Abstract

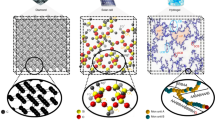

In this review, recent developments in data-driven approaches for structure-property relationships in polymer science are introduced. Understanding the structure-property relationship in polymeric materials is a significant challenge. This is because long molecular chains generate unique structures and properties over a wide range of spatial and temporal scales, which are often difficult to address using theoretical models or single simulation/measurement techniques. Recently, the data-driven modeling of structure-property relationships based on statistical/informatics methods has been employed in polymer science to obtain the desired properties and understand the mechanisms. This review summarizes the reports from this domain in the previous three years. A concept and some methods in data-driven science are first explained to readers unfamiliar with this area. Additionally, various examples, such as the description of a single chain, phase separations, network polymers, and crystalline polymers, are introduced. A topic for dealing with chemically specified coarse-grained simulations is also included. Finally, future perspectives in this area are presented.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Audus DJ, de Pablo JJ. Polymer informatics: opportunities and challenges. ACS Macro Lett. 2017;6:1078–82. https://doi.org/10.1021/acsmacrolett.7b00228.

Butler KT, Davies DW, Cartwright H, Isayev O, Walsh A. Machine learning for molecular and materials science. Nature. 2018;559:547–55. https://doi.org/10.1038/s41586-018-0337-2.

Kim C, Chandrasekaran A, Huan TD, Das D, Ramprasad R. Polymer genome: a data-powered polymer informatics platform for property predictions. J Phys Chem C. 2018;122:17575–85. https://doi.org/10.1021/acs.jpcc.8b02913.

Jackson NE, Webb MA, de Pablo JJ. Recent advances in machine learning towards multiscale soft materials design. Curr Opin Chem Eng. 2019;23:106–14. https://doi.org/10.1016/j.coche.2019.03.005.

Peerless JS, Milliken NJB, Oweida T, Manning MD, Yingling YG. Soft matter informatics: current progress and challenges. Adv Theor Simul. 2019;2:1800129. https://doi.org/10.1002/adts.201800129.

Brinson LC, Deagen M, Chen W, McCusker J, McGuinness DL, Schadler LS, et al. Polymer nanocomposite data: curation, frameworks, access, and potential for discovery and design. ACS Macro Lett. 2020;9:1086–94. https://doi.org/10.1021/acsmacrolett.0c00264.

Chen G, Shen ZQ, Iyer A, Ghumman UF, Tang S, Bi JB, et al. Machine-learning-assisted de novo design of organic molecules and polymers: opportunities and challenges. Polymers. 2020;12:163. https://doi.org/10.3390/polym12010163.

Sherman ZM, Howard MP, Lindquist BA, Jadrich RB, Truskett TM. Inverse methods for design of soft materials. J Chem Phys. 2020;152:140902. https://doi.org/10.1063/1.5145177.

Tran HD, Kim C, Chen LH, Chandrasekaran A, Batra R, Venkatram S, et al. Machine-learning predictions of polymer properties with Polymer Genome. J Appl Phys. 2020;128:171104. https://doi.org/10.1063/5.0023759.

The rise of data-driven modelling. Nat Rev Phys. 2021;3:383. https://doi.org/10.1038/s42254-021-00336-z.

Chen LH, Pilania G, Batra R, Huan TD, Kim C, Kuenneth C, et al. Polymer informatics: current status and critical next steps. Mat Sci Eng R. 2021;144:100595. https://doi.org/10.1016/j.mser.2020.100595.

Clegg PS. Characterising soft matter using machine learning. Soft Matter. 2021;17:3991–4005. https://doi.org/10.1039/d0sm01686a.

Roberts J, Bursten JRS, Risko C. Genetic algorithms and machine learning for predicting surface composition, structure, and chemistry: a historical perspective and assessment. Chem Mater. 2021;33:6589–615. https://doi.org/10.1021/acs.chemmater.1c00538.

Sattari K, Xie YC, Lin J. Data-driven algorithms for inverse design of polymers. Soft Matter. 2021;17:7607–22. https://doi.org/10.1039/d1sm00725d.

Sha WX, Li Y, Tang S, Tian J, Zhao YM, Guo YQ, et al. Machine learning in polymer informatics. Infomat. 2021;3:353–61. https://doi.org/10.1002/inf2.12167.

