Solar power is the cheapest source of renewable energy available to produce hydrogen.Credit: Timothy Hearsum/Getty Images

To steer economies away from fossil fuels and to cut carbon emissions, hydrogen needs to be produced from low-carbon energy sources, such as wind and solar power. This green hydrogen is particularly attractive to certain big-energy users such as the shipping, aviation and steel industries, which would struggle to run on batteries or plug into renewable energy directly through power grids. And producing hydrogen is straightforward: electricity zapped into water splits the H2O molecules into hydrogen and oxygen, which bubble off as gaseous H2 and O2. The hydrogen can then be piped to where energy is needed.

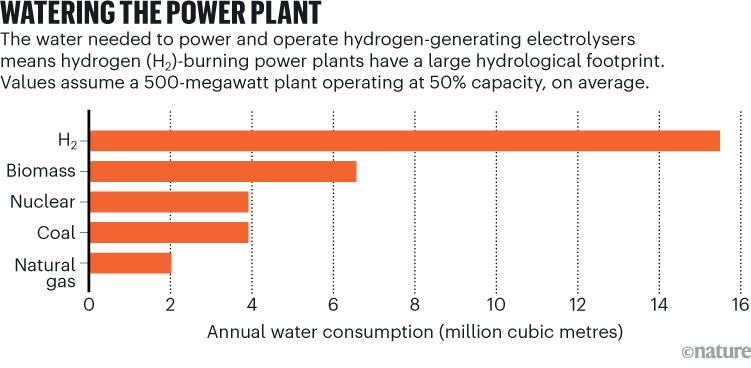

In a world of growing water stress, however, the process’s reliance on water is raising alarm (see ‘Watering the power plant’). Earlier this year, the non-governmental organization Food & Water Watch in Washington DC warned that, by 2050, hydrogen production could gulp down as much water as is used by 34 million US citizens each year. A spate of studies over the past few years provides a more positive picture, however, presenting evidence that scaling up hydrogen production need not threaten water supplies. “Water withdrawals for hydrogen production are negligible compared to total water withdrawals,” says Lorenzo Rosa, an environmental engineer who specializes in links between water, energy and food at the Carnegie Institution for Science in Palo Alto, California.

Source: E. Grubert. Clean. Prod. Lett. 4, 100037 (2023).

Still, Rosa says that water considerations should shape how and where hydrogen is produced, especially because heat and altered precipitation driven by climate change are tightening pressure on water supplies. “Hydrogen’s water consumption is small compared to what’s currently used in fossil-energy conversion and inconsequential compared to agricultural water use,” says Jack Brouwer, director of the Clean Energy Institute at the University of California, Irvine. “But there are serious water availability and delivery challenges at the local and regional levels that will need to be considered.”

Brouwer and Rosa say that expanding hydrogen-production technologies and water-treatment options could enable hydrogen producers to tap into a range of non-potable water resources — including seawater — or to slash their water consumption. At the same time, geospatial analyses that maps water and renewable-energy resources against projected hydrogen production and demand can pinpoint where investing in water-saving technology — or deciding to import rather than produce hydrogen — will be key to minimizing tension between the push for hydrogen and the need to preserve water resources.

A thirsty process

The water requirements for producing hydrogen by electrolysis begin with a simple calculation: every kilogram of H2 molecules requires 9 litres of H2O. Treatment to purify that water — eliminating minerals that would gum up the works — consumes another 15 litres of water per kilogram of H21.

That’s not the end of the story, however. There’s a lot more water use to be counted if the renewable energy that powers the process is included. The operation of solar panels and wind turbines might not consume much water, but manufacturing them does. All told, manufacturing a wind turbine adds 11 litres to green hydrogen’s water footprint. And the manufacture of today’s leading variety of solar power adds a huge 124 litres, mostly from the fabrication of silicon photovoltaic wafers.

Still, the water requirements of hydrogen production seem to be manageable. As part of an analysis co-led by Rosa, one scenario for a net-zero global economy in 2050 that consumes 400 megatonnes of green hydrogen per year would use a meagre 0.13% of the world’s available water supply if the energy came entirely from wind power, and about 0.56% if it all came from solar power 2.

Countries that already face water scarcity, Rosa and his colleagues argue, could choose to import hydrogen to meet domestic needs rather than ramping up production. In fact, many of the countries that their study identified as land-limited are already working to foster a hydrogen trade, including Japan and parts of Europe. Other regions and nations — including areas of sub-Saharan Africa, South America, Canada and Australia — have sufficient land and water to become major hydrogen exporters, and many are already gearing up to fulfil this role.

