Abstract

Template-directed assembly has been shown to yield a broad diversity of highly ordered mesostructures1,2, which in a few cases exhibit symmetries not present in the native material3,4,5. However, this technique has not yet been applied to eutectic materials, which underpin many modern technologies ranging from high-performance turbine blades to solder alloys. Here we use directional solidification of a simple AgCl-KCl lamellar eutectic material within a pillar template to show that interactions of the material with the template lead to the emergence of a set of microstructures that are distinct from the eutectic’s native lamellar structure and the template’s hexagonal lattice structure. By modifying the solidification rate of this material–template system, trefoil, quatrefoil, cinquefoil and hexafoil mesostructures with submicrometre-size features are realized. Phase-field simulations suggest that these mesostructures appear owing to constraints imposed on diffusion by the hexagonally arrayed pillar template. We note that the trefoil and hexafoil patterns resemble Archimedean honeycomb and square–hexagonal–dodecagonal lattices6, respectively. We also find that by using monolayer colloidal crystals as templates, a variety of eutectic mesostructures including trefoil and hexafoil are observed, the former resembling the Archimedean kagome lattice. Potential emerging applications for the structures provided by templated eutectics include non-reciprocal metasurfaces7, magnetic spin-ice systems8,9, and micro- and nano-lattices with enhanced mechanical properties10,11.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data that support the findings of this study are available within the paper, and from the corresponding author on reasonable request.

Code availability

The phase-field simulations were performed using a custom code written in Fortran 90. The code is available from K.T. (kthorn@umich.edu) on reasonable request.

References

Braun, P. V., Osenar, P. & Stupp, S. I. Semiconducting superlattices templated by molecular assemblies. Nature 380, 325–328 (1996).

Tavakkoli, K. G. A. et al. Templating three-dimensional self-assembled structures in bilayer block copolymer films. Science 336, 1294–1298 (2012).

Wu, Y. et al. Composite mesostructures by nano-confinement. Nat. Mater. 3, 816–822 (2004).

Tavakkoli, K. G. A. et al. Rectangular symmetry morphologies in a topographically templated block copolymer. Adv. Mater. 24, 4249–4254 (2012).

Urgel, J. I. et al. Quasicrystallinity expressed in two-dimensional coordination networks. Nat. Chem. 8, 657–662 (2016).

Grünbaum, B. & Shephard, G. C. Tilings by regular polygons. Math. Mag. 50, 227–247 (1977).

Yu, N. & Capasso, F. Flat optics with designer metasurfaces. Nat. Mater. 13, 139–150 (2014).

Wang, R. F. et al. Artificial ‘spin ice’ in a geometrically frustrated lattice of nanoscale ferromagnetic islands. Nature 439, 303–306 (2006); addendum 446, 102 (2007).

Ladak, S., Read, D. E., Perkins, G. K., Cohen, L. F. & Branford, W. R. Direct observation of magnetic monopole defects in an artificial spin-ice system. Nat. Phys. 6, 359–363 (2010).

Schaedler, T. A. et al. Ultralight metallic microlattices. Science 334, 962–965 (2011).

Meza, L. R., Das, S. & Greer, J. R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 345, 1322–1326 (2014).

Pawlak, D. A. et al. How far are we from making metamaterials by self-organization? The microstructure of highly anisotropic particles with an SRR-like geometry. Adv. Funct. Mater. 20, 1116–1124 (2010).

Acosta, M. F., Rodrigo, S. G., Martín-Moreno, L., Pecharromán, C. & Merino, R. I. Micropillar templates for dielectric filled metal arrays and flexible metamaterials. Adv. Opt. Mater. 5, 1600670 (2017).

Sadecka, K. et al. When eutectics meet plasmonics: nanoplasmonic, volumetric, self-organized, silver-based eutectic. Adv. Opt. Mater. 3, 381–389 (2015).

Bei, H., Pharr, G. & George, E. A review of directionally solidified intermetallic composites for high-temperature structural applications. J. Mater. Sci. 39, 3975–3984 (2004).

