Abstract

Antiferromagnetic thin films are currently generating considerable excitement for low dissipation magnonics and spintronics. However, while tuneable antiferromagnetic textures form the backbone of functional devices, they are virtually unknown at the submicron scale. Here we image a wide variety of antiferromagnetic spin textures in multiferroic BiFeO3 thin films that can be tuned by strain and manipulated by electric fields through room-temperature magnetoelectric coupling. Using piezoresponse force microscopy and scanning NV magnetometry in self-organized ferroelectric patterns of BiFeO3, we reveal how strain stabilizes different types of non-collinear antiferromagnetic states (bulk-like and exotic spin cycloids) as well as collinear antiferromagnetic textures. Beyond these local-scale observations, resonant elastic X-ray scattering confirms the existence of both types of spin cycloids. Finally, we show that electric-field control of the ferroelectric landscape induces transitions either between collinear and non-collinear states or between different cycloids, offering perspectives for the design of reconfigurable antiferromagnetic spin textures on demand.

Similar content being viewed by others

Introduction

In ferromagnetic materials, spin textures are conventionally tweaked with a magnetic field. Antiferromagnetic spin textures, on the other hand, are intrinsically insensitive to external magnetic fields, calling for alternative control knobs to manipulate the antiferromagnetic order. The electrical manipulation of antiferromagnetism was recently demonstrated in non-centrosymmetric metallic antiferromagnets1,2,3; however, the spin orbit torque required to either switch by 90° or reverse by 180° the antiferromagnetic vector involves large current densities of the order of 106–107 A cm−2. Furthermore, the efficiency of this writing method faces limitations, since only a small fraction of antiferromagnetic domains is actually switched4,5. An optimal writing mechanism would demand low current densities (or ideally no current) to generate a complete reversal of antiferromagnetic domains or textures. Recent reports have for instance demonstrated that piezoelectric strain can provide low power control of antiferromagnetic memories6,7.

In some materials possessing both antiferromagnetic and electrical orders, the magnetoelectric coupling is an additional means expected to efficiently channel electric-field stimuli onto the antiferromagnetic order. Yet, the fundamental ingredients deterministically governing the imprint of the ferroelectric order to the antiferromagnetic order remain poorly understood. Even in the archetypal room-temperature multiferroic8, BiFeO3, the details of the antiferromagnetic textures are virtually unknown at the scale of ferroelectric domains. The seminal work of Zhao et al. showed promise for the electric control of the antiferromagnetic order in BiFeO3 thin films9. To date, its complex antiferromagnetic order has been solely inferred from volume averaged techniques such as neutron diffraction, Mössbauer spectroscopy, or Raman spectroscopy. Depending on the strain, growth conditions and crystal orientation, the magnetic state of BiFeO3 thin films can either show different types of non-collinear cycloids, canted G-type antiferromagnetic orders, or even a mixture of these10,11. More generally, examples of antiferromagnetic textures being imaged at the nanoscale are extremely scarce in the literature12,13,14. Here we bring deep insight into the strain-dependent interplay between the ferroelectric and antiferromagnetic orders at the local scale and show that electric field can be used to convert between various collinear and non-collinear spin arrangements.

Results

Strain-engineered BiFeO3 with striped ferroelectric domains

BiFeO3 thin films were grown using pulsed laser deposition on various substrates (SrTiO3, DyScO3, TbScO3, GdScO3, SmScO3) with a thin bottom electrode of SrRuO3 (Methods). X-ray diffraction shows the high epitaxial quality of the films with Laue fringes (Fig. 1a–e) attesting for their coherent growth. All films display smooth surfaces with atomic steps, characteristic of a layer-by-layer growth (insets of Fig. 1a–e). The (001) BiFeO3 peak evolves from the left to the right of the substrate (001) peak upon increase of the in-plane pseudo-cubic lattice parameter of the substrate, as observed in the 2θ–ω scans. Reciprocal space maps indicate that the films are fully strained (Supplementary Fig. 1) with only two elastic variants of the BiFeO3 monoclinic phase (Fig. 1f–j). Their peak positions enable us to determine a strain value for each film ranging from −1.35% compressive strain to +0.50% tensile strain (Fig. 1k, Supplementary Fig. 1 and Methods).

