Abstract

In the close vicinity of a hot solid, at distances smaller than the thermal wavelength, a strong electromagnetic energy density exists because of the presence of evanescent field. Here we introduce a many-body conversion principle to harvest this energy using graphene-based pyroelectric conversion devices made with an active layer encapsulated between two graphene field-effect transistors which are deposited on the source and on the cold sink. By tuning the bias voltage applied to the gates of these transistors, the thermal state and the spontaneous polarization of the active layer can be controlled at kHz frequencies. We demonstrate that the power density generated by these conversion systems can reach \(130\,{\rm mW\,cm}^{-2}\) using pyroelectric Ericsson cycles, a value which surpasses the current production capacity of near-field thermophotovoltaic conversion devices by more than three orders of magnitude with low grade heat sources (\(T<500\,{\rm K}\)) and small temperature differences (\(\Delta T\sim 100\,K\)).

Similar content being viewed by others

Introduction

Over 60% of energy used in industry is lost as low grade waste heat. This heat constitutes an important source of available renewable energy. Unfortunately, few thermodynamic cycles can operate at low temperature streams effectively1. Thermophotovoltaic2 (TPV) generation of electricity from thermal radiation emitted by hot sources was expected to play a major role in harvesting this waste heat. However, the energy flux exchanged between the primary source and the cell in these devices is intrinsically limited by the Stefan–Boltzmann law (i.e. the heat flux exchanged between two blackbodies), setting so a relatively low upper bound3 for the generated power. In the 70’s, an important step forward has been taken to improve the performances of this technology. Indeed, when the source and the cell are separated by a subwavelength distance, the near-field energy4 can be transferred to the cell by the tunneling of non-propagating photons5,6,7,8, so that the heat flux can largely exceed the limit set by the blackbody theory. This energy transfer in the near-field regime paved the way for a novel technology, the so-called near-field thermophotovoltaic9,10,11,12 (NTPV) energy conversion. Although theoretically this technology can lead to a generated power of about \(1\,\)W cm\(^{-2}\) with heat sources at \(T>500\,\)K and separation distances with the cell of few hundred nanometers (10 W cm\(^{-2}\) being today the energy demand of a household in US), several hurdles still limit today its development and massive deployment. One of the main limitations is the mismatch between the emission frequency of evanescent modes supported by the source and the gap frequency of the junction, the frequency below which the photon energy is dissipated as heat into the cell, reducing dramatically its performance. So, despite its theoretical potential, only generated powers of few \(\upmu \)W cm\(^{-2}\) were reported11,12 so far with such devices and heat sources around \(T=500\,\)K.

In 2010, Fang et al.13 proposed an alternative way to harvest the near-field thermal energy by using a pyroelectric converter. In this technology, an active layer made with a pyroelectric material undergoes a temporal variation of its temperature in response to a periodic modulation of the separation distance between this layer and two external thermostats (the hot source and the cold sink). With a distance of 100 nm, an operating frequency of a few Hz and an electric power of \(6.5\,\)mW cm\(^{-2}\) were predicted with a source and a sink at temperatures \(T_1=383\,\)K and \(T_3=283\,\)K, respectively. Improving the performances of these converters by increasing their operating frequency up to kHz without reducing the amplitude of the temperature modulation of the active layer could in principle make them competitive with the NTPV technology and could even surpass it. However, this remains today a challenging problem, since it requires working with thin active layers at smaller separation distances from the source and the sink, distances for which the Casimir force induced by the vacuum fluctuations limits the possibility of moving the active layer with a reasonable energy consumption (this force per unit area is of the order of 10 N m\(^{-2}\) for a separation of 100 nm and it increases to 10\(^5\) N m\(^{-2}\) at 10 nm). Here we address these challenges by introducing a static (non-mechanical) pyroelectric converter based on GETs14 (Fig. 1a), whose properties can be externally controlled with an applied voltage in order to modulate at kHz frequencies the near-field interactions between the pyroelectric membrane and both the source and the sink. Rather than using a conversion device based on pyroelectric/graphene heterostructures15, here it is the thermal source and the sink which are coated by graphene in order to be able to actively change their surface state. Hence, by dynamically controlling the charge density of the graphene sheets and exploiting the tunability of surface wave coupling16 between the different elements of the converter, we demonstrate that these pyroelectric devices can generate an electric power larger than a hundred mW cm\(^{-2}\) with low grade heat sources. Moreover, on the contrary to solid-state pyroelectric converters operating at kHz frequencies17,18, we demonstrate that our graphene-based pyroelectric system is a self-powered or autonomous conversion device in which the power required to modulate the temperature is much smaller than the delivered power, opening so a new avenue for high-frequency pyroelectric energy harvesting from stationary thermal sources.

