Today’s crude-oil refineries will need to be replaced with renewable fuel and chemical production to achieve net-zero goals.Credit: Brandon Bell/Getty

Fossil energy sources need to be eliminated — and communities that will be adversely affected during the clean-energy transition supported, as we wrote in an Editorial last week. In this week’s issue, Eelco Vogt and Bert Weckhuysen, chemists at Utrecht University in the Netherlands, lay out what needs to be done to decarbonize an important component of fossil-fuel infrastructure: crude-oil refineries.

Read the paper: The refinery of the future

The workings of refineries are little known to most people outside the oil and gas industries, yet are essential to the global economy. They convert crude oil into liquid fuels used in transportation, notably diesel, petrol and jet fuel. Refineries also provide chemicals and synthetic materials that are used to produce most of today’s consumer and health-care goods. In a Perspective article, Vogt and Weckhuysen set out a blueprint for decarbonizing oil-refinery capacity by mid-century. They acknowledge that the cost and scale of the necessary transition are “staggering”. Their vision deserves attention. Industry leaders and policymakers need to take it seriously.

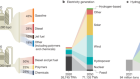

Modern refinery functions include ‘cracking’ crude oil, whereby molecules with long chains of carbon atoms are broken down into shorter ones. This process helps to produce transportation fuels, as well as the chemicals and materials used in many medicines and everyday products, from shampoo to sticky tape. At present, the overwhelming proportion of global refinery output — at least 70% — goes into fuelling transport, including road, rail, shipping and aviation. Under net-zero scenarios, much of this demand will fall with the electrification of transport and with greater use of hydrogen and biomass-derived fuels.

In the net-zero scenario used by the authors, demand for conventionally produced carbon-based transportation fuels is still expected to exist, at around one-third of today’s levels. Such fuels will be needed in part to satisfy future energy needs in Africa, Asia and Latin America as countries there continue to develop economically. Use of fuel in aviation, which is difficult to electrify, will also increase as the tourism industry continues to boom. Some projections forecast less demand for conventionally produced fossil fuels, but all scenarios suggest that alternatives to the production of such fuels are needed.

UN plastics treaty: don’t let lobbyists drown out researchers

The authors propose developing refineries that can make chemicals and materials from biomass and recycled plastic, and synthetic fuels from carbon dioxide and hydrogen, instead of from crude oil. It would be necessary to capture CO2 from existing activities that produce a lot of the gas, such as cement manufacturing, or directly from the air. The hydrogen would come from electrolysing water. The entire process would need to be powered by renewable energy — and is estimated to require ten times as much energy as existing refineries require. In their plan, the authors pose urgent questions. Some are for researchers. Some are for policymakers. Some are for industry. Ideally, answers would come from discussions involving all of these stakeholders.

A key question relates to the energy needed to power refineries. Creating refineries powered entirely by renewables will be a huge challenge. Refineries run continuously, but renewable sources are not always available; for example, solar energy in darkness, or wind energy on a calm day. Technologies that can produce or compensate for energy fluctuations, at the required scale, are still in development.

Refineries’ essential role in the manufacture of drugs and everyday household products also needs to be addressed. For the latter, consideration must be given to the need to reduce humanity’s material footprint — an aim of ongoing talks on the United Nations plastics treaty.

Cost is a third question. Building alternative refinery capacity at large scales won’t come cheap. Here, the obstacles are mostly considerations for decision-makers, rather than technological barriers. In terms of cost, the authors calculate that replacing one oil refinery with technology compatible with net-zero goals would cost between €14 billion (US$15 billion) and €23 billion. They estimate that the total cost of converting the world’s refining capacity by 2050 would be between €320 billion and €520 billion per year.

Chemistry can make plastics sustainable – but isn’t the whole solution

That is a large sum — although it is on existing scales of public and private industrial investment. If the world decides to embark on a path to replacing fossil-fuel refineries with net-zero ones, this change must be mandated or incentivized. To unlock the required funding, the authors call for policies including the implementation of carbon taxes and removal of fossil-fuel subsidies. There will be resistance — not least from fossil-energy companies and their advocates — that will almost certainly slow the authors’ timetable.

We don’t know what the world will look like in 2050. In some future scenarios, fewer refineries might be needed. Some researchers have proposed that ammonia could be produced without the emission of CO2 and used as a fuel for internal combustion engines used in long-distance shipping. That would require less refinery capacity, although large amounts of energy would be needed to generate the hydrogen required to produce the ammonia.

The research community knows enough to start imagining different versions of the future, and recognizing just how hard it might be to reach them before it’s too late. A little over a quarter of a century is a very short period for this scale of technological change. As such, we must take the next step and, following the authors’ advice, evaluate and develop the processes that ensure we reach net-zero targets as soon as and in the most effective way possible.

Read the paper: The refinery of the future

Read the paper: The refinery of the future

UN plastics treaty: don’t let lobbyists drown out researchers

UN plastics treaty: don’t let lobbyists drown out researchers

Chemistry can make plastics sustainable – but isn’t the whole solution

Chemistry can make plastics sustainable – but isn’t the whole solution

Read the paper: Closed-loop recycling of polyethylene-like materials

Read the paper: Closed-loop recycling of polyethylene-like materials