a–e, 2θ–ω X-ray diffraction scans of BiFeO3 (BFO) films grown on SrTiO3 (STO) (a), DyScO3 (DSO) (b), TbScO3 (TSO) (c), GdScO3 (GSO) (d) and SmScO3 (SSO) (e) substrates. The insets are 3 × 3 μm2 topography images acquired by atomic-force microscopy on the same films, showing atomic steps and terraces. The z-scale is 4 nm. f–j Corresponding reciprocal space maps along the different (113) substrate peaks, showing in each case two elastic domains for BiFeO3, i.e. (203) and (023). The r. l. u. units of the in-plane and out-of-plane wavevectors, Qx,y and Qz, respectively, stand for reciprocal lattice units. k Sketch of the evolution of the calculated epitaxial strain in BiFeO3 as a function of the substrate. The scandate and BiFeO3 crystallographic peaks are defined in a monoclinic cell.

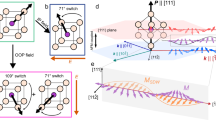

With this set of structurally equivalent BiFeO3 thin films, distinguishable only by their strain level, we now focus on the evolution of the ferroelectric and magnetic textures (Fig. 2). In BiFeO3, the displacement of Bi ions relative to the FeO6 octahedra gives rise to a strong ferroelectric polarisation along one of the <111> directions of the pseudo-cubic unit cell. The out-of-plane and in-plane variants of polarisation were identified in each sample using piezoresponse force microscopy (PFM; Methods). For all the samples, the as-grown out-of-plane polarisation is pointing downward, i.e. towards the bottom electrode (Supplementary Fig. 2a). Figure 2a–e displays similar striped-domain structures with two in-plane ferroelectric variants, which correspond to the two elastic domains observed in reciprocal space maps15. In contrast to the as-grown striped domain patterns of the BiFeO3 films grown on the scandates, the striped domain pattern of the BiFeO3 film on SrTiO3 was defined by PFM (Supplementary Fig. 4). All the samples can be considered as a periodic array of 71-degree domain walls, separated by two ferroelectric variants (Supplementary Figs. 2 and 3). This ordered ferroelectric landscape greatly simplifies the exploration and interpretation of the magnetic configuration for each ferroelectric domain16.

a–e In-plane PFM phase images of BiFeO3 films grown on SrTiO3 (a), DyScO3 (b), TbScO3 (c), GdScO3 (d) and SmScO3 (e) substrates. f Sketch of the evolution of the epitaxial strain in BiFeO3 as a function of the substrate. g–k NV magnetometry images corresponding to the ferroelectric domains depicted in (a–e). The dashed lines in (g–j) are guides to the eyes, reflecting a change of the cycloid propagation vector associated to the ferroelectric domain walls. The symbol AFM in (k) stands for pseudo-collinear antiferromagnetic order.

Influence of the strain on the antiferromagnetic textures

For each sample, the corresponding antiferromagnetic spin textures were imaged in real space with a scanning NV (nitrogen-vacancy) magnetometer17 operated in dual-iso-B imaging mode (Fig. 2g–k, Methods, Supplementary Fig. 5). In the strain range of −1.35 to +0.05%, the NV images display a similar zig-zag pattern of periodic stray fields generated by cycloidal antiferromagnetic orders. More precisely, in each vertical ferroelectric domain (separated by dashed lines in Fig. 2g–j), we observe a single propagation direction of the spin cycloid. As the in-plane variant of polarisation rotates from one domain to another, the spin cycloid propagation direction rotates accordingly. This implies a one-to-one correspondence between the ferroelectric and antiferromagnetic domains. In contrast, for large tensile strain (+0.5%) corresponding to BiFeO3 films grown on SmScO3 substrates, the cycloidal order appears to be strongly destabilized (Fig. 2k and Supplementary Fig. 6). In this specific case, the ferroelectric periodicity is lost in the magnetic pattern, which may suggest a weaker magnetoelectric coupling as compared to other magnetic interactions. This strain dependence of the magnetic textures is reminiscent of previous works where antiferromagnetic order as a function of strain was studied by non-local techniques such as Mössbauer and Raman spectroscopies10,11. Indeed, a canted G-type antiferromagnetic order was identified for tensile strain over +0.5% and a cycloidal order from −1.6% to +0.5%.