Wysmulek, K. et al. A SrTiO3-TiO2 eutectic composite as a stable photoanode material for photoelectrochemical hydrogen production. Appl. Catal. B 206, 538–546 (2017).

Jackson, K. & Hunt, J. Lamellar and rod eutectic growth. Trans. Metall. Soc. AIME 236, 1129–1142 (1966).

Himemiya, T. & Umeda, T. Three-phase planar eutectic growth models for a ternary eutectic system. Mater. Trans. JIM 40, 665–674 (1999).

Choudhury, A., Plapp, M. & Nestler, B. Theoretical and numerical study of lamellar eutectic three-phase growth in ternary alloys. Phys. Rev. E 83, 051608 (2011).

Dennstedt, A. & Ratke, L. Microstructures of directionally solidified Al–Ag–Cu ternary eutectics. Trans. Indian Inst. Met. 65, 777–782 (2012).

Akamatsu, S. & Plapp, M. Eutectic and peritectic solidification patterns. Curr. Opin. Solid State Mater. Sci. 20, 46–54 (2016).

Boley, J. W. et al. High-operating-temperature direct ink writing of mesoscale eutectic architectures. Adv. Mater. 29, 1604778 (2017).

Choi, J. et al. Processing-dependent microstructure of AgCl–CsAgCl2 eutectic photonic crystals. Adv. Opt. Mater. 6, 1701316 (2018).

Darling, S. B. Directing the self-assembly of block copolymers. Prog. Polym. Sci. 32, 1152–1204 (2007).

Ouk Kim, S. et al. Epitaxial self-assembly of block copolymers on lithographically defined nanopatterned substrates. Nature 424, 411–414 (2003).

Shin, D. O. et al. Multicomponent nanopatterns by directed block copolymer self-assembly. ACS Nano 7, 8899–8907 (2013).

Choi, Y. J. et al. Hierarchical directed self-assembly of diblock copolymers for modified pattern symmetry. Adv. Funct. Mater. 26, 6462–6470 (2016).

Jung, H. et al. Hierarchical multi-level block copolymer patterns by multiple self-assembly. Nanoscale 11, 8433–8441 (2019).

Ding, Y. et al. Emergent symmetries in block copolymer epitaxy. Nat. Commun. 10, 2974 (2019).

Kulkarni, A. A. et al. Template-directed solidification of eutectic optical materials. Adv. Opt. Mater. 6, 1800071 (2018).

Kim, J. et al. Template-directed directionally solidified 3D mesostructured AgCl-KCl eutectic photonic crystals. Adv. Mater. 27, 4551–4559 (2015).

Kulkarni, A. A., Kohanek, J., Hanson, E., Thornton, K. & Braun, P. V. Control of lamellar eutectic orientation via template-directed solidification. Acta Mater. 166, 715–722 (2019).

Yan, Z. et al. Three-dimensional mesostructures as high-temperature growth templates, electronic cellular scaffolds, and self-propelled microrobots. Proc. Natl Acad. Sci. USA 114, E9455–E9464 (2017).

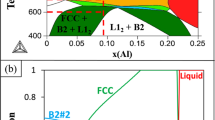

Fischer, E. Thermodynamic optimization of the AgCl-KCl and BaCl2-LiCl systems. J. Phase Equilibria 24, 228–235 (2003).

Chen, Y., Geddes, J. III, Lee, J., Braun, P. & Wiltzius, P. Holographically fabricated photonic crystals with large reflectance. Appl. Phys. Lett. 91, 241103 (2007).

Kim, J., Ou, Z., Jones, M. R., Song, X. & Chen, Q. Imaging the polymerization of multivalent nanoparticles in solution. Nat. Commun. 8, 761 (2017).

Ma, J. et al. Coherent phonon-grain boundary scattering in silicon inverse opals. Nano Lett. 13, 618–624 (2013).

Whitelaw, J. H. Convective heat transfer. In Thermopedia (ed. Hewitt, G. F.) https://doi.org/10.1615/AtoZ.c.convective_heat_transfer (Begell House Inc., 2011).

