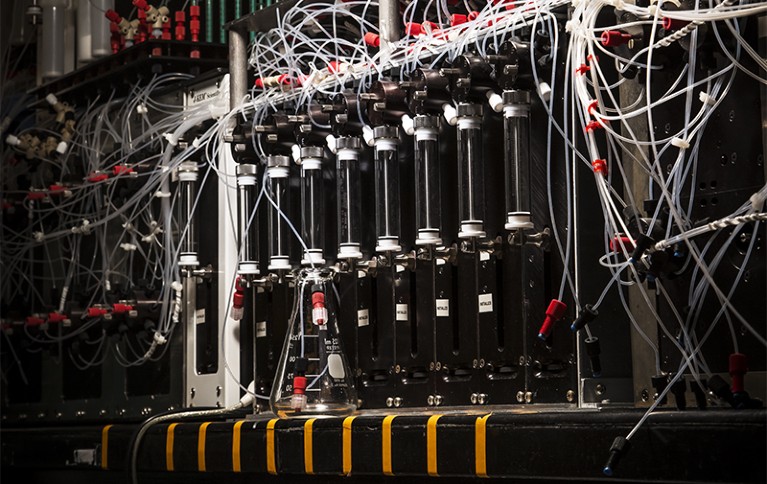

A machine for synthesizing small molecules at the University of Illinois at Urbana–Champaign relies on syringe pumps to push reagents into reaction stations.Credit: L. Brian Stauffer, Univ. Illinois

In a laboratory at the University of Liverpool, UK, a chemist painstakingly mixes, measures, weighs and analyses, trying to find new materials that might be used to make hydrogen from water and light. But this chemist is not your average scientist. It is a robot.

The robot is just one example of numerous efforts to automate the time-consuming process of making molecules. Back in 1972, the synthesis of vitamin B12 took 91 postdocs and a dozen PhD students 12 years to complete. Almost five decades later, some syntheses remain nearly as complex.

But a growing group of researchers hopes to reduce some of that complexity to push-button simplicity, using automation to accelerate the field, just as has been achieved for molecular biology.

“Automated synthesis of DNA and biological polymers enabled molecular biology,” says Peter Seeberger, director of the Max Planck Institute of Colloids and Interfaces in Potsdam, Germany. “It’s so well established, most people don’t think about it any more.”

But automating the synthesis of all possible compounds is entirely different. The number of ways to combine atoms into molecules is astronomical, and the technology to build any arbitrary molecule doesn’t yet exist. But researchers are making slow, steady progress by focusing on certain compounds, such as small molecules that are potential drug candidates.

The resulting systems could shake up synthetic chemistry by automating not only the repetitive legwork, but also decision-making and recipe development. The technical challenges are substantial, says chemist Martin Burke at the University of Illinois at Urbana–Champaign, but the time is right. He compares the state of the field to the early stages of the Human Genome Project. At the time, he says, the technology to do the sequencing work didn’t exist, but researchers pushed ahead anyway. “People assumed that they were going to figure it out.” The same, Burke argues, is true of chemistry today. “Chemistry now has its opportunity for its Moon mission. This is it.”

‘Chemputer’ upgrade

One argument in favour of automation is that chemical synthesis is tedious and difficult, even for experts. For many researchers, the process is as much art as science. Burke says that chemistry has become “an artistic expression of oneself through our molecule making”. Mimi Hii, director of Imperial College London’s Centre for Rapid Online Analysis of Reactions, argues that this is a bad thing. “Chemistry is a science, it shouldn’t be an art.”

The US Defense Advanced Research Projects Agency (DARPA) in Arlington, Virginia, has set up a programme called Make-It to develop a machine to help remove those barriers.

Make-It is pursuing both hardware and software solutions for automation, says programme manager Anne Fischer. One approach the programme supports is a robotic arm, developed at the Massachusetts Institute of Technology in Cambridge, which uses preloaded cartridges to automate synthetic steps such as heating, mixing and separating chemicals.

Lee Cronin’s ‘Chemputer’ exemplifies a second approach. Cronin, a DARPA-funded chemist at the University of Glasgow, UK, describes Chemputer as a modular desktop-sized robotic synthesizer, which ‘compiles’ text-based recipes into instructions to drive laboratory automation hardware.

A robot chemist at the University of Liverpool, UK, sifts through thousands of materials to find a photocatalyst.Credit: Univ. Liverpool

Cronin has eight Chemputers in his lab, each costing £25,000–30,000 (US$33,000–39,500), including all the associated chemistry kit, such as stirrers, evaporators and hotplates. His team has so far used those instruments to assemble six compounds, including a generic form of Pfizer’s Viagra (sildenafil). Synthetic schemes are in development for 20 other compounds. “To make sildenafil takes 30 hours of lab time,” Cronin says. But it takes under an hour to program Chemputer to do the same thing, so researchers are freed to spend more time on other tasks.

“No reactions that are out of reach for the human are out of reach for the Chemputer, in principle,” Cronin says, although new modules would be needed to expand the number of possible molecules the instrument can create — that is, its ‘chemical space’. His team has set up an online platform, Chemify, from which interested chemists can download Chemputer assembly instructions.

Back to the future

A team led by Jeffrey Bode, an organic chemist at the Swiss Federal Institute of Technology (ETH) in Zurich, Switzerland, and Benedikt Wanner, co-founder of Synple Chem, an ETH Zurich start-up company, described a similar concept on the ChemRxiv preprint server at the end of March — a ‘console’-like computer with preloaded chemical applications that the team used to drive several classes of organic reaction commonly applied in drug discovery (T. Jiang et al. Preprint at ChemRxiv http://doi.org/c4nd; 2019).