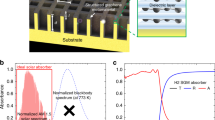

Graphene-based pyroelectric converter. (a) Schematic illustration of the device: a pyroelectric membrane (active zone) is suspended between two GFETs (thermal reservoirs) held at two different temperatures \(T_1\) (primary source) and \(T_3<T_1\) (thermal sink). A modulation of bias voltages \(V_{g1}\) and \(V_{g2}\) applied to the GFET gates allows to oscillate the temperature \(T_2\) of the membrane which generates useful power due to pyroelectric effect. The electrodes in the active zone serve to extract electric charge and apply electric field. (b) Crystallographic structure of BaTiO\(_3\) showing that a permanent polarization \(\mathbf{P} \) exists in the c-direction when T is smaller than the Curie temperaure \(T_C\). (c) Heat flux received by the membrane during the heating-cooling steps induced by the bias voltages cycling for a layer of BaTiO\(_3\) of thickness \(\delta _p=3\,\upmu \)m. (d) Temporal evolution of the membrane while the bias voltages are modulated at frequency \(f=0.2\,\)kHz with turn-on values \(V_{g1}=V_{g2}=1\,\)V. (e) Short-circuit pyroelectric current density.

Results

Pyroelectric conversion of near-field energy in three-body systems

The proposed device consists in an active membrane made with a pyroelectric layer of thickness \(\delta _p\) which is covered on both sides by a gold (Au) layer, acting as electrode, and a superficial silica (SiO\(_2\)) layer which supports a surface wave in the infrared. The electrodes are taken sufficiently thick (here 200 nm) in order to screen the incoming electromagnetic field in the infrared, while the thickness of SiO\(_2\) layers is chosen small enough (here 50 nm) to limit the thermal inertia of the active membrane. As sketched in Fig. 1a, this membrane (body 2) at temperature \(T_2\) is encapsulated without contact between a hot source (body 1) and a cold sink (body 3) at temperatures \(T_1\) and \(T_3\), respectively. These two thermal reservoirs consist in a multilayer structure made with a n-doped silicon (Si) substrate surmounted by a SiO\(_2\) layer of thickness \(\delta _g=5\,\)nm which is itself covered by a graphene sheet, the whole constituting a GFET. By applying an external bias voltage \(V_{gi}\) on the gate of each of these GFETs operating in cut-off mode (i.e. no current flows from the GFET source to the drain), the superficial carrier density14 \(n_{gi}=C_gV_{gi}/e\) on the graphene sheet and therefore its chemical potential \(\mu _{gi}= \hbar v_F\sqrt{\pi n_{gi}}\) can be actively controlled (here e is the electron charge, \(\hbar \) is the reduced Planck constant, \(v_F=10^6\) m/s is the Fermi velocity and \(C_g=\varepsilon _g/\delta _g\) is the capacitance per unit surface of the GFET, \(\varepsilon _g\) being the permittivity of the dielectric layer). It follows that the radiative coupling between the active membrane and the two thermal reservoirs can also be dynamically tuned with the modulation of these bias voltages.