Upadhya R, Kosuri S, Tamasi M, Meyer TA, Atta S, Webb MA, et al. Automation and data-driven design of polymer therapeutics. Adv Drug Deliv Rev. 2021;171:1–28. https://doi.org/10.1016/j.addr.2020.11.009.

Zhu MX, Deng T, Dong L, Chen JM, Dang ZM. Review of machine learning-driven design of polymer-based dielectrics. Iet Nanodielectr. 2021;1–15. https://doi.org/10.1049/nde2.12029.

Chaikittisilp W, Yamauchi Y, Ariga K. Material evolution with nanotechnology, nanoarchitectonics, and materials informatics: what will be the next paradigm shift in nanoporous materials? Adv Mater. 2022;2107212. https://doi.org/10.1002/adma.202107212.

Patara TK. Data-driven methods for accelerating polymer design. ACS Polym Au. 2022;2:8–26.

Bishop MC. Pattern recognition and machine learning. New York: Springer; 2006.

Hastie T, Tibshirani R, Friedman J. The elements of statistical learning. New York, NY: Springer-Verlag; 2009.

Kruschke KJ. Doing bayesian data analysis: a tutorial with R, JAGS, and Stan. London: Academic Press/Elsevier; 2015.

Goodfellow I, Bengio Y, Courville A. Cambridge, Mass: Deep learning. MIT Press; 2016.

Raschka S, Mirjalili V. Python machine learning: machine learning and deep learning with Python, scikit-learn, and TensorFlow 2, 3rd ed. Birmingham: Packt Publishing, 2019.

Singh V, Kodamana H. Reinforcement learning based control of batch polymerisation processes. Ifac Papersonline. 2020;53:667–72. https://doi.org/10.1016/j.ifacol.2020.06.111.

Endo K, Tomobe K, Yasuoka K. Multi-step time series generator for molecular dynamics. In: Thirty-Second AAAI Conference on Artificial Intelligence/Thirtieth Innovative Applications of Artificial Intelligence Conference/Eighth AAAI Symposium on Educational Advances in Artificial Intelligence, Palo Alto, CA; 2018;2192–9.

Hagita K, Higuchi T, Jinnai H. Super-resolution for asymmetric resolution of FIB-SEM 3D imaging using AI with deep learning. Sci Rep. 2018;8:5877.

Deringer VL, Bartok AP, Bernstein N, Wilkins DM, Ceriotti M, Csanyi G. Gaussian process regression for materials and molecules. Chem Rev. 2021;121:10073–141. https://doi.org/10.1021/acs.chemrev.1c00022.

Motoyama Y, Tamura R, Yoshimi K, Terayama K, Ueno T, Tsuda K. Bayesian optimization package: PHYSBO. Preprint at https://arxiv.org/abs/2110.07900. 2021.

Kaneko H. Data visualization, regression, applicability domains and inverse analysis based on generative topographic mapping. Mol Inf. 2019;38:1800088. https://doi.org/10.1002/minf.201800088.

Shimizu N, Kaneko H. Direct inverse analysis based on Gaussian mixture regression for multiple objective variables in material design. Mater Des. 2020;196:109168. https://doi.org/10.1016/j.matdes.2020.109168.

Yang XF, Zhang JZ, Yoshizoe K, Terayama K, Tsuda K. ChemTS: an efficient python library for de novo molecular generation. Sci Technol Adv Mat. 2017;18:972–6. https://doi.org/10.1080/14686996.2017.1401424.

Takasao G, Wada T, Thakur A, Chammingkwan P, Terano M, Taniike T. Machine learning-aided structure determination for TiCl4-capped MgCl2 nanoplate of heterogeneous Ziegler-Natta catalyst. Acs Catal. 2019;9:2599–609. https://doi.org/10.1021/acscatal.8b05080.

Wu S, Kondo Y, Kakimoto MA, Yang B, Yamada H, Kuwajima I, et al. Machine-learning-assisted discovery of polymers with high thermal conductivity using a molecular design algorithm. Npj Comput Mater. 2019;5, https://doi.org/10.1038/s41524-019-0203-2.

Hatakeyama-Sato K, Oyaizu K. Generative models for extrapolation prediction in materials informatics. Acs Omega. 2021;6:14566–74. https://doi.org/10.1021/acsomega.1c01716.