Often, researchers start off small, and limit their chemistry to a simple set of starting materials. In 2015, for instance, Burke showcased an automated building-block approach using small organic molecules known as MIDA boronates (J. Li et al. Science 347, 1221–1226; 2015).

Assembled from a blend of commercially available parts and components, Burke’s $75,000-machine drives syringe pumps to push solvents, reagents, products and waste through three reaction stations. The first makes the MIDA boronates reactive by removing the protective molecular group that keeps them stable; the second gets the molecules to join together in a reaction; and the third washes away any side products to leave the purified final molecule. Burke’s team has used its design to create a range of molecules, including drug compounds, enzyme inhibitors and components for light-emitting diodes and solar cells, all through the same sequence of molecular steps. Moving forwards, Burke hopes to use the equipment to create an on-demand service through which researchers can order any chemical they desire.

But automation in chemistry has a chequered past. In the 1990s, it was mistakenly lauded as the saviour of the drug industry, says US-based industrial chemist Derek Lowe, with promises of myriad molecules that would be the next blockbuster drugs. The process, then known as combinatorial chemistry, involved setting up multiple parallel reactions on solid supports, filtering those reactions through cartridges and using multichannel pipettes. The idea was that libraries of potential drug molecules would be made in the blink of an eye. But the amount of data being produced was too large to analyse in a meaningful way, says Hii. And the resulting compounds made for disappointing drug candidates, says Lowe, who writes the Science blog ‘In the Pipeline’. “The hangover from this stuff was severe, because the promises had been so inviting,” says Lowe.

The way we flow

Today, chemists are again embracing automation to reduce the repetitive work of synthesis. And one promising technology is flow chemistry, in which reactions take place in channels that have a constant flow of reactants pumped through their innards, rather than in a single vessel. Over the past decade, flow chemistry has grown from a trickle of papers in 2007 to tens of thousands being published each year, says Omar Jina, chief commercial officer at Syrris, an automation-technology company in Royston, UK, which has been selling flow chemistry set-ups since 2004.

One of the benefits of the technology, Jina says, is that a reaction optimized to work on a small scale is “absolutely reproducible on a large scale”. In industry, flow chemistry is used mainly for process optimization, says Seeberger. And the technology struggles with some classes of chemical, notes Annette Doherty, senior vice-president for product development and supply at drug-maker GlaxoSmithKline in Ware, UK.

But Lowe sees a bright future for the technology — at least in industry, where identical reactions can be repeated time and again. “Not many in academia would have a use for such things, but those of us in industry do, and we’re willing to pay for it, as well.”

The robot chemist at the University of Liverpool has been programmed and tested to work in the university’s materials innovation factory, where factory director Andy Cooper is working on finding catalysts that can help to make the process of extracting hydrogen from water more efficient. It is a painstaking process that Cooper says might require sifting through 250,000 potential materials. “A PhD student would never do it. It would be a ghastly project,” he says.

The best catalyst that humans have developed for using light to produce hydrogen (known as a photocatalyst) is just 1% efficient. “It’s taken the whole world 20 years to get to that,” says Cooper. His goal is a material with 5% efficiency. “The robot would need to run continuously for months” to achieve that, he says.

Cooper’s PhD student Benjamin Burger has spent three years building and programming the robot. The device is about the same size as a person, and has a robotic arm that sits atop a moving box.

Cooper estimates that mobile robots cost £30,000–120,000 to build. The hardware in his factory is configured to make multicomponent catalyst formulations that involve both solids and liquids, but a different set-up would be needed to do multistep organic synthesis, he says. The robot is built to handle solids, with up to 100 cartridges of solid compounds to choose from.

At the moment, the robot has no real user interface and requires a programmer to instruct it. But once that is up and running, Burger says, “any lab technician could be trained on this in a matter of weeks”.

The goal is not to create a mindless worker bee, Cooper says. The robot has an algorithm that will instantaneously determine its next step or action, on the basis of an iterative process that relates chemical composition to the catalytic activity, thus allowing the prediction of material compositions that are better than any studied so far. This, he says, is very different from how a human would approach the problem. “It’s selection, it’s not design.”

The system has already discovered competitive photocatalysts, he notes, and can even handle solids, a key ingredient in the development of catalysts. Analysing solids, dispensing them and using them in tiny channels is a huge technological challenge, Cooper says. But he notes that his robot is already capable of dispensing solids, and his team is working on automating analytical techniques, such as powder X-ray diffraction, to determine the molecular structure of the compounds.

Researchers who hope to test-drive chemistry automation can also look to Imperial’s Centre for Rapid Online Analysis of Reactions, which was officially opened in January. The facility, which cost more than £4.5 million, includes two commercially available continuous-flow reactors, a host of analytical equipment and a suite of robotic reactor platforms.

Ben Partridge, an organic chemist at the University of Sheffield, UK, has booked time at the centre. Automation, he says, allows more data to be gathered in less time, and with greater accuracy. “You can get more information from fewer chemical reactions. Ultimately, it will also give students more time to think and be creative, as they do not need to spend as many hours at the bench.”

And that’s true for students and professionals alike. Automation, says Seeberger, “empowers the chemist”. In 2015, when Burke reported his synthesis machine, some chemists debated whether automation would spell the end for synthetic chemistry. For Burke, the opposite is true. “It doesn’t mean synthesis is no longer important,” he says. “It means we get to aim higher.”

The drug-maker’s guide to the galaxy

The drug-maker’s guide to the galaxy

Complex molecules made to order in synthesis machine

Complex molecules made to order in synthesis machine

NatureTech hub

NatureTech hub