In contrast to the Fang et al. converter13, in our three-terminal device the separation distance between the active membrane and the two reservoirs is kept fixed and equal to \(d=20\,\)nm while the bias voltages \(V_{g1}\) and \(V_{g2}\) applied on the GFETs undergo periodic rectangular modulations at frequency f in phase opposition. According to the theory of radiative heat transfer in many-body systems19,20, the net power per unit surface received by the active layer reads

Here \(\varphi _{mn}(\omega )= \theta _{mn}(\omega )\sum _{l = \{{\mathrm{TE,TM}}\}} \int \frac{d^2{\mathbf {k}}}{(2\pi )^2} {\mathcal {T}}_l^{mn}(\omega ,k)\) represents the spectral flux at frequency \(\omega \), weighted by the transmission coefficient \({\mathcal {T}}_l^{mn}(\omega ,k)\) which describes the coupling efficiency, in polarization l, of the mode \((\omega ,k)\) between bodies m and n, \({\mathbf {k}}\) being the wavevector parallel to the surfaces (\(k=|{\mathbf {k}}|\)) and \(\hbar \omega \) the energy carried by the mode (see “Methods”). In this expression \(\theta _{mn}(\omega )=\theta (\omega ,T_m)-\theta (\omega ,T_n)\) denotes the difference of photon mean energies at temperatures \(T_m\) and \(T_n\), associated to bodies m and n, respectively. Since the gate voltages \(V_{gi}\) are dynamically modulated, the temperature variation of the active membrane (pyroelectric material covered by the electrodes and the SiO\(_2\) layers) is driven by the energy balance equation \(c_v\delta \,dT_2/dt={\mathcal {P}}_{r}(V_{gi};T_2,t)\), where \(c_v\) is the volumetric heat capacity of the membrane and \(\delta \) its thickness (see Supplementary Information, Section 1).

Electric current generation and performances of the pyroelectric converter

To demonstrate the potential of these converters, we first consider barium titanate (BaTiO\(_3\)) ceramic layer of thickness \(\delta _p=3\,\upmu \)m in the ferroelectric phase (Fig. 1b) as the pyroelectric material21 and reservoir temperatures \(T_1=400\,\)K and \(T_3=300\,\)K. The cyclic modulation of the energy flux (Fig. 1c) received by the active membrane induces a time variation of its temperature as shown in Fig. 1d. This leads to a change in the spontaneous electric dipolar moment of pyroelectric material and modifies the density of interfacial charges on the electrodes. This variation is characterized by the pyroelectric coefficient21 \(p=\frac{\partial P}{\partial T}\) in the direction of the poling field, P being the electric polarization. If the electrodes of the pyroelectric capacitor are connected to an electric circuit, the generated current density is given by22 \(i_p=p(T_2)\, dT_2/dt\), which is plotted in Fig. 1e for \(f=0.2\,\)kHz and \(V_{g1}=V_{g2}=1\,\)V (temperature-dependent pyroelectric coefficient, specific heat23 and permittivity24 of BaTiO\(_3\) are given in Supplementary Information, Section 2). It is noteworthy that the thermal response \(T_2(t)\) of the BaTiO\(_3\) layer becomes periodic at the same frequency as the bias voltages after a transient delay (corresponding to the loss of memory of initial conditions). Implementing the so-called synchronized electric charge extraction (SECE) cycle25, which consists in extracting the electric charge stored in the active material when its temperature \(T_2(t)\) reaches the maximum and minimum values \(T_{\rm max}\) and \(T_{\rm min}\), respectively, the energy per unit surface generated during a cycle reads

where \(\varepsilon _{33}\) denotes the permittivity of the pyroelectric material in the polarization direction (see Supplementary Information, Section 3 for details). Besides, the energy dissipated to charge the graphene capacitors during a cycle is given by \(W_g=\frac{1}{2}C_g(V_{g1}^2 + V_{g2}^2)\), so that the net power per unit surface delivered by a converter with operating frequency f can be estimated as \({\mathcal {P}}=f(W_p-W_g)\). Thus, the conversion efficiency is \(\eta =(W_p-W_g)/W_{\rm in}\), where the input energy \(W_{\rm in}\) corresponds to the energy absorbed by the active layer during the heating stage of cycle, \(W_{\rm in}=\delta \int _{T_{\rm min}}^{T_{\rm max}} c_v(T_2)\,dT_2\).