In the present sample set, the magnetic image of BiFeO3 films grown on DyScO3 substrates (Fig. 2h) with −0.35% strain corresponds to the configuration already observed by Gross et al.16. The 90-degree in-plane rotation of the ferroelectric polarisation imprints the 90-degree in-plane rotation of the cycloidal propagation direction. This corresponds to one of the three bulk-like cycloids (cycloid I) with propagation vectors contained in the (111) plane orthogonal to the polarisation18,19 (Fig. 3a, b). Among them, the observed k1 vector lies in the (001) plane of the film, for both ferroelectric variants (Fig. 2h). For lower compressive strain (−0.10%, TbScO3), the magnetic configuration is found to be identical (Fig. 2i), also corresponding to the bulk-like cycloid (cycloid I, k1).

A subtle change of the strain towards the tensile side (+0.05%, GdScO3) greatly influences the magnetic landscape. Indeed, the spin texture can no longer be explained by the bulk-like cycloid as the zig-zag features are no longer orthogonal to each other, but rather at 120 ± 5 degrees (Fig. 2j). Interestingly, for (001)BiFeO3 films grown under low tensile strain (+0.2%), previous reports have shown evidence for exotic spin cycloids10,11. In these works, Mössbauer and nuclear resonant scattering data suggested a propagation vector contained in the (1̄10) plane10,11. This result was recently supported by neutron diffraction experiments on Co-doped BiFeO3 films grown on SrTiO3(110), where the propagation vector of the spin cycloid was found to be along the [112̄] direction20. Guided by these observations, here we consider three possible propagation directions (k1′, k2′, k3′) for the cycloid II; namely along [2̄11], [12̄1], and [112̄], respectively (Fig. 3c, d). In the case of BiFeO3 thin films on GdScO3 substrates (Fig. 2j), the angle of the zig-zag pattern is only compatible with alternating k1′, k2′ propagation vectors, giving rise to an angle of 127 degrees, as projected on the film surface. Surprisingly, a similar scenario takes place for large compressive strain (−1.35%, SrTiO3) as the zig-zag angle (Fig. 2g) is the same as for BiFeO3 grown on GdScO3. This unprecedented real-space observation of the cycloid II under both large compressive strain and low tensile strain calls for further theoretical input to explain the interplay between strain and antiferromagnetic textures.

Insights into the different spin cycloids

To further corroborate the nanoscale real-space images of the magnetic arrangements, complementary macroscopic investigations were performed by X-ray resonant elastic scattering on BiFeO3 samples21,22 grown on both DyScO3 (cycloid I) and GdScO3 (cycloid II) substrates (Fig. 4a, c). As the spin cycloid is a periodic magnetic object, it gives rise to a diffracted pattern at the Fe resonant L-edge. In order to select the diffracted signal of magnetic origin, the difference between left and right circularly polarized light is plotted as a dichroic diffracted pattern (Fig. 4a, red and blue correspond to positive and negative dichroism, respectively). In both diagonals from the specular spot, the inverted contrast between +q and −q spots is a signature of chirality. Indeed, BiFeO3 spin cycloids in which spins rotate in a plane defined by the polarisation (P) and the propagation vector (k) are chiral objects.

a Resonant X-ray elastic scattering at the Fe L-edge for BiFeO3 grown on DyScO3. The square pattern indicates a bulk-like cycloid (cycloid I) with propagation vectors aligned 90 degrees from each other. b Corresponding NV magnetometry image zoomed in, with the propagation vectors sketched for both polarisation variants. c Resonant X-ray elastic scattering at the Fe L-edge for BiFeO3 grown on GdScO3. The rectangular pattern corresponds to the cycloid II with propagation vectors lying at 110 ± 5 degrees from each other. d Corresponding NV magnetometry image zoomed in, with the propagation vectors sketched for both polarisation variants. The dashed lines in b, d are guides to the eyes, reflecting a change of the cycloid propagation vector associated to the ferroelectric domain walls.

