Abstract

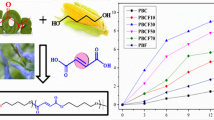

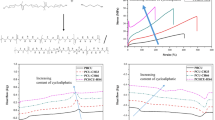

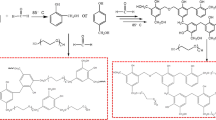

The development of recyclable polymers has attracted considerable attention for realizing the development of a sustainable society. Polycarbonates (PCs) are engineering plastics with high thermal stability and transparency. We focused on poly(isosorbide carbonate) (PIC), a bio-based PC synthesized from isosorbide (ISB) derived from glucose. PIC is expected to function as an alternative to conventional PCs because of its outstanding transparency and thermal and physical properties. This study prepared PIC copolymers with several types of diol comonomers to clarify the effect of copolymerization on the decomposition reaction with ammonia, i.e., ammonolysis for converting PIC copolymers into monomers and urea. The thermal and physical properties of the resulting copolymers were also investigated. The thermal stability of the PIC copolymers remained stable after copolymerization, and the glass transition temperature was affected mainly by the flexibility of the structure of the introduced comonomer. A drastic change in mechanical properties was observed for the copolymer synthesized with 1,4-butanediol, which provides guidelines for toughening PIC with a small comonomer ratio. Finally, we investigated the decomposition behavior of the copolymers by treatment with aqueous ammonia. The PIC copolymers were decomposed into ISB, comonomers, and urea, and the ammonolysis rate was affected by the introduced structure. This study promotes the effective use of ISB as a biomass resource through ammonolysis, which is an effective chemical recycling process for polycarbonate.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Inkinen S, Hakkarainen M, Albertsson A-C, Södergård A. From Lactic Acid to Poly(lactic acid) (PLA): Characterization and analysis of PLA and its precursors. Biomacromolecules. 2011;12:523–32.

Chen G-Q, Patel MK. Plastics derived from biological sources: present and future: a technical and environmental review. Chem Rev. 2012;112:2082–99.

Pang J, Zheng M, Sun R, Wang A, Wang X, Zhang T. Synthesis of ethylene glycol and terephthalic acid from biomass for producing PET. Green Chem. 2016;18:342–59.

Cui Y, Deng C, Fan L, Qiu Y, Zhao L. Progress in the biosynthesis of bio-based PET and PEF polyester monomers. Green Chem. 2023;25:5836–57.

Siracusa V, Blanco I. Bio-Polyethylene (Bio-PE), Bio-Polypropylene (Bio-PP) and Bio-Poly(ethylene terephthalate) (Bio-PET): Recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers. 2020;12:1641.

Hayes G, Laurel M, MacKinnon D, Zhao T, Houck H, Becer CR. Polymers without petrochemicals: sustainable routes to conventional monomers. Chem Rev. 2023;123:2609–734.

Eo YS, Rhee H-W, Shin S. Catalyst screening for the melt polymerization of isosorbide-based polycarbonate. J Ind Eng Chem. 2016;37:42–46.

Zhang M, Lai W, Su L, Lin Y, Wu G. A synthetic strategy toward isosorbide polycarbonate with a high molecular weight: The effect of intermolecular hydrogen bonding between isosorbide and metal chlorides. Polym Chem. 2019;10:3380–9.

Ochoa-Gómez JR, Gil-Río S, Maestro-Madurga B, Gómez-Jiménez-Aberasturi O, Río-Pérez F. Synthesis of isosorbide bis(methyl carbonate) by transesterification of isosorbide with dimethyl carbonate, and evidence of its usefulness as a monomer for manufacturing polycarbonates. Arab J Chem. 2019;12:4764–74.

Qian W, Ma X, Liu L, Deng L, Su Q, Bai R, et al. Efficient synthesis of bio-derived polycarbonates from dimethyl carbonate and isosorbide: Regulating: exo-OH and endo-OH reactivity by ionic liquids. Green Chem. 2020;22:5357–68.

Zhang Z, Xu F, He H, Ding W, Fang W, Sun W, et al. Synthesis of high-molecular weight isosorbide-based polycarbonates through efficient activation of endo-hydroxyl groups by an ionic liquid. Green Chem. 2019;21:3891–901.

Qian W, Liu L, Zhang Z, Su Q, Zhao W, Cheng W, et al. Synthesis of bioderived polycarbonates with adjustable molecular weights catalyzed by phenolic-derived ionic liquids. Green Chem. 2020;22:2488–97.

Abe T, Takashima R, Kamiya T, Foong CP, Numata K, Aoki D, et al. Plastics to fertilizers: chemical recycling of a bio-based polycarbonate as a fertilizer source. Green Chem. 2021;23:9030–7.

Abe T, Kamiya T, Otsuka H, Aoki D. Plastics to fertilizer: guiding principles for functionable and fertilizable fully bio-based polycarbonates. Polym Chem. 2023;14:2469–77.