Performances of the converter with SECE cycles. (a) Ratio of the energy \(W_p\) generated per cycle to the energy \(W_g\) required to tune the gate voltages. (b) Power generated by the converter in response to the periodically varying (rectangular) bias voltage applied on the gate of the GFETs at the frequency f with a primary source at \(T_1=400\,\)K. (c) Conversion efficiency \(\eta =(W_p-W_{g})/W_{\rm in}\) normalized by the Carnot efficiency \(\eta _C\). (d) Time variation of the active layer temperature. (e) Generated power and (f) conversion efficiency with respect to the FOM \(p^2/\varepsilon _{33}\). In all figures, \(T_3=300\,\)K and \(V_{g1}=V_{g2}=1\,\)V when these voltages are switched on.

The ratio \(W_p/W_g\) plotted in Fig. 2a, shows that a small amount of energy is used to charge the GFETs capacitor up to a modulation frequency of about 1.5 kHz. This ratio is approximately constant for small frequencies, the variation amplitude of the active layer temperature having reached its upper value. Beyond this plateau, \(W_p/W_g\) decreases while the variation amplitude of the temperature decreases as well. Since \(W_p/W_g>1\) at kHz frequencies, the energy generated per cycle is larger than the energy used to tune the state of GFETs, demonstrating so that these devices can be self-powered throughout the conversion process. The corresponding useful (net) power \({\mathcal {P}}\) is shown in Fig. 2b and the conversion efficiency in Fig. 2c, the latter being rescaled with the Carnot efficiency \(\eta _C=1-T_3/T_1\). The delivered power with this material reaches values around 10 mW cm\(^{-2}\) at frequencies of fraction of kHz. To assess the potential of this technology with other pyroelectric materials we consider a simplified form for the generated energy25 \(W_p=\delta _p (T_{\rm max}-T_{\rm min})^2p^2/\varepsilon _{33}\) when the materials properties are assumed to be independent of temperature. This expression depends on the figure of merit (FOM) \(p^2/\varepsilon _{33}\) characterizing the pyroelectric performance of the material22. Parametrizing material properties with this FOM, in Fig. 2d–f we estimate the performance of the converter for different source temperatures. The specific heat of different pyroelectric materials is set to \(2.5\times 10^6\,\)J m\(^{-3}\) K\(^{-1}\), a value which is representative of most ferroelectric materials25 as indicated in Fig. 2e for some of them for guidance reasons. We observe that a power of a few mW cm\(^{-2}\) can be obtained even for small temperature differences. Moreover, neglecting the temperature dependence in \(W_p\) and writing \(W_g\) in terms of the carrier densities \(n_{gi}\) in the graphene sheets, we find that

showing a certain flexibility for those systems to achieve \(W_p/W_g>1\) by an appropriate choice of thicknesses (capacitances) in the GFETs and the active layer.

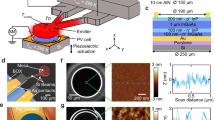

Coupling tunability in near-field regime. (a)–(d) Transmission coefficients \({\mathcal {T}}^{\text {12}}_{\rm TM}\) and \({\mathcal {T}}^{\text {23}}_{\rm TM}\) in the \((\omega ,k)\) plane between the primary source at \(T_1=383\,\)K and the active layer and between the active layer and the thermal sink at \(T_3=283\,\)K, respectively, for \(T_2=343\,\)K. Cyan curves represent the light line \(\omega =ck\). Dashed red and blue lines denote the difference of Planck functions \(\omega ^2\theta _{12}\) and \(\omega ^2\theta _{23}\) (Planck windows), respectively, where heat transfer takes place. Resonances around the frequencies \(0.9\times 10^{14}\,\)rad/s and \(2.2\times 10^{14}\,\)rad/s correspond to the symmetric and antisymmetric SPPs supported by the SiO\(_2\) layers, while dashed green lines repesent the surface plasmon dispersion relation of graphene for chemical potentials \(\mu _{g1}=0.33\,\)eV in (b) and \(\mu _{g2}=0.48\,\)eV in (c). The anticrossing curves in (b) and (c) show the strong coupling between the SPPs of silica and the delocalized plasmon of graphene. (e) Spectrum of the heat exchange between the source and the active zone (\(\varphi _{12}\)) and between the active zone and the sink (\(\varphi _{23}\)). (f) Radiative heat flux on the active zone for the heating and cooling processes.