Cappella, A. et al. High temperature thermal conductivity of amorphous Al2O3 thin films grown by low temperature ALD. Adv. Eng. Mater. 15, 1046–1050 (2013).

Folch, R. & Plapp, M. Quantitative phase-field modeling of two-phase growth. Phys. Rev. E 72, 011602 (2005).

Yu, H.-C., Chen, H.-Y. & Thornton, K. Extended smoothed boundary method for solving partial differential equations with general boundary conditions on complex boundaries. Model. Simul. Mater. Sci. Eng. 20, 075008 (2012).

Acknowledgements

This work was supported through the Air Force Office of Scientific Research Multidisciplinary University Research Initiative FA9550-12-1-0471. This work was carried out in part in the Materials Research Laboratory Central Facilities, and in the Beckman Institute for Advanced Science and Technology, University of Illinois. E.H. and K.T. acknowledge use of the computational resources in the Department of Defense High-Performance Computing Modernization Program. We thank J. Kohanek for suggestions and discussions on solidification in pillar templates, Z. Ou and Q. Chen for help with image analysis, G. Huang for help with thermal profile simulations, and K. Tyler and V. Mohan for critical feedback on the manuscript.

Author information

Authors and Affiliations

Contributions

A.A.K. and E.H., under the supervision of P.V.B. and K.T., respectively, designed the study. A.A.K. and R.Z. fabricated the templates. A.A.K. performed solidification experiments and sample characterization. E.H. performed the simulations. A.A.K., E.H. and R.Z. analysed the data. All authors prepared the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks Elizabeth Dickey, Alain Karma and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Directional solidification of AgCl-KCl lamellar eutectic and experiment schematic for pillar-template-directed eutectic solidification.

a, Plot of the average lamellar spacing (λ) of AgCl-KCl eutectic directionally solidified using the hot-stage setup at set cooling rates (plotted in orange) and the tube-furnace setup at set draw rates (plotted in blue). b, Experiment schematic for infilling the pillar template with eutectic, subsequent directional solidification of the eutectic in the pillar template, and characterization of the resultant microstructures. c, SEM image showing the eutectic solidified within and outside the pillar template. The solidification direction is out of the image (z axis), as indicated by the red dotted circle. See Methods for details. Scale bar, 1 μm.

Extended Data Fig. 2 Nomenclature of the patterns.

a–d, Schematic showing the number of KCl spokes per unit cell of the pillar template for a, trefoil (three), b, quatrefoil (four), c, cinquefoil (five) and d, hexafoil (six) patterns. The KCl spokes are coloured blue, pillars black, and the unit cell is marked by red dashed lines.

Extended Data Fig. 3 No-foil and trefoil patterns.

Uncoloured SEM images of the samples, showing the variety of no-foil (a–d) and trefoil (e–j) patterns mapped in Fig. 3. Values of edge gap, g, and average lamellar spacing, λ, are given under each image. The solidification direction is out of the image (z axis), as indicated by the red dotted circle. All scale bars, 1 μm.

Extended Data Fig. 4 Quatrefoil, cinquefoil and hexafoil patterns.

Uncoloured SEM images of the samples showing the variety of quatrefoil (a, b), cinquefoil (c) and hexafoil (d–f) patterns mapped in Fig. 3. Values of edge gap, g, and average lamellar spacing, λ, are given under each image. The solidification direction is out of the image (z axis), as indicated by the red dotted circle. All scale bars, 1 μm.

Extended Data Fig. 5 Image analysis of local and long-range order in the patterns.

a, SEM image of a trefoil pattern. b, Histogram representing a simple counting of the number of spokes in each unit cell. The dominant feature in the 12 μm × 17 μm SEM image in a is the three-spoke pattern. We also include in the histogram the number of unit cells that have missing pillars or other defects. c, A unit cell of the phase-field-simulated trefoil pattern. d, Mean unit cell obtained by averaging the intensity at each pixel from a false-coloured version of the SEM image in a. The experimental average matches the ideal simulated unit cell well. e, Map of deviation between the simulated trefoil pattern and each unit cell of the experimental image. The unit cells having the lowest deviation are denoted in blue and those with the greatest deviation in red. Cells where the template pillars appeared damaged were not included in the analysis. f, Unit cell of the simulated cinquefoil pattern. g, Averaged unit cell obtained from the SEM image shown in Extended Data Fig. 4c. h, Unit cell of the simulated hexafoil pattern. i, Averaged unit cell obtained from the SEM image shown in Extended Data Fig. 4e. All scale bars, 1 μm.