Hockett RC, Fletcher HG, Sheffield EL, Goepp RM Jr. Hexitol Anhydrides.1 The Structure of Isosorbide, a Crystalline Dianhydrosorbitol2. J Am Chem Soc. 1946;68:927–30.

Hoffer BW, Crezee E, Devred F, Mooijman PRM, Sloof WG, Kooyman PJ, Van Langeveled AD, Kapteijn F, Moulijn JA. The role of the active phase of Raney-type Ni catalysts in the selective hydrogenation of D-glucose to D-sorbitol. Appl Catal, A. 2003;253:437–52.

Schimpf S, Louis C, Claus P. Ni/SiO2 catalysts prepared with ethylenediamine nickel precursors: Influence of the pretreatment on the catalytic properties in glucose hydrogenation. Appl Catal, A. 2007;318:45–53.

Dussenne C, Delaunay T, Wiatz V, Wyart H, Suisse I, Sauthier M. Synthesis of isosorbide: An overview of challenging reactions. Green Chem. 2017;19:5332–44.

Guerrero AR, Ramírez JC. Photodegradation of poly(methyl methacrylate)/ bisphenol A polycarbonate blends. Polym Bull. 1994;33:541–8.

Li Q, Zhu W, Li C, Guan G, Zhang D, Ziao Y, et al. A non-phosgene process to homopolycarbonate and copolycarbonates of isosorbide using dimethyl carbonate: Synthesis, characterization, and properties. J Polym Sci, A: Polym Chem. 2013;51:1387–97.

Lee CH, Takagi H, Okamoto H, Kato M. Preparation and mechanical properties of a copolycarbonate composed of bio-based isosorbide and bisphenol A. Polym J. 2015;47:639–43.

Yokoe M, Aoi K, Okada M. Biodegradable polymers based on renewable resources. VII. Novel random and alternating copolycarbonates from 1,4:3,6-dianhydrohexitols and aliphatic diols. J Polym Sci, A: Polym Chem. 2003;41:2312–21.

Han R, Kida T, Yamaguchi M. Viscoelastic properties of copolycarbonates comprising isosorbide and 1,4-cyclohexanedimethanol. Colloid Polym Sci. 2023;301:1231–8.

Park S-A, Choi J, Ju S, Jegal J, Lee KM, Hwang SY, et al. Copolycarbonates of bio-based rigid isosorbide and flexible 1,4-cyclohexanedimethanol: Merits over bisphenol-A based polycarbonates. Polymer. 2017;116:153–9.

Kricheldorf HR, Sun S-J, Gerken A, Chang T-C. Polymers of Carbonic Acid. 22. Cholesteric polycarbonates derived from (S)-((2-Methylbutyl)thio)hydroquinone or Isosorbide. Macromolecules. 1996;29:8077–82.

Ma C, Xu F, Cheng W, Tan Z, Su Q, Zhang S. Tailoring molecular weight of bioderived polycarbonates via bifunctional ionic liquids catalysts under metal-free conditions. ACS Sustain Chem Eng. 2018;6:2684–93.

Hult D, García-Gallego S, Ingverud T, Andrén OCJ, Malkoch M. Degradable high Tg sugar-derived polycarbonates from isosorbide and dihydroxyacetone. Polym Chem. 2018;9:2238–46.

Chatti S, Kricheldorf HR, Schwarz G. Copolycarbonates of isosorbide and various diols. J Polym Sci, A: Polym Chem. 2006;44:3616–28.

Fang W, Zhang Z, Yang Z, Zhang Y, Xu F, Li C, et al. One-pot synthesis of bio-based polycarbonates from dimethyl carbonate and isosorbide under metal-free condition. Green Chem. 2020;22:4550–60.

Yang Z, Zhang Z, Fu M, Wang W, Shi Y, Li C, et al. One-pot synthesis of isosorbide-based copolycarbonate with good flexibility and tunable thermal property. J Macromol Sci Part A: Pure Appl Chem. 2021;58:398–407.

Yu D, Zhong J, Pu Z, Hou H, Li X, Zhu R, et al. Synthesis and properties of biobased polycarbonate based on isosorbitol. J Polym Res. 2023;30:204.

Wu DH, Chen AD, Johnson CS. An Improved Diffusion-Ordered Spectroscopy Experiment Incorporating Bipolar-Gradient Pulses. J Magn Reason Ser A. 1995;115:260–4.

Rieger J. The glass transition temperature of polystyrene. J Therm Anal. 1996;46:965–72.

Acknowledgements

This work was supported by the JST CREST grant JPMJCR22L1.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rikiyama, K., Matsunami, A., Yoshida, T. et al. Characterization and ammonolysis behavior of poly(isosorbide carbonate)-based copolymers. Polym J 56, 443–453 (2024). https://doi.org/10.1038/s41428-023-00878-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00878-2