Switchability of surface modes coupling with the graphene plasmon

To give an insight into the coupling mechanism of thermal photons in the converter, we show in Fig. 3a–d the transmission coefficients for TM polarization (strongly dominant) of the energy carried by the electromagnetic modes \((\omega ,k)\) between the active zone and the GFETs. We also show the Planck windows where the heat transfer takes place (dashed blue and red lines). For \(V_{gi}=0\), we see in Fig. 3a, d that the heat transfer is mainly mediated by hybridized (symmetric and antisymmetric) surface phonon polaritons (SPPs) supported by the SiO\(_2\) layers on both the GFETs and the active zone, at frequencies about \(0.9\times 10^{14}\,\)rad s\(^{-1}\) and \(2.2\times 10^{14}\,\)rad s\(^{-1}\). When the bias voltage is switched on, the coupling of SPPs through the gap is reduced by the presence of delocalized graphene plasmon on the GFET, whose dispersion relation is shown in dashed green lines in Fig. 3b, c. Consequently, the number of modes participating in the heat transfer around the SPP resonances decreases significantly when the GFET is charged. Hence, by tuning the gate voltage in the GFETs we can actively and locally (Fig. 3e) control the near-field heat exchanges in the converter during the heating and cooling stages of the cycle (Fig. 3f).

Performances of the converter with Ericsson cycles. (a) Maximum and minimum temperatures of the active zone during the modulation as a function of the frequency f. The active material is the relaxor ferroelectric 0.9PMN–0.1PT with an overall thickness \(\delta _p=3\,\upmu \)m. (b) Temperature of the active zone and cut of the configuration space \((f,V_{g1},V_{g2})\) leading to temperature oscillations with \(T_{\rm max}=348\,\)K and \(T_{\rm min}=338\,\)K. (c) Generated power as a function of the turn-on voltage \(V_{g2}\). (d) Generated power as a function of the modulation frequency f. The insets in (c) and (d) show the ratio of the energy \(W_p\) generated per cycle to the energy \(W_g\) required to tune the gate voltages.

Near-field pyroelectric conversion in Ericson-cycle mode

Implementing the SECE cycle as previously discussed is efficient when the temperature changes of ferroelectric materials take place close to their Curie temperature. Unfortunatly, when we move away from this critical temperature their pyroelectric coefficient drops sharply limiting so the electric current generation25. However, more efficient thermodynamic cycles can be used to improve the performances of conversion process, such as Ericsson cycles consisting in two isothermal and two isoelectric stages26. These cycles require the action of an external electric field E on the pyroelectric material. By neglecting the temperature dependence of the pyroelectric coefficient in the considered working temperature range and assuming that the heat capacity does not depend on the electric field, the energy per unit surface generated with this cycle can be written as27