Tao L, Chen G, Li Y. Machine learning discovery of high-temperature polymers. Patterns. 2021;2:100225, https://doi.org/10.1016/j.patter.2021.

Lee FL, Park J, Goyal S, Qaroush Y, Wang SH, Yoon H, et al. Comparison of machine learning methods towards developing interpretable polyamide property prediction. Polymers. 2021;13:3653. https://doi.org/10.3390/polym13213653.

Wu S, Kondo Y, Kakimoto MA, Yang B, Yamada H, Kuwajima I, et al. Machine-learning-assisted discovery of polymers with high thermal conductivity using a molecular design algorithm. Npj Comput Mater. 2019;5:66. https://doi.org/10.1038/s41524-019-0203-2.

Barnett JW, Bilchak CR, Wang YW, Benicewicz BC, Murdock LA, Bereau T, et al. Designing exceptional gas-separation polymer membranes using machine learning. Sci Adv. 2020;6:eaaz4301. https://doi.org/10.1126/sciadv.aaz4301.

Hatakeyama-Sato K, Tezuka T, Umeki M, Oyaizu K. Al-assisted exploration of superionic glass-type Li+ conductors with aromatic structures. J Am Chem Soc. 2020;142:3301–5. https://doi.org/10.1021/jacs.9b11442

Xu QS, Jiang JW. Machine learning for polymer swelling in liquids. Acs Appl Polym Mater. 2020;2:3576–86. https://doi.org/10.1021/acsapm.0c00586.

Gurnani R, Kamal D, Tran H, Sahu H, Scharm K, Ashraf U, et al. polyG2G: a novel machine learning algorithm applied to the generative design of polymer dielectrics. Chem Mater. 2021;33:7008–16. https://doi.org/10.1021/acs.chemmater.1c02061.

Wan YY, Ramirez F, Zhang X, Nguyen TQ, Bazan GC, Lu G. Data driven discovery of conjugated polyelectrolytes for optoelectronic and photocatalytic applications. Npj Comput Mater. 2021;7:69. https://doi.org/10.1038/s41524-021-00541-5.

Kim C, Chandrasekaran A, Jha A, Ramprasad R. Active-learning and materials design: the example of high glass transition temperature polymers. Mrs Commun. 2019;9:860–6. https://doi.org/10.1557/mrc.2019.78.

Schustik SA, Cravero F, Ponzoni I, Diaz MF. Polymer informatics: expert-in-the-loop in QSPR modeling of refractive index. Comp Mater Sci. 2021;194:110460. https://doi.org/10.1016/j.commatsci.2021.110460.

Khan PM, Rasulev B, Roy K. QSPR modeling of the refractive index for diverse polymers using 2D descriptors. Acs Omega. 2018;3:13374–86. https://doi.org/10.1021/acsomega.8b01834.

Reis M, Gusev F, Taylor NG, Chung SH, Verber MD, Lee YZ, et al. Machine-learning-guided discovery of F-19 MRI agents enabled by automated copolymer synthesis. J Am Chem Soc. 2021;143:17677–89. https://doi.org/10.1021/jacs.1c08181.

Kuenneth C, Schertzer W, Ramprasad R. Copolymer informatics with multitask deep neural networks (vol 54, pg 5957, 2021). Macromolecules. 2021;54:7321–7321. https://doi.org/10.1021/acs.macromol.1c01539.

Lin TS, Coley CW, Mochigase H, Beech HK, Wang WC, Wang Z, et al. BigSMILES: a structurally-based line notation for describing macromolecules. Acs Cent Sci. 2019;5:1523–31. https://doi.org/10.1021/acscentsci.9b00476.

Schustik SA, Cravero F, Martinez MJ, Ponzoni I, Diaz MF. PolyMaS: a new software to generate high molecular weight polymer macromolecules from repeating structural units. Polimery. 2021;66:293–7. https://doi.org/10.14314/polimery.2021.5.2.

Venkatram S, Kim C, Chandrasekaran A, Ramprasad R. Critical assessment of the hildebrand and hansen solubility parameters for polymers. J Chem Inf Model. 2019;59:4188–94. https://doi.org/10.1021/acs.jcim.9b00656.