For BiFeO3 thin films grown on DyScO3, the presence of two orthogonal cycloid propagation directions (red arrows in Fig. 4a) with identical periods gives rise to two orthogonal lines of diffracted spots, thus defining a square diffracted pattern. The fine structure of this pattern is rendered more complex by additional spots that arise from the modulation of the magnetic periodicity by the ferroelectric domain structure;23 however, here our focus is on the cycloid propagation direction and periodicity. The spacing between the +q and −q spots corresponds to a cycloid period of 72 ± 5 nm for both spin cycloids with k1 propagation vector. Consistently at the local scale, the combination of PFM and scanning NV magnetometry allows to identify the relative orientation of the ferroelectric polarisation (P, grey arrows in Fig. 4b) and cycloid propagation direction (k1, red arrows in Fig. 4b) on both sides of a domain wall. Thus, our microscopic real-space experiments and macroscopic reciprocal-space observations both attest for a single cycloidal vector (k1) in BiFeO3 thin films under moderate compressive strain.

In contrast, for BiFeO3 films grown on GdScO3 imposing slight tensile strain, the dichroic diffracted pattern is no longer square but rectangular (Fig. 4c). Hence, we preclude the above-mentioned scenario with two bulk-like (cycloid I) orthogonal vectors. The two diagonals of the rectangular pattern (green arrows in Fig. 4c) form an angle of about 110 ± 5 degrees, in accordance with the typical angles observed in NV magnetometry images. The only plausible scenario, therefore, corresponds to two types of ferroelectric domains respectively harbouring alternating k1′ and k2′ propagation vectors of the cycloid II, as observed in real space (Fig. 4d). These two cycloid propagation variants appear to be energetically degenerated and favoured over the more out-of-plane k3′ vector (Fig. 3c). Consequently, these cycloidal BiFeO3 films, under either compressive or tensile strain, exhibit a one-to-one imprint between ferroelectric and antiferromagnetic order.

Electric-field control of antiferromagnetic textures

Beyond the observations on pristine configurations of ferroelectric domains in which the cycloid propagation is locked onto the polarisation, we now manipulate the ferroelectric order using electric fields, with the aim to design antiferromagnetic landscapes on demand. We first use PFM to draw micron-size ferroelectric domains (Supplementary Fig. 7) by virtue of the so-called trailing field24,25,26. Using microdiffraction experiments, we checked that no strain difference could be detected between artificially written and as-grown striped-domains (Methods and Supplementary Fig. 8). NV magnetometry is then performed on these artificial domains to reveal the corresponding magnetic textures (Fig. 5 and Supplementary Fig. 7). For strain states ranging from −0.35 to +0.50%, single ferroelectric domains always correspond to a spin cycloid with a single propagation vector. For BiFeO3 films grown on DyScO3 (−0.35%, Fig. 5a) or TbScO3 (−0.10%, Fig. 5b), the spin cycloid propagates in a direction perpendicular to the ferroelectric polarisation. This implies that the in-plane k1 propagation is still favoured, switching from two pristine cycloid Is to a single written cycloid I. Interestingly, the spin cycloid period λ decreases from about 78 ± 5 nm in the pristine (two domain) state to 65 ± 2 nm for the switched (single domain) state. In single domains, the spin cycloid period thus appears closer to that observed in bulk BiFeO3 (λbulk = 64 nm, ref. 19), suggesting that periodic electric/elastic boundary conditions influence the cycloid period.

a–d NV magnetometry images in single ferroelectric domains defined by PFM for BiFeO3 thin films grown on DyScO3 (a), TbScO3 (b), GdScO3 (c), and SmScO3 (d). The corresponding strain values are depicted in the first row and the second row presents the evolution of the magnetic textures from striped domains to single ferroelectric domains. The propagation vector of the spin cycloid relative to the ferroelectric polarisation is sketched below each image. The symbol AFM in (d) stands for the pseudo-collinear antiferromagnetic order.