where \(E_{\rm max}\) is the maximum value of the applied field (see Supplementary Information, Section 4 for details). In this case the net power \({\mathcal {P}}\) and the conversion efficiency \(\eta \) take the same form as previously but the input energy becomes \(W_{\rm in}=\delta \int _{T_{\rm min}}^{T_{\rm max}} c_v(T_2)\,dT_2 + \delta _pT_{\rm max}\int _0^{E_{\rm max}} p(E)\,dE\). Indeed in Ericsson cylces it includes also heat absorption due to electrocaloric effect at the high temperature isotherm. Hence, high performances can be achieved with materials showing a large electrocaloric activity27, as reported, for instance, in the thin film relaxor ferroelectric28 0.90Pb(Mg\(_{1/3}\)Nb\(_{2/3}\))O\(_3\)-0.10PbTiO\(_3\) (also denoted as 0.9PMN–0.1PT) for a field \(E_{\rm max}=895\,\)kV/cm. An energy density of pyroelectric conversion \(W_p/\delta _p=0.432\,\)J cm\(^{-3}\) has been estimated27 for this material, with working temperatures corresponding to \(T_{\rm min}=338\,\)K and \(T_{\rm max}=348\,\)K. This allows us to evaluate the performance of our converter under these conditions, as also considered by Fang et al.13 To enhance the generated current we structure the pyroelectric material (0.9PMN–0.1PT) in a series of ten parallel thin films of thickness 300 nm separated by Au electrodes of thickness 50 nm, so that \(\delta _p=3\,\upmu \)m, and the specific heat of 0.9PMN–0.1PT is taken as27 \(3\times 10^6\,\)J m\(^{-3}\) K\(^{-1}\). For a source and a sink at temperatures \(T_1=383\,\)K and \(T_3=283\,\)K, respectively, we show in Fig. 4a the evolution of \(T_{\rm max}\) and \(T_{\rm min}\) as a function of the driving frequency f in the GFETs with actuated voltages \(V_{g1}=1.9\,\)V and \(V_{g2}=4\,\)V (as shown in Fig. 3). The proper range of working temperatures is achieved at \(f=1.02\,\)kHz for this configuration, but other possibilities exist because of the freedom to choose the control parameters of the device. In Fig. 4b we show a cut of the configuration space \((f,V_{g1},V_{g2})\) leading to the required temperature oscillations in the active zone. The corresponding power \({\mathcal {P}}\) reaches values of about \(130\,\)mW cm\(^{-2}\) with energy ratios \(W_p/W_g\gg 1\), which are both plotted in Fig. 4c, d as a function of the frequency f and actuated voltage \(V_{g2}\), respectively. Moreover, ignoring the loses \(W_g\), the efficiency ratio \(\eta /\eta _C\) for these configurations takes a value of 3.2%. It is worthwhile to note that the power density is about 200 times larger than the result reported by Fang et al.13.

Conclusions

We have introduced an innovative solution to harvest energy from low-grade heat sources using many-body pyroelectric systems driven at kHz frequencies by GFETs. We have shown that these converters are very efficient for the conversion of the low grade heat into electricity. Generated power densities up to 130 mW cm\(^{-2}\) have been predicted with relaxor ferroelectrics used in Ericsson cycles with temperatures differences of 100 K between the primary source and the cold sink. In addition, we have shown that the power generated by these autonomous systems surpasses the current production of NTPV devices11,12 by several orders of magnitude. Beyond its potential for near-field energy conversion, nanoscale solid-state cooling and nanoscale thermal management could also benefit from this technology.

Methods

Energy transmission coefficients

In a three-body system as sketched in Fig. 1a, the radiative heat exchange takes place, in general, through all bodies in the system, including a direct exchange between the source and the sink when the active zone is partially transparent to electromagnetic radiation. However, under the assumption that the electrodes in the active zone are opaque, meaning that these layers are optically thick, there is no direct heat exchange between the source and the sink. This amounts to consider the electrodes as semi-infinite slabs, for which the many-body energy transmission coefficients20 in this case reduce to

with the source-sink coupling \({\mathcal {T}}^{13}_l=0\), where \(d_{mn}\) is the separation distance between bodies m and n, \(k_z = \sqrt{\omega ^2/c^2 -k^2}\) is the normal component of wavevector in vacuum, \(\rho ^m_l\) is the Fresnel reflection coefficients of body m, and \(\Pi ^{\rm pw}=h(\omega -ck)\) and \(\Pi ^{\rm ew}=h(ck-\omega )\) are the propagating and evanescent wave projectors, respectively, c being the speed of light and h(x) the Heaviside step function. Here the coefficients \(\rho _l^1\) and \(\rho _l^3\) correspond to the reflection coefficient of a bilayer with n-doped Si as substrate and a superficial layer of SiO\(_2\) covered by the graphene sheet, while the coefficient \(\rho _l^2\) correspond to a bilayer with Au as substrate and a superficial layer of SiO\(_2\).