Extended Data Fig. 6 Eutectic phase boundary alignment and thermal profile in the bulk of the pillar template.

a, SEM image of a cross-section, showing a tilted alignment of eutectic phase boundaries within the pillars. b, Calculated thermal profile in the bulk of the template during directional solidification of eutectic-infiltrated Ni pillar template at a set cooling rate of 10 °C min−1. The isothermal solidification front at the eutectic temperature (591.73 K) is denoted by a thick black line; the eutectic temperature is also indicated by a black line in the key. The black arrow denotes the direction of solidification. Scale bar, 1 μm.

Extended Data Fig. 7 Effect of pillar diameter on the emergence of patterns.

a–e, Phase-field-simulated steady-state patterns for a fixed lattice constant of 780.6 nm, varying edge gaps, g, and lamellar spacing, λ. These results suggest the possibility of obtaining new patterns by varying the parameter associated with pillar diameter as well as g/λ. The solidification direction is out of the image (z axis). The images show the x–y plane cross-section of the simulation domain repeated once in each direction. The template pillars are displayed as black, AgCl as yellow, and KCl as blue.

Extended Data Fig. 8 Phase-field simulations for different shapes of pillars.

a–c, A variety of patterns in templated-eutectic obtained by changing the shapes and orientations of the pillars: a, oval; b, circle; c, same as a but rotated by 90°. Characteristic features depend on the pillar shape and orientation. The solidification direction is out of the image (z axis), as indicated by the red dotted circle. The images show the x–y plane cross-section of the simulation domain repeated once in each direction. The template pillars are displayed as black, AgCl as yellow, and KCl as blue.

Extended Data Fig. 9 Solidification of AgCl-KCl eutectic in a monolayer silica colloidal crystal.

a, An oblique-view SEM image of the monolayer silica colloidal crystal used as a template. b, Plan-view SEM image of a disordered structure observed in AgCl-KCl eutectic solidified (with λ = 1.7 μm) within a monolayer silica colloidal crystal of diameter 560 nm. The solidification direction in b is into the image (z axis), as indicated by the black crossed circle. c, Calculated thermal profile in the bulk of the template during directional solidification of the eutectic-infilled silica colloidal crystal template at a set cooling rate of 10 °C min−1. The isothermal solidification front at the eutectic temperature (591.73 K) is denoted by a thick black line; the eutectic temperature is also indicated by a black line in the key. The black arrow denotes the direction of solidification. d, Cross-sectional-view SEM image, with false colouring denoting AgCl as yellow, and KCl as blue. All scale bars, 1 μm.

Rights and permissions

About this article

Cite this article

Kulkarni, A.A., Hanson, E., Zhang, R. et al. Archimedean lattices emerge in template-directed eutectic solidification. Nature 577, 355–358 (2020). https://doi.org/10.1038/s41586-019-1893-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-019-1893-9

This article is cited by

-

Understanding and design of metallic alloys guided by phase-field simulations

npj Computational Materials (2023)

-

Robustness of Flat Bands on the Perturbed Kagome and the Perturbed Super-Kagome Lattice

Annales Henri Poincaré (2023)

-

Oscillatory bifurcation patterns initiated by seeded surface solidification of liquid metals

Nature Synthesis (2022)

-

Unique surface patterns emerging during solidification of liquid metal alloys

Nature Nanotechnology (2021)

-

Bulk nanocomposite made of ZnO lamellae embedded in the ZnWO4 matrix: growth from the melt

Journal of Materials Science (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.