Kurotani A, Kakiuchi T, Kikuchi J. Solubility prediction from molecular properties and analytical data using an in-phase deep neural network (Ip-DNN). Acs Omega. 2021;6:14278–87. https://doi.org/10.1021/acsomega.1c01035.

Hagita K, Aoyagi T, Abe Y, Genda S, Honda T. Deep learning-based estimation of Flory-Huggins parameter of A-B block copolymers from cross-sectional images of phase-separated structures. Sci Rep. 2021;11:12322. https://doi.org/10.1038/s41598-021-91761-8.

Kumar JN, Li QX, Tang KYT, Buonassisi T, Gonzalez-Oyarce AL, Ye J. Machine learning enables polymer cloud-point engineering via inverse design. Npj Comput Mater. 2019;5:73. https://doi.org/10.1038/s41524-019-0209-9.

Terayama K, Tamura R, Nose Y, Hiramatsu H, Hosono H, Okuno Y, et al. Efficient construction method for phase diagrams using uncertainty sampling. Phys Rev Mater. 2019;3:033802. https://doi.org/10.1103/PhysRevMaterials.3.033802.

Aoyagi T. Deep learning model for predicting phase diagrams of block copolymers. Comp Mater Sci. 2021;188:110224. https://doi.org/10.1016/j.commatsci.2020.110224.

Arora A, Lin TS, Rebello NJ, Av-Ron SHM, Mochigase H, Olsen BD. Random forest predictor for diblock copolymer phase behavior. ACS Macro Lett. 2021;10:1339–45. https://doi.org/10.1021/acsmacrolett.1c00521.

Ethier JG, Casukhela RK, Latimer JJ, Jacobsen MD, Shantz AB, Vaia RA. Deep learning of binary solution phase behavior of polystyrene. ACS Macro Lett. 2021;10:749–54. https://doi.org/10.1021/acsmacrolett.1c00117.

Zhao C, Cai TY, Zhang LS, Li WH, Lin JP. Autonomous construction of phase diagrams of block copolymers by theory-assisted active machine learning. ACS Macro Lett. 2021;10:598–602. https://doi.org/10.1021/acsmacrolett.1c00133.

Aoyagi T. High-throughput prediction of stress-strain curves of thermoplastic elastomer model block copolymers by combining hierarchical simulation and deep learning. Mrs Adv. 2021;6:32–36. https://doi.org/10.1557/s43580-021-00008-1.

Hiraide K, Hirayama K, Endo K, Muramatsu M. Application of deep learning to inverse design of phase separation structure in polymer alloy. Comp Mater Sci. 2021;190:110278. https://doi.org/10.1016/j.commatsci.2021.110278.

Shibayama S, Funatsu K. Industrial case study: identification of important substructures and exploration of monomers for the rapid design of novel network polymers with distributed representation. B Chem Soc Jpn. 2021;94:112–21. https://doi.org/10.1246/bcsj.20200220.

Yan C, Feng XM, Wick C, Peters A, Li GQ. Machine learning assisted discovery of new thermoset shape memory polymers based on a small training dataset. Polymer. 2021;214:123351. https://doi.org/10.1016/j.polymer.2020.123351.

Kang HS, Lee JH, Choe Y, Lee SG. Prediction of lap shear strength and impact peel strength of epoxy adhesive by machine learning approach. Nanomaterials. 2021;11:872. https://doi.org/10.3390/nano11040872.

Ghaderi A, Morovati V, Dargazany R. A physics-informed assembly of feed-forward neural network engines to predict inelasticity in cross-linked polymers. Polymers. 2020;12:2628. https://doi.org/10.3390/polym12112628.

Menon A, Thompson-Colon JA, Washburn NR. Hierarchical machine learning model for mechanical property predictions of polyurethane elastomers from small datasets. Front Mater. 2019;6:87. https://doi.org/10.3389/fmats.2019.00087.

Morita H, Miyamoto A, Kotani M. Recoverably and destructively deformed domain structures in elongation process of thermoplastic elastomer analyzed by graph theory. Polymer. 2020;188:122098. https://doi.org/10.1016/j.polymer.2019.122098.

Amamoto Y, Kojio K, Takahara A, Masubuchi Y, Ohnishi T. Complex network representation of the structure-mechanical property relationships in elastomers with heterogeneous connectivity. Patterns. 2020;1:100135.