Multiple factors suggest that the impacts of green hydrogen on regional water could be even more limited than Rosa’s findings suggest. For example, over the past few years analysts and energy planners have lowered their estimates of how much green hydrogen will be produced over the long term. In its September prediction for limiting global temperature rise to 1.5 °C, the International Energy Agency (IEA) projects there will be one-fifth less hydrogen use in 2050 than it had predicted in its 2021 report.

Another important consideration when computing hydrogen’s hydrological footprint is the capacity of hydrogen to be a substitute for fossil fuels, which are themselves water-intensive sources of energy. Most studies so far do not account for the effect of such a substitution. Rosa and his colleagues, for example, assume a fivefold reduction in petroleum refining between 2020 and 2050, as the use of gasoline and diesel is phased down. But they do not work in a corresponding reduction in water use, which could further improve hydrogen’s hydrological footprint. And if green hydrogen replaces natural gas, the substantial water consumption by gas producers that use hydraulic fracturing will be reduced. For example, many jurisdictions in the United States and Europe are considering using green hydrogen to fuel gas-fired power plants to cover gaps in supply from solar and wind farms.

Love that dirty water

In many cases, hydrogen producers might be able to avoid adding strain to potable water supplies by tapping polluted or salty water, instead of potable water. Options include municipal waste water, waste water from oil and gas production and even seawater. Water treatment and desalination plants are expensive to build, but the investment is comparatively small relative to the overall cost of hydrogen production.

Jack Brouwer, director of the Clean Energy Institute at the University of California, Irvine, demonstrates the electrolysis stack in a system used to make renewable hydrogen.Credit: Steve Zylius/UCI

In 2022, an analysis 3 by a team at Yale University in New Haven, Connecticut, concluded that even to treat seawater — the toughest water source to prepare as input to such a facility — would require only 0.3% of an electrolysis plant’s total energy budget. “The bottom line is that “we do not need to consume freshwater resources used for drinking” to produce hydrogen, says Lea Winter, a chemical and environmental engineer at Yale and the study’s lead author. The International Renewable Energy Agency agrees, concluding in 2020 that: “Even in places with water stress, seawater desalination can be used with limited penalties on cost or efficiency.”

In California, electrolyser manufacturer Plug Power in New York plans to build a water-treatment plant and hand it over to the local municipality, in return for a source of water for hydrogen production. Mendota, where the plant is to be built, is currently depleting ground water to meet demand for potable water. City officials say that the new plant will clean up sewage to increase the city’s water supply, so that it can reduce its use of ground water and sell water to Plug Power.

Using seawater presents almost limitless potential, but also troubling environmental impacts. Some desalination plants release heated brines laden with treatment chemicals back into the sea; they can also suck in and destroy marine creatures. The most significant ecosystem impact of these plants, according to a 2020 review4, is lethal osmotic shock to marine organisms, including fish, plankton and algae when super-salty brines cause their cells to dehydrate. Most at risk are organisms in semi-closed seas such as the Red Sea, the Mediterranean and the Persian Gulf. Nearly half of the world’s desalination capacity is concentrated in the Persian Gulf.

Some observers, however, foresee potential environmental dividends if hydrogen producers tap seawater and waste water. Thomas Adisorn, a political scientist at Germany’s Wuppertal Institute for Climate, Environment and Energy, sees potential for projects such as that of Plug Power to improve the environment by supporting international development. “Putting more effort into using recycled waste water in developing countries that are exporting hydrogen could raise their capacity to build wastewater infrastructure,” says Adisorn, who organized a meeting in 2022 to help officials from water-scarce Jordan who were planning its hydrogen economy.

New technology and engineering integrations promise to trim the cost of non-conventional water use even further, while capturing other valuable benefits that pay for the extra water treatment. One active area of research and development, for example, would monetize green hydrogen’s oxygen by-product. Aerobic treatment tanks at wastewater plants rely on pumped air to sustain their waste-eating microbes. According to Brouwer, some large wastewater plants pump in pure oxygen instead of air to spur faster digestion. With an electrolyser they could get that oxygen for free, says Brouwer, rather than operating pricey air-separation units.