Optical properties

For the materials in the source and sink, we consider an n-type heavily doped Si substrate whose dielectric properties are given by the Drude model

where29,30 the high-frequency dielectric constant is \(\varepsilon _{\infty }=11.7\), the plasma frequency is given by \(\omega _p=\sqrt{Ne^2/(m^*\varepsilon _0)}\) and the scattering rate is obtained as \(\gamma =e/(\mu _e m^*)\), where \(\varepsilon _0\) is the vacuum permittivity, N is the carrier concentration, \(m^*= 0.27m_0\) is the carrier effective mass and \(\mu _e\) is the carrier mobility, \(m_0\) being the free electron mass. In the present study we take the carrier concentration as \(N=10^{20}\,\)cm\(^{-3}\). Furthermore, the dielectric permittivity of the Au electrodes in the active zone are also described by the Drude model (6) with \(\varepsilon _{\infty }=1\), \(\gamma =5.32\times 10^{13}\,\)s\(^{-1}\) and \(\omega _p=1.37\times 10^{16}\,\)rad s\(^{-1}\). The dielectric permittivity of SiO\(_2\) is tabulated in Ref.31.

The response of the graphene sheets is described in terms of a 2D frequency-dependent conductivity \(\sigma (\omega )=\sigma _D(\omega )+\sigma _I(\omega )\) with intraband and interband contributions respectively given by32

where \(G(x)=\sinh (x/k_BT)/[\cosh (\mu /k_BT)+\cosh (x/k_BT)]\). As these expressions show, the conductivity depends explicitly on the temperature T of the graphene sheet, its chemical potential \(\mu \) and the relaxation time \(\tau \) for which we have used the value33 \(\tau =10^{-13}\,\)s. Since the graphene sheet lays on the surface of a medium with permittivity \(\varepsilon (\omega )\) (this medium here is SiO\(_2\)), the conductivity \(\sigma (\omega )\) modifies the vaccum-medium Fresnel reflection and transmission coefficients of the interface \(r_l\) and \(t_l\), respectively, which for the two polarizations take the form32,34

where \(\mu _0\) is the vacuum permeability and \(k_{zm}=\sqrt{\varepsilon (\omega ) \omega ^2/c^2-k^2}\) is the normal component of the wave vector in the medium. The dispersion relation of graphene plasmon is given by the zeros of the denominator of Fresnel coefficients in TM polarization.

References

DiSalvo, F. J. Thermoelectric cooling and power generation. Science 285, 703–706 (1999).

Lenert, A. et al. A nanophotonic solar thermophotovoltaic device. Nat. Nanotechnol. 9, 126–130 (2014).

Coutts, T. J. A review of progress in thermophotovoltaic generation of electricity. Renew. Sustain. Energy Rev. 3, 77–184 (1999).

Eckhardt, W. Radiation laws in the vincinity of metallic boundaries. Z. Phys. B Condens. Matter 46, 85–94 (1982).

Polder, D. & Van Hove, M. Theory of radiative heat transfer between closely spaced bodies. Phys. Rev. B 4, 3303 (1971).

Ottens, R. S. et al. Near-field radiative heat transfer between macroscopic planar surfaces. Phys. Rev. Lett. 107, 014301 (2011).

Song, B. et al. Radiative heat conductances between dielectric and metallic parallel plates with nanoscale gaps. Nat. Nanotechnol. 11, 509–514 (2016).

St-Gelais, R., Zhu, L., Fan, S. & Lipson, M. Near-field radiative heat transfer between parallel structures in the deep subwavelength regime. Nat. Nanotechnol. 1, 515–519 (2016).

DiMatteo, R. S. et al. Enhanced photogeneration of carriers in a semiconductor via coupling across a nonisothermal nanoscale vacuum gap. Appl. Phys. Lett. 79, 1894 (2001).

Narayanaswamy, A. & Chen, G. Surface modes for near field thermophotovoltaics. Appl. Phys. Lett. 82, 3544 (2003).

Fiorino, A. et al. Nanogap near-field thermophotovoltaics. Nat. Nanotechnol. 13, 806–811 (2018).

Bhatt, G. R. et al. Integrated near-field thermo-photovoltaics for heat recycling. Nat. Commun. 11, 2545 (2020).

Fang, J., Frederich, H. & Pilon, L. Harvesting nanoscale thermal radiation using pyroelectric materials. J. Heat Transf. 132, 092701 (2010).

Novoselov, K. et al. Electric field effect in atomically thin carbon films. Science 306, 666 (2004).

