantum wells for green light-emitting diodes. Sci. Rep. 5, 9373 (2015).

Lee, M., Yang, M., Song, K. M. & Park, S. InGaN/GaN Blue Light Emitting Diodes Using Freestanding GaN Extracted from a Si Substrate. ACS Photonics, https://doi.org/10.1021/acsphotonics.7b01453 (2018).

Cho, J. et al. Analysis of reverse tunnelling current in GaInN light-emitting diodes. Electron. Lett. 46, 156–158 (2010).

Cao, X., Sandvik, P., LeBoeuf, S. & Arthur, S. Defect generation in InGaN/GaN light-emitting diodes under forward and reverse electrical stresses. Microelectron Reliab. 43, 1987–1991 (2003).

Yanagisawa, T. Estimation of the degradation of InGaN/AlGaN blue light-emitting diodes. Microelectron Reliab. 37, 1239–1241 (1997).

Le, L. et al. Suppression of electron leakage by inserting a thin undoped InGaN layer prior to electron blocking layer in InGaN-based blue-violet laser diodes. Opt. Express 22, 11392–11398 (2014).

Kim, H.-M., Huh, C., Kim, S.-W., Park, N.-M. & Park, S.-J. Suppression of leakage current in InGaN/GaN multiple-quantum well LEDs by N2O Plasma Treatment. Electrochem. Solid-State Lett. 7, G241–G243 (2004).

Liu, X. et al. Effects of p-AlGaN EBL thickness on the performance of InGaN green LEDs with large V-pits. Semicond. Sci. Technol. 31, 025012 (2015).

Yang, H. S. et al. Comparison of Surface Passivation Layers on InGaN/GaN MQW LEDs. J. Semicond. Tech. Sci. 5, 131 (2005).

Yang, C.-C. et al. Wet mesa etching process in InGaN-based light emitting diodes. Electrochem. Solid-State Lett. 11, H169–H172 (2008).

Cao, X., Teetsov, J., D’Evelyn, M., Merfeld, D. & Yan, C. Electrical characteristics of InGaN∕ GaN light-emitting diodes grown on GaN and sapphire substrates. Appl. Phys. Lett. 85, 7–9 (2004).

Cao, X. et al. Diffusion and tunneling currents in GaN/InGaN multiple quantum well light-emitting diodes. IEEE Electron Device Lett. 23, 535–537 (2002).

Shan, Q. et al. Transport-mechanism analysis of the reverse leakage current in GaInN light-emitting diodes. Appl. Phys. Lett. 99, 253506 (2011).

Look, D. C. et al. Deep‐center hopping conduction in GaN. J. Appl. Phys. 80, 2960–2963 (1996).

Kuksenkov, D., Temkin, H., Osinsky, A., Gaska, R. & Khan, M. Origin of conductivity and low-frequency noise in reverse-biased GaN pn junction. Appl. Phys. Lett. 72, 1365–1367 (1998).

Kim, J. et al. Investigation of reverse leakage characteristics of InGaN/GaN light-emitting diodes on silicon. IEEE Electron Device Lett. 33, 1741–1743 (2012).

Zhou, S. et al. Reverse leakage current characteristics of InGaN/GaN multiple quantum well ultraviolet/blue/green light-emitting diodes. Jpn. J. Appl. Phys. 57, 051003 (2018).

Sze, S. M. & Ng, K. K. Physics of semiconductor devices. (John wiley & sons, 2006).

Simmons, J. Conduction in thin dielectric films. J. Phys. D: Appl. Phys. 4, 613 (1971).

Hirsch, L. & Barriere, A.-S. Electrical characterization of InGaN/GaN light emitting diodes grown by molecular beam epitaxy. J. Appl. Phys. 94, 5014–5020 (2003).

Zhi, T. et al. Reverse leakage current characteristics of GaN/InGaN multiple quantum-wells blue and green light-emitting diodes. IEEE Photonics Journal 8, 1–7 (2016).

Miller, E., Yu, E., Waltereit, P. & Speck, J. Analysis of reverse-bias leakage current mechanisms in GaN grown by molecular-beam epitaxy. Appl. Phys. Lett. 84, 535–537 (2004).

Cao, X. et al. Blue and near-ultraviolet light-emitting diodes on free-standing GaN substrates. Appl. Phys. Lett. 84, 4313–4315 (2004).

Zhou, S. et al. The effect of nanometre-scale V-pits on electronic and optical properties and efficiency droop of GaN-based green light-emitting diodes. Sci. Rep. 8, 11053 (2018).

Liu, S., Zheng, C., Lv, J., Liu, M. & Zhou, S. Effect of high-temperature/current stress on the forward tunneling current of InGaN/GaN high-power blue-light-emitting diodes. Jpn. J. Appl. Phys. 56, 081001 (2017).

Zhou, S. et al. Highly efficient and reliable high power LEDs with patterned sapphire substrate and strip-shaped distributed current blocking layer. Appl. Surf. Sci. 355, 1013–1019 (2015).

Acknowledgements

This work was supported by the research fund of Hanyang University (HY-2017-N) and the Korea Basic Science Institute research Grant No. C38116.

Author information

Authors and Affiliations

Contributions

M. Lee conceived the idea and constructed the InGaN/GaN LED structures and T-I-V characteristic interpretation, and wrote the manuscript. H. U. Lee conducted T-I-V measurements, and its interpretation. K.M. Song fabricated the InGaN/GaN LED. J. Kim conceived the idea. All authors discussed and reviewed the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lee, M., Lee, H., Song, K.M. et al. Significant improvement of reverse leakage current characteristics of Si-based homoepitaxial InGaN/GaN blue light emitting diodes. Sci Rep 9, 970 (2019). https://doi.org/10.1038/s41598-019-38664-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-019-38664-x

This article is cited by

-

Impact of Substrate Morphology and Structural Defects in Freestanding Gallium Nitride on the Breakdown Characteristics of GaN-on-GaN Vertical Diodes

Journal of Electronic Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.