Ito MI, Amamoto Y, Ohnishi T. Change of weighted network structure of elastomer during uniaxial elongation. J Comput Chem JPN. 2021;20:89–91. https://doi.org/10.2477/jccj.2021-0040.

Amamoto Y. Quantitative evaluation of connectivity in elastomers for describing rubber elasticity based on network theory. J Soc Rheol Jpn. 2022;50:95–8. https://doi.org/10.1678/rheology.50.95.

Amamoto Y, Kikutake H, Kojio K, Takahara A, Terayama K. Visualization of judgment regions in convolutional neural networks for X-ray diffraction and scattering images of aliphatic polyesters. Polym J. 2021;53:1269–79. https://doi.org/10.1038/s41428-021-00531-w.

Takahashi KK, Amamoto Y, Kikutake H, Ito MI, Takahara A, Ohnishi T. Random forest analysis of X-ray diffraction and scattering data on crystalline polymer. J Comput Chem JPN. 2021;20:103–5. https://doi.org/10.2477/jccj.2021-0042.

Friederich P, Hase F, Proppe J, Aspuru-Guzik A. Machine-learned potentials for next-generation matter simulations. Nat Mater. 2021;20:750–61. https://doi.org/10.1038/s41563-020-0777-6.

Batra R, Sankaranarayanan S. Machine learning for multi-fidelity scale bridging and dynamical simulations of materials. J Phys Mater. 2020;3:031002. https://doi.org/10.1088/2515-7639/ab8c2d.

Takamoto, S, Shinagawa, C, Motoki, D, Nakago, K, Li, W, Kurata, I, et al. PFP: universal neural network potential for material discovery applicable to arbitrary combination of 45 elements. arXiv. 2021. https://ui.adsabs.harvard.edu/abs/2021arXiv210614583T.

Hong SJ, Chun H, Lee J, Kim BH, Seo MH, Kang J, et al. First-principles-based machine-learning molecular dynamics for crystalline polymers with van der Waals interactions. J Phys Chem Lett. 2021;12:6000–6. https://doi.org/10.1021/acs.jpclett.1c01140.

Dhamankar S, Webb MA. Chemically specific coarse-graining of polymers: methods and prospects. J Polym Sci. 2021;59:2613–43. https://doi.org/10.1002/pol.20210555.

Wang J, Olsson S, Wehmeyer C, Perez A, Charron NE, de Fabritiis G, et al. Machine learning of coarse-grained molecular dynamics force fields. Acs Cent Sci. 2019;5:755–67. https://doi.org/10.1021/acscentsci.8b00913.

Webb MA, Jackson NE, Gil PS, de Pablo JJ. Targeted sequence design within the coarse-grained polymer genome. Sci Adv. 2020;6:eabc6216. https://doi.org/10.1126/sciadv.abc6216.

Wang YM, Xie T, France-Lanord A, Berkley A, Johnson JA, Shao-Horn Y, et al. Toward designing highly conductive polymer electrolytes by machine learning assisted coarse-grained molecular dynamics. Chem Mater. 2020;32:4144–51. https://doi.org/10.1021/acs.chemmater.9b04830.

Giuntoli A, Hansoge NK, van Beek A, Meng ZX, Chen W, Keten S. Systematic coarse-graining of epoxy resins with machine learning-informed energy renormalization. Npj Comput Mater. 2021;7:168. https://doi.org/10.1038/s41524-021-00634-1.

Li W, Burkhart C, Polinska P, Harmandaris V, Doxastakis M. Backmapping coarse-grained macromolecules: an efficient and versatile machine learning approach. J Chem Phys. 2020;153:041101. https://doi.org/10.1063/5.0012320.

Sivaraman G, Jackson NE. Coarse-grained density functional theory predictions via deep kernel learning. J Chem Theory Comput. 2022;1129−1141. https://doi.org/10.1021/acs.jctc.1c01001.

Acknowledgements

This work was supported by the JSPS Grant-in-Aid for Scientific Research on Innovative Areas, Discrete Geometric Analysis for Materials Design: 20H04644, by the Grant-in-Aid for Scientific Research (B): 20H02800, and by Early-Career Scientists: 18K14273 from JSPS.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amamoto, Y. Data-driven approaches for structure-property relationships in polymer science for prediction and understanding. Polym J 54, 957–967 (2022). https://doi.org/10.1038/s41428-022-00648-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-022-00648-6