Han, Z. et al. The thermal-to-electrical energy conversion in (Bi0.5Na0.5)0.94Ba0.06TiO3/graphene oxide heterogeneous structures. Ceram. Int.45, 24493–24499 (2019).

Messina, R. & Ben-Abdallah, P. Graphene-based photovoltaic cells for near-field thermal energy conversion. Sci. Rep. 3, 1383 (2013).

Bhatia, B. et al. High power density pyroelectric energy conversion in nanometer-thick BaTiO\(_3\) films. Nanoscale Microscale Thermophys. Eng. 20, 137–146 (2016).

Pandya, S. et al. Pyroelectric energy conversion with large energy and power density in relaxor ferroelectric thin films. Nat. Mater. 17, 432–438 (2018).

Ben-Abdallah, P., Biehs, S.-A. & Joulain, K. Many-body radiative heat transfer theory. Phys. Rev. Lett. 107, 114301 (2011).

Latella, I., Ben-Abdallah, P., Biehs, S.-A., Antezza, M. & Messina, R. Radiative heat transfer and nonequilibrium Casimir–Lifshitz force in many-body systems with planar geometry. Phys. Rev. B 95, 205404 (2017).

Lang, S. B., Rice, L. H. & Shaw, S. A. Pyroelectric effect in barium titanate ceramic. J. Appl. Phys. 40, 4335 (1969).

Bowen, C. R. et al. Pyroelectric materials and devices for energy harvesting applications. Energy Environ. Sci. 7, 3836 (2014).

Davitadze, S. T. et al. Specific heat and thermal conductivity of BaTiO\(_3\) polycrystalline thin films. Appl. Phys. Lett. 80, 1631 (2002).

Merz, W. J. The electric and optical behavior of BaTiO\(_3\) single-domain crystals. Phys. Rev. 76, 1221 (1949).

Sebald, G., Lefeuvre, E. & Guyomar, D. Pyroelectric energy conversion: optimization principles. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 55, 3 (2008).

Olsen, R. B., Bruno, D. A. & Briscoe, J. M. Pyroelectric conversion cycles. J. Appl. Phys. 58, 4709–4716 (1985).

Sebald, G., Pruvost, S. & Guyomar, D. Energy harvesting based on Ericsson pyroelectric cycles in a relaxor ferroelectric ceramic. Smart Mater. Struct. 17, 015012 (2008).

Mischenko, A. S., Zhang, Q., Whatmore, R. W., Scott, J. F. & Mathur, N. D. Giant electrocaloric effect in the thin film relaxor ferroelectric 0.90Pb(Mg\(_{1/3}\)Nb\(_{2/3}\))O\(_3\)\(-\)0.10PbTiO\(_3\) near room temperature. Appl. Phys. Lett.89, 242912 (2006).

Basu, S., Lee, B. & Zhang, Z. M. Infrared radiative properties of heavily doped silicon at room temperature. J. Heat Transf. 132, 023301 (2010).

Fu, C. J. & Zhang, Z. M. Nanoscale radiation heat transfer for silicon at different doping levels. Int. J. Heat Mass Transf. 49, 1703 (2006).

Palik, E. Handbook of Optical Constants of Solids (Academic Press, London, 1998).

Falkovsky, L. A. Optical properties of graphene. J. Phys: Conf. Ser. 129, 012004 (2008).

Jablan, M., Buljan, H. & Soljačić, M. Plasmonics in graphene at infrared frequencies. Phys. Rev. B 80, 245435 (2009).

Stauber, T., Peres, N. M. R. & Geim, A. K. Optical conductivity of graphene in the visible region of the spectrum. Phys. Rev. B 78, 085432 (2008).

Acknowledgements

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie Grant Agreement No. 892718 (I.L.).

Author information

Authors and Affiliations

Contributions

I.L. and P.B.-A. contributed equally to this work.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Latella, I., Ben-Abdallah, P. Graphene-based autonomous pyroelectric system for near-field energy conversion. Sci Rep 11, 19489 (2021). https://doi.org/10.1038/s41598-021-98656-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-021-98656-8

This article is cited by

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.