For BiFeO3 films grown on GdScO3 (+0.05%, Fig. 5c), the spin cycloid propagates horizontally, i.e. at 45 degrees from the in-plane polarisation variant of the single ferroelectric domain. This implies that the cycloid I out-of-plane propagation vector (k2, Fig. 3a, b) is selected, corresponding to a switching from two cycloid IIs (k1′, k2′) to a single cycloid I (k2). In addition, the apparent cycloid period of 92 ± 3 nm in the single domain is compatible with its projection onto the sample surface (\(\lambda _{{\mathrm{surf}}} = \sqrt 2 \times \lambda\)), giving rise to an intrinsic period of λ = 65 ± 2 nm, close to the bulk value. These experiments on single domains suggest that strain primarily has an influence on the direction of the bulk-like cycloid propagation (in-plane for compressive and out-of-plane for tensile strains). In the case of BiFeO3 films grown on SmScO3 (+0.50%, Fig. 5d), the cycloid is observed to propagate in a direction almost parallel to the in-plane variant of polarisation. Considering the three vectors of each cycloid type (Fig. 3), this is only compatible with the k3′ propagation vector of cycloid II. In this case, we find an apparent cycloid period of 146 ± 5 nm leading to an intrinsic period of 84 ± 3 nm (\(\lambda _{{\mathrm{surf}}} = \sqrt 3 \times \lambda\)). The enhanced period compared to the bulk value is here attributed to the significant tensile strain of BiFeO3 films grown on SmScO3 (Ref. 11.). In this latter example, we have demonstrated electric-field switching from a G-type antiferromagnetic order to a cycloidal state.

In this work, we have shown real-space evidence of multiple antiferromagnetic landscapes in BiFeO3 epitaxial thin films. Depending on the strain level, bulk-like cycloids, exotic cycloids, and G-type collinear order are observed. The exotic cycloid is, rather unexpectedly, shown to exist for two very different strain states: one being compressive and the other tensile. Combining multiple scanning probe techniques, we provide direct correspondence between ferroelectric domains and complex antiferromagnetic textures. These local observations are supported by macroscopic resonant X-ray scattering on both types of cycloids. Although the cycloid is often not considered in the literature of BiFeO3 thin films27, our observations show that only the cycloidal state enables a full one-to-one correspondence between ferroic orders in the native striped-domains as well as in artificially-designed single domains. The electric field enables toggling either from one type of cycloid to another or from collinear to cycloidal states. More specifically, we are now able to electrically design single spin cycloids on demand with controlled propagation either in the plane or out of the film plane. This fully mastered magnetoelectric system is an ideal playground to investigate reconfigurable low-power antiferromagnetic spintronic1,28,29 or magnonic30 architectures at room temperature.

Methods

Sample fabrication

BiFeO3 thin films were grown by pulsed laser deposition on various substrates using a KrF excimer laser (248 nm) with a fluence of 1 J cm−2. Prior to film growth, the scandate substrates (DyScO3, TbScO3, GdScO3, SmScO3) were ex-situ annealed for 3 h at 1000 °C under flowing oxygen. The SrTiO3 substrate was chemically etched with a buffered HF solution before following the same annealing procedure. For all the samples, a SrRuO3 bottom electrode (3–5 nm) was first grown at 660 °C under 0.2 mbar of oxygen pressure with a laser repetition rate of 5 Hz. The BiFeO3 thin film (30–60 nm) was subsequently grown at the same temperature under 0.36 mbar of oxygen pressure and a repetition rate of 2 Hz. Following the growth of the bilayer, the samples were cooled down to room temperature under an oxygen pressure of 300 mbar.