Researchers with the municipal water authority Sydney Water and the University of Sydney, Australia, estimated in 2022 that integrating electrolysers into wastewater treatment plants could save the city about US$1.5 million per year 5. They calculate that the city’s 13.7 gigalitres per year of unused effluent could yield 0.88 megatonnes of green hydrogen per year — one-tenth of the amount Australia and New Zealand are expected to produce in 2030, according to analysts S&P Global in New York. Sydney Water says that its unpublished research confirms the viability of hydrogen and oxygen production using its treated water, following further purification.

Another innovation that could prove a major benefit to using seawater for hydrogen production is the ability to operate electrolysers offshore. Over the past year, teams in China and Europe have deployed platforms combining desalination equipment and electrolysers. The hope is that the floating electrolysis plants — if they can operate reliably amid storms and other assaults to offshore hardware — will cut the cost of offshore wind energy. Shipping hydrogen through pipelines is generally cheaper than moving the equivalent amount of energy through electrical transmission lines, and hydrogen proponents are betting that this rule will hold for passing energy from offshore wind farms back to land.

The hydrogen producer Lhyfe’s 1-megawatt pilot platform operated offshore for 5 months this year using desalinated seawater, and a 10-megawatt platform is planned for Belgian waters in 2026. Lhyfe in Nantes, France, wants to mitigate the impact of desalination by eschewing chemical additives in its treatment process, and by diluting brine with extra seawater, says Stéphane Le Berre, Lhyfe’s offshore project manager.

Lhyfe is now exploring whether the oxygen from offshore electrolysis could counteract declining levels of dissolved oxygen in the ocean — conditions that are stunting marine ecosystems in some regions. In July, researchers projected that artificial oxygenation from global deployment of offshore wind farms and electrolysers could reduce the volume of severely hypoxic zones by 1.1–2.4%6. But they also reported some counterintuitive regional impacts. For example, their simulation projected that oxygen injection might enlarge an existing hypoxic zone in the Indian Ocean’s Bay of Bengal.

Known unknowns

Technological wild cards, meanwhile, could alter water consumption calculations around hydrogen production. In a review, the IEA identified 40 companies that are exploring a potential hydrogen source that might be cleaner than electrolysis: natural pockets of the gas, some of which might be tapped using little water. But, as with injecting oxygen in to the sea, seemingly water-saving technologies could have perverse effects. Accessing ‘geological’ hydrogen might require fracturing of rock layers akin to hydraulic fracturing or ‘fracking’ used to recover oil and gas. And some of the hydrogen prospectors plan to stimulate hydrogen production in situ by injecting water into iron-rich rock formations.

Green-energy company Eden GeoPower in Somerville, Massachusetts, plans to test hydrogen stimulation in the peridotite rock formations of water-scarce Oman, in collaboration with the country’s Ministry of Energy and Minerals. The company hopes to increase underground permeability using its water-free electrical fracturing technology. Chief executive Paris Smalls, says “back of the envelope calculations” suggest that net water consumption will be comparable with that of electrolysis per kilogram of hydrogen delivered.

Eden GeoPower’s attention to water resources is the exception to the rule among hydrogen producers. Water supply is not mentioned in the IEA report or in a 2022 “critical” review of hydrogen-production technology 7.

Given that hydrogen production and water use are inextricably bound, it is unlikely that water supply will continue to be omitted. The inconvenient truth, say both Brouwer and Rosa, is that solar energy is the cheapest source of low-carbon power available to produce hydrogen, but the regions with the best solar resources are also some of the most parched.

Brouwer is one of the main team members behind California’s hydrogen-development programme, which picked up $1.2-billion of the $7 billion in US federal funds awarded in October to regional ‘hydrogen hubs’ that link producers and consumers. He says that hydrogen plants can tap into conventional water supplies or clean up waste water, but that reaching net-zero carbon emissions in California will ultimately require a lot more solar panels in the desert.

Converting that solar energy to hydrogen will force the state to build more infrastructure, and to make an important choice. As Brouwer puts it: “We’re going to eventually have to figure out whether we want to run big wires from the solar resource to where the water is, or big pipes sending water to the desert.”

Water: a source of life and strife

Water: a source of life and strife

The most important issue about water is not supply, but how it is used

The most important issue about water is not supply, but how it is used

Fresh water from thin air

Fresh water from thin air

How to take ‘forever’ out of forever chemicals

How to take ‘forever’ out of forever chemicals

The human factor in water disasters

The human factor in water disasters

Water and warfare: the battle to control a precious resource

Water and warfare: the battle to control a precious resource

Webcast: How water researchers are rethinking the global flood crisis

Webcast: How water researchers are rethinking the global flood crisis