Structural characterisations

The structural properties of the films were determined by X-ray diffraction (XRD) using a Panalytical Empyrean diffractometer equipped with a hybrid monochromator for Cu Kα1 radiation and a PIXcel3D detector. Full 2θ–ω XRD scans (not shown) indicate that all films are single phase with a monoclinic (001) orientation. To gain further insight into the elastic domains and strain of the films, we carried out reciprocal space maps (RSMs) around the (103), (013), (113), and (1̄1̄3) substrate peaks (Fig. 1f–j and Supplementary Fig. 1). The (110) orthorhombic scandates (XSO with X = Dy, Tb, Gd, Sm) are all described in a (001) monoclinic (which is only a slight correction from pseudo-cubic) notation for simplicity31. All the RSMs are consistent, with only two monoclinic ferroelastic variants of BiFeO3 with the following epitaxial relationship: (001)BFO|| (001)XSO, [100]BFO|| [110]XSO (green) and (001)BFO|| (001)XSO, [100]BFO|| [11̄0]XSO (blue). The same epitaxial relationship is established for BiFeO3 films grown on cubic (001)SrTiO3 substrates. The BiFeO3 thin films are fully strained by the substrates as indicated by the alignment of the in-plane reciprocal peaks with the (103) and (013) substrate peaks (Supplementary Fig. 1). The monoclinic cell parameters (am,bm,cm,β) of each BiFeO3 film were calculated independently from the peak positions around the (113) and (1̄1̄3) RSMs of XSO. The strain values were then estimated by comparing the average in-plane lattice parameter with the volume of the unit-cell as:

Considering the small deviation from the cubic unit cell, cell, throughout the manuscript, descriptions of the ferroelectric and magnetic properties are given in the pseudo-cubic perovskite lattice for simplicity.

Piezoresponse force microscopy

The experiments were conducted with an atomic force microscope (Nanoscope V multimode, Bruker) and two external lock-in detectors (SR830, Stanford Research) for the simultaneous acquisition of in-plane and out-of-plane responses. An external ac source (DS360, Stanford Research) was used to excite the SrRuO3 bottom electrode at a frequency of 35 kHz while the conducting Pt-coated tip was grounded. We used stiff cantilevers (40 N m−1) for accurate out-of-plane detection and softer ones (3-7 N m−1) for the in-plane detection. In all the BiFeO3 samples, the as-grown out-of-plane signal is homogeneous (Supplementary Fig. 2a) indicating a uniform out-of-plane component of polarisation pointing downwards, i.e. towards the SrRuO3 bottom electrode. In Fig. 2a–e and Supplementary Figs. 2–5 and Supplementary Fig. 7, the phase shift between the in-plane and out-of-plane domains is 180 degrees and the phase scale is fixed at 360 degrees to avoid saturation of the image. Before designing artificial domains in the BiFeO3 thin films, a radio frequency antenna and markers are defined by laser lithography and lift-off of a Au/Ti sputtered layer (Supplementary Fig. 5). These markers are typically less than 10 μm away from the antenna and are visible with an optical microscope. Optical microscopy allows for coarse repositioning, and maps provided by PFM measurements (including markers; Supplementary Fig. 5) are used to precisely relocate NV imaging.

Scanning NV magnetometry

Scanning-NV magnetometry was performed under ambient conditions with commercial all-diamond scanning-probe tips containing single NV defects (QNAMI, Quantilever MX). The tip was integrated into a tuning-fork-based atomic force microscope (AFM) combined with a confocal microscope optimized for single NV defect spectroscopy. Magnetic fields emanating from the sample are detected by recording the Zeeman shift of the NV defect’s electronic spin sublevels through optical detection of the electron spin resonance17.

The scanning-NV magnetometer was operated in the dual-iso-B imaging mode by monitoring the signal S = PL(υ2)−PL(υ1), corresponding to the difference of photoluminescence (PL) intensity for two fixed microwave frequencies, υ1 and υ2, applied consecutively at each point of the scan through a gold stripline antenna directly fabricated onto the BiFeO3 sample (see the description before)17. Experiments were performed with a NV-to-sample distance of 60 nm and a bias magnetic field of 2 mT applied along the NV quantization axis. The standard error of the cycloid period measurement is limited by the calibration of the scanner.

Resonant X-ray elastic scattering

Resonant X-ray scattering measurements were performed at the Fe L and O K edges using the RESOXS diffractometer32 at the SEXTANTS beamline33 of the SOLEIL synchrotron. Data were collected using nearly fully circular left and right X-ray polarisations delivered by the HU44 Apple2 undulator located at the I14-M straight section of the storage ring.

Microdiffraction

The experiments were performed using a Bruker D8 Discover diffractometer with a high brilliance microfocus Cu rotating anode generator, hybrid Montel optics, a 20 µm diameter circular pinhole beam collimator, and an EIGER2 R 500 K area detector. No monochromator was used to maximize the flux from the microfocus lab source, leading to the characteristic Kα1,2 peak splitting. Prior to the microdiffraction experiments, a lithographically defined hard mask of 90 nm thick Au with 30 µm wide square openings was applied by sputtering and lift-off for precise alignment and orientation on the sample. Selected areas, written and pristine, with different domain wall densities were first analysed by PFM and subsequently by microdiffraction at the same area to obtain local structural information.

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Wadley, P. et al. Electrical switching of an antiferromagnet. Science 351, 587–590 (2016).

Godinho, J. et al. Electrically induced and detected Néel vector reversal in a collinear antiferromagnet. Nat. Commun. 9, 4686 (2018).

Bodnar, S. Y. et al. Writing and reading antiferromagnetic Mn2Au by Néel spin-orbit torques and large anisotropic magnetoresistance. Nat. Commun. 9, 348 (2018).

Grzybowski, M. J. et al. Imaging current-induced switching of antiferromagnetic domains in CuMnAs. Phys. Rev. Lett. 118, 057701 (2017).

Wadley, P. et al. Current polarity-dependent manipulation of antiferromagnetic domains. Nat. Nanotechnol. 13, 362–365 (2018).

Chen, X. et al. Electric field control of Néel spin–orbit torque in an antiferromagnet. Nat. Mater. 18, 931–935 (2019).

Yan, H. et al. A piezoelectric, strain-controlled antiferromagnetic memory insensitive to magnetic fields. Nat. Nanotechnol. 14, 131–136 (2019).

Catalan, G. & Scott, J. F. Physics and applications of bismuth ferrite. Adv. Mater. 21, 2463–2485 (2009).

Zhao, T. et al. Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nat. Mater. 5, 823–829 (2006).

Sando, D. et al. Crafting the magnonic and spintronic response of BiFeO3 films by epitaxial strain. Nat. Mater. 12, 641–646 (2013).

Agbelele, A. et al. Strain and magnetic field induced spin-structure transitions in multiferroic BiFeO 3. Adv. Mater. 29, 1602327 (2017).

Heinze, S. Real-space imaging of two-dimensional antiferromagnetism on the atomic scale. Science 288, 1805–1808 (2000).

Scholl, A. Observation of antiferromagnetic domains in epitaxial thin films. Science 287, 1014–1016 (2000).

Wiesendanger, R. Spin mapping at the nanoscale and atomic scale. Rev. Mod. Phys. 81, 1495–1550 (2009).

Chu, Y.-H. et al. Nanoscale control of domain architectures in BiFeO 3 thin films. Nano Lett. 9, 1726–1730 (2009).

Gross, I. et al. Real-space imaging of non-collinear antiferromagnetic order with a single-spin magnetometer. Nature 549, 252–256 (2017).

Rondin, L. et al. Magnetometry with nitrogen-vacancy defects in diamond. Rep. Prog. Phys. 77, 056503 (2014).

Sosnowska, I., Neumaier, T. P. & Steichele, E. Spiral magnetic ordering in bismuth ferrite. J. Phys. C. Solid State Phys. 15, 4835–4846 (1982).

Lebeugle, D. et al. Electric-field-induced spin flop in BiFeO3 single crystals at room temperature. Phys. Rev. Lett. 100, 227602 (2008).

Burns, S. R. et al. Expansion of the spin cycloid in multiferroic BiFeO3 thin films. Npj Quantum Mater. 4, 18 (2019).

Johnson, R. D. et al. X-ray imaging and multiferroic coupling of cycloidal magnetic domains in ferroelectric monodomain BiFeO3. Phys. Rev. Lett. 110, 217206 (2013).

Waterfield Price, N. et al. Coherent magnetoelastic domains in multiferroic BiFeO3 films. Phys. Rev. Lett. 117, 177601 (2016).

Chauleau, J.-Y. et al. Electric and antiferromagnetic chiral textures at multiferroic domain walls. Nat. Mater. https://doi.org/10.1038/s41563-019-0516-z (2019)

Balke, N. et al. Deterministic control of ferroelastic switching in multiferroic materials. Nat. Nanotechnol. 4, 868–875 (2009).

Crassous, A., Sluka, T., Tagantsev, A. K. & Setter, N. Polarization charge as a reconfigurable quasi-dopant in ferroelectric thin films. Nat. Nanotechnol. 10, 614–618 (2015).

Chauleau, J.-Y., Haltz, E., Carrétéro, C., Fusil, S. & Viret, M. Multi-stimuli manipulation of antiferromagnetic domains assessed by second-harmonic imaging. Nat. Mater. 16, 803–807 (2017).

Heron, J. T. et al. Deterministic switching of ferromagnetism at room temperature using an electric field. Nature 516, 370–373 (2014).

Jungwirth, T., Marti, X., Wadley, P. & Wunderlich, J. Antiferromagnetic spintronics. Nat. Nanotechnol. 11, 231–241 (2016).

Kimata, M. et al. Magnetic and magnetic inverse spin Hall effects in a non-collinear antiferromagnet. Nature 565, 627–630 (2019).

Lebrun, R. et al. Tunable long-distance spin transport in a crystalline antiferromagnetic iron oxide. Nature 561, 222–225 (2018).

Uecker, R. et al. Properties of rare-earth scandate single crystals (Re=Nd−Dy). J. Cryst. Growth 310, 2649–2658 (2008).

Jaouen, N. et al. An apparatus for temperature-dependent soft X-ray resonant magnetic scattering. J. Synchrotron Radiat. 11, 353–357 (2004).

Sacchi, M. et al. The SEXTANTS beamline at SOLEIL: a new facility for elastic, inelastic and coherent scattering of soft X-rays. J. Phys. Conf. Ser. 425, 072018 (2013).

Acknowledgements

We acknowledge support from the French Agence Nationale de la Recherche (ANR) through the PIAF and SANTA projects, the European Research Council (ERC-StG-2014, Imagine), the EU Quantum Flagship project ASTERIQS (820394) and the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 846597. This work was supported by a public grant overseen by the ANR as part of the ‘Investissement d’Avenir’ programme (LABEX NanoSaclay, ref. ANR-10-LABX-0035). FG acknowledges the Graphene flagship 696656 and 785219. We also acknowledge the company QNAMI for providing all-diamond scanning tips containing single NV defects.

Author information

Authors and Affiliations

Contributions

V.G., S.F. and V.J conceived and coordinated the experiment. J.F. and C.C. prepared the samples. J.F. carried out the X-ray diffraction experiments and analysed the structural properties of the samples with D.S. and V.G. S.F. and F.G. patterned the microwave antennas and markers for repositioning. J.F., S.F. and V.G. performed the piezoresponse force microscopy experiments. A.H., W.A., A.F. and V.J. conducted the scanning NV magnetometry experiments. J.-Y.C., N.J. and M.V. performed the resonant X-ray scattering experiments. Y.A.B. conducted microdiffraction experiments. V.G. and S.F. wrote the paper with inputs from J.F., M.B., D.S. and V.J. All the authors discussed the data and commented on the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Haykal, A., Fischer, J., Akhtar, W. et al. Antiferromagnetic textures in BiFeO3 controlled by strain and electric field. Nat Commun 11, 1704 (2020). https://doi.org/10.1038/s41467-020-15501-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-020-15501-8

This article is cited by

-

Switching the spin cycloid in BiFeO3 with an electric field

Nature Communications (2024)

-

Structural phase transition and multiferric properties of Y, Eu co-doped BiFe0.97Mn0.03O3 nanoparticles

Journal of Materials Science: Materials in Electronics (2024)

-

Voltage-based magnetization switching and reading in magnetoelectric spin-orbit nanodevices

Nature Communications (2024)

-

Manipulating chiral spin transport with ferroelectric polarization

Nature Materials (2024)

-

Self-organization of ferroelectric domains induced by water and reinforced via ultrasonic vibration

Communications Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.